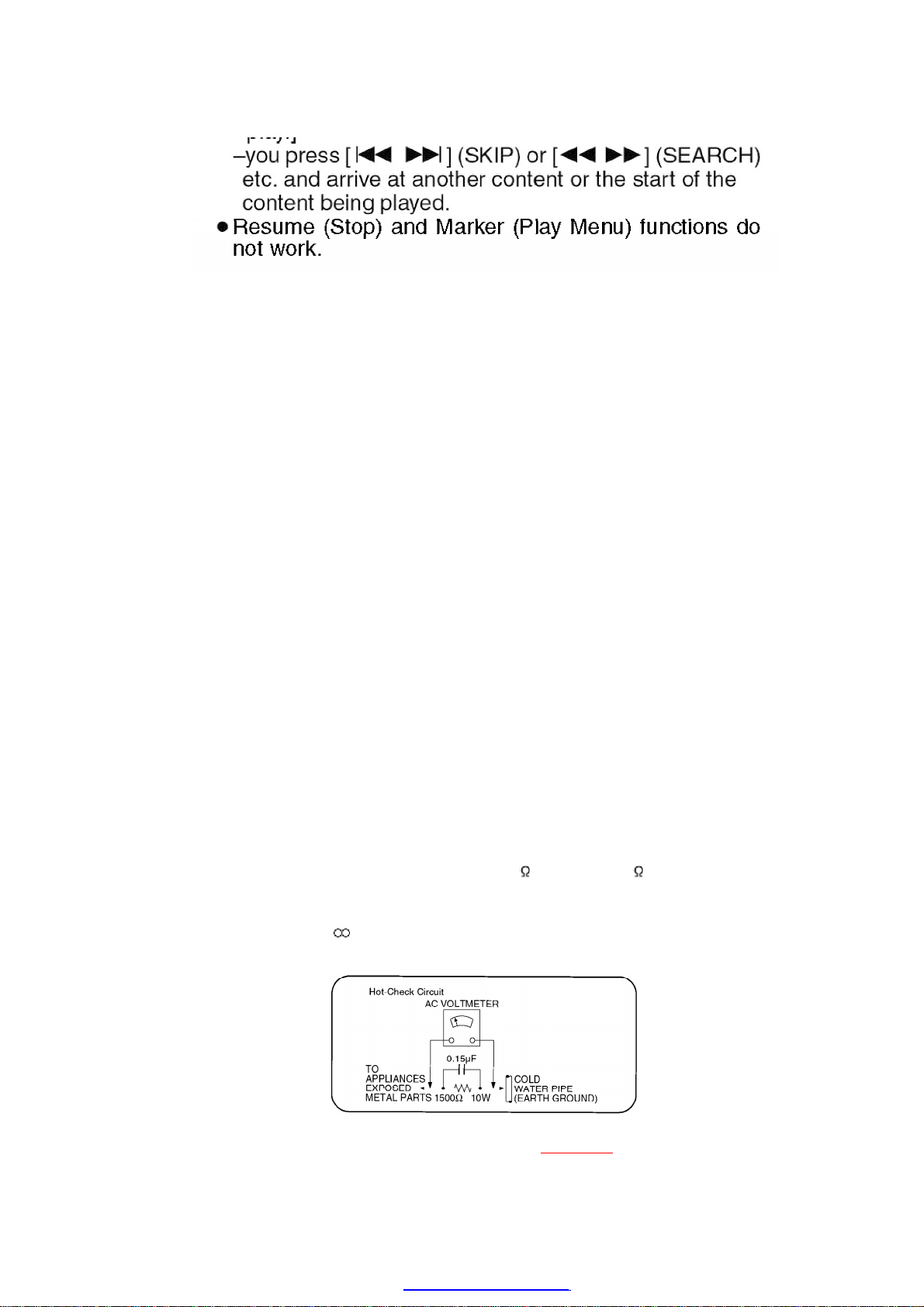

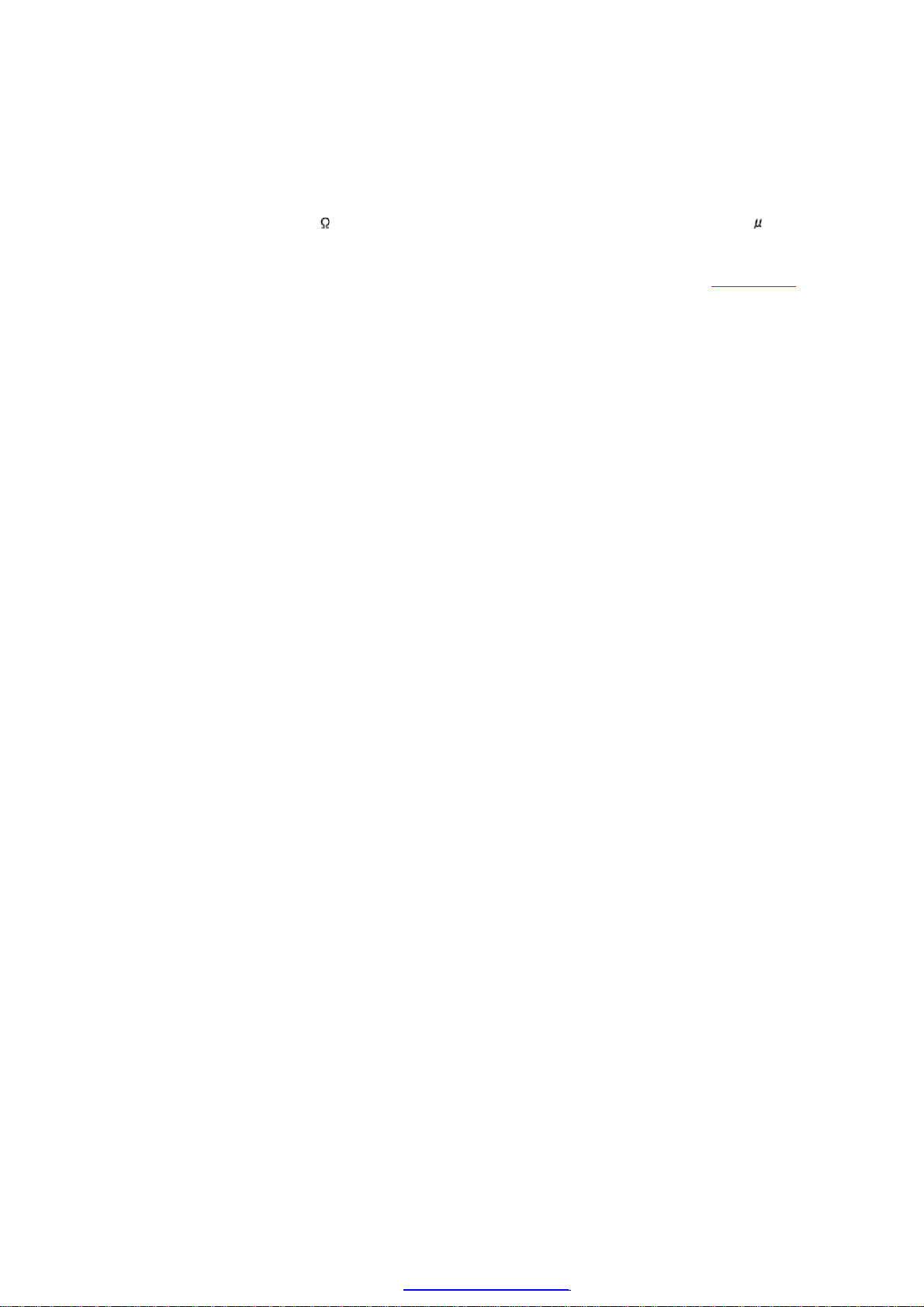

1. Plug the AC cord directlyinto the AC outlet. Donot use an

isolation transformer for thischeck.

2. Connect a1.5k , 10 watts resistor, inparallel with a0.15 F

capacitors, between each exposed metallicpart on the set and a

good earth ground such as awater pipe, as shownin Figure 1.

3. Use an AC voltmeter, with 1000 ohms/voltor more sensitivity, to

measure the potential across the resistor.

4. Check each exposed metallicpart, and measure the voltage at

each point.

5. Reverse the AC plug inthe AC outlet and repeat each of the above

measurements.

6. The potential at anypoint shouldnot exceed 0.75 volts RMS. A

leakage current tester (Simpson Model 229 or equivalent) maybe

used to make the hot checks, leakage current mu3st not exceed 1/

2milliamp. Incase ameasurement isoutsideof the limits

specified, there isapossibilityof ashock hazard, and the

equipment shouldbe repaired and rechecked before itisreturned

to the customer.

3. PREVENTION OF ELECTRO STATIC DISCHARGE

(ESD) TO ELECTROSTATICALLY SENSITIVE (ES)

DEVICES

Some semiconductor(solidstate) devices canbe damagedeasilybystatic electricity. Such

components commonlyare calledElectrostaticallySensitive (ES) Devices. Examples of typical

ES devices are integratedcircuits and some field-effect transistorsand semiconductor"chip"

components. The following techniques shouldbe usedtohelpreduce the incidence of

component damage causedbyelectrostatic discharge (ESD).

1. Immediatelybefore handling anysemiconductor component or

semiconductor-equipped assembly, drainoff anyESDon your

bodybytouching aknownearth ground. Alternatively, obtainand

wear acommerciallyavailabledischargingESDwrist strap, which

shouldbe removed for potential shock reasons prior to applying

power to the unitunder test.

2. After removing an electrical assemblyequipped with ES devices,

place the assemblyon aconductive surface such as alminum foil,

7

PDFcreated withpdfFactoryProtrialversion www.pdffactory.com