General Information

Power Module DN Version 09.2019 Page 4/43

Table of contents

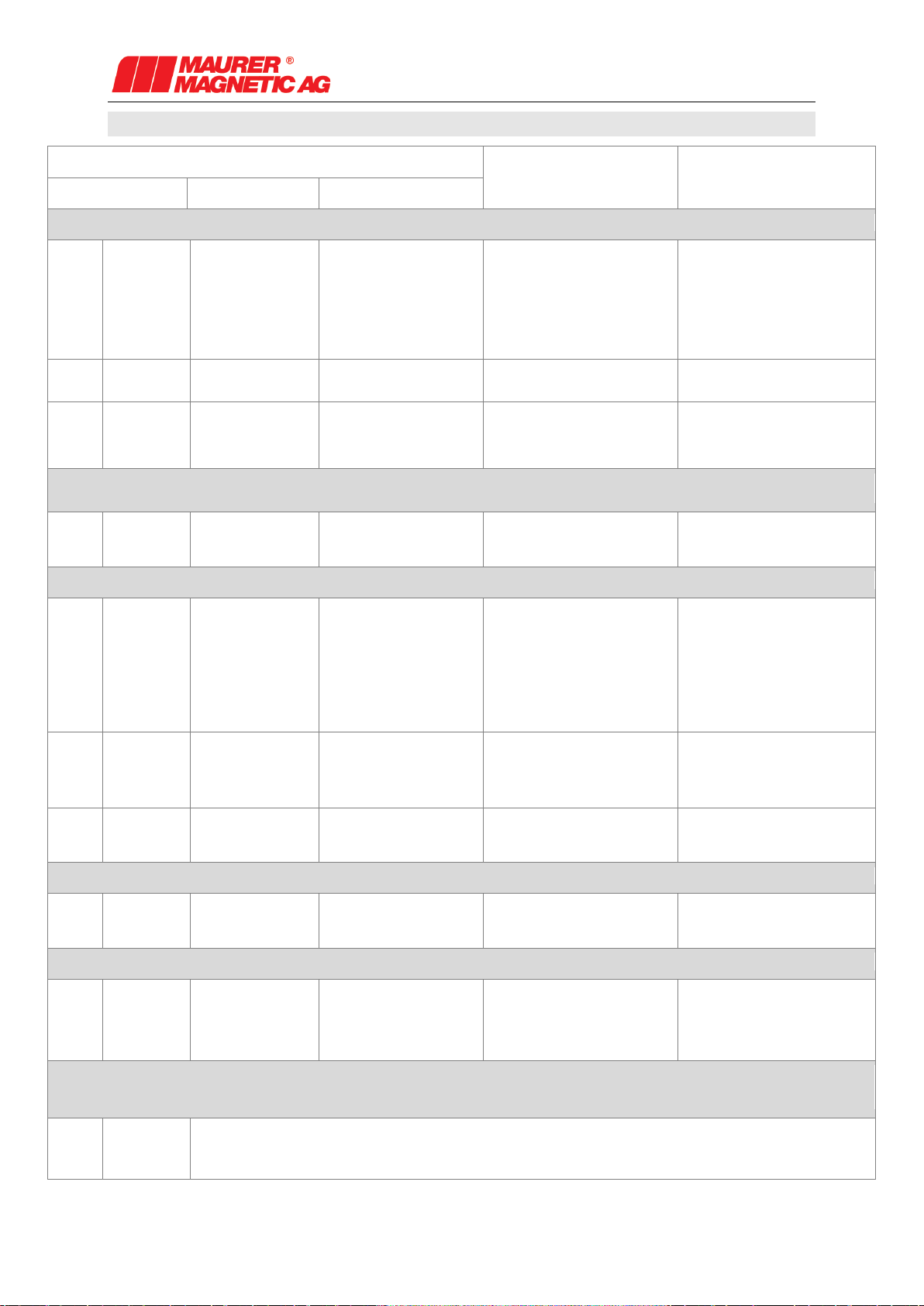

1Safety instructions ....................................................................................................................6

1.1 Symbols...................................................................................................................................................6

1.2 Information on restrictive risks.................................................................................................................6

1.3 Notes on restrictive risks..........................................................................................................................7

1.4 Safety electromagnetic fields...................................................................................................................8

2Intended use...............................................................................................................................9

2.1 Compatibility MM coil modules................................................................................................................9

3Device characteristics............................................................................................................ 10

3.1 Scope of delivery...................................................................................................................................10

3.2 MM DN150 ............................................................................................................................................11

3.2.1 Controls ............................................................................................................................................. 11

3.2.2 Connectors ........................................................................................................................................ 11

3.3 MM DN750…DN1850............................................................................................................................12

3.3.1 Controls ............................................................................................................................................. 12

3.3.2 Connectors ........................................................................................................................................ 12

4Installation............................................................................................................................... 13

4.1 Transport...............................................................................................................................................13

4.2 Installation process................................................................................................................................13

4.3 Mounting................................................................................................................................................14

4.1 Connection to grid .................................................................................................................................14

4.1.1 DN150................................................................................................................................................ 14

4.1.2 Power cable (DN150)......................................................................................................................... 14

4.1.3 DN DN750…1850.............................................................................................................................. 15

4.2 Prefuse..................................................................................................................................................15

4.2.1 Operator Protection ........................................................................................................................... 15

4.3 Coil module connector HAN 3/HAN 10 B...............................................................................................15

4.4 Fan connector........................................................................................................................................16

4.4.1 Fan connector DN150 (optional)........................................................................................................ 16

4.4.2 Fan connector DN750-1850............................................................................................................... 16

4.5 Control signals.......................................................................................................................................16

4.5.1 Coil module monitoring M8................................................................................................................ 16

4.5.2 Sensor connector M12....................................................................................................................... 16

4.5.3 D-Sub15 Control Interface................................................................................................................. 16

4.5.4 D-Sub9 power setting interface (DN750…1850, optional) ................................................................. 16

4.6 Modification ...........................................................................................................................................17

5Commissioning....................................................................................................................... 18

5.1 Power on ...............................................................................................................................................18

5.2 Trigger demagnetization pulse ..............................................................................................................18

5.3 Demagnetisation test with intended object ............................................................................................18

5.4 Control via interface (if applicable) ........................................................................................................18

6Operation................................................................................................................................. 19

6.1 Operation mode.....................................................................................................................................19

6.1.1 Manual operation............................................................................................................................... 19

6.1.2 Integration in production line.............................................................................................................. 20

6.2 Controls.................................................................................................................................................20

6.2.1 Main switch........................................................................................................................................ 20

6.2.2 Start/Pulse button .............................................................................................................................. 20

6.3 Indicators...............................................................................................................................................20

6.3.1 Operation lamp .................................................................................................................................. 20

6.3.2 Ready lamp........................................................................................................................................ 20

6.3.3 Fault lamp.......................................................................................................................................... 20

6.3.4 Active lamp........................................................................................................................................ 20

6.3.5 Process OK lamp (Process Monitoring Step 1, optional)................................................................... 21

6.4 Sensor connection M12.........................................................................................................................21

6.5 D-Sub15 Control Interface (isolated) .....................................................................................................21

6.5.1 Configuration D-Sub15 connector...................................................................................................... 21

6.5.2 PIN2 Start.......................................................................................................................................... 21

6.5.3 PIN3 Ready ....................................................................................................................................... 21