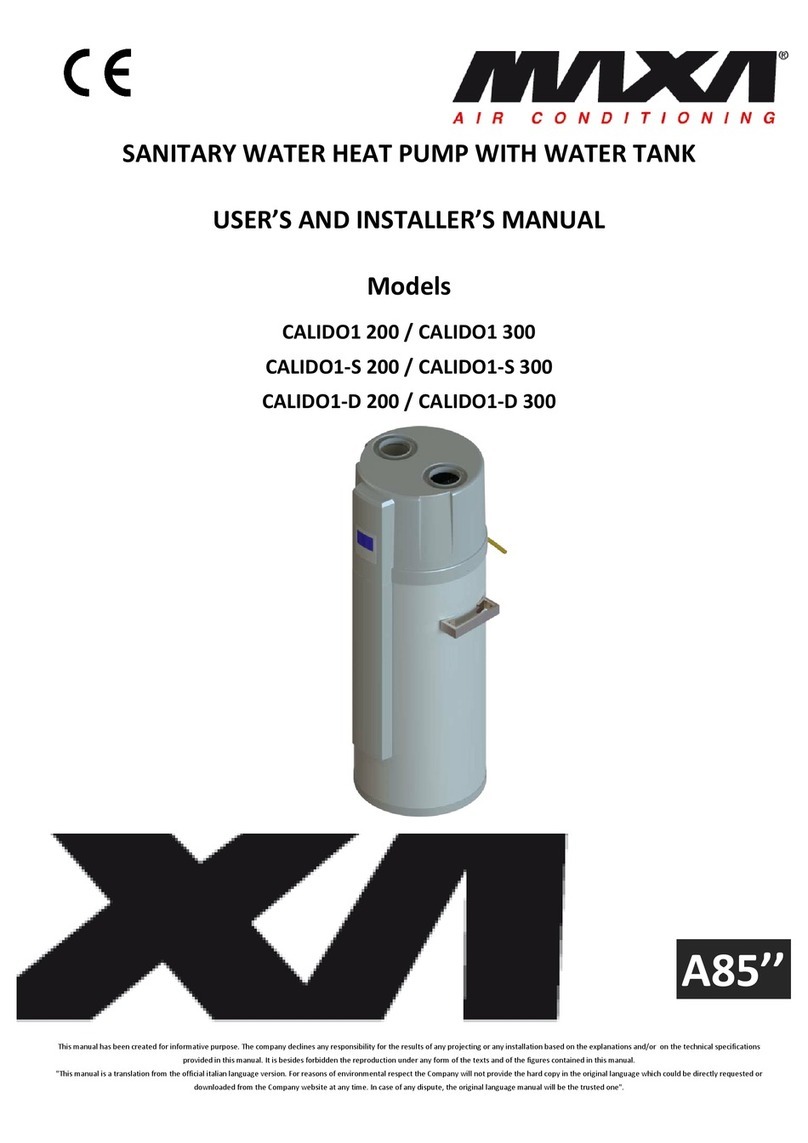

CALIDOSanitarywaterheatpump

4

INDEX

1PURPOSESANDCONTENTSOFTHEMANUAL......................................................................................................................6

1.1CONSERVATIONOFTHEMANUAL..........................................................................................................................................6

1.2GRAPHICSYMBOLSUSEDINTHEMANUAL............................................................................................................................6

2SAFETYLAWS.....................................................................................................................................................................6

3PERMITTEDUSE.................................................................................................................................................................6

4GENERALSAFETYGUIDELINES............................................................................................................................................7

4.1WORKERS’HEALTHANDSAFETY............................................................................................................................................7

4.2PERSONALSAFETYEQUIPMENTS...........................................................................................................................................7

4.3SAFETYSYMBOLS...................................................................................................................................................................7

4.4REFRIGERANTSAFETYDATASHEET........................................................................................................................................8

5GENERALCHARACTERISTICS..............................................................................................................................................11

5.1FLEXIBILITYANDBENEFITSOFCALIDOINSTALLATION.........................................................................................................11

5.2COMPACTDESIGN................................................................................................................................................................11

5.3AVAILABLEACCESSORIES.....................................................................................................................................................11

6TECHNICALFEATURES.......................................................................................................................................................11

7ITEMSINSIDETHEPACKING‐BOX.......................................................................................................................................12

8OVERVIEWOFTHEUNIT....................................................................................................................................................13

8.1HYDRAULICCONNECTIONS..................................................................................................................................................13

8.2DIMENSIONS........................................................................................................................................................................13

8.3ACCESSTOTHEFRONTPART................................................................................................................................................14

8.4ACCESSTOTHEBOTTOMPART............................................................................................................................................14

8.5HOWTOREPLACETHEMAGNESIUMANODE.......................................................................................................................14

8.6REGULATIONTHERMOSTATOFTHEELECTRICHEATER........................................................................................................15

8.7SCHEMATICOVERVIEWOFTHEWATERANDGASCIRCUIT..................................................................................................15

9INSTALLATION...................................................................................................................................................................15

9.1GENERALITY.........................................................................................................................................................................15

9.2SAFETYINSTRUCTIONS.........................................................................................................................................................15

9.2.1Warnings......................................................................................................................................................................16

9.2.2Cautions........................................................................................................................................................................16

9.3HANDLINGOFTHEUNIT.......................................................................................................................................................16

9.3.1Handlingoftheunitwithforklift..................................................................................................................................16

9.3.2Manualhandlingoftheunit.........................................................................................................................................16

9.4WALLMOUNTING................................................................................................................................................................17

9.5REQUIREDSERVICESPACE....................................................................................................................................................18

9.6INSTALLATIONOVERVIEW...................................................................................................................................................19

9.7HYDRAULICCONNECTIONS..................................................................................................................................................20

9.7.1Waterconnections.......................................................................................................................................................20

9.7.2Waterloading...............................................................................................................................................................20

9.7.3Unloadofwaterfromthetank.....................................................................................................................................21

9.8ELECTRICALCONNECTIONS..................................................................................................................................................21

10STARTUP..........................................................................................................................................................................21

11APPLIANCEOPERATION.....................................................................................................................................................22

11.1USERINTERFACE..................................................................................................................................................................22

11.2OPERATION..........................................................................................................................................................................22

11.3LCDICONS..............................................................................................................................................................................24

11.4MAINLOGICSOFOPERATION..............................................................................................................................................24

11.4.1Automode....................................................................................................................................................................25

11.4.2Greenmode..................................................................................................................................................................25

11.4.3Boostmode...................................................................................................................................................................25

11.4.4E‐heatermode..............................................................................................................................................................25