Maxair Velox Revolution II User manual

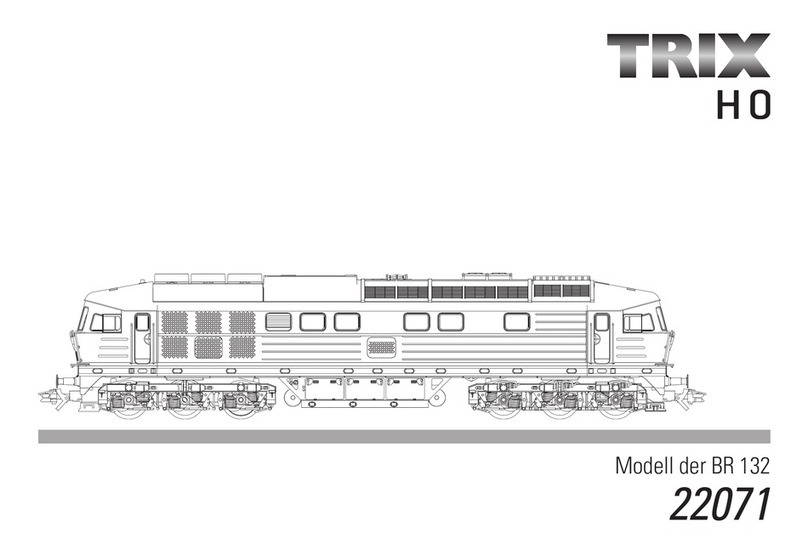

Velox Revolution II Specs:

Metric Imperial

Wingspan : 1730 mm 68 in

Wing Area : 62 dm2965 in2

Length : 1460 mm 57.5 in

Recommended Engine : 2C - .91 to 1.0 4C - .91 to 1.1

Radio : 4 Channels – 6 servos (Hi-torque recommended)

Weight : 3.7 to 4 kg 8.1 to 8.8 lbs

Maxair Model Products

https://www.maxairrc.com

www.maxairrc.com Page 2 of 19

Introduction

The MAXAIR Velox Revolution II was designed with nothing but performance in mind. You name it, it

can do it. Whether your thing is down on the deck 3D, or the precision required while performing scale

aerobatic, the MAXAIR Velox Revolution II is for you! The MAXAIR Velox Revolution II tracks as

straight as an arrow but will tumble with the best of them. Its super light weight makes for an extremely

low wing loading and extreme performance.

Let’s start building!

Using the Assembly Manual

The assembly of the MAXAIR Velox Revolution II is very straightforward. Follow these instructions

and your MAXAIR Velox Revolution II should be ready to fly in 4 to 6 hours.

ÅBe extra careful when you encounter items marked with the red alert icon.

ÅItems denoted with the green tip icon offer suggestions that may be helpful in assembling

your model.

Read through the entire manual before starting the assembly of your model

MAXAIR Model Products Warrantee

MAXAIR Model Products guarantees this product to be free from defects in both material and

workmanship at the time of purchase. The warranty does not cover any component damaged by use or

modification. MAXAIR Model Products shall in no case be liable for more than the original cost of this

product. MAXAIR Model Products reserves the right to modify this warrantee without notice.

No liability shall be assumed or accepted by MAXAIR Model Products for any damage caused or

resulting from the use by the user of the final assembled product. By using this product, the user accepts

all resulting liability. If the buyer is not ready to accept the liability associated with the purchase and use

of this product, the buyer is advised to return the product in new and unused condition to the place of

purchase.

To make a warrantee claim, send the defective part to:

MAXAIR Model Products

105 Barrington Cr.,

Moncton, NB

Canada

E1G 4V4

You may contact MAXAIR Model Products through their support website at: http://maxairrc.com

WARNING

Radio Controlled Model Aircraft are not toys! This model is a high performance model and can cause

harm if misused. This plane is not for beginners. Only experienced pilots should fly it.

Fly in open spaces away from structures and people. Always do a pre-flight check of the aircraft before

flying it. Always follow all safety precautions set forward by MAAC and the AMA.

Have fun and be safe!

www.maxairrc.com Page 3 of 19

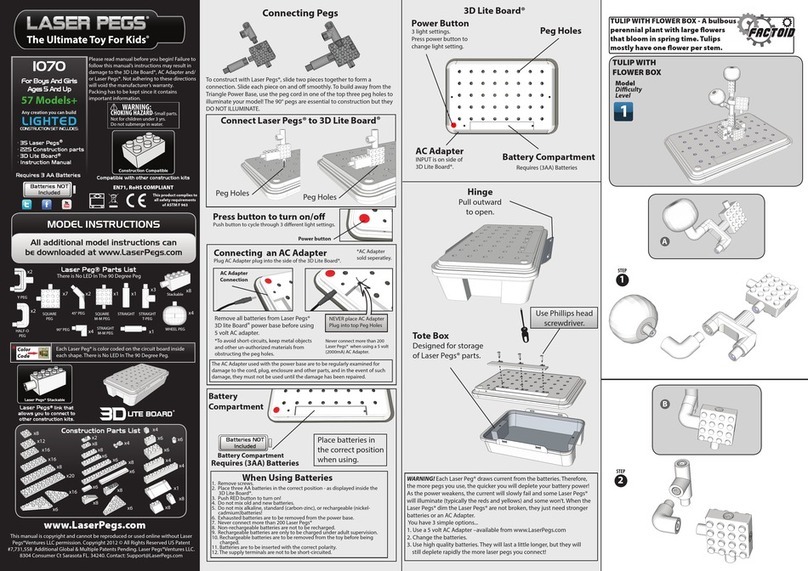

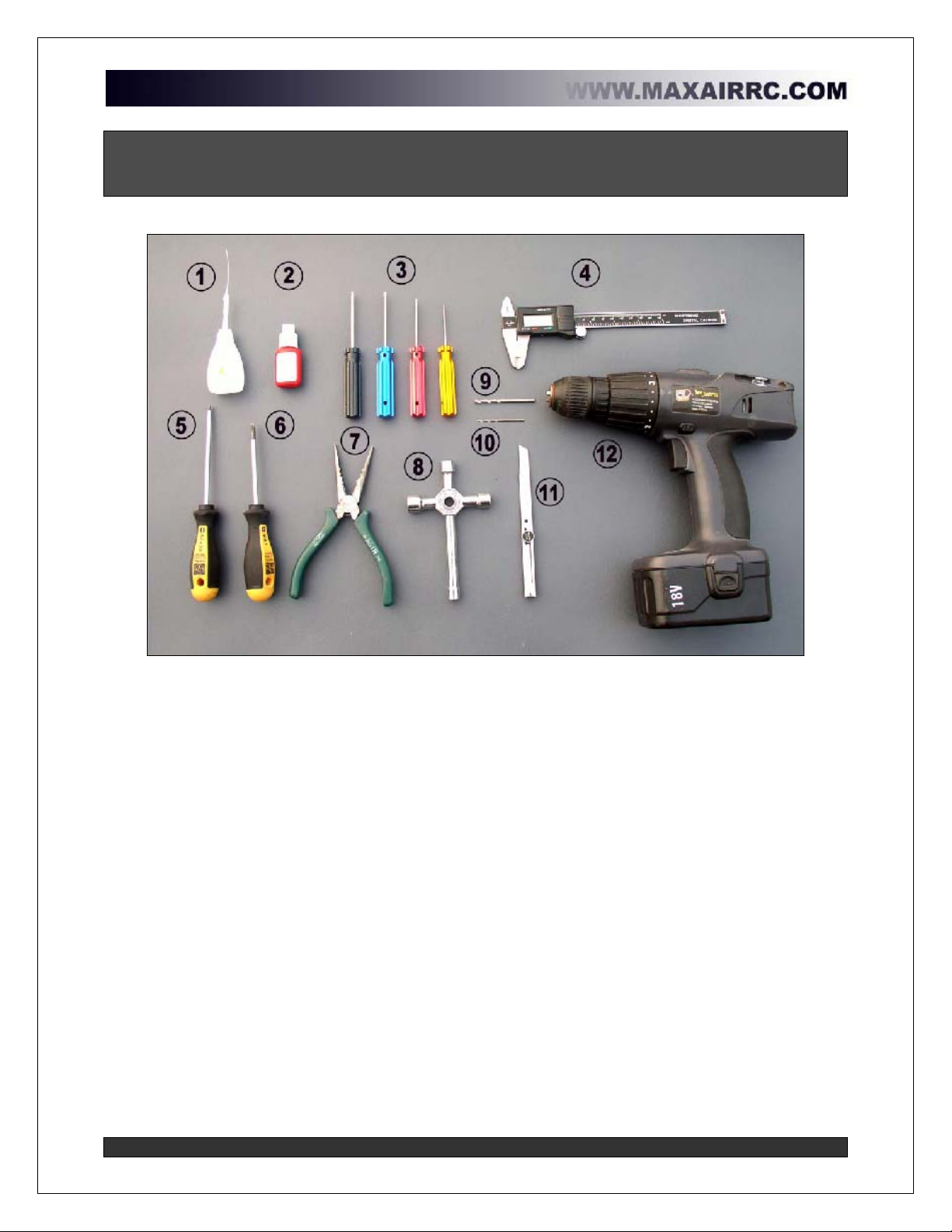

Required Items to complete

(The following items are not included in the kit and must be purchased

separately)

1. CA (thin and medium or thick)

2. Thread Locking Compound

3. Hex head screw drivers

4. Vernier Callipers

5. Flat head screw driver

6. Phillips head screw driver

7. Needle nose pliers

8. Plug wrench or other wrenches

9. 4mm drill bit

10. 1.5mm drill bit

11. Hobby knife

12. Drill

Items required but not shown above:

-30 min Epoxy

-Covering Iron

-Servo Extensions

-Foam rubber padding

-Double sided padded tape

www.maxairrc.com Page 4 of 19

Parts included in the kit

Package

b

Part Description Quantity Condition

Fuselage 1pc Finished

Rudder servo mount 1pc Included

Cockpit hatch/cover 1pc Included

Fix screw M3x8 4pcs Included

Belly pan 1pc Included

1 Fuselage

Screws - M3x15 2pcs Included

Main wing 1set Finished

Ailerons 1set Included

CA hinges 8pcs Included

Nylon screw M6x25 4pcs Finished

Wingnuts - M6 4pcs Included

2 Main wing

Carbon wing tubing - 22x750mm 1pc Included

Horizontal stabilizers & Elevators 1set Finished

Rudder 1pc Finished

3

Horizontal

stabilizers and

rudder CA hinges 4pcs Included

Cowl 1pc Finished

Blind nuts - M3 4pcs Finished

4 Cowling

Screws – M3x10 4pcs Included

Wheels D=70mm 2pcs Included

Wheel pants 1set Included

Blind nuts - M4 3pcs Finished

Aluminum landing gear 1pc Included

Screws M4x20 3pcs Included

Washers - D4 4pcs Included

Screws - M4x40 2pcs Included

Lock Nuts - M4 4pcs Included

5 Wheel

Tail wheel 1set Finished

Engine mount 1set Included

Blind nuts - M4 4pcs Included

Screws - M4x25 4pcs Included

Washers - D4 4pcs Included

Screws for engine - M4x25 4pcs Included

6 Engine mount

Nuts for engine - M4 4pcs Included

Canopy 1pc Finished

7 PVC Canopy Canopy screws - M3x8 4pcs Included

Control horns 2sets Included

Fix screw M3x8 6pcs Included

8 Aileron hardware

Carbon/steel control rods -120mm 2sets Finished

www.maxairrc.com Page 5 of 19

Carbon tube - D8x128 1pc Included

Carbon tube - D8x213 1pc Included

Screws - M3x20 2pcs Included

Control horns 2sets Included

Screws - M3x8 6pcs Included

Carbon/steel control rods -200mm 1set Finished

9

Elevator and

vertical stabilizer

hardware

Carbon/steel control rods 260mm 1set Finished

Fuel tank -550cc 1set Included

Nylon bind tape 300mm 1pc Included

10 Fuel tank

Foam tape - 120mm 2pcs Included

Metal clevis - M3 4pcs Included

Metal control rod - M3 4pcs Included

Pull-pull wire - D1x1800mm 1pc Included

Pull-pull aluminum control horn 2sets Included

Screws - M3x18 1pc Included

11 Rudder hardware

Crimp metal tubing 4pcs Included

Manual 1pc

Included

Heat shrink tubing 300mm 1pc Included

Double sided foam tape 2pcs Included

Nylon tape 200mm 4pcs Included

12 Manual

Nylon tape 250mm 2pcs Included

www.maxairrc.com Page 6 of 19

Main Wing Assembly

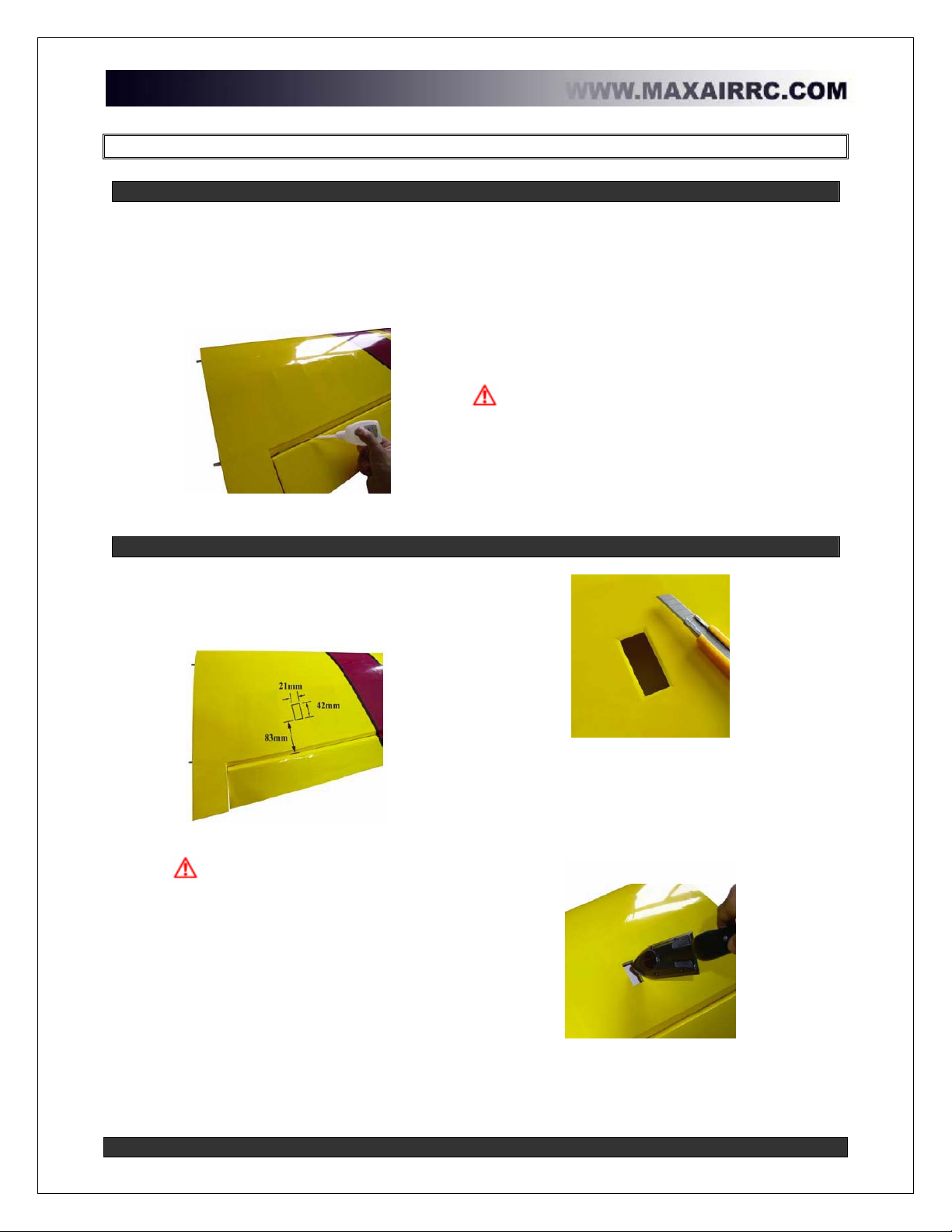

Step 1 – Install the ailerons

a. Remove the aileron from the wing.

b. Adjust the CA hinges so that they are

aligned properly in the hinge slots.

c. A pin can be inserted through the center

of the hinge to make sure it stays

centered.

d. Slide the aileron onto the hinges and butt the

aileron up against the wing.

e. Make sure there is no gap between the

aileron and the wing.

f. Drip some CA onto the CA hinges from the

top and the bottom of the wing.

g. Repeat for the opposite wing.

Be careful not to drip any CA onto the wing

covering.

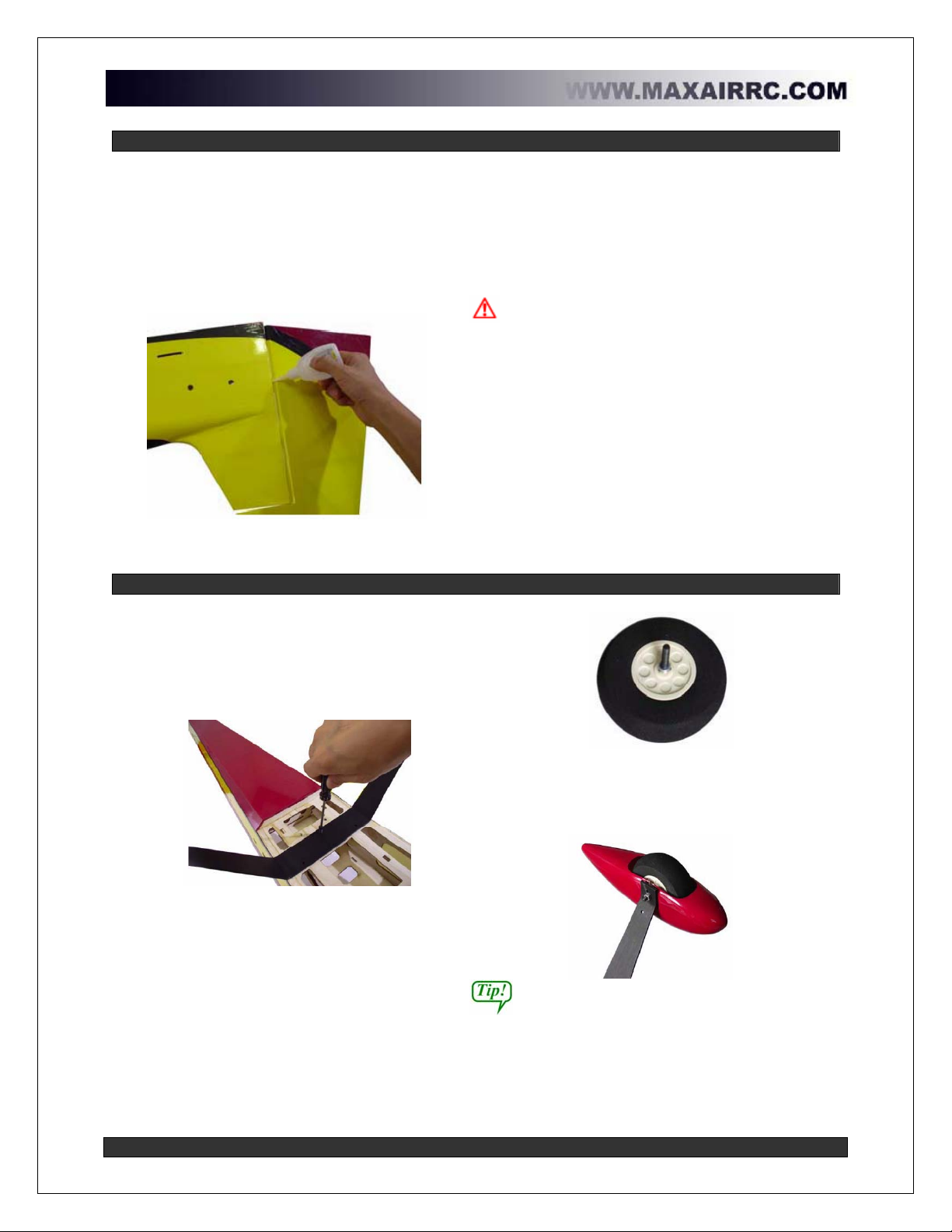

Step 2 – Prepare the servo cutout

a. Locate the servo cutout on the bottom of

the wing. The dimensions can be seen

in the picture below.

Aileron servo cutout dimensions

b. When cutting the covering to install

the servo, make sure to leave a 3mm

(1/8in) wide strip of covering that can be

ironed down in the servo cutout.

c. Cut the covering.

Leave a 3mm (1/8in) strip around the cutout

d. Iron down the overlapping covering and

around the servo cutout to make sure the

covering is secure.

e. The cutout allows for a standard size servo.

A high-torque servo is recommended.

Iron down the overlapping covering

f. Repeat for the opposite wing.

www.maxairrc.com Page 7 of 19

Step 3 – Install the aileron servos

Items required

a. One servo is required for each aileron.

(High-torque servos are required due to

the large size ailerons.)

b. Prepare the servos by installing the

rubber grommets.

c. It is important to note that the

copper inserts that are fit into the rubber

servo grommet must be installed with the

flange facing downwards. See image

below.

Flange on copper inserts facing downwards

d. A servo extension is required. It is

always a good idea to secure the servo

connector to the extension. We like to

use heat shrink tubing to ensure a

secure installation. See image below.

Secure servo connector to servo extension

e. Run the servo extension through the servo

cutout and out to the root of the wing panel.

f. Insert the servo into the cutout. Make sure

the servo goes in freely.

g. Mark and drill 1.5mm holes for the servo

screws by using the servo as a guide.

h. Do not try to screw servo screws

without drilling pilot holes first as this will

crack the servo mount.

Mark and drill 1.5mm pilot holes

i. A drop of thin CA in the pilot hole will harden

it and make for a strong servo installation.

Strengthen pilot holes with CA

j. Once the CA is dry, screw the servo in place.

k. Repeat for the opposite wing.

www.maxairrc.com Page 8 of 19

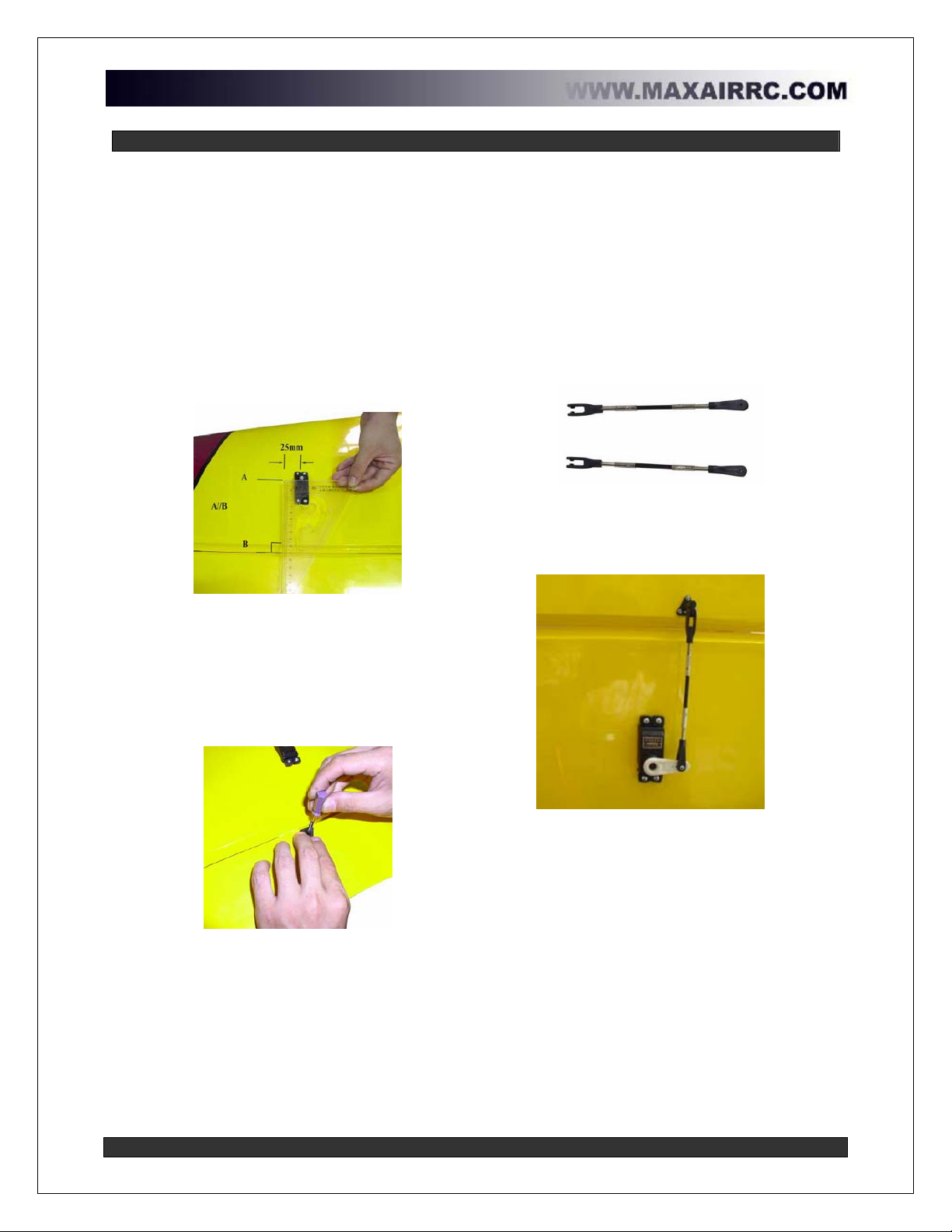

Step 4 – Install aileron linkage

It is very important that the aileron control

linkage be installed at a 90º angle to the

aileron hinge line.

a. Place a servo horn onto the servo output

shaft. The distance between the center

of the servo output shaft and the control

rod will vary depending on your flying

style. For 3D flying, a distance of 25mm

(1in) is required.

b. Using a square, determine the mounting

location of the aileron control horn.

c. Line A must be parallel to line B (hinge

line) to ensure a square installation.

How to square aileron linkage

d. Once you have determined where the

aileron control horn must be installed,

use a control horn to mark where the

pilot holes must be drilled.

Note: The control horn must be at the

very edge of the aileron.

Mark pilot holes for control horn

e. Drill the pilot holes and strengthen holes with

thin CA. Once dry, screw the control horn to

the aileron.

f. The control horns supplied with the kit are

infinitely adjustable which allow for maximum

adjustment to your flying style.

g. Adjust the length of the control rod so that

the aileron is at neutral position when the

aileron servo is at neutral,

Aileron control Horns

h. Repeat for the opposite wing.

Completed aileron linkage assembly

www.maxairrc.com Page 9 of 19

Fuselage Assembly

Step 5 – Prepare the servo cutouts

The first step in assembling the fuselage is to

prepare the servo cutouts. The MAXAIR Velox

RII was designed to allow for multiple servo

configurations. Pull-pull hardware is included

with the kit, but if required, the rudder servo can

be installed in the tail.

a. Cut the covering off of the left side

elevator servo cutout. Don’t forget to

leave a 3mm (1/8) wide strip around the

inside of the cutout that you will iron

down to the sides of the cutouts.

The cutout can be found using the

dimension in the image below.

Left side elevator servo cutout location

b. Repeat with the right side servo cutout

using the dimensions in the image

below.

Right side elevator servo cutout location

If you opt to put the rudder servo in the tail, the

rudder servo cutout can be found on the left side

of the fuselage below and behind the elevator

servo cutout as seen in the picture below.

The pull-pull wire exit is also shown in the picture

below.

Elev., rudder and pull-pull cutouts

Do not remove covering from all servo cutouts

and exit holes. Only remove the covering from the

servo cutouts and exit holes required.

www.maxairrc.com Page 10 of 19

Step 6 – Install the rudder

a. The rudder is installed exactly like the

ailerons were installed. Start by

adjusting the CA hinges so that the line

properly in the hinge slots.

b. A pin can be inserted through the center

of the hinge to make sure it stays

centered.

Install the rudder to the fuselage

c. Slide the rudder onto the hinges and butt the

rudder up against the vertical stabilizer.

d. Make sure there is no gap between the

rudder and the vertical stabilizer.

e. Drip some CA onto the CA hinges from each

side of the rudder.

Be careful not to drip any CA onto the covering.

The rudder must be able to move freely without any

binding.

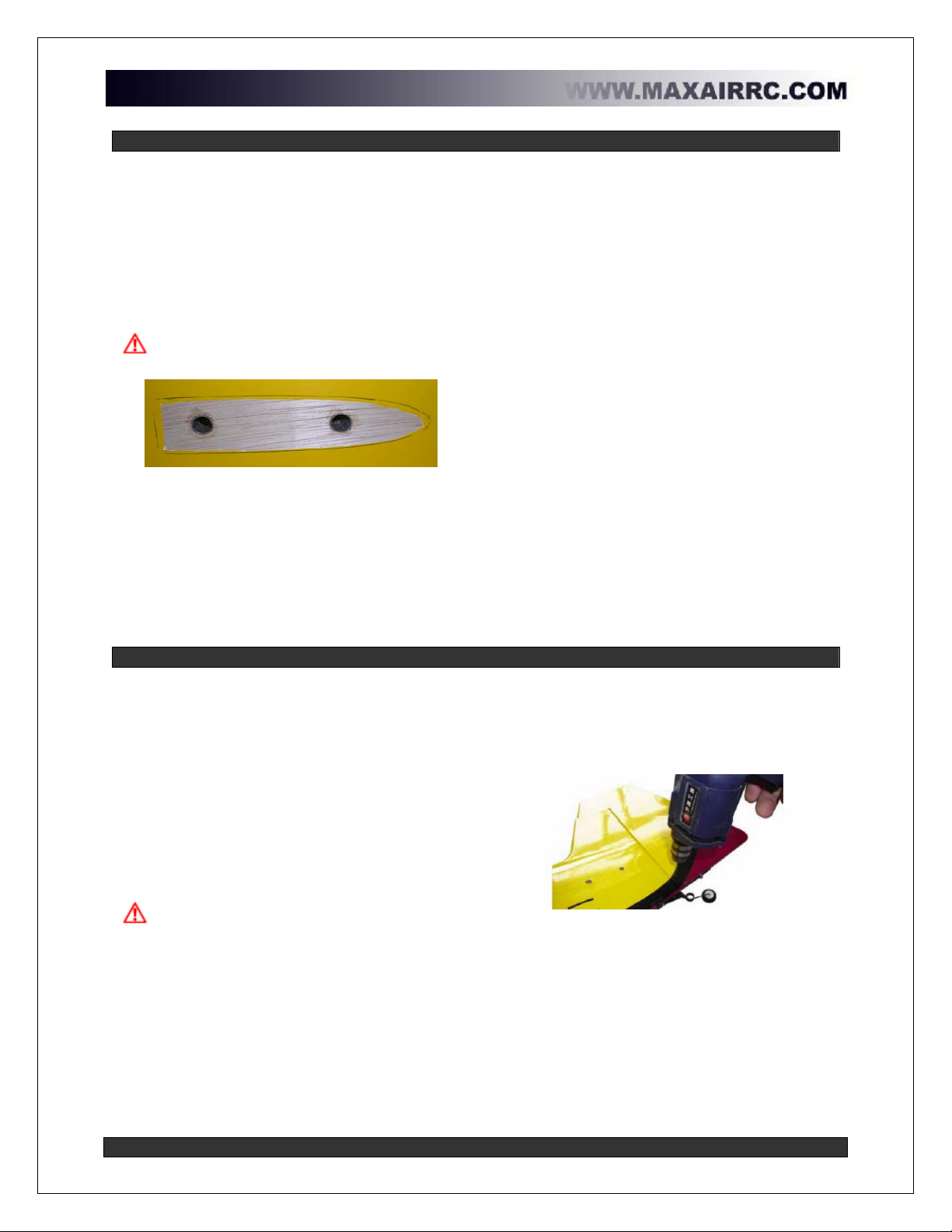

Step 7 – Install the landing gear, wheels and wheel pants

a. Remove the belly pan from the fuselage.

b. Install the landing gear with the supplied

screws. Use some removable thread

locking compound to secure the screws

to the blind-nuts.

Install the landing gear

c. Next, prepare the wheels. Insert the

screw included with the wheels through

the wheel hub. Screw a locknut onto the

screw. The wheel must be free to rotate.

Wheel assembly

d. Slide the wheel into the wheel pant and fix

the wheel pant assembly to the landing gear

using the remaining locknut.

Double sided padded tape placed between the

landing gear and the wheel pant assembly makes for an

even stronger assembly.

www.maxairrc.com Page 11 of 19

Step 8 – Install the tailwheel assembly

a. Insert the tail wheel axle wire through the

tail wheel mount. Bend the tail wheel

axle wire as shown in picture below.

Make sure that the tail wheel axle wire

rotates freely in the bracket.

b. Drill a 1.5mm hole at a distance of 50mm

(2in) from the leading edge of the rudder

as shown in picture below. The hole

should be about 10mm (0.4in) deep.

Drill 1.5mm hole 50mm (0.4in) from rudder leading

edge

c. Drip some thin CA into the hole to

strengthen it.

d. Once dry, fix the tail wheel axle wire

retainer into the 1.5mm hole. This will

turn the tail wheel when the rudder turns.

Tail wheel axle wire bracket

e. Place the tail wheel bracket on the bottom

rear of the fuselage and mark the where you

will need to drill the pilot holes.

f. Drill 1.5mm holes and drip some thin CA into

the holes to strengthen.

g. Once dried, mount the tail wheel bracket to

the fuselage with the included screws.

Mount the tail wheel bracket to the fuse

h. The portion of the tail wheel axle wire that

goes through the axle wire retainer should

be allowed to free float.

i. Mount the tail wheel and secure the wheel

collar in place.

Mount the tail wheel

j. Make sure that the rudder assembly can

move freely in both directions.

Rudder must move freely in both directions

Be careful not to drip any CA onto the covering

when strengthening the pilot holes.

www.maxairrc.com Page 12 of 19

Step 9 – Install the elevator

a. The elevator halves are installed exactly

like the ailerons and the rudder. Start by

adjusting the CA hinges so that they line

up properly in the hinge slots.

b. A pin can be inserted through the center

of the hinge to make sure it stays

centered.

Install the elevator halves

c. Slide the elevator half onto the hinges and

butt it up against the horizontal stabilizer.

d. Make sure there is no gap between the

elevator and the horizontal stabilizer.

e. Drip some CA onto the CA hinges from each

side of the elevator.

f. Repeat for the opposite elevator half.

Be careful not to drip any CA onto the covering.

Step 10 – Install the elevator control horns

To install the elevator control horns, we will

temporarily mount the horizontal stabilizers so

we can get proper alignment with the elevator

servos.

a. Locate the holes in the rear of the

fuselage where the 8mm (0.31in)

carbon fiber support tubes are slid

through the fuse. Remove the

covering from these holes and slide

the horizontal stabilizer 8mm carbon

fiber support tubes through them. The

shorter of the two goes in the front

hole.

Locate the horizontal stab. support tube holes

b. Slide one of the elevator halves onto the 8mm

(0.31in) carbon support tubes.

c. Place a servo in the elevator servo cutout so

you can align the control horn with the servo

horn.

d. Once aligned, mark and drill the holes for the

elevator control horn. Drip some thin CA into

the holes to strengthen.

e. Once dried, mount the elevator control horn to

the elevator.

Mount the elevator control horn

f. Repeat for the opposite elevator half.

Be careful not to drip any CA onto the covering.

www.maxairrc.com Page 13 of 19

Step 11 – Install the horizontal stabilizers

a. The horizontal stabilizers are mounted

onto the 8mm (0.31in) carbon fiber

tubes as described earlier.

b. Mark around the horizontal stabilizer

on the side of the fuselage.

c. Cut the covering inside of the marked

off area. Make sure to leave a 3mm

(1/8in) strip inside of the marked off

area as shown below. Do both sides.

Make sure to only cut the covering and

not cut into the wood.

Remove the covering inside of the marked off area

d. Test fit the horizontal stabilizers onto

the 8mm (0.31in) carbon fiber tubes.

Once you are happy with the fit, you

are ready to glue the horizontal

stabilizer to the fuselage.

e. The next step is very important. You must

prepare your epoxy, coat the 8mm (0.31in)

carbon fiber tubes and the size of both

horizontal stabilizers with epoxy and assemble

them. 30 minute epoxy is recommended for

this step. Make sure all your parts are in place

and you have a rag and some alcohol or

acetone to wipe up the excess epoxy before it

cures.

¾Mix the epoxy.

¾Coat the outside of the carbon fiber

tubes with epoxy and slide into the

fuselage support holes.

¾Coat the sides of each horizontal

stabilizer with epoxy.

¾Slide the horizontal stabilizers in

place.

¾Wipe off the excess epoxy that

squeezes out when horizontal

stabilizers are slid into place.

¾Secure horizontal stabilizers to

fuselage while epoxy cures.

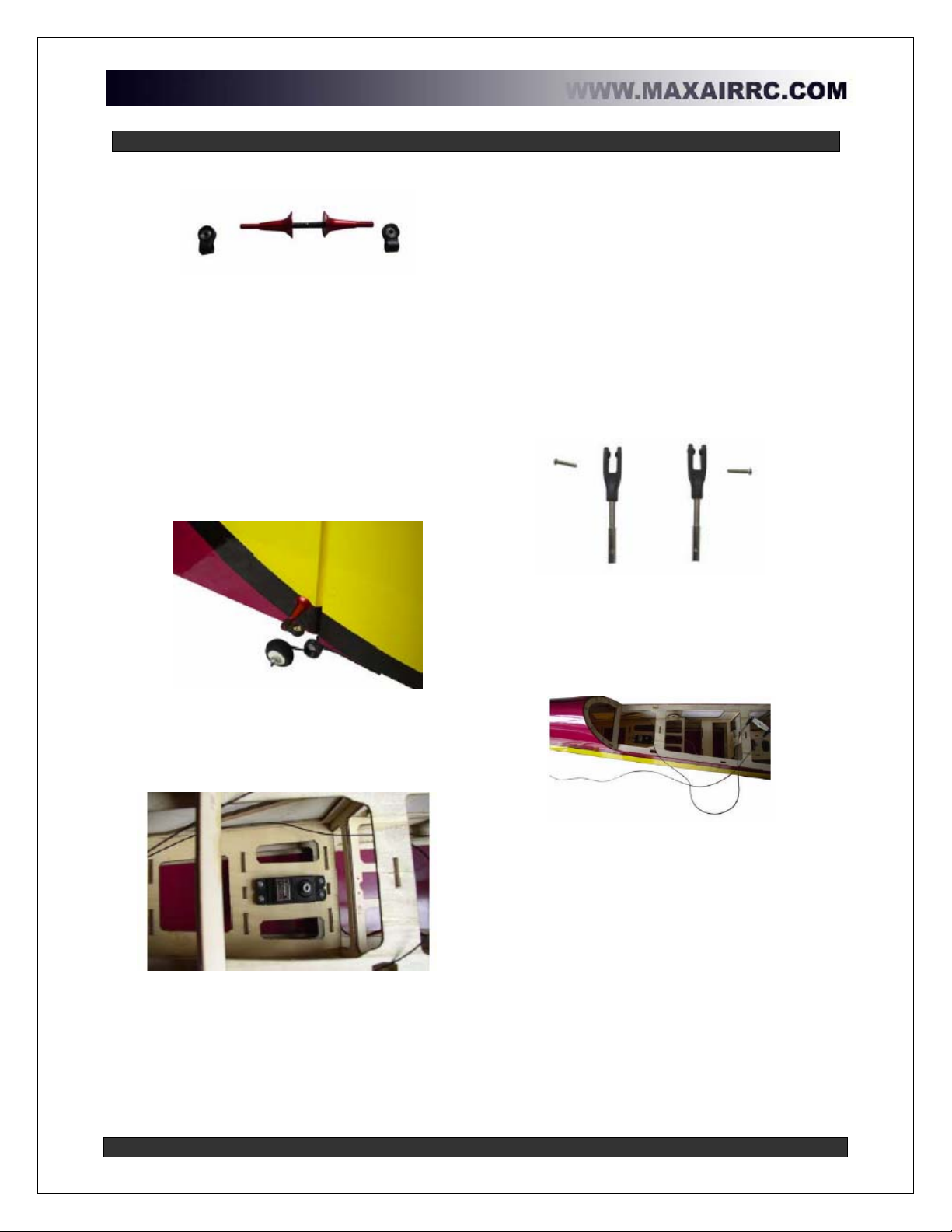

Step 12 – Install the rudder servo and pull-pull control horn

a. Align the rudder pull-pull control horn

with the exit cutout in the fuselage and

the rudder servo so that the pull-pull wire

makes a straight line out of the fuselage.

b. The distance from the pull-pull control

horn and the leading edge of the rudder

should be such that hole in the plastic

part of the pull-pull control horn is

aligned with the hinge line.

c. When satisfied with the placement of the

control horn, drill a 3mm hole through

the rudder.

The hole must be drilled perfectly straight

so that the control horn is as the same position

on both sides of the rudder.

d. Drip some thin CA into the hole to strengthen

it.

Drill pull-pull control horn hole

Continued…

www.maxairrc.com Page 14 of 19

Step 12 (Continued…) – Install the rudder servo and pull-pull control horn

Pull-pull control horn hardware

e. Once the CA has dried, unscrew the

aluminum support pieces from the pull-

pull control horns and screw the

threaded rod through hole in the rudder.

f. Replace the aluminum support pieces on

each side of the threaded rod making

sure the same amount of rod sticks out

of each side of the rudder.

g. Screw the plastic end pieces onto the

threaded rod. These can be infinitely

adjusted to suit your flying style.

Completed pull-pull control horn assembly

h. Place the rudder servo in the rudder

servo cutout in the main area of the

fuselage.

Rudder servo in place

i. Mark and drill the holes with a 1.5mm drill

bit. Drip some thin CA into the holes to

strengthen them.

j. When dry, screw the rudder servo to its

mount.

k. Prepare the pull-pull clevises by screwing

them onto the threaded end pieces.

Pull-pull clevises

l. Run the pull-pull wires through the fuselage

and out the exit cutouts to adjust the length.

m. Once the length of wire is determined, run

the wire through the threaded end pieces.

Run the pull-pull wire through the fuselage

n. When the proper length has been set, crimp

metal tubing over the pull-pull wire to secure.

Continued…

www.maxairrc.com Page 15 of 19

Step 12 (Continued…) – Install the rudder servo and pull-pull control horn

o. Adjust the pull-pull wire tension by

screwing the threaded end rod in or out

of the clevises.

Final pull-pull assembly

Pull-pill cables must cross over

Note: If you opted to mount your rudder

servo in the tail of your Velox, you will need

to mount a conventional control horn as

described in the earlier steps.

Step 13 – Install the elevator servos and linkages

a. Since the elevator servos are in the tail,

you will need servo extensions. As in

the aileron step, it is a good idea to

secure the servo connector to the servo

extensions. We like to use heat shrink

tubing to secure the two connectors

together.

Secure the servo connector to the servo extension

b. Place the elevator servos in the elevator

servo cutouts that you prepared earlier.

c. Mark and drill the holes with a 1.5mm

drill bit. Drip some thin CA into the holes

to strengthen them.

d. When the CA has dried, screw the

elevator servos to the fuselage.

e. Center the elevator servos and place a servo

horn on the servo output shaft.

f. Adjust the elevator control rod on the left

side to 270mm (10.6in) and the elevator

control rod on the right side to 212mm

(8.35in).

Left elevator half control rod (270mm / 10.6in)

Right elevator half control rod (212mm / 8.35in)

g. Install the control rods.

www.maxairrc.com Page 16 of 19

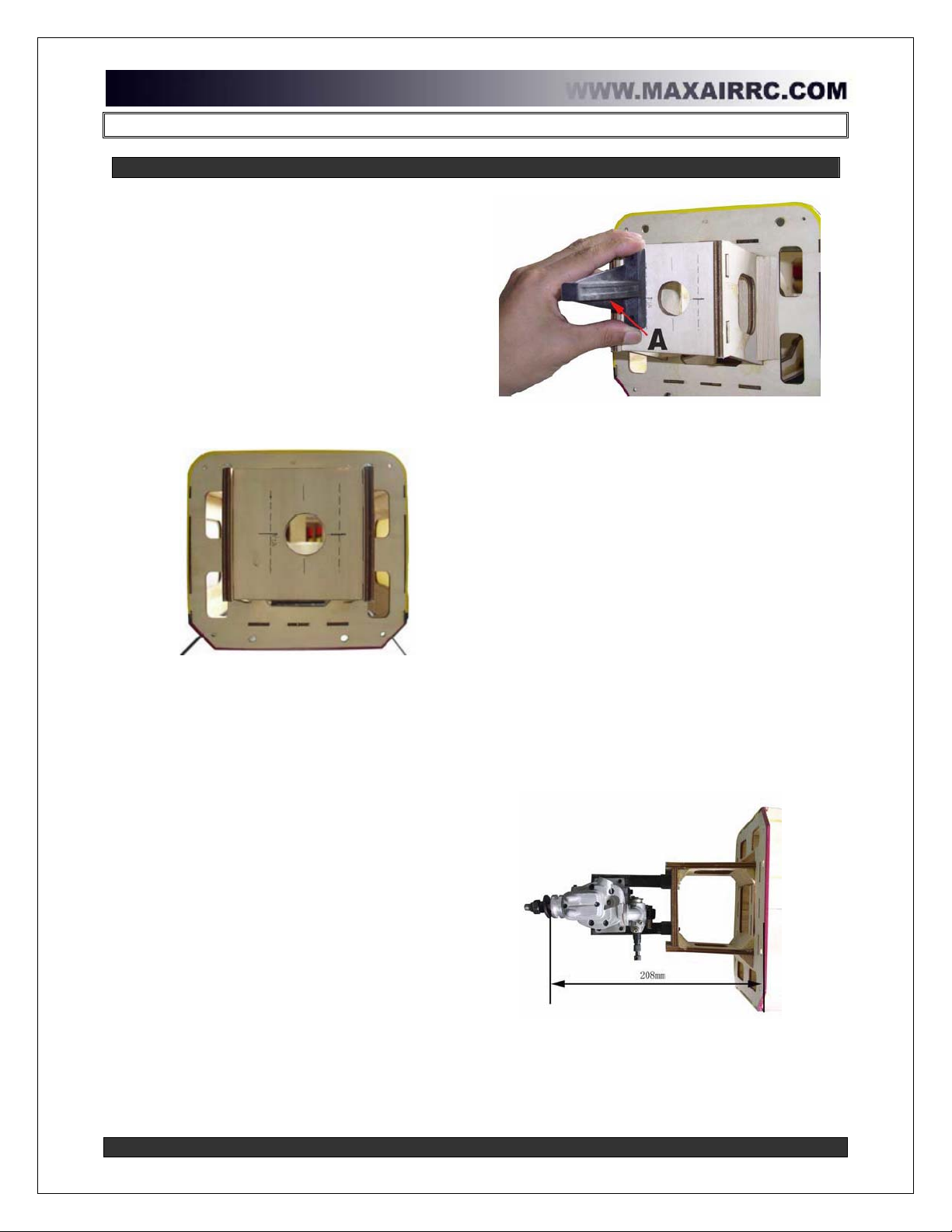

Engine Mounting

Step 14 – Mount the engine

Mounting the engine may be a little different

depending on the engine size you choose to

install in you Velox Revolution II.

The engine installation we will describe in this

section is for an inverted engine.

a. The center of the hole in the front of the

motor box indicates the thrust line for the

aircraft. Locate the top, bottom and

each side of the hole as shown in the

picture below.

Locate thrust line based on hole center

b. Once you have marked the center of the

hole as indicated, mark the distance for

the engine mount holes. This distance

will vary depending on the width of the

engine you choose. See picture above.

c. Now that your motor box is marked as

described, you need to locate the engine

mount holes.

d. Place one side of the engine mount on

the engine mount line you just drew on

the motor box. The surface of the

engine mount that the motor will sit on, in

this case it’s the bottom since it’s an

inverted installation, needs to line up

perfectly with the horizontal mark from

the center hole, Confused yet? Look at

the picture below. In this case, the

surface ‘A’ needs to be aligned with the

aircraft thrust line.

Align the engine mount surface with the aircraft thrust line

e. Now that the engine mount has been

properly located, mark the engine mount

holes.

f. Check the alignment of the engine with the

cowl to make sure the engine is properly

aligned.

g. When satisfied, drill and mount the engine

mount.

h. The next step is to locate the engine on the

mount and adjust it so that it will be set at the

proper distance from the firewall so that the

engine is sitting in the proper position in

relation to the cowl.

i. Sit the engine on the mount and measure

208mm (8.2in) from the firewall to the front of

the engine’s propeller hub.

j. Test fit the cowl at this position. If you are

happy with this position, mark the engine

mount holes, drill the engine mount and

secure the engine to the mount.

Proper engine position from the firewall (208mm / 8.2in)

Continued…

www.maxairrc.com Page 17 of 19

Step 14 (continued…) – Mount the engine

The next step to complete the engine

installation is to mount the throttle servo.

The Velox Revolution II was designed to allow

for the throttle servo to be mounted on the right

or left hand side of the fuselage.

k. Place the throttle servo in the throttle

servo mount on the side of the fuselage

where the throttle assembly on your

engine is located.

l. Align the throttle so that the control rod

to the engine is able to move freely with

no binding.

m. Mark the holes and drill with a 1.5mm drill

bit. Drip some thin CA in the holes to

strengthen the hole.

n. When the CA has dried screw the throttle

servo to the mount and finish installing the

throttle control rod.

Install the throttle servo

Step 15 - Assemble and mount the fuel tank

a. The first step in assembling the fuel tank

is to slide plastic cover onto the supplied

screw. The slide the rubber stopper onto

the screw and sandwich the rubber

stopper with the metal base plate.

Screw the assembly together, but do not

tighten yet.

b. Slide the copper tubes into the stopper

assembly. You may use a 2 or 3 line

setup as per your needs.

c. Make sure that the vent tube is bent

upwards into the tank.

d. Slide the silicone fuel tubing onto the fuel

feed tube. Place the clunk on the other

end of the silicone fuel tubing and make

sure the length of the silicone tubing

allows it to move freely in the tank when

assembled.

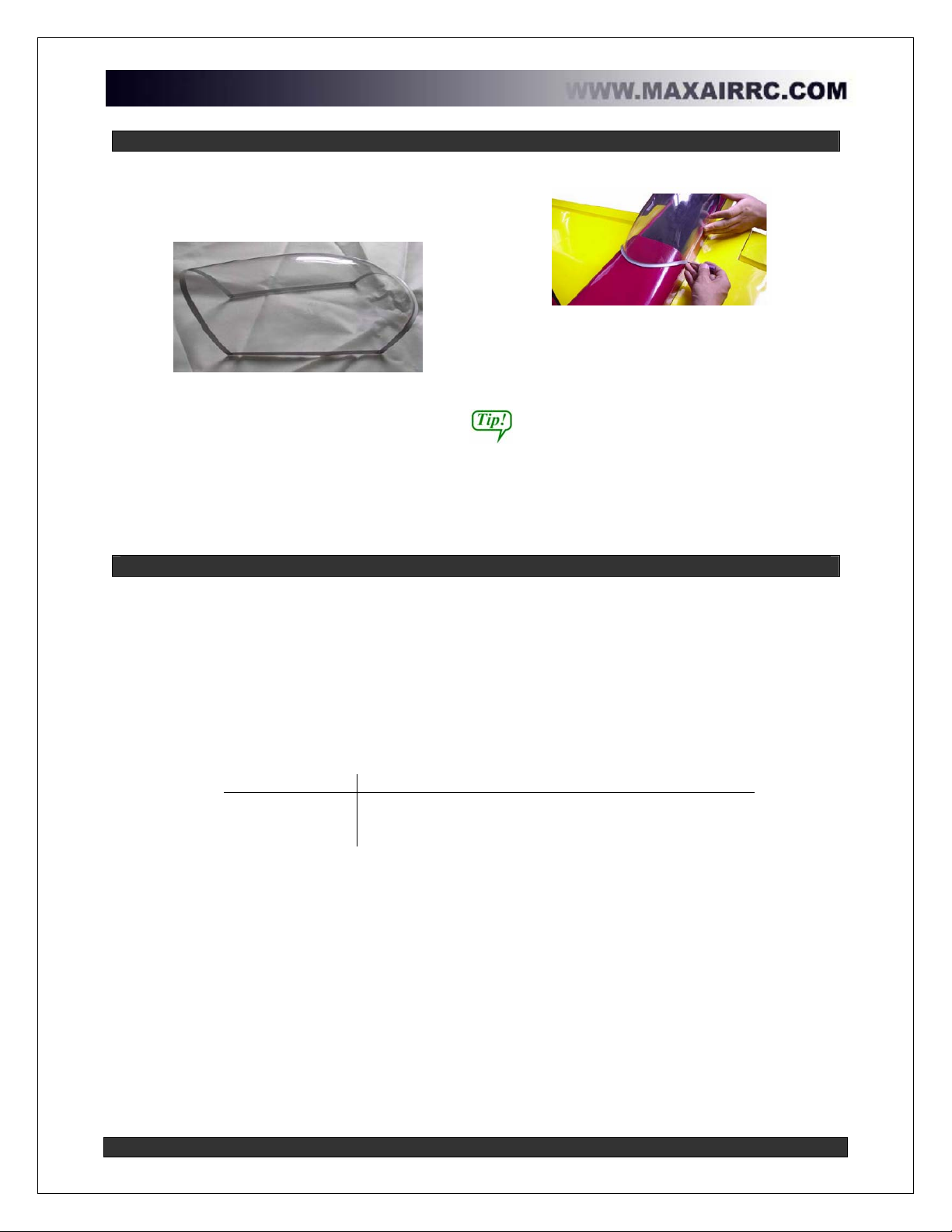

Fuel tank components

e. Insert the stopper assembly in the tank and

tighten the screw to seal the tank.

f. Once the tank is assembled, place the fuel

tank on the fuel tank shelf in the front of the

fuselage as show below. Place some foam

rubber under the tank and secure to the

shelf. We like to use zip ties to secure the

tank.

Fuel tank secured to the fuselage

www.maxairrc.com Page 18 of 19

Step 16 - Final Assembly

Belly pan

a. Replace the belly pan and screw into

place. Use a little bit of removable

thread locking compound on the screws.

Replace the belly pan

Fasten the belly pan with included screws

Prepare fuselage wing holes

b. Remove the covering from the holes on

the side of the fuselage where the wing

tube, wing support nylon bolts and servo

extension pass through. It’s always a

good idea to iron down the covering

once the hole has been cut.

c. Slide the wing tube onto the fuselage.

d. Remove the wingnuts from the wing

nylon support bolts and trial fit the wing

on the plane.

Trial fit the wings

Prepare the canopy/hatch hold downs

e. Place the top hatch on the fuselage. Find

the screw holes on the side of the fuselage.

There are two on each side.

f. Cut the covering off of the screw holes.

g. Drill the top hatch support tab through the

screw hole to ensure perfect alignment.

h. Once drilled, drip some thin CA into the

screw holes in the side of the fuselage as

well as the ones on the top hatch support

tabs to strengthen them.

Mark and drill a 2mm hole for the

Strengthen the holes with thin ca

Be careful not to drip any CA onto the covering.

i. Fix the top hatch to the fuselage using M2.5

x 8 self-tapping screws.

Fix the top hatch to the fuselage

Continued…

www.maxairrc.com Page 19 of 19

Step 16 (Continued…) - Final Assembly

Attach the canopy

j. Prepare the canopy as illustrated below.

Test fit the canopy before cutting.

Prepare the canopy for installation

k. Place the canopy on the fuselage and

temporarily hold down with tape. Once

satisfied with the position, mark and drill

the pilot holes for the screws that will

hold down the canopy.

Mark and drill pilot holes

l. Drip some CA into the pilot holes to

strengthen.

m. Once dry, attach the canopy with the

included screws.

Canopy glue can be used to help strengthen

the canopy installation, but this makes it a

permanent installation.

Step 17 Final adjustments

Your MAXAIR Velox Revolution II is almost ready to fly. A few more adjustments and a final

pre-flight check and you’re ready to go!

-Center of Gravity: A good starting point for the balance of the plane is 145mm (5.7in)

from the leading edge at the root of the wing.

-Lateral balance: Do not forget to balance your model laterally (side to side). This is very

important.

-Control throws: Adjust your control thrown as per the table below:

Recommended Control Throws

Low rates High rates

Rudder 20º 35º

Aileron 15º 25º

Elevator 15º 40º

-Surface Deflection: The elevator uses split surfaces. It is very important that each half

moves the same amount as the other half to fly properly. Measure and adjust the

deflection as necessary.

-Perform you final check to make sure everything is secured properly and go flying!

-After your first flight, check everything to make sure none of the screws have vibrated

loose.

Be safe and have fun!

Table of contents