©2003 JoTiKa Ltd. 9

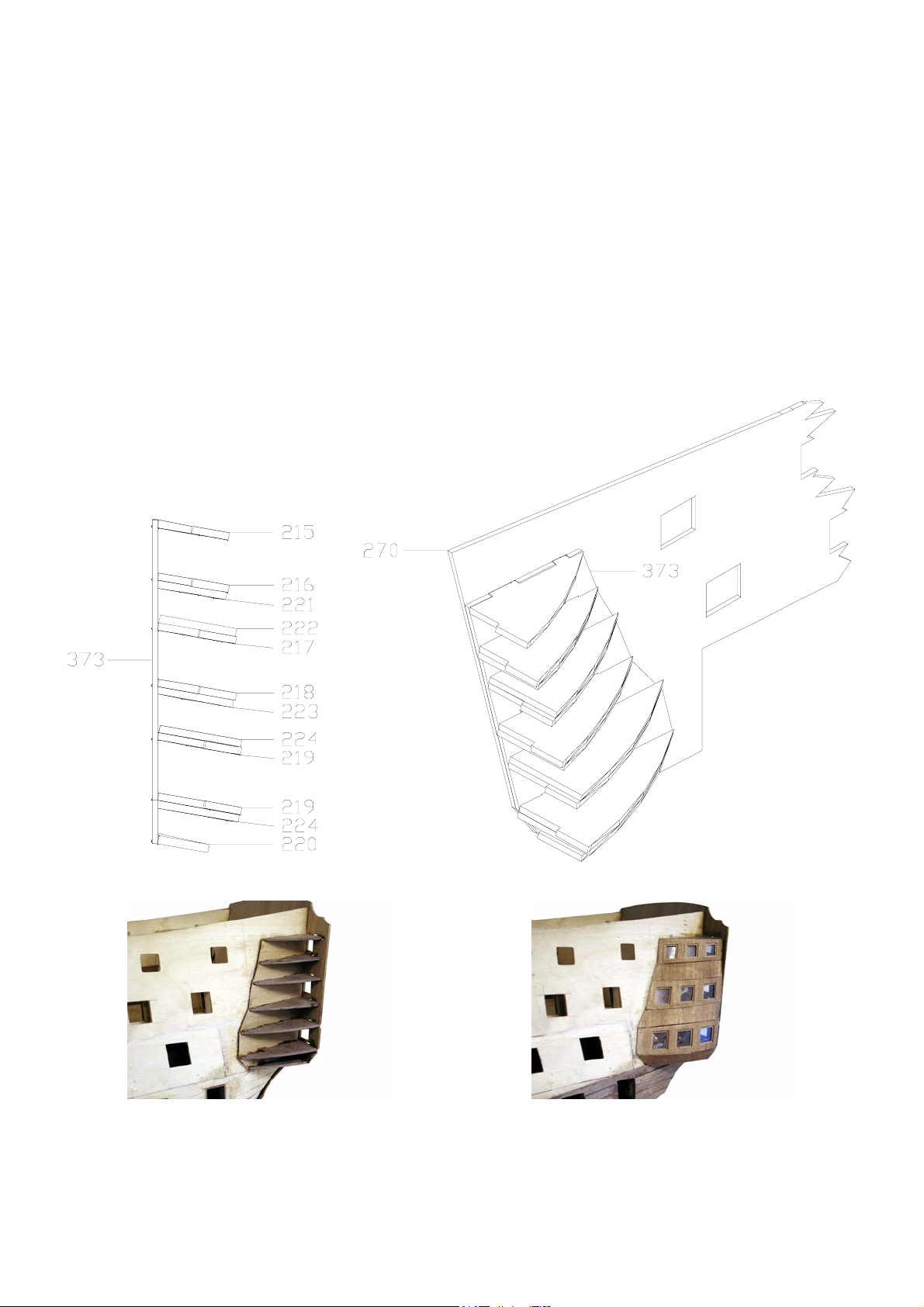

Once this stage has been completed, it will become obvious that the 1.5mm walnut quarter gallery skins (365-370) will join

along these patterns, you will also notice the downward and outward lie of these skins. N.B. All trimming of these skins

should be made along the foremost edge, do not trim the rear edge that sits flush against the stern fascia (374)!

The 2mm walnut quarter gallery insert patterns (221-224) can now be glued into position (Fig 001). They will require

bevelling to form the basic shape, it is advisable to check the skins against their respective locations as you progress down the

galleries. Again work on alternating sides.

Before the quarter gallery skins with windows (365, 367 & 369) are glued into position, it is advisable to clean out the corners

of the recess in preparation of fitting the window frames, also they will have to be glazed with the plastic glazing provided.

Glue the sheet to the inside of the skin to cover the three openings. Use PVA to do this as the fumes from super glue will

discolour and cloud the glazing, (Photo 009).

In conjunction with the drawings provided, work down the skins fitting and gluing into position. Bevelling and shaping will be

required.

Take extra care not to damage the glazing on the skins.

The stern fascia will be glazed at a later time between the inner and outer patterns.

Middle Gun Deck Planking

A small area of this gun deck will be visible through the upper gun deck companionways and the side entry ports. Using

1x4mm Tanganyika, plank the middle gun deck between bulkheads (4) and (12) and across the beam to the bulkhead risers and

plank completely across the beam at the side entry ports position. Make sure the main mast hole is cleared. Glue into position

the main mast sleeves (154), the mast sleeves will requiring filing to allow the main mast to pass through at the correct angle

(as determined by the slot in the keel).

When planked, lightly sand the deck smooth. Apply a coat or two of matt polyurethane varnish to seal the grain.

It is advisable at this stage to paint the areas between the outside faces of the dummy barrel strip and the deck area up to the

inner side of the ships sides. These areas will be visible to some degree and painting is better achieved at this stage, paint the

areas matt black (Humbrol 85).

Using 1x16mm walnut strip, line the entry ports.

Cut the strips to length and glue on the vertical sides first, followed by the top and bottom sills. When complete, sand the outer

sills flush with the side of the hull. If necessary, a smear of super glue over the strip, prior to cutting, can be used to avoid

splitting.

Second Planking

The second planking is laid using 1x5mm walnut. The gluing of the second planking also differs from the first as the whole

under surface of the walnut strip is glued to the surface of the first planking as well as edge to edge.

Before progressing, taper the first planking as previously instructed on page 3.

Referring to Plan Sheet 2, mark the position of the upper edge of the middle wale onto the hull, this is best achieved by

measuring the distance from each gunport lower edge to the point of intersection with the wale and joining these points with a

smooth line (formed by temporarily positioning a plank against the hull). This line now denotes the upper edge of the first

plank, of the second planking, which can now be laid.

Once the first walnut strip has been laid, work down to the keel using the same planking method as the first planking. Some

slight tapering will be required at the bows and it should be treated in a similar manner to the first planking method. The

walnut planking around the bows will have to be soaked in water first.

The best glue to use above the waterline is medium super glue. This is to avoid the use of pins, eliminating pinholes that would

have to be filled prior to painting. Super glue will stick the planks as well, if not better than, PVA wood glue. Around the bow

area, where the walnut strip has been soaked in water, take extra care – wet wood and super glue will bond more or less

instantly! Great care is needed to attain as neat a job as possible to minimise the need for filling. If desired, PVA wood glue

can be used for the planking beneath the waterline in conjunction with pins temporarily pushed half way in, until the glue has

cured.

After the lower planking has been laid, identify and fit the back keelson (57) and stern post (58).

Note: Lay one or two planks on alternative sides when planking, to avoid ‘pulling’ the keel out of shape, cutting the gunport

openings as you progress: cut the gunports to exactly the same size as the gunport patterns.

Note: With the lower planking completed, you can continue to plank upwards but at this stage do not plank over any of the

gunport openings of the upper deck! This area will be planked at a later stage because eight of the centre gunports have to be

lined first and this cannot be done until the upper deck inner bulwark pattern (275) has been fitted.