maxon motor control ADS_E 50/5

Order number 166143

Operating Instructions June 1999 edition

The ADS_E 50/5 is a powerful servo-

amplifier for driving permanent magnet

DC motors up to 250 Watts.

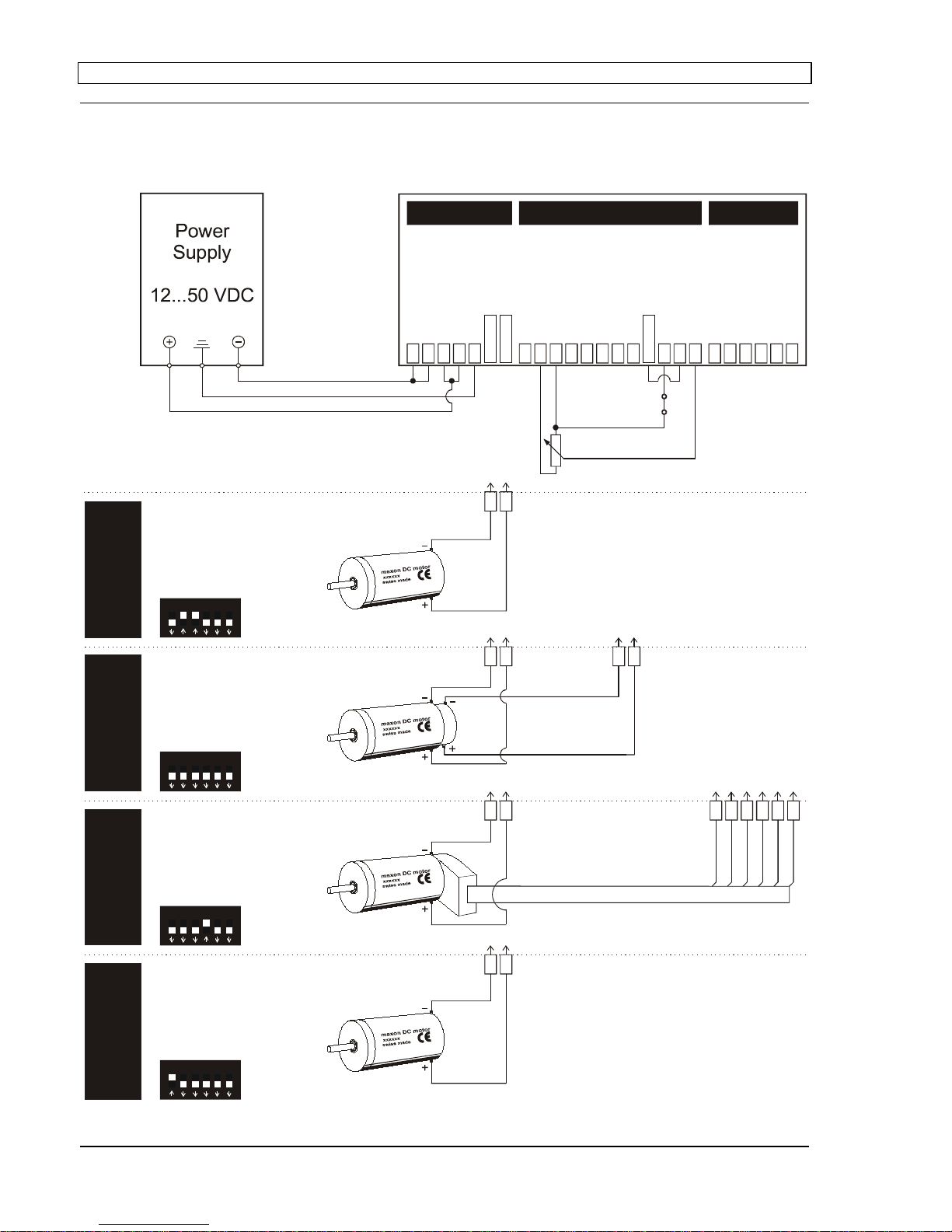

Four modes can be selected by

DIP switches on the board:

•Speed control using tacho signals

•Speed control using encoder signals

•I x R compensated speed control

•Torque or current control

The ADS_E 50/5 is protected against

excess current, excess temperature and

short circuit on the motor winding.

With the FET power transistors incorpo-

rated in the servoamplifier, an efficiency of

up to 95% is achieved.

A built in motor choke combined with the

high PWM frequency of 50 kHz allows the

connection of motors with a very low

inductivity.

In most cases an external choke can be

omitted.

Thanks to the wide input power supply range of 12 - 50 VDC, the ADS_E 50/5 is very versatile and can be used

with various power supplies.

The Europa card size allows the unit to be installed in a 19“-subrack or in a plug-in card system. Thanks to the

controller circuit design, the ADS_E 50/5 is easily and quickly installed.

Table of Contents

1 Safety Instructions.............................................................................................................................................2

2 Performance Data..............................................................................................................................................3

3 Minimum External Wiring for Different Modes of Operation ..............................................................................4

4 Operating Instructions........................................................................................................................................5

5 Functions ...........................................................................................................................................................7

6 Additional Possible Adjustments......................................................................................................................10

7 Error Handling..................................................................................................................................................11

8 Block Circuit Diagram......................................................................................................................................12

9 Pin Allocation Connector DIN 41612 Version H7/F24...................................................................................12

10 Dimension Drawing..........................................................................................................................................13

11 Accessories (not part of delivery) ...................................................................................................................13

The latest edition of this operating instructions may also be found in the internet under

http://www.maxonmotor.com («Downloads» in the category «Service & Support»).