MAX-VAC.COMDV15 Hydro

8

USING THE APPLIANCE

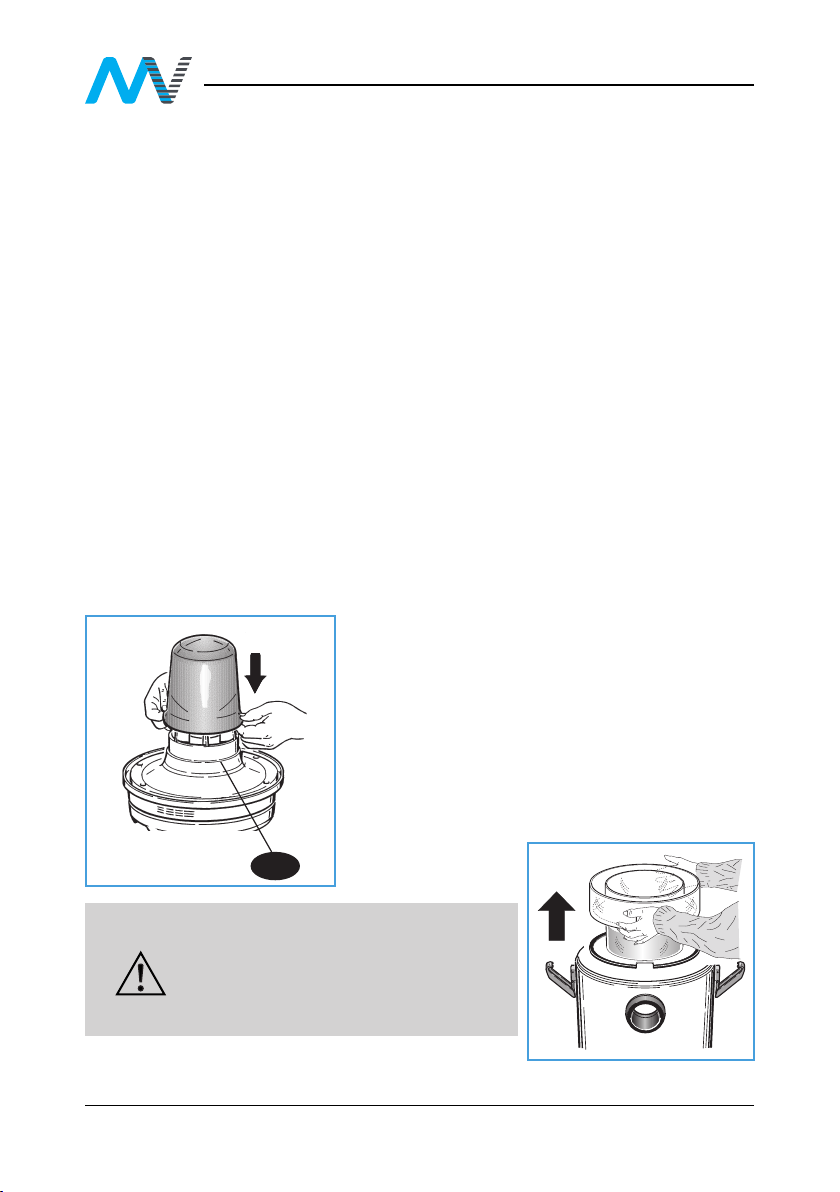

• Remove the motor unit (gures “A1” - “A2”).

• Fit the “long” conveyor attachment onto the air inlet connector (g. “C1”).

• Add clean water to the particle separator up to the level indicated

(MAX 2.5 litres)

• (g. “C2”); then pour water into the drum (g. “C3”).

• Place the particle separator “without water” into the drum (g. “C4”).

• Ret the motor unit (g. “A3”).

•

1. FOR USE AS A DRY VACUUM CLEANER

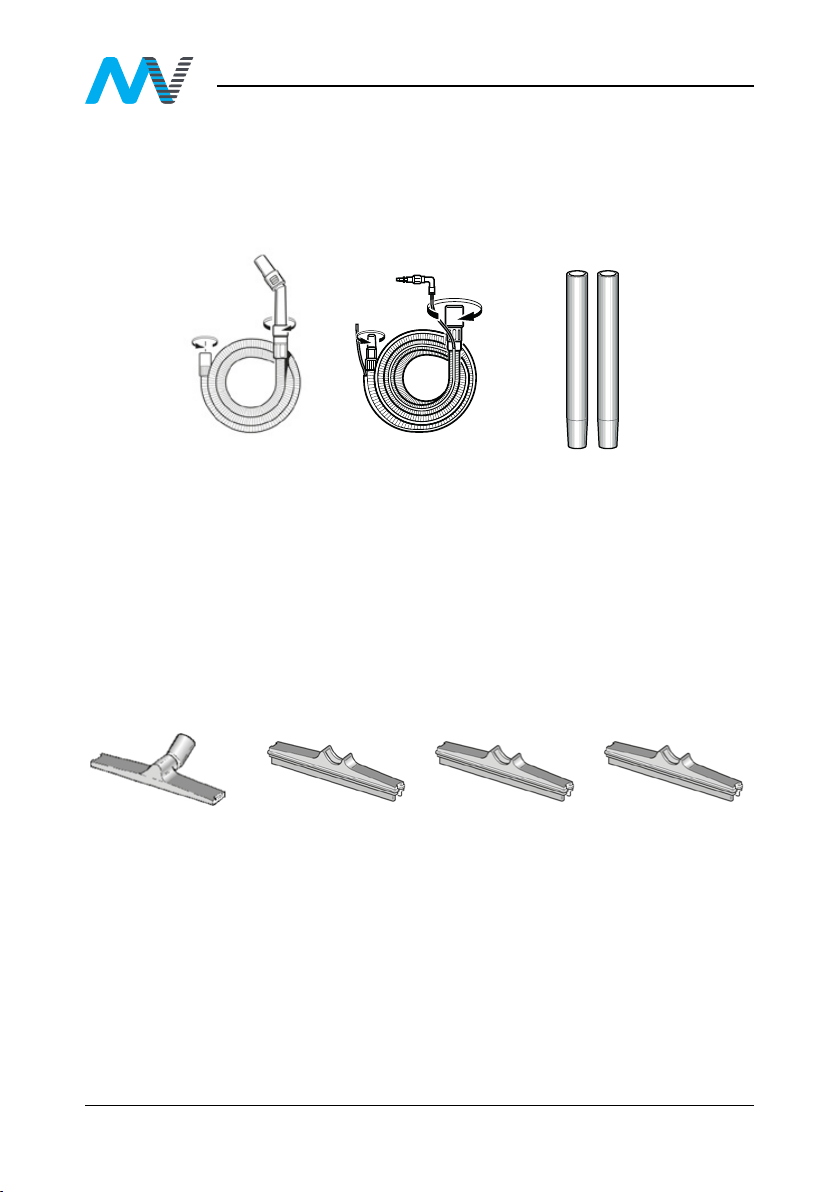

• Connect the following attachments in order:

1- Flexible hose connector “x” to the air inlet connector “y” (g. “C5”).

2- The ergonomic grip to the plastic extension wand (g. “C6”).

3- The extension wand to the attachment to be used.

2. FOR USE AS A WET VACUUM CLEANER

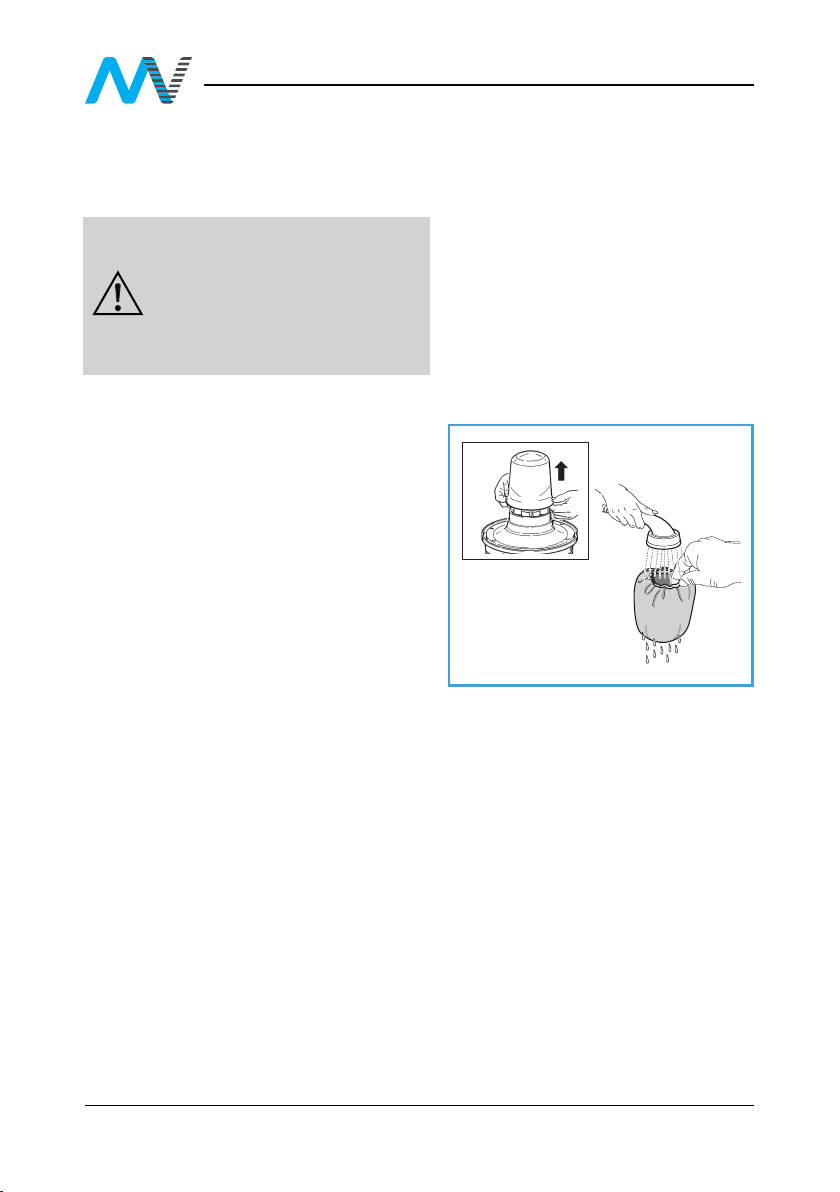

• Release the motor unit (gures “A1” - “A2”).

• Remove the particle separator

• Replace the “long” conveyor attachment with the

• “short” one (g. “C7”).

• Ret the motor unit (g. “A3”).

• Fit the attachments as described in the preceding

3. TO VACUUM LARGE QUANTITIES OF LIQUID

• When vacuuming liquids from containers, make sure the crevice tool is never

fully submerged to ensure partial air ow.

CAUTION

When the vacuumed liquids reach the maximum level inside

the drum suction is automatically shut off by the safety float

and the noise level of the appliance gets rapidly louder.

Switch off the appliance immediately, release the motor unit

and empty the drum.

LEVELWATER