c. Astheamelightsup,keepthevalvebuttonpushedfor10secondsapprox.Shouldthe

heater stop when the valve button has been released, wait one minute and repeat the

starting operation keeping the valve button pushed for a longer time.

d. Regulatethegasowpressureaccordingtothethermalpowerdesired,byturningthewheel

of the pressure reducer anticlockwise to increase the pressure or clockwise to decrease.

e. Contact your supplier should any problem continue.

CAUTION

If ignition is difcult or irregular before repeating the ignition operations make sure that the fan is

not locked and the air inlet and outlet are unobstructed.

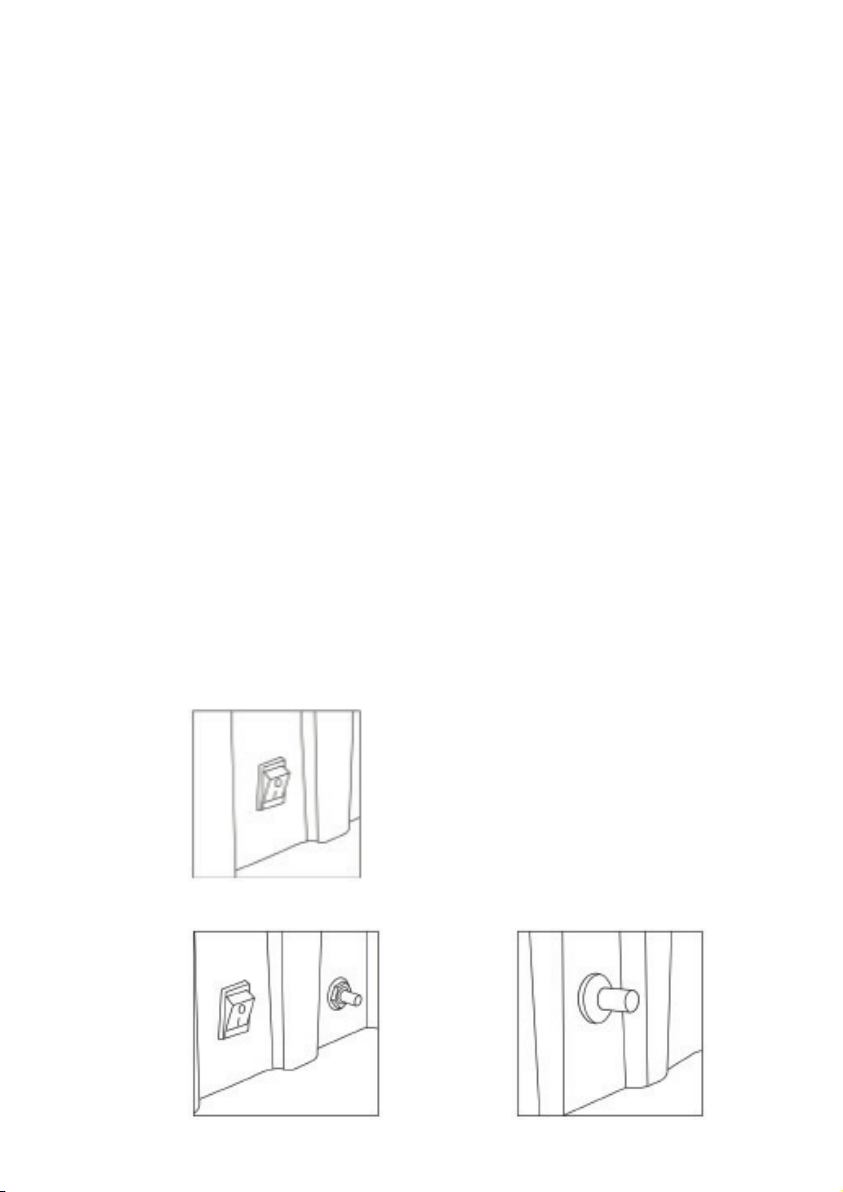

3.2 SWITCH OFF

Tostoptheheater,shutoffthegascylindertap.Letthefanrununtiltheameshutsdownandthen

turn the fan switch to position O.

3.3 AIR CONDITIONING

a. The heater can also be used as a ventilator.

b. In this case remove the gas supply hose and connect the plug of heater to a suitable

electrical supply.

c. SetthefanswitchtopositionI.

ODOR FADE WARNING

!!! WARNING

Asphyxiation Hazard

1. Do not use heater for heating human quarters.

2. Do not use in unventilated areas.

3. Theowofcombustionandventilationairmustnotbeobstructed.

4. Proper ventilation air must be provided to support the combustion air requirements of

the heater being used.

5. Lack of proper ventilation air will lead to improper combustion.

6. Improper combustion can lead to carbon monoxide poisoning leading to serious injury or

death.Symptomofcarbonmonoxidepoisoningcanincludeheadachesdizzinessand

difcultyinbreathing.

FUEL GAS ODOR

LP gas and natural gas have manmade odorants added specically for detection of fuel gas leaks.

If a gas leak occurs you should be able to smell the fuel gas. Since Propane (LP) is heavier than

air you should smell for the gas odor low to the oor. ANY GAS OROR IS YOUR SIGNAL TO GO INTO

IMMEDIATE ACTION!

1. Do not take any action that could ignite the fuel gas. Do not operate any electrical switches.

Do not pull any power supply or extension cords. Do not light matches or any other source of

ame.Donotuseyourtelephone.

2. Get everyone out of the building and away from the area immediately.

3. Closeallpropane(LP)gastankorcylinderfuelsupplyvalves,orthemainfuelsupplyvalve

located at the meter if you use natural gas.

4. Propane(LP)gasisheavierthanairandmaysettleinlowareas.Whenyouhavereasonto

suspect a propane leak, keep out of all low areas.

5. Useyourneighbor’sphoneandcallyourfuelgassupplierandyourredepartment.

Do not reenter the building or area.

6. Stayoutofthebuildingandawayfromtheareafromtheareauntildeclaresafebythe

reghtersandyourfuelgassupplier.

7. FINALLY,letthefuelgasservicepersonandthereghterscheckforescapedgas.

Have them air out the building and area before you return. Properly trained service people

must repair any leaks, check for further leakages, and then relight the appliance for you.