MAY DMZ329 User manual

Stand 40-081 English page 1 of 9

Installation instruction DMZ329 and DMZ330

Ground screw for MEZZO / DACAPO / FILIUS

The following instructions include all information necessary for the correct mounting and

operation of your MAY screw-in ground anchor. For absolute safety, please read these

instructions carefully and then keep them for later reference.

Non- observation of operating instructions can result in personal

injuries or damage to property.

Please note that if these instructions are not observed, the manufacturer cannot

assume any liability or guarantee.

Always follow the safety regulations.

Should you not understand any part of these operating instructions, please

contact your MAY dealer.

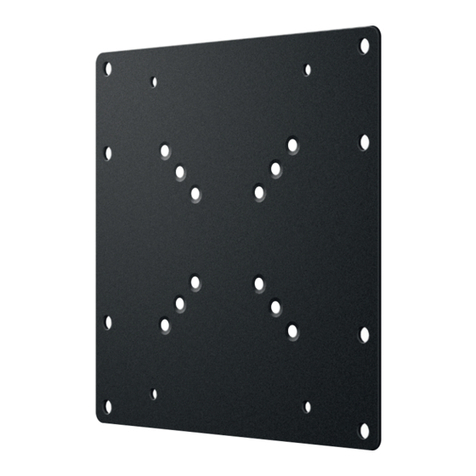

Mounting drawing

1x ground screw, length: 2 m

bore hole for theft and anti-twisting

lock

1x flange plate

1x hexagon screw, M16x30mm

1x washer

1x upper anchor tube

3x countersunk screw M16

3 x nut M16

+ 3x washer

3x set screw for vertical adjustment

Caution

Stand 40-081 English page 2 of 9

Service: Installation of ground screw

Preconditions:

-DMZ329 / DMZ330 must be purchased (upper tube and ground screw)

-Make sure there are no pipes, tubes, gas pipes, water or power supply in the ground. The

property owner / customer must sign the foundation installation conditions (you will find

the template on the last page of these instructions). By this written confirmation, the

buyer / customer assumes liability and duty of care.

-There must be free access to the installation area.

1. Check online where to find the next available Krinner sales partner (go to

https://www.schraubfundamente.de/en/kontakt/regions/ and enter your postal code).

2. Contact your Krinner sales representative and clarify the installation. Optimally forward

this instruction manual (digital version available) and ask for your individual offer, possibly

a quote with hourly rate and call-out charge.

3. Your Krinner sales partner must view the terrace and identify the soil class by a test

drilling. The soil class must not exceed class 4, down to 2 m below ground level (length of

the ground screw). This helps to clarify whether the KR20 screwing machine is suitable or

whether a larger machine must be used. This soil analysis is only binding in case of a

homogeneous soil fabric.

4. This manual illustrates the “5 steps to fasten the ground screw“. As soon as the SZ329 /

SZ330, the ground screw and the MAY parasol has been delivered to the terrace, the

service technician can start with the installation according to step 1, 2 and 3. Mainly tools

needed: Screwing machine KR20, hammer drill, a ø40x800mm rock drill, a Krinner screw-

in attachment F1234567, a 1.2 m ground screw and in case of multiple parasols an optical

level. In order to coordinate this project, it is recommended to have a MAY representative

on site.

Placing the ground screw

1. Allow sufficient space between parasols or between the wall of the house and the parasol.

Parasols that are located too close together wear sooner.

Parasols may sway slightly. If there is not enough space between them, they

may touch and abrade or scour the canopy fabric at the spoke ends.

Make sure that there is a clearance of 15-20 cm between the parasols (or

between the parasol and the wall of the house).

2. Bear in mind, we are able to compensate any unevenness of the ground by adjusting the

height of each individual parasol. Extra - length upper tubes are available at 10 cm

gradation and can be adjusted and accommodated on-site.

Caution

Stand 40-081 English page 3 of 9

5 steps to fasten the ground screw

Preliminary, let the property owner / customer sign the foundation installation conditions (see

page 8) and archive it legally.

1. Step 1: Removal and primary drilling

Remove paving and gravel until a depth of approximately 15 cm. Use a ø 40 mm drill for

the vertical predrill. Pay attention to the chapter “Placing the ground screw“.

2. Step 2: Preparation

For preparation for the 2 m ground screw a smaller ground screw, about 1.2 m long, must

be screwed-in and out again.

3. Step 3: Screwing-in

Screw-in the 2 m ground screw until there is a space of 19 mm between top of terrace and

top of ground screw. This ensures the winter coverage will be even with the ground. In

case of multiple parasols use an optical level to have all ground screws screwed-in to the

same depth.

19mm

Stand 40-081 English page 4 of 9

Step 4 and 5 and the erection of the parasol must be carried out by your MAY dealer.

1. Step 4: Alignment

See chapter „Alignment and fixation of upper anchor tube“ for detailed instruction.

4. Step 5: Finish

Fill up the gravel and place the paving as close as possible to the flange. That way the

ground screw disappears completely below the pavement.

Stand 40-081 English page 5 of 9

Alignment and fixation of upper anchor tube

1. Attach the 16 mm washers onto the M16x35 hexagon screws and tighten them to fix the

upper anchor tube onto the flange plate, the countersinking must face upward /see fig.)

Use the enclosed size 14 hexagon key with extension.

Screws that are not tightened correctly will work loose.

If screws are not tightened firmly enough, there will not be sufficient tensile

force to trigger self-locking. If the screws are tightened too firmly and over-

stressed, the screw connection may slacken.

Tighten the three M16 screws manually using the enclosed hex key and

extension. Exert as much force as possible. With the enclosed tools there is

virtually no risk of over-stressing.

The correct torque for a torque wrench is 210 Nm.

countersinking

flange plate

upper anchor tube

extension for size 14 hexagon key

hexagon key size 14

Caution

Stand 40-081 English page 6 of 9

2. Insert the M16 countersunk screws into the bore holes of the coupling plate and so screw

the upper anchor tube with coupling plate onto the flange plate (see fig. below). Attach the

nuts from the bottom. Do not tighten the screw connection firmly yet.

3. As a practical matter, the ground screw is never screwed in 100% straight. Therefore, the

upper part must be aligned with a water spirit level (see fig.). Adjust the set screw and the

M 16 screw as long as your spirit level indicates that the plate is horizontal. Then apply

210 Nm to tighten the screw connection.

90°

90°

M16 countersunk screw

M16 nut

+ 16 mm washer

upper tube

ground screw

check 2 sides with

the spirit level

set screw

M16 countersunk screw

set screw

Stand 40-081 English page 7 of 9

Storage / dismounting

1. Lift the parasol from the anchor tube.

2. Remove the upper anchor tube completely.

3. Screw threaded pins into the bore holes flush with the plate (see fig.)

The thread may get damaged.

Without cover plate, dirty water or sand may be washed into the flanks of the

thread. As sand is harder than steel, the thread may get damaged when the

screw is turned.

Screw in the threaded pins flush with the plate.

4. In case you have two or more parasols, each parasol and its corresponding accessories

should be marked during dismounting (with punch marking or waterproof marker, e.g. for

winter storage).

Marking saves a lot of time and helps to keep things in order.

If clearly marked, each sunshade can easily be assigned to its proper location

and re-erected parallel to the wall of the house or next to the others.

For clear and easy later assignment use the same number to mark the centre

pole, the anchor tube and the ground tube. For example, for sunshade No. 1,

all three parts should carry number 1, all three parts of sunshade No. 2

should be marked with a 2, etc.

5. Lubricate the screws on a regular basis to prevent rust.

Caution

threaded pins M16

Tip

Stand 40-081 English page 8 of 9

Mounting –Tools required

1. SZ329 / SZ330 (upper anchor tube + ground screw KSF F 140x1200-M by Krinner)

including MAY standard parts.

2. Hammer drill with ø40 rock drill.

3. Krinner screw-in machine KR20, telescopic guiding rod system, guiding safety bar, screw-

in attachment F1234567.

4. Cable reel

5. 1.2 m ground screw

6. Spade, shovel, small trowel

7. Spirit level + tape measure (possibly)

8. Folding rule

9. Hexagon key in size 3, 4, 8 and 14

10. Open-ended spanner size 17 + 19

11. Ring spanner size 24

12. In case of multiple parasols: optical level, ground marking spray, centring plate for rock

drill and soil spikes for fixation (custom made).

Stand 40-081 English page 9 of 9

Foundation installation conditions

Before installation of a ground screw, a foundation installation condition sheet must be signed. This

template is a translation of a year 2011 copy from the Krinner company. If applicable, please request an

updated version. A signed copy should be archived by the “ground screw service”.

Project:

Scheduled date: Scheduled time:

The points of installation have been checked and are free of obstacles such as ground cables or

underground constructions.

The points of installation are marked and levelled.

Cable diagrams are available.

It is confirmed there are no underground cables (gas pipes, water, telephone, power supply, etc.)

within a radius of 50 cm around the point of installation.

There must be free access for the installation machines to the points of installation plus 3m x 3m

around, installation points must be marked.

In case the start of construction cannot be met as scheduled, please inform us 2 working days

ahead.

paved ground ________________________ yes no

tarred ground ________________________ yes no

underground construction/waste _________ yes no

Soil class:

Terrain characteristic:

Installation of ground screws into a rocky ground or into a rock, removal of paving and core drilling though

asphalt are available at special service.

Further information:

Remark: In case of swampy ground, increased groundwater level, flood, muddy ground caused by strong

rain or ground frost, ground screws cannot be installed. The offered price applies to the specified

service. Any additional effort or service must be invoiced based on hourly rate. If during

assembly it turns out that the installation of the ground screws cannot be conducted or only with

excessive material and cost expenditure, we are not obliged to provide any service at these

positions. This does not affect any further parts of the contract. The German law on contracts

for work & services (BGB), current version, applies.

Warranty: Warranty excluded in case of natural changes of the ground like sinking, landslide, flood,

earthquake.

Date Signature customer, stamp

This manual suits for next models

1