3

THE UNIT HAS ITS OWN PUMP-DOWN MODE. USE THE PUMP-DOWN

MODE WHILE VACUUMING THE UNIT. VACUUMING TOO LOW CAN

CAUSE INTERNAL ELECTRICAL ARCING, RESULTING IN ADAMAGED OR

FAILED COMPRESSOR.

CAUTION

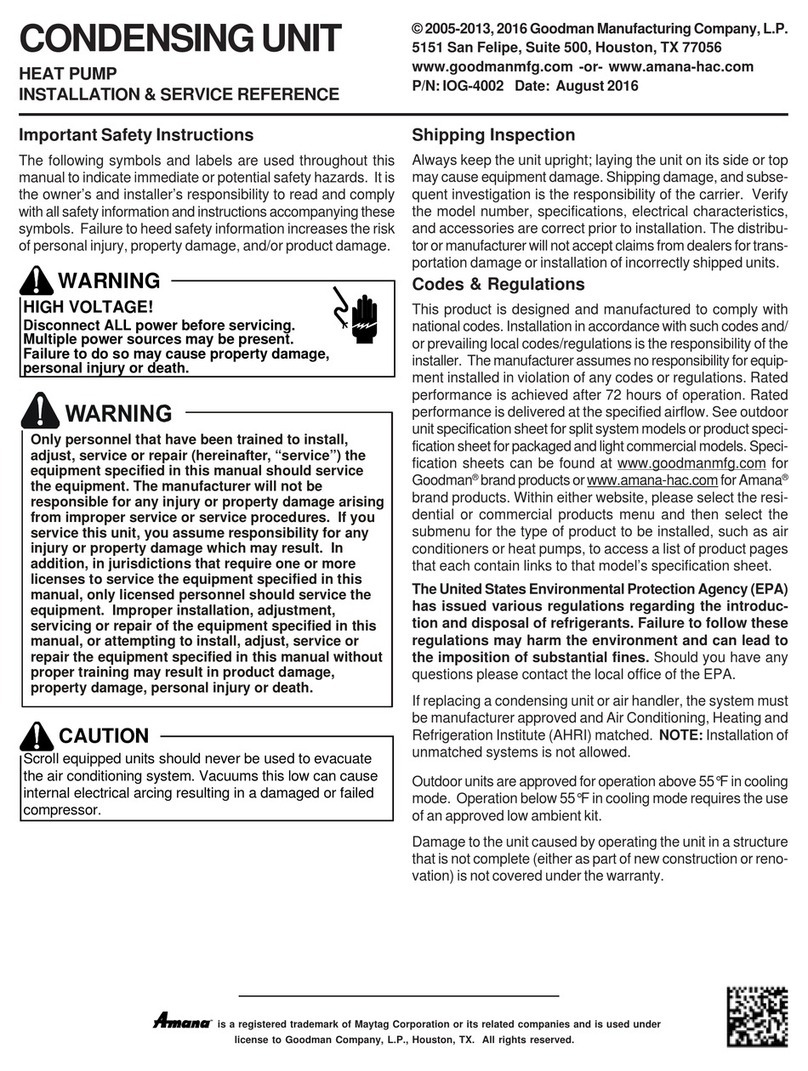

SHIPPING INSPECTION

Always keep the unit upright; laying the unit on its side

or top may cause equipment damage. Shipping damage,

and subsequent investigation is the responsibility of

the carrier. Verify the model number, specications,

electrical characteristics, and accessories are correct

prior to installation. The distributor or manufacturer will not

accept claims from dealers for transportation damage or

installation of incorrectly shipped units.

This product is designed and manufactured to comply

with national codes. Installation in accordance with such

codes and/or prevailing local codes/regulations is the

responsibility of the installer. The manufacturer assumes

no responsibility for equipment installed in violation of any

codes or regulations. Rated performance is achieved after

20 hours of operation. Rated performance is delivered at

the specied airow. See outdoor unit specication sheet

for split system models or product specication sheet for

packaged and light commercial models. Specication

sheets can be found at www.goodmanmfg.com for

Goodman®brand products or www.amana-hac.com for

Amana®brand products. Within the website, please select

the residential or commercial products menu and then

select the submenu for the type of product to be installed,

such as air conditioners or heat pumps, to access a list

of product pages that each contain links to that model’s

specication sheet.

The United States Environmental Protection Agency (EPA)

has issued various regulations regarding the introduction

and disposal of refrigerants. Failure to follow these

regulations may harm the environment and can lead to

the imposition of substantial nes. Should you have any

questions please contact the local oce of the EPA.

If replacing a condensing unit, heat pump or air handler,

the system must be manufacturer approved and Air

Conditioning, Heating and Refrigeration Institute (AHRI)

matched.

NOTICE

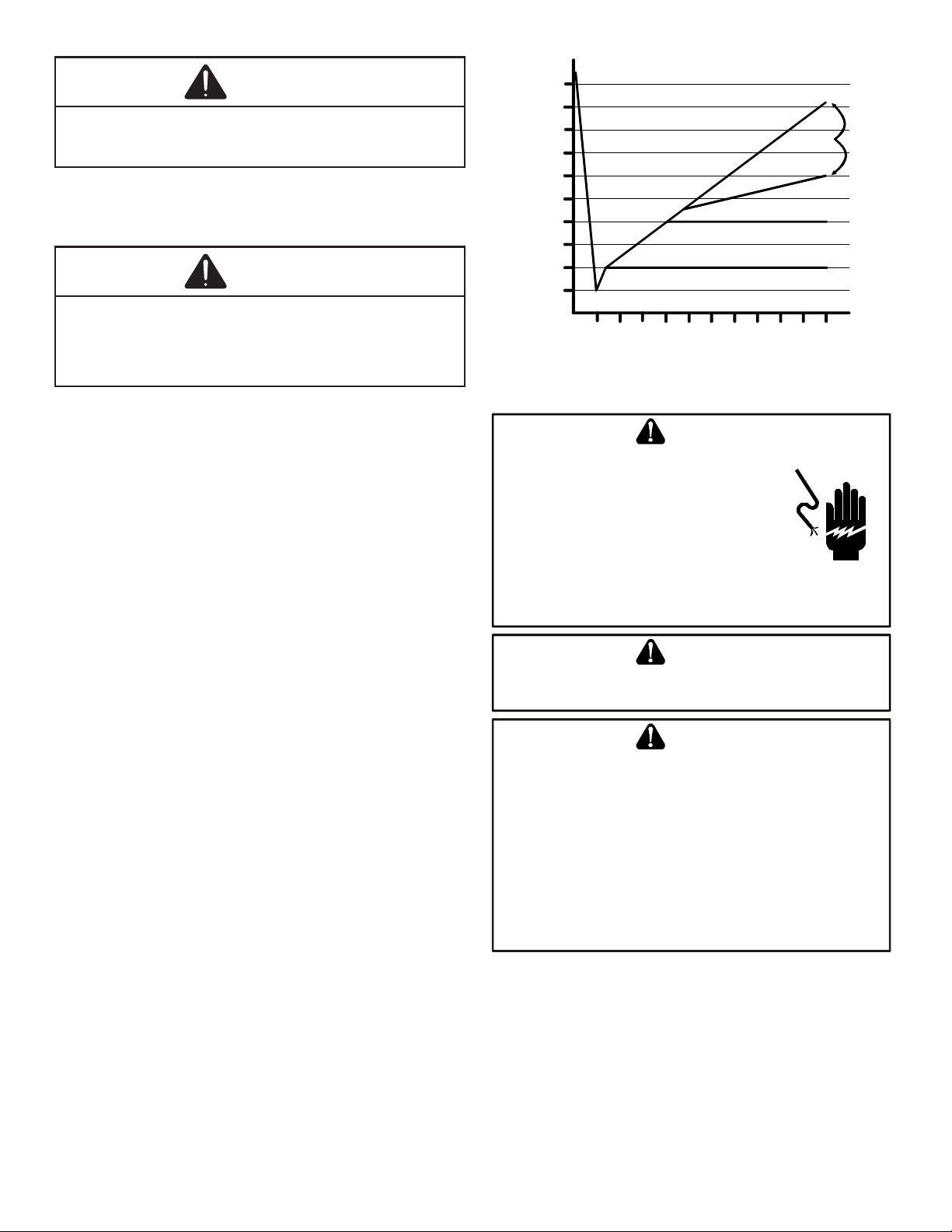

Outdoor inverter units are approved for operation above

0°F in cooling mode and -20°F (RH10%) in heating mode

with no additional kit necessary.

Damage resulting from operation of the units in a structure

that is not complete (either as port of new construction or

renovation) is not covered by our warranties.

FEATURES

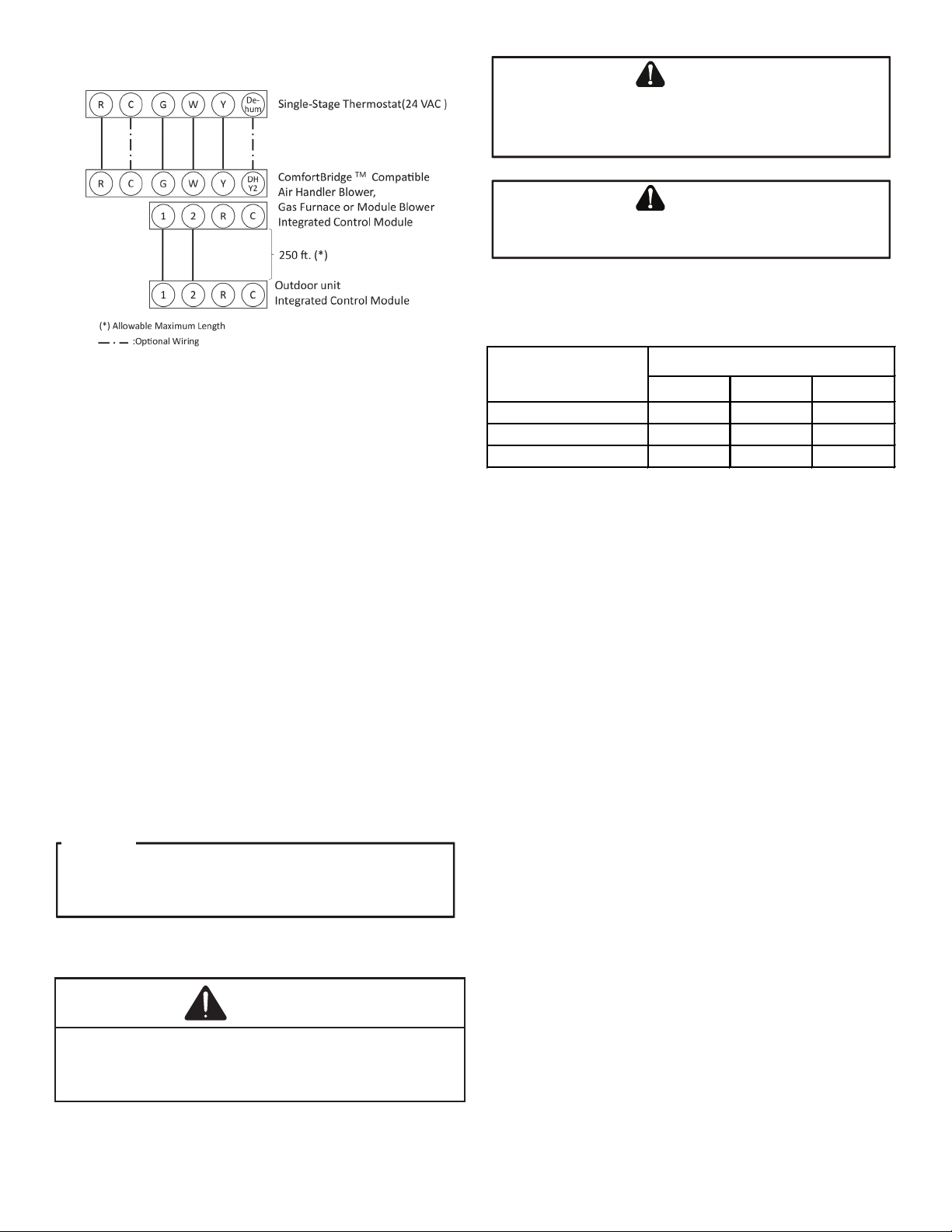

This heat pump is part of a ComfortBridge™ control system

that uses inverter technology to more eciently control

heat gain/loss with better eciency and achieve targeted

comfort conditions.

The system utilizes digital communication between the

indoor and outdoor equipment and can be controlled by

any single-stage thermostat.

The ComfortBridge control system reduces the number

of required thermostat wires, provides additional setup

features and enhanced diagnostics through Bluetooth

connectivity with the CoolCloud™ app.

Due to components using inverter technology, the heat

pump will not function properly if used with a non-approved

control system.

NOTICE

Special consideration must be given to location of the heat

pump unit(s) in regard to structures, obstructions, other

units, and any/all other factors that may interfere with air

circulation. Where possible, the top of the unit should be

completely unobstructed; however, if vertical conditions