Maytag JENN-AIR User manual

Other Maytag Washer manuals

Maytag

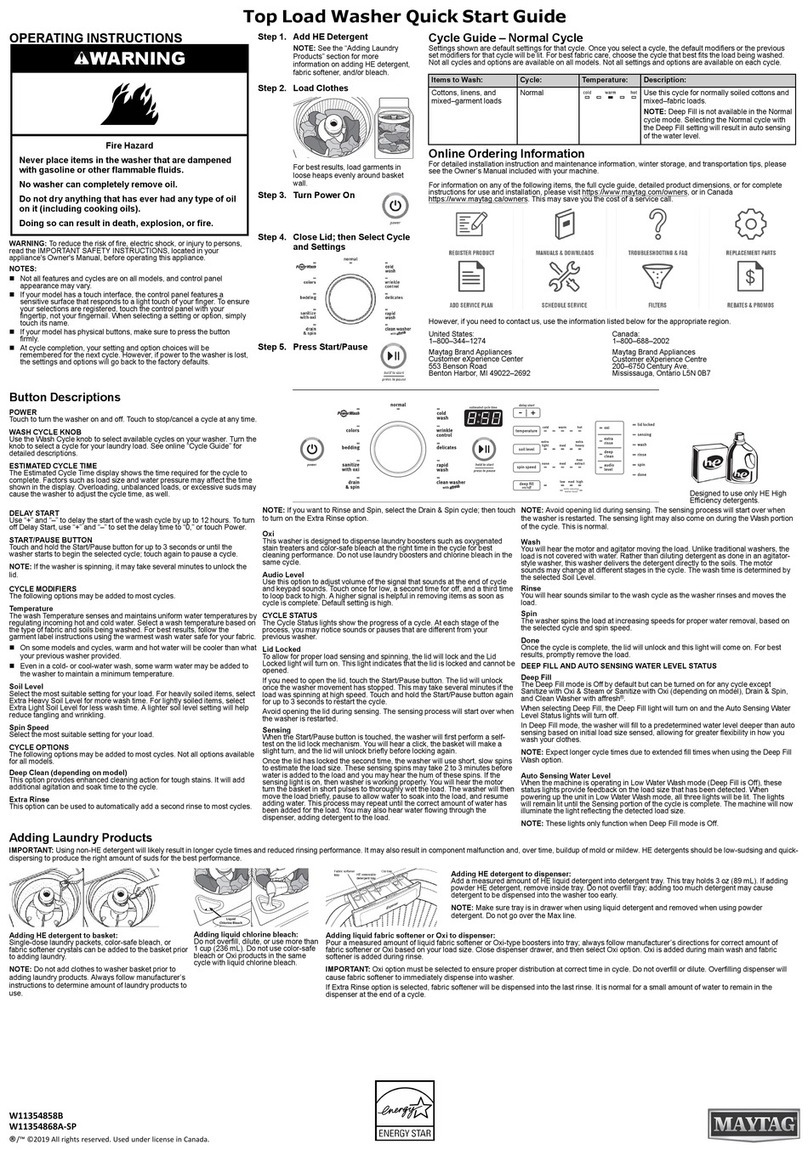

Maytag W11354858B User manual

Maytag

Maytag MTW6300TQ - 28" Washer With 3.8 cu. Ft.... Installation instructions

Maytag

Maytag TOP-LOADING User manual

Maytag

Maytag MVWC300VW - Centennial Washer User manual

Maytag

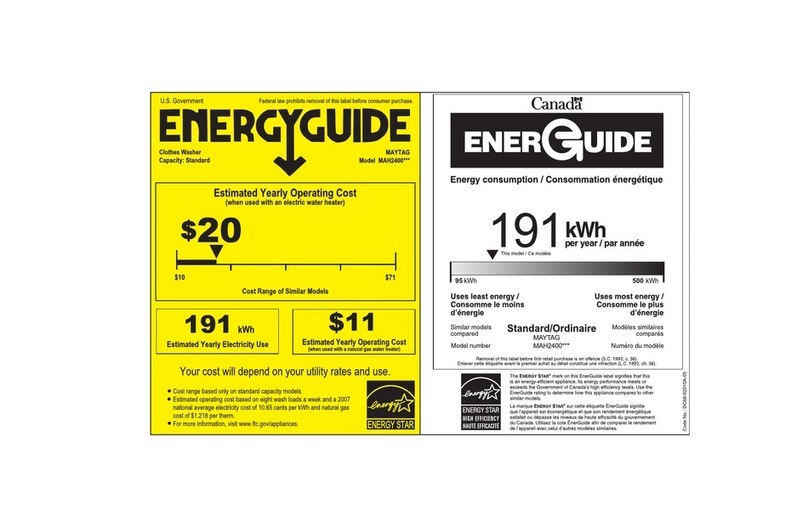

Maytag MAH2400AWW - 2.4 cu. Ft. Compact Front Load... Assembly instructions

Maytag

Maytag W-5 User manual

Maytag

Maytag NEPTUNE MAH-1 User manual

Maytag

Maytag 35-6923 User manual

Maytag

Maytag BRAVOS User manual

Maytag

Maytag W10280465C User manual

Maytag

Maytag MHW6000X Series User manual

Maytag

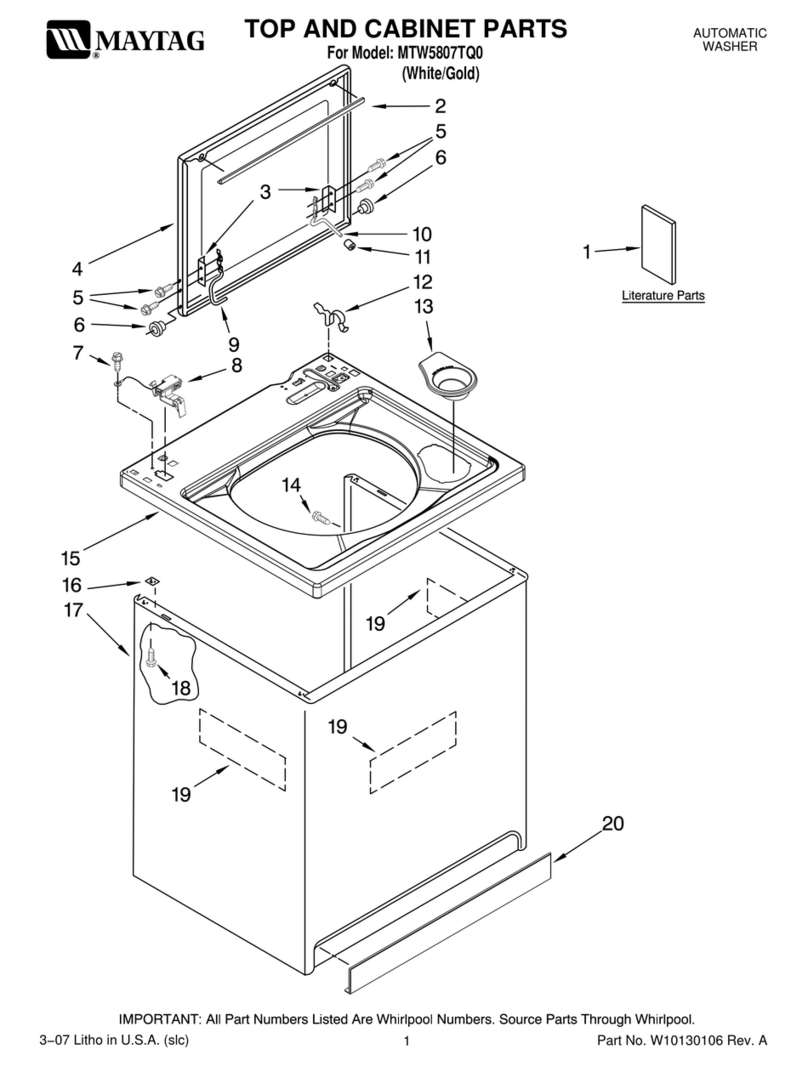

Maytag MTW5807TQ0 User manual

Maytag

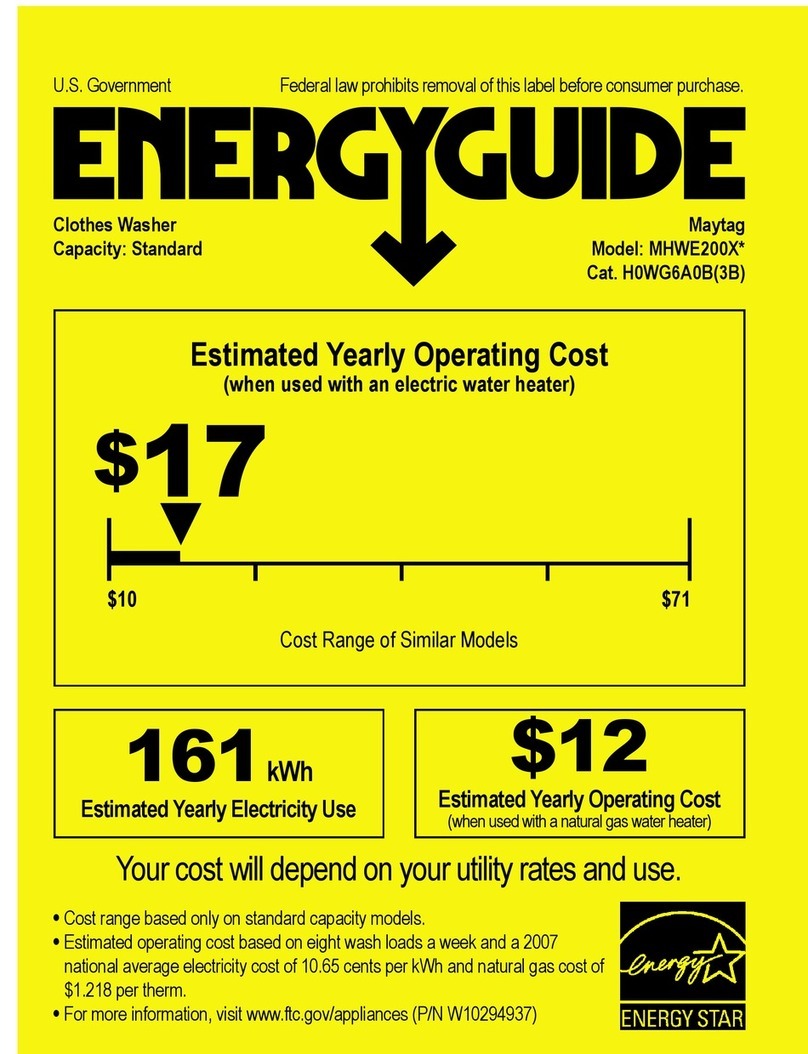

Maytag MHWE200XW Assembly instructions

Maytag

Maytag PAVS234AWW User manual

Maytag

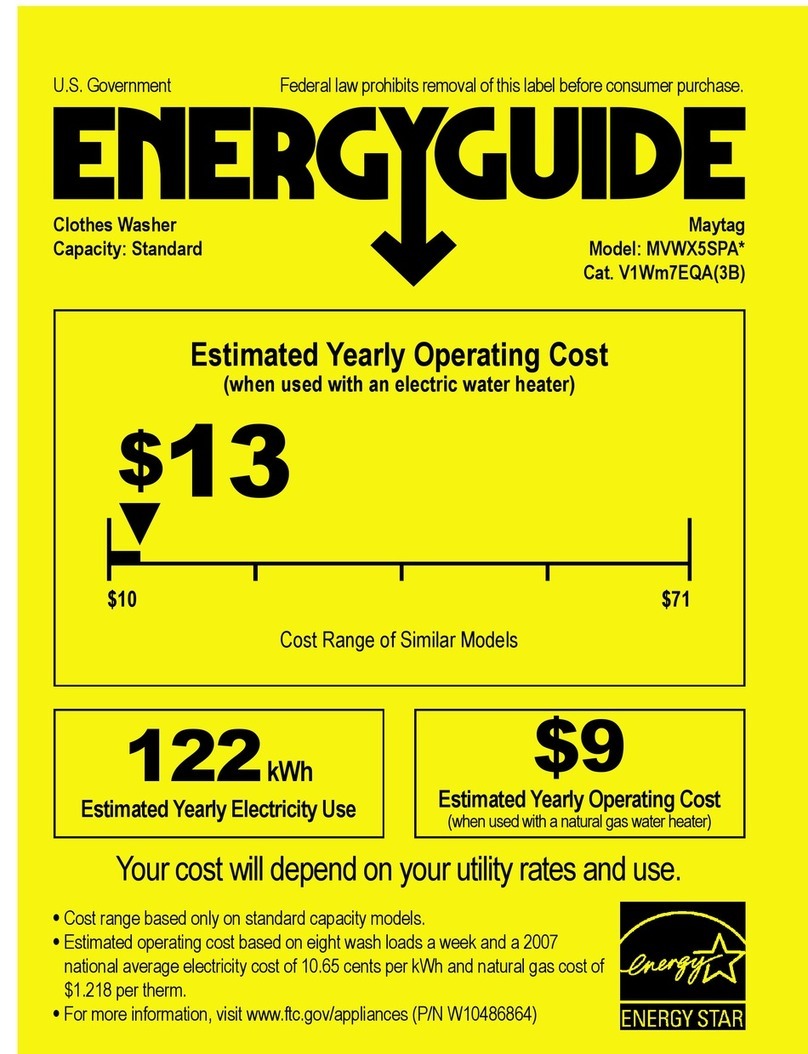

Maytag MVWX5SPAW Assembly instructions

Maytag

Maytag 120-volt User manual

Maytag

Maytag Performa PAV1000 User manual

Maytag

Maytag W10280548F User manual

Maytag

Maytag MAV8757AWW User manual

Maytag

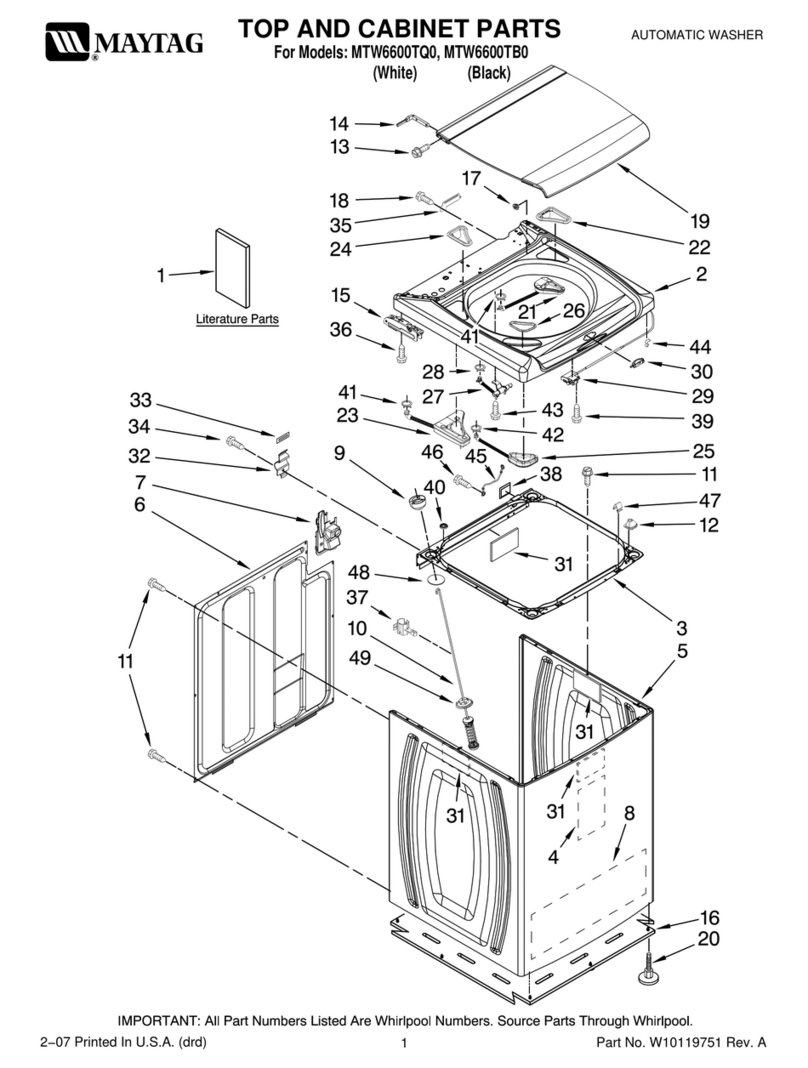

Maytag BRAVOS MTW6600TB0 User manual