3

Inverter Heat Pump Owner’s Manual

Notices and Warnings����������������������������������������������������������������������������������������������������������������������������4

Ecoclear® Contents and Overview ������������������������������������������������������������������������������������������������������6

Ecoclear® Inverter Heat Pump Package Contents ......................................................................................................................................6

Ecoclear® Inverter Heat Pump Overview........................................................................................................................................................6

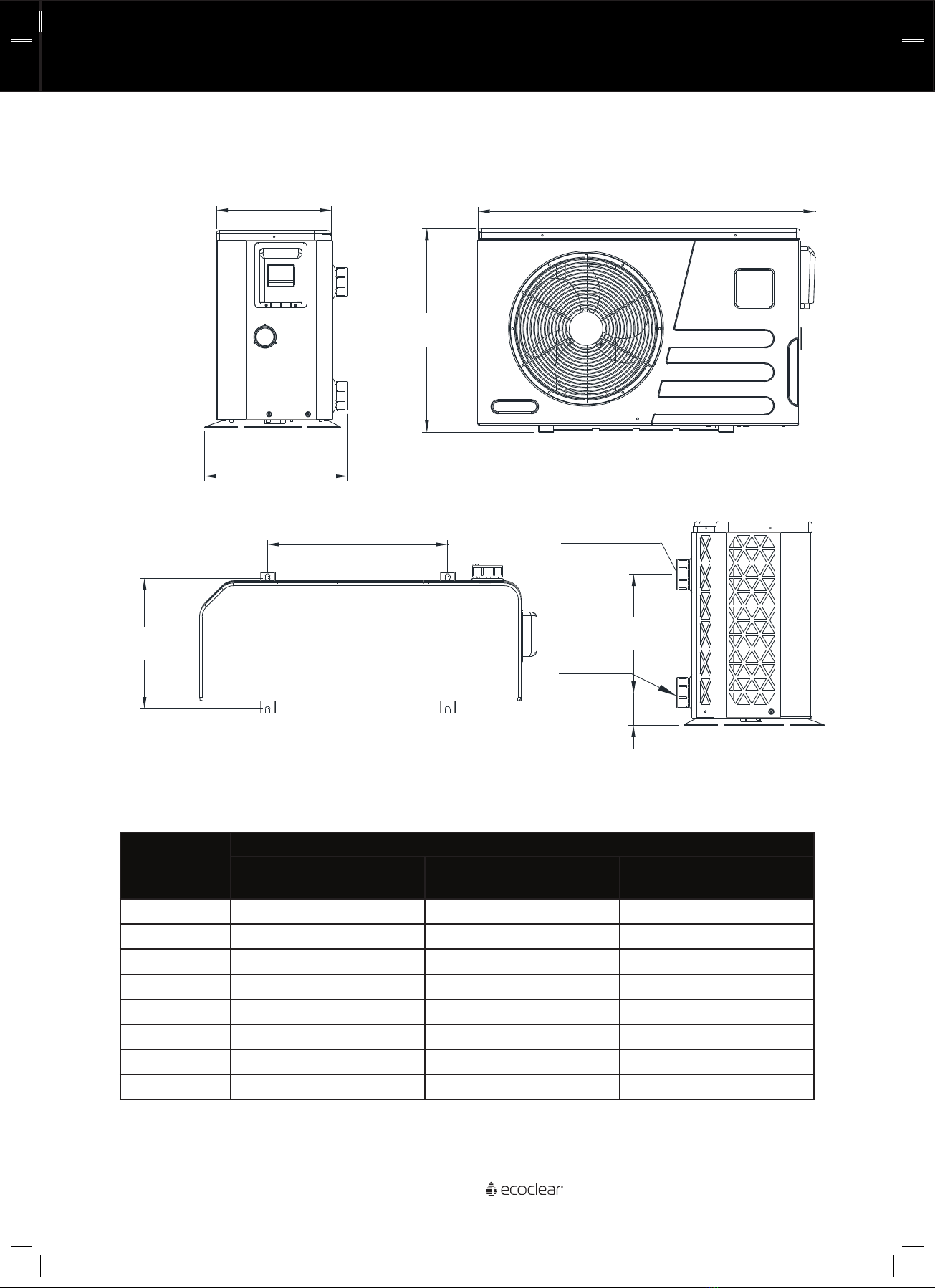

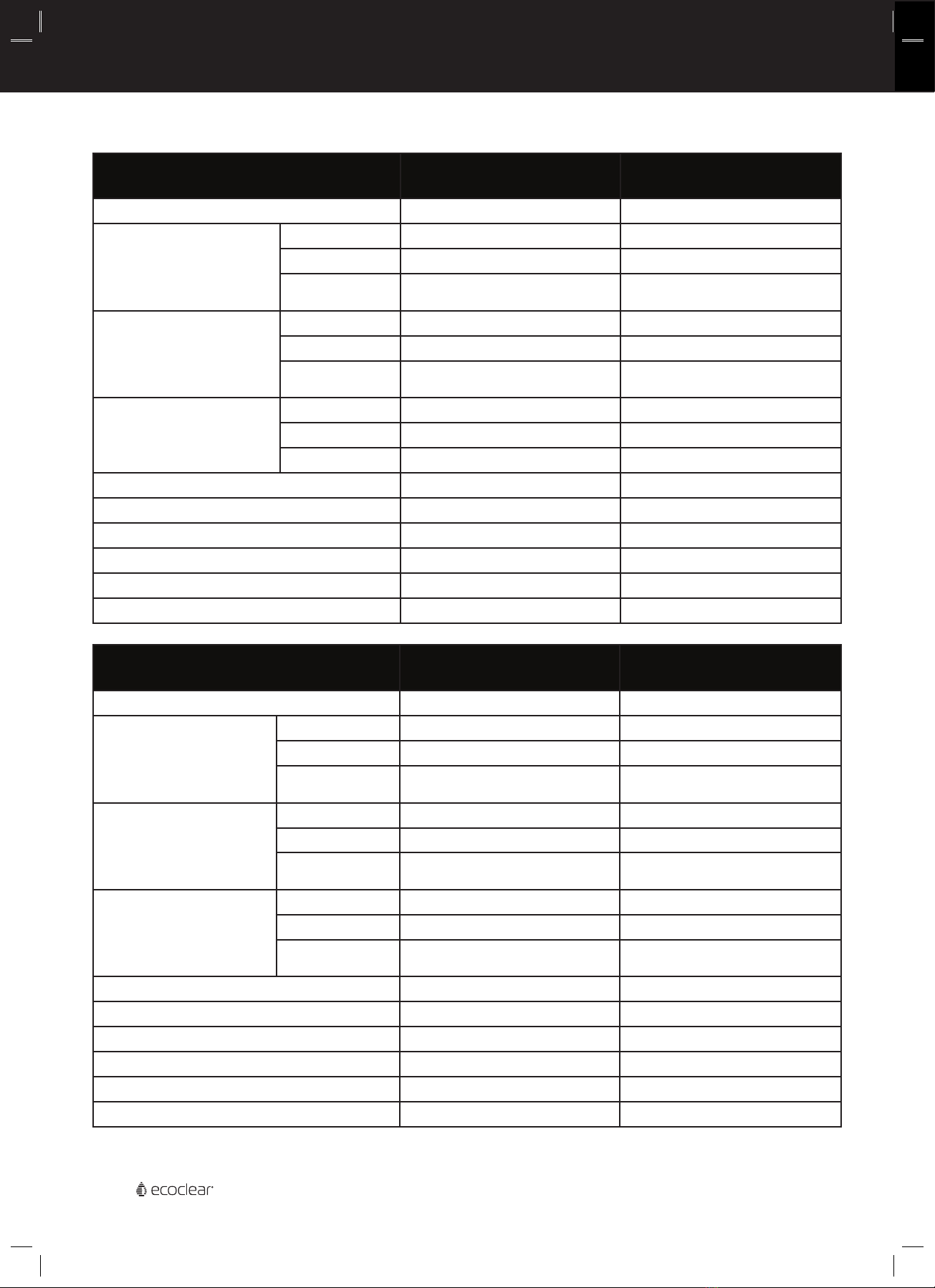

Dimensions & Specifications ���������������������������������������������������������������������������������������������������������������� 7

Dimensions .................................................................................................................................................................................................................. 7

Specifications ..............................................................................................................................................................................................................8

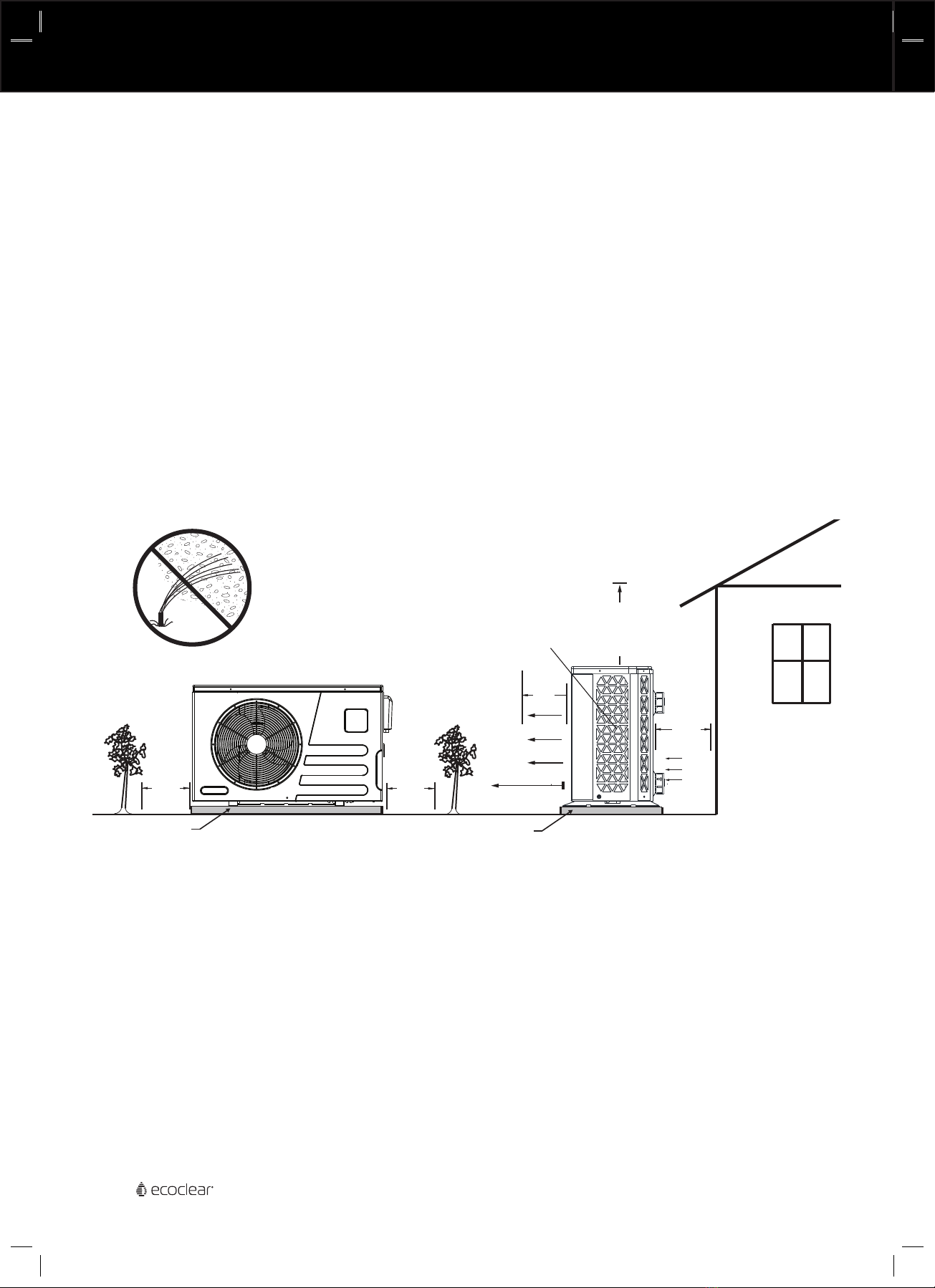

Installation����������������������������������������������������������������������������������������������������������������������������������������������9

Location and Clearances......................................................................................................................................................................................10

Anchor Clamp Installation ...................................................................................................................................................................................10

Water Connections to the Heat Pump............................................................................................................................................................ 11

Plumbing Connections - Standard................................................................................................................................................................... 12

Plumbing Connections - Separate Circulation System............................................................................................................................ 13

Multiple Heater Type Installation ..................................................................................................................................................................... 14

Multiple Heat Pump Installation....................................................................................................................................................................... 14

Electrical Connections ��������������������������������������������������������������������������������������������������������������������������15

General Information............................................................................................................................................................................................... 15

Equipotential Bonding........................................................................................................................................................................................... 15

Main Power................................................................................................................................................................................................................ 15

Configuration�����������������������������������������������������������������������������������������������������������������������������������������17

Control Panel..............................................................................................................................................................................................................17

Setting the Clock...................................................................................................................................................................................................... 19

Setting the On/O Timer ..................................................................................................................................................................................... 21

Setting the Mute Timer ........................................................................................................................................................................................ 21

Menu / Setting Parameters................................................................................................................................................................................ 21

Forced Defrost Mode............................................................................................................................................................................................. 21

Turning Heat Pump On and O........................................................................................................................................................................ 20

Setting the Temperature and Mode .............................................................................................................................................................. 20

Status Query..............................................................................................................................................................................................................22

Scenario (Operating Mode) ................................................................................................................................................................................ 23

Connecting the Heat Pump to Automation���������������������������������������������������������������������������������������24

Pool/Spa Heating Combinations (Recommended Configurations) ................................................................................................. 24

Maintenance & Troubleshooting ��������������������������������������������������������������������������������������������������������26

Water Chemistry..................................................................................................................................................................................................... 26

Inspection and Service ........................................................................................................................................................................................ 26

Owner Inspection................................................................................................................................................................................................... 26

Professional Maintenance and Service.........................................................................................................................................................27

Winterising .................................................................................................................................................................................................................27

Troubleshooting...................................................................................................................................................................................................... 29

System Protections / Error Codes ................................................................................................................................................................... 30

Replacement Parts ������������������������������������������������������������������������������������������������������������������������������34

Wiring Diagrams�����������������������������������������������������������������������������������������������������������������������������������35

Environmental Information�����������������������������������������������������������������������������������������������������������������38

Disposal Requirements ....................................................................................................................................................................................... 38

Table of Contents

Table of Contents