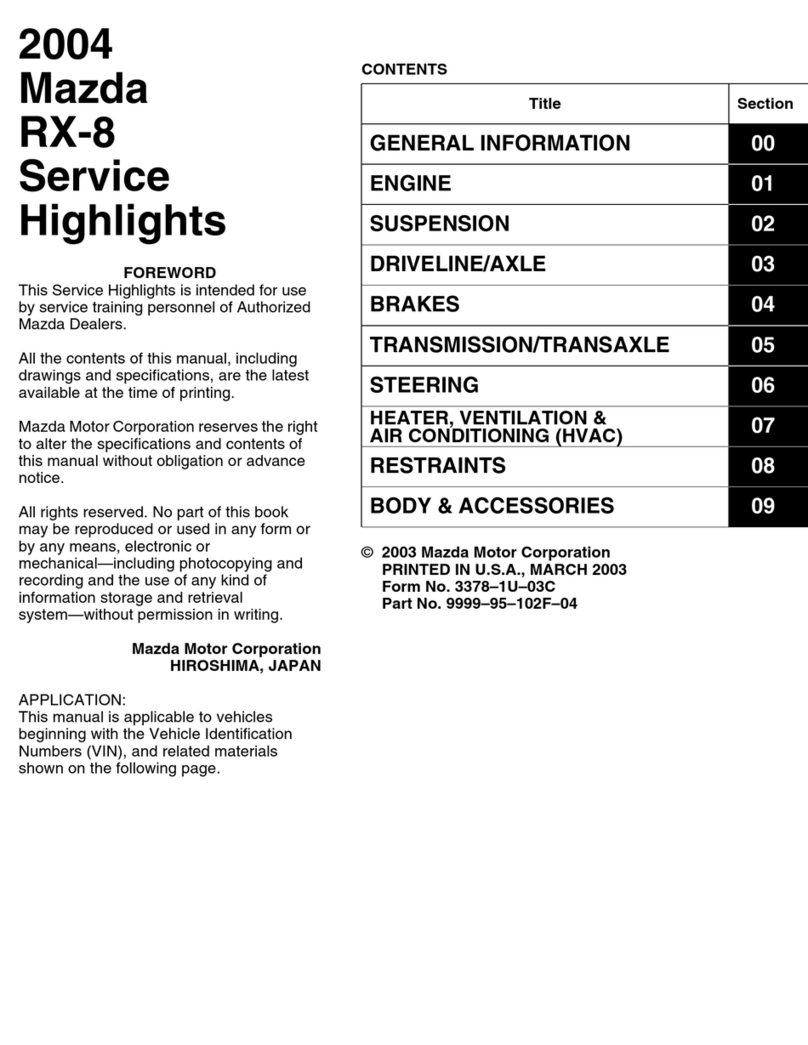

GENERAL INFORMATION 00

SECTION

GENERAL INFORMATION .... 00-00

00-00 GENERAL INFORMATION

HOW TO USE THIS MANUAL

................

00-00-2

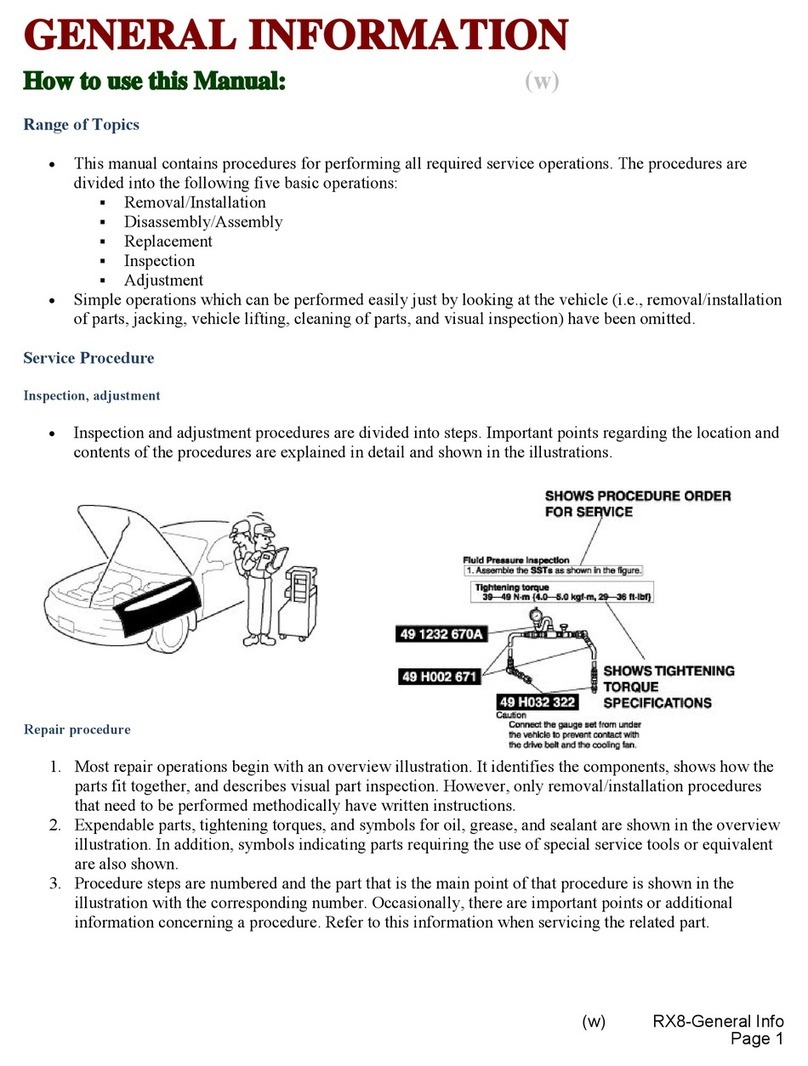

Range of Topics

...................................

00-00-2

Ser ice Procedure

...............................

00-00-2

Symbols

.................................................

00-00-4

Ad isory Messages

.............................

00-00-4

Upper and Lower Limits

.......................

00-00-4

Troubleshooting Procedure

..................

00-00-4

Procedures for Use

.............................

00-00-5

Text Sequence

.....................................

00-00-7

UNITS

.........................................................

00-00-8

Con ersion to SI Units

(Système International d'Unités) 00-00-8

Rounding O ff

.........................................

00-00-8

Upper and Lower Limits........................ 00-00-8

SAE STANDARDS

...................................

00-00-8

FUNDAMENTAL PROCEDURES

..........

00-00-10

Protection of the Vehicle

......................

00-00-10

Preparation of Tools and Mesuring

Equipment

...........................................

00-00-10

Special Tools

.........................................

00-00-11

Disconnection of the Negati e Battery

Cable

...................................................

00-00-11

Remo al of Parts

.................................

00-00-11

Disassembly

.........................................

00-00-11

Inspection During Remo al,

Disassembly

.......................................

00-00-11

Arrangement of Parts

...........................

00-00-11

Cleaning of Parts

.................................

00-00-11

Reassembly

...........................................

00-00-12

Adjustments

...........................................

00-00-12

Rubber Parts and Tubing

....................

00-00-12

Hose Clamps

.........................................

00-00-12

Torque Formulas

...................................

00-00-12

V ise

.........................................................

00-00-13

Dynamometer

.......................................

00-00-13

INSTALLATION OF RADIO SYSTEM .. 00-00-13

ELECTRICAL SYSTEM

............................

00-00-13

Electrical Parts

.....................................

00-00-13

Connectors

...........................................

00-00-13

Terminals

...............................................

00-00-14

Sensors, Switches, and Relays

..........

00-00-15

Wiring Harness

.....................................

00-00-15

Fuse

.......................................................

00-00-15

Electrical Troubleshooting Tools 00-00-15

JACKING POSITIONS

.............................

00-00-16

VEHICLE LIFT (2 SUPPORTS) AND

SAFETY STAND (RIGID RACK)

POSITION

...............................................

00-00-17

Vehicle Lift Positions

............................

00-00-17

Safety Stand Positions

..........................

00-00-17

TOWING

.....................................................

00-00-17

Tiedown Hooks

.....................................

00-00-18

IDENTIFICATION NUMBER

LOCATIONS

...........................................

00-00-18

Vehicle Identification Number (VIN)... 00-00-18

Chassis Number

...................................

00-00-18

Engine Identification Num ber

..............

00-00-19

Automatic Transaxle Number

..............

00-00-19

ABBREVIATIONS

.....................................

00-00-19

PRE-DELIVERY INSPECTION

................

00-00-22

Pre-Deli ery Inspection Table

..............

00-00-22

SCHEDULED MAINTENANCE

..............

00-00-23

Scheduled Maintenance Table

(Except Canada)

.................................

00-00-23

Scheduled Maintenance Table

(Canada)

.............................................

00-00-25

00-00-1