Litho in U.S.A. 1-2015

SEAMER SPECIFICATIONS

AND MAINTENANCE

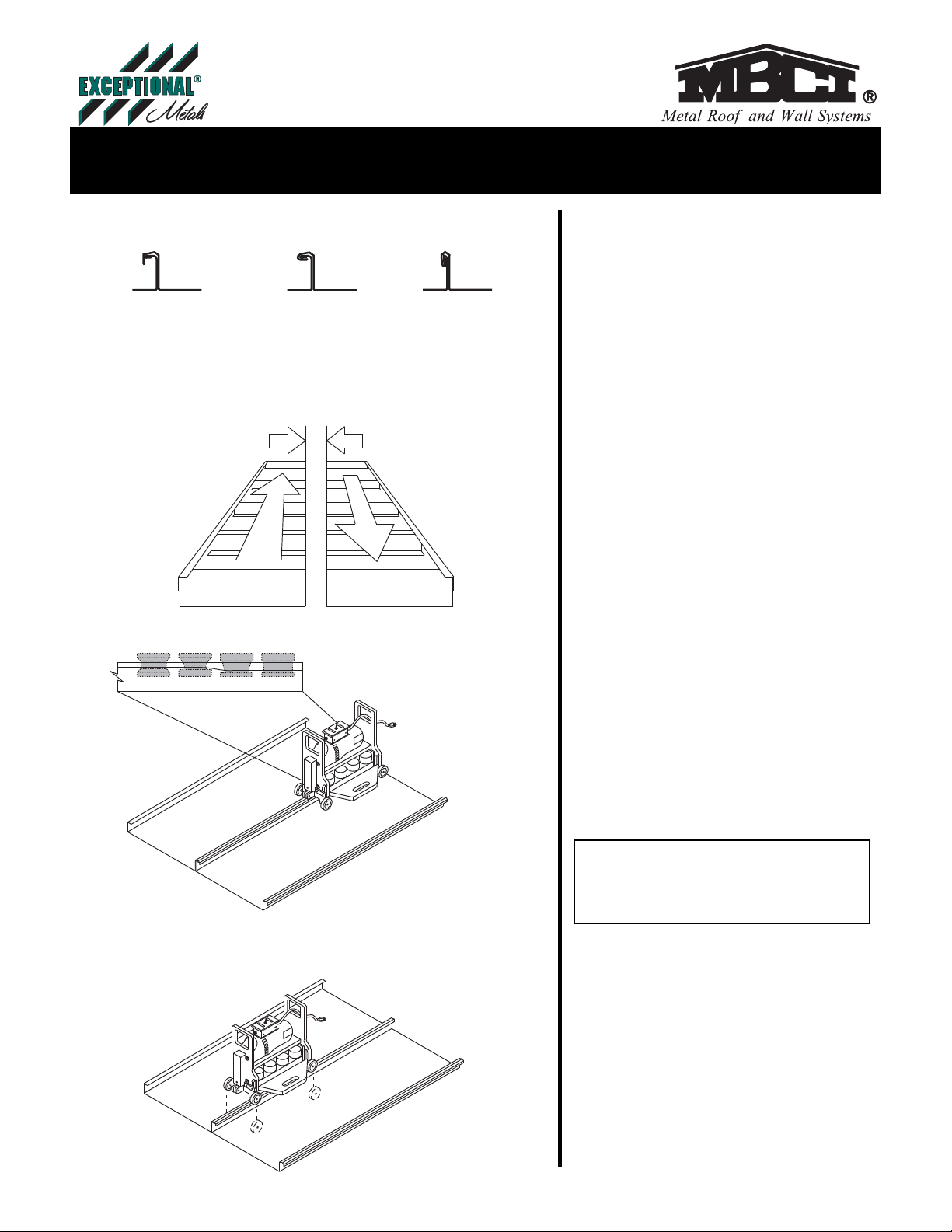

Seamer will seam 20 to 30 F.P.M. depending on

gauge of panels and pitch of roof.

Seamer has 10 amp., 120 v., AC/DC motor.

All zerk fittings on seamer should be greased

with lithium based grease, once a day during

continuous duty.

Seamer should be cleaned with a nonflammable

solvent, often, to prevent a build-up of galval-

ume or sealant on the rolls. DO NOT SPILL

CLEANING SOLVENT ON ROOF PANELS.

THIS WILL VOID THE WARRANTIES ON THE

ROOF PANELS FINISHES.

Any adjustments, maintenance, modification, or

repair not otherwise specifically set forth in this

manual, must be conducted by MBCI.

If seamer motor should stop suddenly, check

reset button located on the side of the electrical

box on top of seamer motor. CONTINUED

RESETTING OF MOTOR COULD BE INDICA-

TIVE OF LOW VOLTAGE AND WILL CAUSE

DAMAGE TO SEAMING MACHINE. Check

size and length of electric cords. If problem still

persists, use an alternate power source.

SHIPPING INSTRUCTIONS

Replace the seaming machine in the box. All items

should be clean and in proper working condition.

A $50 minimum charge will be assessed for equip-

ment improperly cleaned or damaged.

Return seamer as soon as you are finished. For

seamer pick-up, please call FedEx Freight at 877-

918-6012 extension #5091070. If possible, call

the shipper the day before you are finished.

TOTAL SHIPPING WEIGHT — 177 LBS.

(Electric Seamer & Phase I/Phase II)

HAND CRIMPER SHIPPING WEIGHT - 42 LBS.

DESCRIPTIONS AND SPECIFICATIONS CONTAINED HEREIN WERE IN EFFECT AT THE TIME THIS PUBLICATION WAS APPROVED FOR

PRINTING. In a continuing effort to refine and improve products, MBCI reserves the right to discontinue products at any time or change spec-

ifications and/or designs without incurring obligation. To insure you have the latest information available, please inquire or visit our Web

Site at www.mbci.com. Application details are for illustration purposes only and may not be appropriate for all environmental conditions, build-

ing designs, or panel profiles. Projects should be engineered to conform to applicable building codes, regulations, and accepted industry prac-

tices. Insulation is not shown in these details for clarity. If there is a conflict between this manual and the erection drawings, the erection

drawings will take precedence.

For the most current information available, visit our Web Site at www.mbci.com

Houston,TX Lubbock, TX Oklahoma City, OK San Antonio, TX Dallas, TX Atlanta, GA Phoenix, AZ Richmond, VA

14031 West Hardy 5711 East FM-40 7000 S. Eastern Ave. 8677 I-10 East 1804 Jack McKay Blvd. 2280 Monier Ave. 660 South 91st Avenue 801 South Ave.

P.O. Box 38217 P.O. Box 10133 P.O. Box 95998 P.O. Box 69 Grand Prairie, TX 75053 P.O. Box 44729 P.O. Box 739 P.O. Box 239

Houston, TX 77238 Lubbock, TX 79408 Oklahoma City, OK 73143 Converse, TX 78109 800/653-6224 Atlanta, GA 30336 Tolleson, AZ 85353 Colonial Heights, VA 23834

877/713-6224 800/758-6224 800/597-6224 800/598-6224 877/512-6224 888/533-6224 800/729-6224

Indianapolis, IN Omaha, NE Memphis, TN Rome, NY Adel, GA Salt Lake City, UT Atwater, CA Tampa, FL (Sales Office)

1780 McCall Dr. 1011 Ellison Ave. 300 Highway 51 North 6168 State Route 233 1601 Rogers Rd. 1155 West 2300 North 550 Industry Way 402 N. Frontage Rd.

P.O. Box 657 P.O. Box 19085 P.O. Box 366 P.O. Box 4141 P.O. Box 1107 P.O. Box 16027 P.O. Box 793 P.O. Box 2418

Shelbyville, IN 46176 Omaha, NE 68119 Hernando, MS 38632 Rome, NY 13442 Adel, GA 31620 Salt Lake City, UT 84116 Atwater, CA 95301 Plant City, FL 33564

800/735-6224 800/458-6224 800/206-6224 800/559-6224 888/446-6224 800/874-2404 800/829-9324 800/359-6224