1

CONTENTS

1. Components................................................................................................................................... 4

1.1 Overview......................................................................................................................... 4

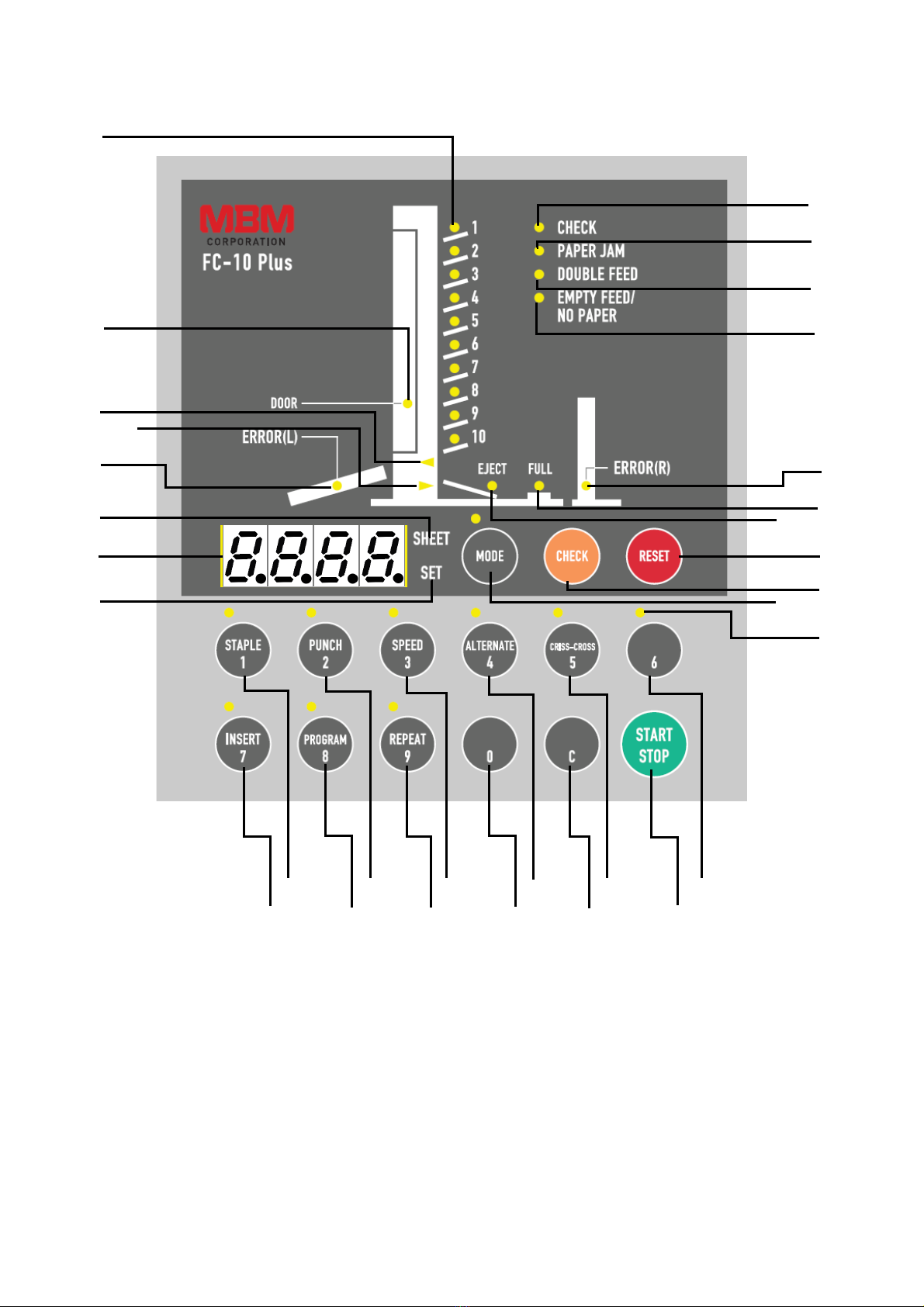

1.2 Operation Panel............................................................................................................... 6

2. Precaution for Maintenance and Inspection.................................................................................. 8

2.1 Usual maintenance.......................................................................................................... 8

2.1.1 Clean-up paper feed roller, separator and Paper Ejection sheet photo sensor .......... 8

2.1.2 Cleaning of Paper Ejection sheet photo sensor.................................................. 10

3. Preparation for use................................................................................................................... 11

3.1 Installing attachments.................................................................................................. 11

3.1.1 Mount the plate to prevent the machine from falling......................................... 11

3.1.2 Power connection............................................................................................... 11

3.1.3 Stacking table assembly...................................................................................... 12

3.1.4 Stacking table..................................................................................................... 12

3.1.5 Switch Single/Option.......................................................................................... 13

3.1.6 Display of total count of sheets.......................................................................... 14

3.1.7 Setting paper feed pressure................................................................................. 14

3.1.8 Setting separator pressure................................................................................... 14

4. Setting Paper.............................................................................................................................. 15

4.1 Precautons for setting paper......................................................................................... 15

4.2 Order of loading paper................................................................................................. 16

4.3 Loading paper in Alternate mode................................................................................. 16

4.4 Loading paper in Insert and Program mode................................................................. 17

5. Response to Light and Flashing of Lamps (ERROR MESSAGE)............................................ 18

6. Main printed circuit board.......................................................................................................... 20

7. Wiring Diagram.......................................................................................................................... 21

8. Paper detection wire angle adjustment procedures.................................................................... 22

9. How to replacement of Parts..................................................................................................... 23

9.1 Operation panel side..................................................................................................... 23

9.1.1 Power switch....................................................................................................... 23

9.1.2 Long distance transmission sensor (Receiving)................................................. 25

9.1.3 Paper Ejection sheet switching micro switch..................................................... 25

9.1.4 Paper detection micro switch.............................................................................. 25

9.1.5 Door open detection micro switch...................................................................... 26