MBV SCHUG SAXONIAN IK 0-6-0T User manual

Page 1

MBV SCHUG

Accucraft Distributor Europe

Neustrasse 18

D-54340 Detzem / Germany

Tel. +49 (0) 6507-802326

Fax +49 (0) 6507-802327

www.accucraft.de

INSTRUCTION MANUAL

“SAXONIAN IK 0-6-0T”

Page 2

Safety first

All our locomotives are safe to run, and will give many hours of pleasure,

providing the following safety procedures are followed:

1. Please read the instructions thoroughly before running fort he first

time.

2. Always do a complete refill of gas, oil and water. Never refill just

the gas to prolong the run.

3. Never let the engine run out of water.

4. When refilling the gas, do not have any naked flame present, and

NO SMOKING!

5. Do not pickup the engine by the bodywork, chimney or boiler,

especially when hot.

6. Only pick up the engine by the buffer beams and, when hot, use

old cloves or a cloth.

7. Do not stand over the chimney. Ejected boiling water or steam may

cause serious injury.

8. Do not open the smoke box door while the engine is alight.

9. If the locomotive gets slower and finally stops the gas is all. Please

close the gas and steam regulator.

10. If the locomotive comes to an aprupt halt, the water is all. Please

close immediatly the gas supply, otherwise you will risk a boiler

overheating.

11. This live steam model is not a toy and does not belong in reach of

children under 14 years. Adults should exercise particular caution

in steam-operation in the presence of children.

Generell Hints

As with all operating machinery, whether model or full size, wear will

occur. In the model steam locomotive much can be done help prolong its

life and decrease the amount of time required in the workshop for

servicing.

Keep the engine as clean as possible, and the motion free from dirt and

garden debris. The valve gear, axles and crank pins should be oiled

sparingly with light oil, e.g. our special lubrication oil. Over-oiling attracts

dirt and grit, which will increase wear.

Regularly check that all screws and motion bolts are firm. Do not over-

tighten, as this strips threads and shares bolts.

Page 3

When filling the lubricator, always use a high temperate steam oil; this is

available from us or other retailers. Failure to use the correct grade of oil

can lead to blocked steam pipes, and will invalidate the guarantee.

When running your engine avoid excessive speed and acceleration, both

will cause premature wear in the valve gear. Prototypically, narrow

gauge locomotives ran at speed of between 10 and 20 M.P.H. and never

exceeded 25 M.P.H.

Positions of Fillers and Drains etc.

The cab roof lifts up and tilts to the right hand side to give access to all

fillers.

The gas inlet valve is in front near side corner of the cab, at the top of the

gas tank turret. The gas control valve is attached to this turret, and can

be operated through the nearside cab doorway or open backside.

The lubricator is in the offside front of the cab, just forward of the

doorway and reverse lever. The filler cap has a “T” bar in it to aid

removal. The lubricator drain is directly beneath the lubricator. To drain,

open the ball valve downwards.

The boiler water filler is on top of the steam turret on the boiler in the

middle of the cab. Undo the knurled cap to fill with water.

The main steam regulator valve is located on the rear of the boiler-filling

turret and can be controlled through to open backside of the cab.

The water gauge is on the backside of the boiler in the middle of the cab

near the burner.

The cylinders have drain cocks. To open them please bring the levers in

vertical position, to close them in horizontal position. Be careful when

you like to drive with open cylinder drain cocks. They can touch the rails

and your loco will de-rail !

The direction control is the lever in the offside cab door. To operate pull

gently outwards and move to the desired direction. The control is “gated”,

and will therefore hold itself in the full forward or reverse position.

Page 4

1. Boiler Water Filler

2. Pressure Gauge

3. Lubricator

4. Reverse Lever

5. Steam-Regulator

6. Gas Inlet Valve

(Ronson Type)

7. Water-Gauge

8. Gas Control

9. Burner with Nozzle

10. Safety Valve inside

11. Box for RC-Receiver

12. Lubricator Drain

13. Cylinder Drain Cocks

Page 5

Preparation for running

The Saxonian IK is fitted with a water gauge; this allows the driver to

keep the model in steam continuosly for longer periods of time than the

usual single fill system. This is done using a boiler Top-up System

avaiable from us or your dealer. The initial fill up with gas, oil and water

is the same as for a basic run, but then to carry on and run for longer

periods requires supervision of the boiler water level, topping up of the

lubricator and refilling of the gas. These procedures will be explained in

another section after the Running section instructions.

Always service the engine in the following order; first gas, oil then water.

To fill the gas tank: invert the gas can and apply the nipple to the gas

inlet valve on the top of the tank turret. It is advisable to support the loco

under the gas tank whilst filling, to prevent the engine tipping over. You

will know when the tank is full; gas will blow back from the inlet valve in a

strong jet. A small amount of gas and air will escape during filling, but the

difference between this and when the gas tank is full is always clear.

Always keep the gas can vertical when filling the gas tank.

Filling the lubricator: as you will read in the instructions for the end of the

run, the lubricator should be empty of oil and water with the valve left in

open position. Now close the valve and remove the lubricator filler cap.

Fill up the lubricator with steam oil to about ¼ of an inch (about 1 cm)

below the top. Leave the filler cap off for the present, so that any tapped

air can escape. It can be refitted after you have filled up the boiler.

To fill the boiler: remove the filler cap and fill up the boiler approximately

¾ with water - ideally use filtered rainwater or distilled water using the

large syringe provided. Replace the boiler filler cap, check that the

lubricator does not need topping up, and then replace its filler cap also

Filler caps should be firm tight. They are sealed with a trapped “O” ring

and, therefore should no be over-tightened.

Page 6

Lighting Up

Open the smokebox door; just pull it open by the door handle. Light your

lighter/match etc. and gently open the gas control valve until a gentle

hiss is heard in the burner. Apply your light into the smokebox and the

flame should “pop” down the fire tube and ignite the burner inside the fire

tube.

If the gas valve is open too much the flame will not pop back; it will either

fail to ignite, will roar in flame out of the smokebox, or there will be a ball

of flame around the front of the engine, which will then blow the whole

fire out (after giving the driver a fright)!

When the fire sound has stabilised, after about 30 seconds the gas can

be turned up until a healthy roar is heard. The smoke box door may be

shut after about two minutes. Now leave the locomotive to raise steam.

When the pressure starts to rise, water will be seen running out of the

boiler blow down valve. When the water reaches its correct level steam

will be seen. Now close the check valve and let the locomotive raise at

least 40 p.s.i..

Running

When the engine has raised about 40 p.s.i. you are ready to start

running. Open the cylinder drain cocks with the levers in vertical position.

Be sure that the levers did not touch the rails (the loco would derail), now

open carefully the steam regulator.

It is advisable to run the engine in reverse first; it clears the condensed

water from the cylinders best this way. When no more water comes out

of the drain cocks please close them by bringing the levers in the

horizontal position.

Before commencing your first run of the day, it is advisable to put a cloth

loosely over the chimney for a few minutes, as condensed water will be

ejected from the chimney. This is quite normal; the motion of the engine

will be jerky until all condensate has been ejected. Do not stand over the

chimney as ejected boiling water/steam could cause serious scalding.

Place the direction lever into the reverse position, and than open the

main steam valve. The engine should start to move off in the reverse

direction. From starting from cold it will be jerky, this is normal, as it has

Page 7

to clear the condensate from the system. The more the main steam valve

is opened, the faster the engine will go; our advise is to start slowly and

learn the road with your engine.

After a minute or so, remove the cloth and continue running. I running it

is correct practice to balance the boiler pressure against the load being

pulled and the track conditions.

With a light load and level track the pressure may need to be only 25-30

p.s.i. therefore, turn the gas control valve down to keep this pressure.

When running a heavy train with steep gradients, increase the pressure

by turning up the gas.

The ideal running pressure can be learned by experience and is one of

the pleasures of running a live steam engine.

There is no need to have the safety valve constantly blowing off (it is

what its name implies - a safety vent for excess steam pressure). In all

our designs, the gas has been programmed to run out just before the

water, thus it is important not to refill with gas alone in order to lengthen

the run by a few minutes. When the gas runs out a complete gas, oil and

water service must be done (remember GOW, also remember to shut the

gas regulator before refilling, and do not refill with gas near any other

live steam loco).

When the locomotive slows as the pressure falls at the end of a run, stop

the engine. Gently open the lubricator valve and blow out any condensed

water. If you intend to continue running, close the drain when you see oil

coming out of it and carry out a general refill. If it is the last run of the

day, leave the lubricator open and blow the lubricator clean.

Continuous Running

To run for longer periods of time than the normal “one fill” system you will

require a Boiler Filling system. This consists a pump bottle with tube

attached and a replacement boiler filler cab, which has a non-return

valve on its underside. For the first fill service in the normal way. Then

run for about 15 minutes, now have a look at the water level. You will

probably need to pump some water into the boiler. Lift and tilt over the

cab roof to uncover the filler cap, place the tube in the hole and holding it

firmly, pump water into the boiler untilo the gauge glass is showing ¾ full.

Keep an eye on the water gauge and try to run between ½ and ¾ of the

glass.

Page 8

After another 15 minutes running you will need to refill the lubricator and

top up the gas tank. Also check the water level and top up if necessary.

Stop the loco in a convenient location, away from other locomotives and

turn off the gas. Ensure the fire is completely out and then top up the gas

tank.

Blow around the engine so there is no residual gas about, then re-light

the fire. To refill the lubricator first put the loco in neutral (mid gear).

Open the under floor drain valve then gently open the steam regulator.

When the lubricator has blown clean, close the regulator and remove the

lubricator cap. Now close the drain valve and refill with superheat steam

oil to the correct level. Re-fit the lubricator cap. All this time the engine

has had the fire alight and will have a good head of steam, so now carry

on running.

Keep an eye on the water level at all times and try to refill the gas tank

and lubricator every 20 minutes to half an hour.

End of Run

As previously mentioned, the locomotive will slow (due to pressure

dropping) when the fire has gone out, stop at a convenient place and

open the lubricator drain valve. Blow out all condensed water and the

remaining oil. Leave the drain valve open and allow the remaining steam

to blow out. The locomotive should be allowed to cool. When cool clean

the engine, check the motion and oil if necessary. The locomotive should

always be put away in a clean condition as it attracts less dust and is

always ready for the next run (or to be shown to an admiring friend).

Always leave the lubricator drain valve open so that the boiler will not be

strained if subject to any temperature change. It is advisable to store the

locomotive where any residual drips of oil or water do not matter.

Blocked Gas Jets

If the gas jet becomes blocked with particles of dirt within the gas, the jet

will have to be removed and cleaned. With a spanner or pliers carefully

undo the pipe union on the gas control valve. Remove the pipe hand jet

holder assembly from the burner. Holding the jet gently in vice, unscrew

the jet. To clear, place the jet nozzle against the inverted gas can nozzle

and clear the jet with a blast of gas. Under no circumstances use a

pricker wire, this will damage the jet hole.

Page 9

Replace the jet in the holder, ideally using a thread sealant sparingly on

the threads. Ensure it is tightened up firmly. Replace the assembly into

the burner and re-connect the pipe to the control valve. Ensure this is

done up tightly, test CAREFULLY for gas leaks, first with a 50/50 mixture

of washing up liquid and water, and then if no bubbles are showing, with

a flame and the gas “just on”. Tighten if required.

Note on Radio Control

The IK is ready for Radio Control. We recommend the metal geared

Servos Hitec HS85MG and Hitec HS125MG (one of each). The receiver

should be housed in the box under the cab floor and the batteries in the

right water tank.

Technical Details

Scale - 1:20.3

Gauge - adjustable between 32 and 45 mm

Height - 147 mm

Width - 93 mm

Lenght - 277,3 mm

Minimum Radius - 76 cm (LGB R2)

Weight - 3,27 kg

Cylinder with Piston Valve and Drain Cocks, Pressure Gauge, Water

Gauge, Lubricator with Drain, Ready for Radio Control

(All Specifications and Designs are subject to change without notice)

Optionally available accessories

Gas Filling Adapter (for Rothenberger Multigas 300 Cans)

Brass syringe (to suck off the oiler)

Steam Cylinder Oil ISO 220 (250 ml squeeze bottle)

Steam Cylinder Oil ISO 460 (250 ml squeeze bottle)

Lubricant Oil (100 ml squeeze bottle)

Goodall Valve

Feedbottle for Goodall Valve

Page 10

Page 11

History

Starting in 1881, numerous narrow gauge lines were opened in the

Kingdom of Saxony which partly showed a tilt and tortuous course. For

this purpose the Royal Saxon State Railways ordered 39 small three-

coupled tank locomotives from the Saxon Machine Factory in Chemnitz.

1906 five more to the private Zittau-Oybin-Jonsdorfer Railway Company

(ZOJE) delivered specimens were taken over by the state railway. First,

they were classified in the genus H V TK, which was changed in 1896 in

K I and from 1900 in I K.

27 locomotives arrived in 1920 still in the possession of the Deutsche

Reichsbahn. In 1925 they received the new numbers from 99 7501 to 99

7527. A little later, all locomotives were retired.

After First World War, five locomotives were made as War reparations to

Poland. During the Second World War, two of this were re-introduced

into the herd of the Deutsche Reichsbahn and designated as 99 2504

and 99 2505. They arrived in 1945 to Polish Railways PKP again.

The Saxonian IK - Rebirth of a Legend

In 2006, the delivery of the first three narrow gauge locomotives of the

genus IK from the Saxon Machine Factory formerly Richard Hartmann

AG to the Royal Saxon State Railways has her 125th anniversary. Until

1892 a total of 44 of this small, strong, three-coupled tender locomotives

leaves the factory in Chemnitz. The last locomotive of this genus was

scrapped in 1964 after considerable 80 years of service in

Schmiedeberg.

From 2006-2009 a unique project was realized in the Free State of

Saxony: the faithful reproduction of Saxony’s first narrow-gauge

locomotive. In this period, a copy of the for decades no longer existing

Lokomotive Type was build from ground on new using old and new

drawings. After three years of dedicated work, the IK No. 54 was officially

privy on 04. July 2009 in Radebeul. Since 29.August 2009 the IK No. 54

locomotive comes to the Saxon narrow gauge railways. Railway

enthusiasts and tourists enjoy the rides of the striking train with great

enthusiasm.

For the small green black red painted machine were cash and in-kind

donations collected valued at more than 800.000 EUR.

Page 12

She wears now significantly to the increasing of the tourist attractiveness

of the Saxon narrow gauge railways.

About the impressive path from the idea to build a replica up to the

commissioning of the final locomotive is reported in the book about the

IK No. 54 and honors thus the accomplished achievements of many

volunteer supporters.

The IG Preßnitztalbahn e.V. as railway transport company has taken

over the complete support of the I K No. 54, also for the deployment

planning (http://www.ssb-sachsen.de).

*******************************************************************

HAPPY STEAMING!

*******************************************************************

Guarantee: we will remedy any defect or malfunction occurring with this

product during a one year guarantee period from date of purchase.

This guarantee does not extend to malfunctions or defects causes by

damage or unreasonable use, including the failure to provide the correct

types of lubrication and water.

This guarantee is quoted in addition to all legal right of the purchaser

under the Sale of Goods Act, and shall expire one year from the date of

purchase. Under no circumstances shall we be responsible for any

consequential damages arising in regards to any of our products.

Please read the instructions carefully and note the hints for professional

operation!

Produced in a limitierted edition

of 30 units for MBV SCHUG from:

ACCUCRAFTCOMPANY

33268 Central Avenue

Union City, CA94587USA

Tel.1-510-324-3399 Fax 1-510-324-3366

www.accucraft.com

Table of contents

Popular Toy manuals by other brands

Mattel

Mattel HotWheels RC MONSTER JAM W5697-0920 quick start guide

Heli-Max

Heli-Max AXE100CX instruction manual

Fisher-Price

Fisher-Price LEARNING BUNNY G2810 instruction sheet

Fisher-Price

Fisher-Price FPM20 quick start guide

Radica Games

Radica Games 73011 instruction manual

Hasbro

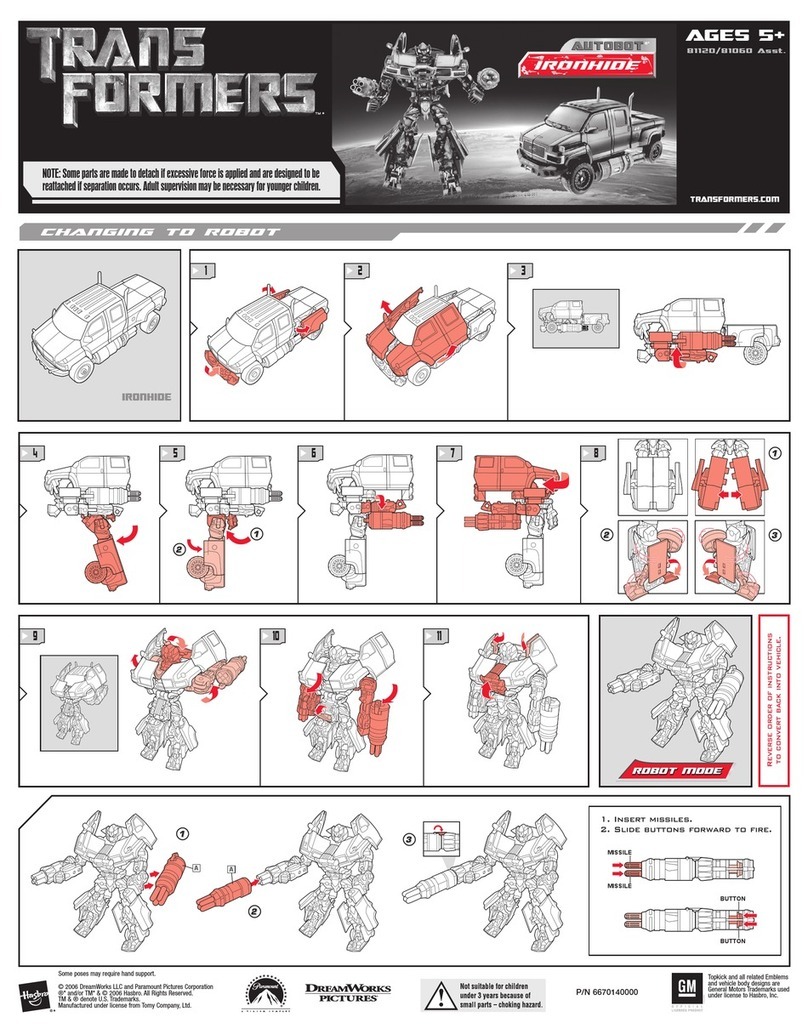

Hasbro Transformers Ironhide 81120/81060 instruction manual

REVELL

REVELL Fokker Dr. I Manfred von Richthofen Assembly manual

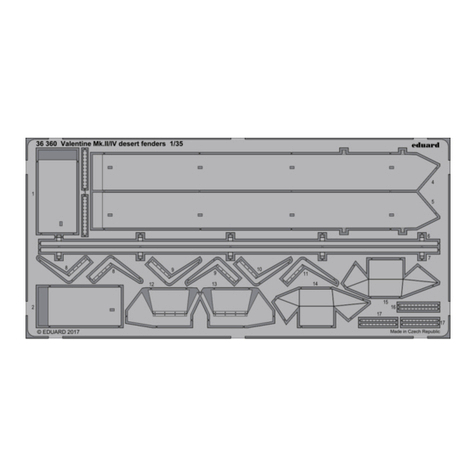

Eduard

Eduard Valentine Mk.II/IV desert fenders Assembly instructions

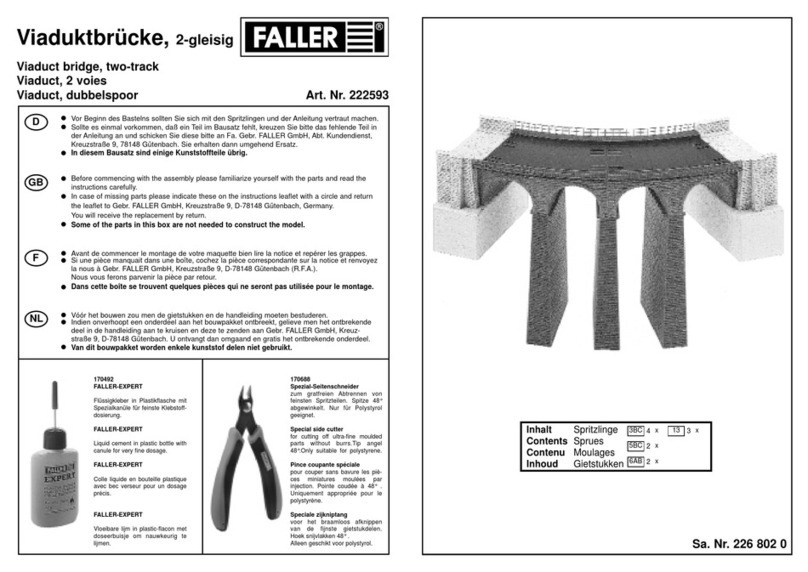

Faller

Faller 222593 manual

RJX Hobby

RJX Hobby CAOS 330 Assembly manual

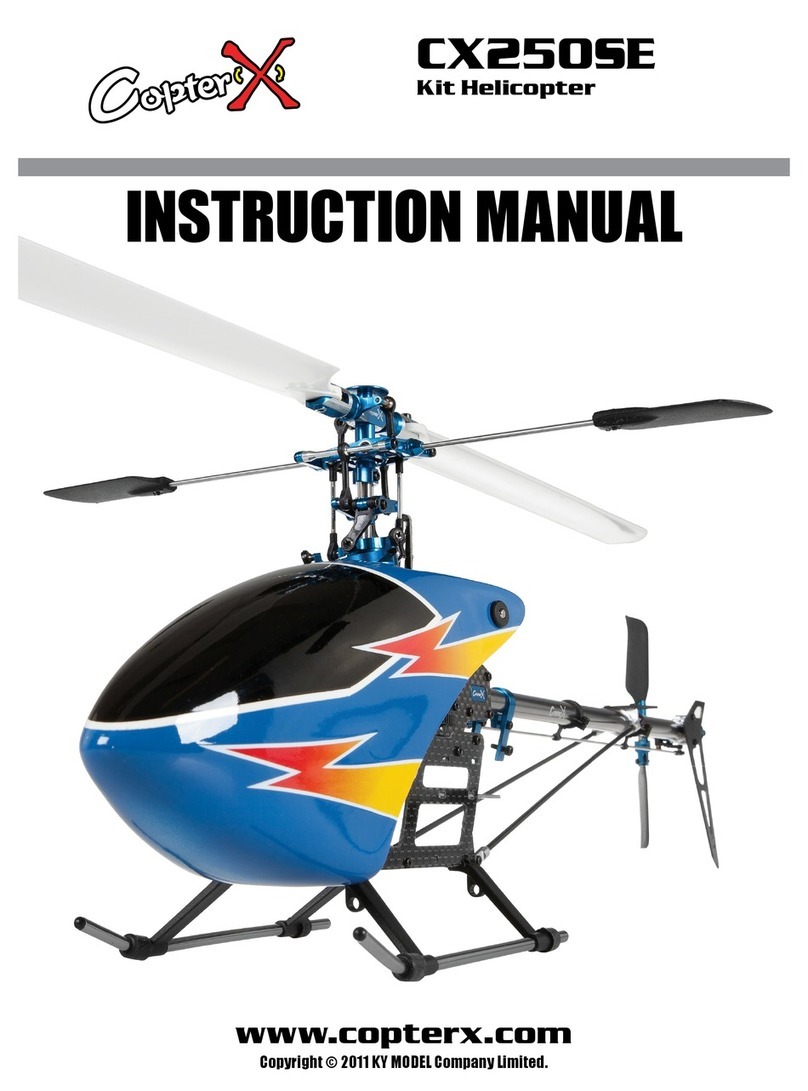

CopterX

CopterX CX250SE instruction manual

Klaus Krick Modelltechnik

Klaus Krick Modelltechnik roMarin ro1100 Building instructions