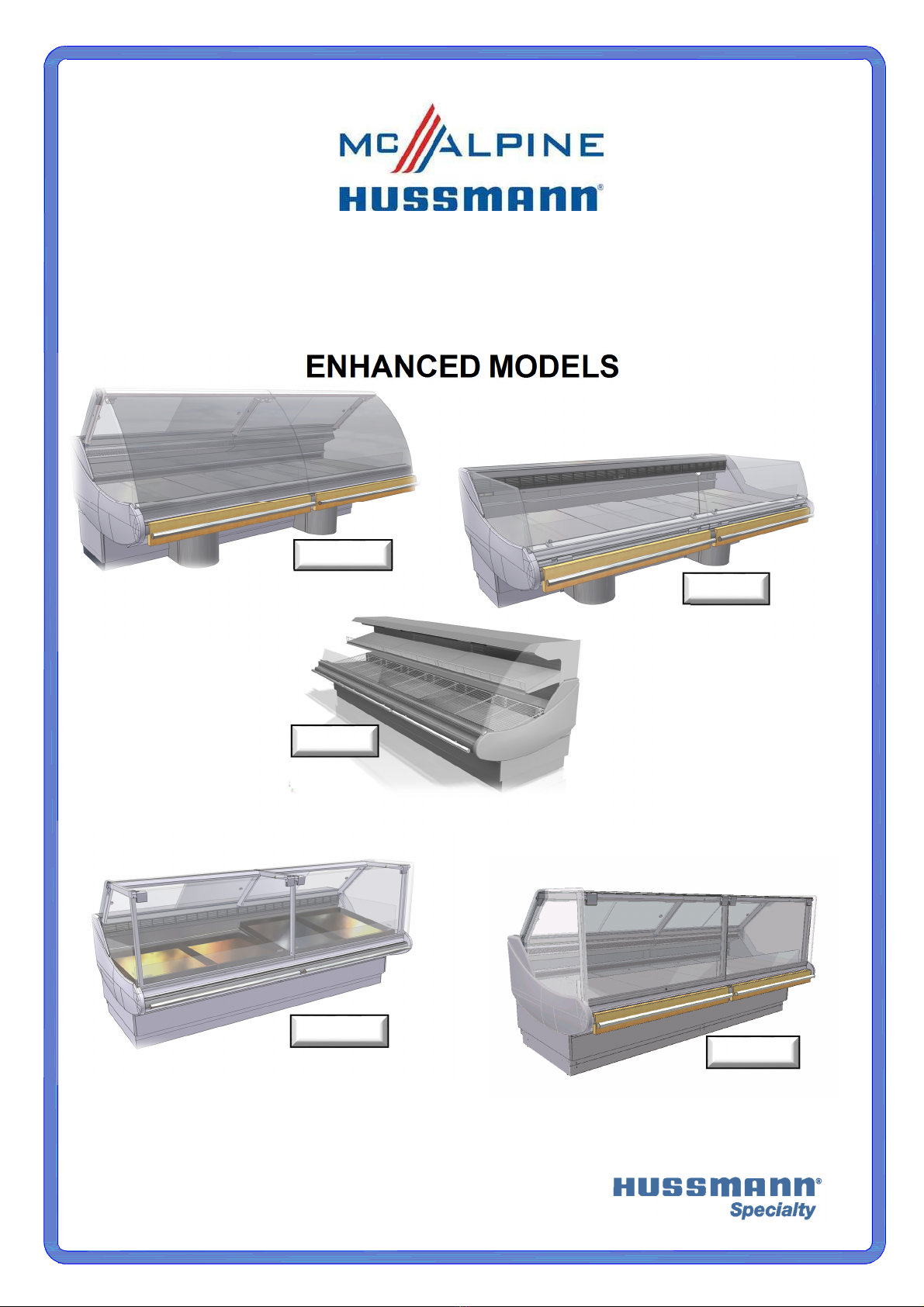

McAlpine Hussmann VLL726E User manual

SPECIALTY CASE FACILITY

VLL726E/VLL726BL/VLL727BL/VSS726E/VVS727E

REFRIGERATED DISPLAY CABINETS

ENHANCED

MODELS

INSTALLATION AND MAINTENANCE INSTRUCTIONS

MAN147/1

April 2013

VLL726E

VLL727BL

VSS726E

VVS727E

VLL726BL

CONTENTS

AMBIENT OPERATING CONDITIONS ………………………...................... 3

LOCATION CONDITIONS ……………………………………...........… 3

KEY OPERATION POINTS ……………………………………………… 4

RECEIVING CABINETS …………………………………….........….. 4

CABINET INSTALLATION ….............................................................. 5

JOINING CABINETS

BASE OPTIONS

KITS

ATTACHING THE FRONT BUMPER

ADJUSTING FRONT GLASS

ELECTRICAL INSTALLATION

DRAIN INSTALLATION

PRE-START CHECK LIST

CABINET OPERATION ……………………………………………... 13

LOADING LIMITS

FITTINGS AND ACCESSORIES

TEMPERATURE CHECKING

MAINTENANCE …………………………….....................… 19

CLEANING

REGULAR INSPECTION

DISPOSAL OF THE CABINET

REPLACEMENT PARTS

CABINET SECTIONAL VIEWS …………....................……………………. 21

CABINET JOINING DIAGRAMS …………………………………………..…. 26

CABINET FOOTPRINTS ……………………….........………………. 29

HAZARD ASSESSMENT …............................................................. 33

Page 3

AMBIENT OPERATING CONDITIONS

All “V” series Refrigerated Display Cabinets have been designed to operate

under the following conditions:

Class 3M1 Ambient temperature 25ºC

Relative humidity 60%

Max cross draft 0.2 m/sec

Product Temperature -1˚C to +5˚C

Class 3M0 (VVS727E Cabinet – with shelf in angled position only)

Ambient temperature 25ºC

Relative humidity 60%

Max cross draft 0.2 m/sec

Product Temperature -1˚C to +4˚C

Ambient conditions greater than those stated may result in poorer performance

of the cabinet and higher running costs.

LOCATION CONDITIONS

Cabinets should be sited so that external influences are minimized. Situations

to avoid are:

•

Air draughts from: Air conditioning,

Ventilation,

Heating outlets,

Entranceways,

•

Heat sources: Sunlight,

Spotlights,

Hot cabinets,

Concentrated external

lighting,

Non-insulated roofs and

walls,

•

Mechanical damage:

Shopping trolleys,

Forklift trucks,

Pallet jacks,

Floor polishers,

Extra protection may be required to minimize damage.

Any of these situations could prevent this cabinet from performing correctly.

NOTE: Unless specified, there should be a 100mm gap between the cabinet and

a wall. This is to allow sufficient airflow to prevent condensation

Page 4

KEY OPERATION POINTS

•

Always keep rear doors closed when not using the cabinet

•

Do not overload the cabinet with product (see loading limits pp 13~16)

•

Do not block air delivery or air return vents

•

Do not add display ice to VLL726E and VSS726E cabinets. This will cause

fan motor damage. VLL727E cabinets are designed for display ice.

•

Do not use mechanical devices or other means to accelerate the defrosting

process, other than those recommended by the manufacturer.

•

Do not use electrical appliances inside the food storage compartmentsof the

appliance, unless they are of the type recommendedby the manufacturer.

•

Always clean cabinet as described in the cleaning section of this manual and

on the cleaning instruction label on the cabinet.

•

However, if a liquid spill should occur, the spill should be cleaned as

soon as practicable. Liquids can be acetic, and if left will risk damage

to some components in the cabinet.

RECEIVING CABINETS

Cabinets will always be dispatched in good condition. Always inspect the cabinet

and packaged accessories for damage. Note any damage on the carrier’s

consignment note prior to signing.

For concealed damage that is found later, notify McAlpine Hussmann in the relevant

country within 3 working days. Any issues will be addressed and rectified as

applicable.

Australia: McAlpine Hussmann Ltd

Email: [email protected]

Ph. 1300 36 38 40

New Zealand: McAlpine Hussmann Ltd

Tauranga

Ph. 07 578 0965

NOTE: A photographic record of any damage found is required.

Also quote cabinet serial number and a brief description of the damage.

A check should also be made to ensure:

•

That all loose parts listed on the outside packaging are present and

undamaged,

•

That glass has not moved during shipment. Test any lifting glass carefully to

ensure there is no rubbing or knocking of glass that may cause future

damage. There are glass adjustment instructions in this manual

NOTE: Any shortages will follow the same procedure as concealed damage.

Page 5

CABINET INSTALLATION

JOINING CABINETS

Cabinets shall be installed level front to back and side to side to allow correct

operation of lifting glass, and allow condensate to drain freely.

There is a 150 psig Dry Nitrogen (+/- 10psig) holding charge in the evaporator

coil, please check the pressure before safely releasing the holding charge. If

Dry Nitrogen holding charge is found to be below 140 psig, please undertake

additional leak checks of the evaporator coil.

1. Always identify the highest point on the floor where the cabinets are to be

installed. Cabinets will need to be levelled from this point.

2. Mark a line on the floor that shows the position of the rear skid rail for the line-

up.

3. Position the first cabinet, level end to end and front to back. Ensure the

footbolts are adjusted (50mm nominal adjustment range) to accommodate the

highest point in the floor. All footbolts must be adjusted to the floor. This will

ensure hinged glass maintains its position over time as the cabinet settles.

4. Apply a non-hardening, flexible sealant to the end of the cabinet to ensure a

seal between the refrigerated area of the cabinet and the ambient

environment.

5. It is advisable to apply masking tape to any visible joints to be sealed later,

before butting up the adjacent cabinet.

6. Place the next cabinet as close as possible to first cabinet and set the height of

the second cabinet to roughly match the first following the procedures in steps

3, 4, and 5.

7. Push the cases together and insert joining bolts. Make any minor adjustments

to exactly align the two cabinets and tighten the joining bolts.

8. Check cabinet is level from end to end and front to back at both ends.

9. Repeat procedures until all cabinets are aligned.

10.Apply finishing sealants and any jointer items. Remove masking tape from

sealed joins. Tidying up any excess sealant.

11.Fit bumper assemblies. Detailed instructions are on the following page.

12.Check all glass gaps on lift front cabinets. Adjust as required to have a 3mm

gap between each glass. A larger gap can be closed using a wiper strip

adjacent to ends on box cabinets.

13.Fit wiper strips to the ends of box cabinets where required to close any glass

gaps. Use RTV to glue to glass

14.After all services have been installed and completed, fit coving angles and

dress panels.

15.Clean the condensate deck of any filings and rubbish that may have

accumulated during installation. These may block drains or cause rust damage

to panels over time.

16.Fit any internal panels that have been removed for installation.

17.Fit all supplied accessories. A list of separately wrapped loose items should be

on the cabinet

NOTE: The front glass may be packed loose in VSS726E and VVS727E cabinets.

NOTE: There are joining diagrams at the back of this manual.

Page 6

BASE OPTIONS

These cabinets are supplied as standard with removable base extensions. This allows

the cabinet to be sited on a plinth and stillmaintain the optimum access and working

height for the cabinet. A full set ofpanels should besupplied with each cabinet to make

this change. If theyare not included, contact McAlpine Hussmann for the required panels

and instructions.

KITS

There are also various kits to change cabinet configurations. Instructions for the fitting of

these will be supplied with each kit. Contact Hussmann for kit options and instructions.

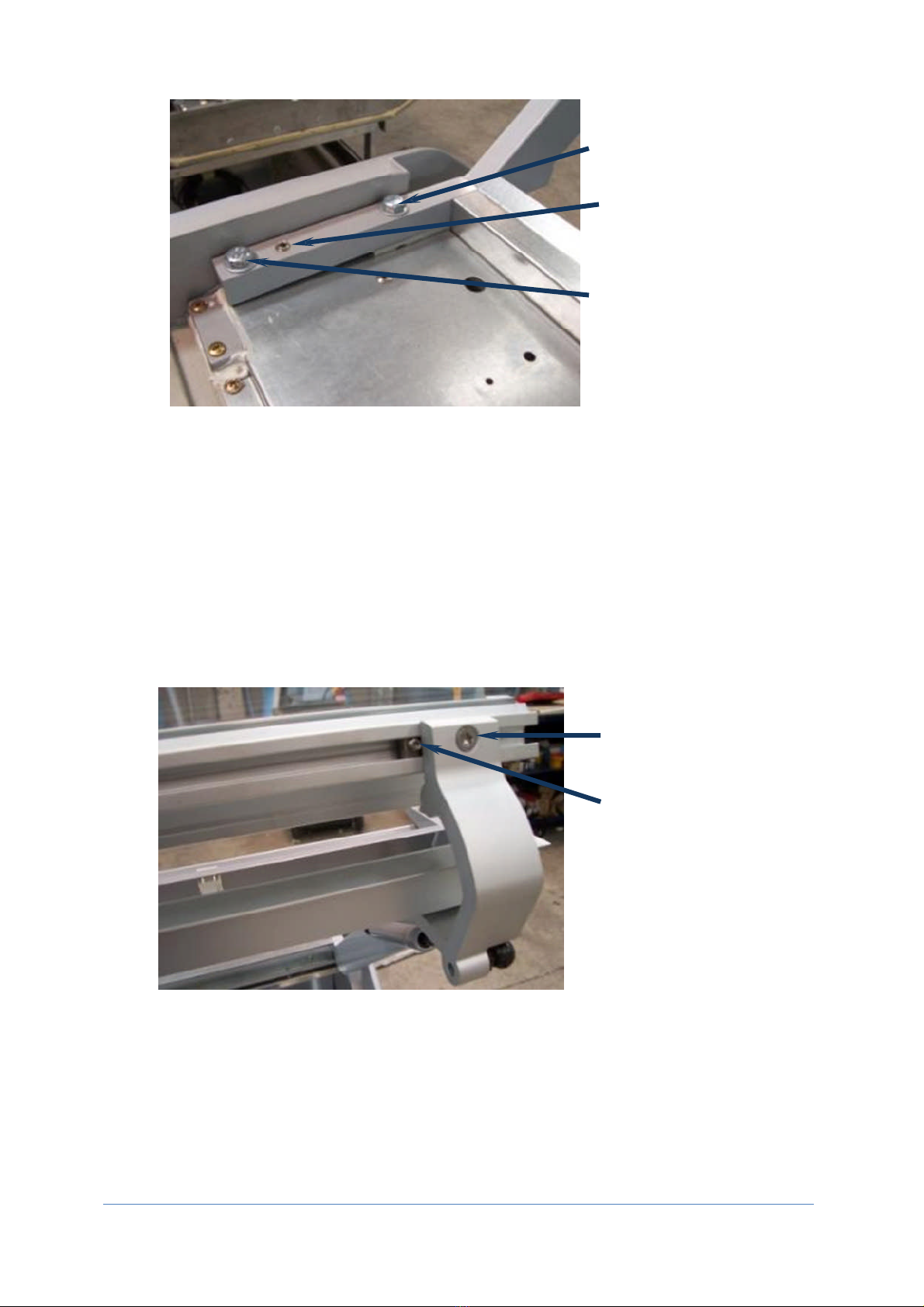

ATTACHING THE FRONT BUMPER

IMPORTANT!

Bumper assembly securing screws must be fitted to all

bumper assemblies.

Bumper assemblies are sent unattached for transport reasons. Therefore,

securing them correctly to prevent dislodgement and possible injury is very

important.

The following instructions should be followed carefully.

1. Unwrap the bumper assembly. You should find a pre-assembled bumper

assembly and a number of securing screws to match the number of pre-drilled

white plastic clips on the front of the cabinet.

PRE

-

DRILLED WHITE PLASTIC CLIPS

Page 7

2. Before fitting the upper colour panel (painted panel that sits at 45°), fit the

bumper assembly.

3. Align the bottom groove in the aluminium extrusion with the bottom tag on the

plastic clips.

4. Push the top of the bumper assembly on to the plastic clips.

BOTTOM GROOVE

Page 8

NOTE: If some bottom tags on the plastic clips do not sit in the extrusion

correctly they can be pushed into place once the assembly has been fitted.

This can be done using your fingers from below the assembly.

5. Pre-drill the bumper assembly aluminium extrusion at every white plastic bumper

clip with a 4.5mm drill bit, taking care not to drill through the front bumper rubber

(see insert picture for drilling depth)

4.5mm DRILL BIT

Page 9

6. Fit hex head securing screws to every white plastic bumper clip. It is advised

that the screws provided are used to ensure secure fixing

7. Front colour panels can now be fitted

USE SCREWS PROVIDED

Page 10

ADJUSTING FRONT GLASS (VLL726E ONLY)

IMPORTANT! Ensure the power to the cabinet has been disconnected before

commencing work.

Adjusting the rear posts will require the following tools:

•

Cross head screwdriver (Philips) PH2

•

Square drive screw driver S2

•

Star drive keys

•

Allen keys

•

Adjustable wrench

Adjusting the rear posts.

1. Remove the screws on the rear work top. Taking care not to damage the

trace heating wires, unhook the front of the work top and roll the back

forward to lay the work top against the canopy arms.

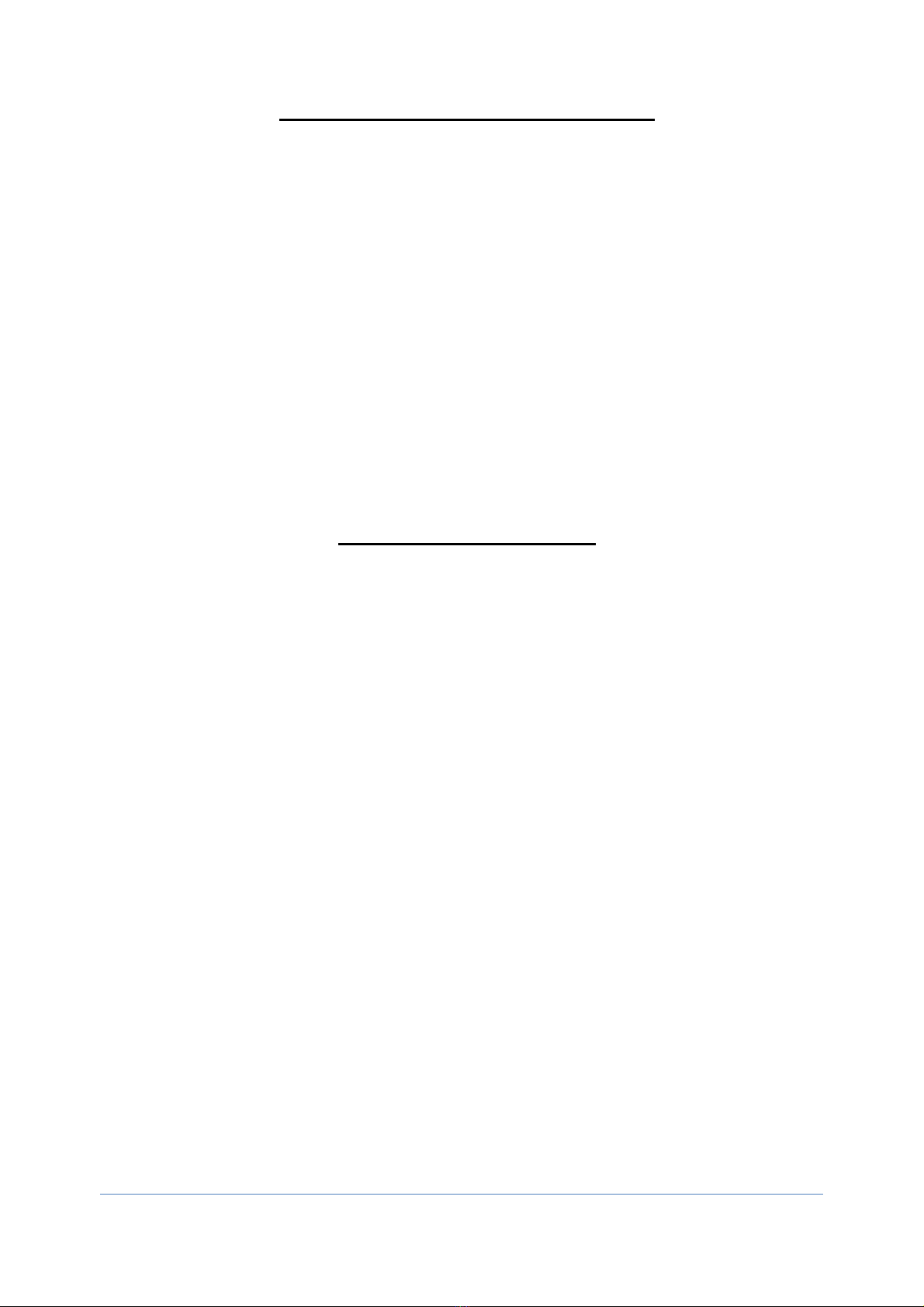

Screws to remove are

along the rear edge and

into each arm at

the front

Page 11

2. Loosen the grub screw on the foot of the rear post.

Front bolt

Grub screw

Rear bolt

3. Adjust the post by loosening or tightening the rear bolt. This will tilt the

post forward or backwards. You may need to slightly loosen the front bolt.

You will need to adjust all the posts on a cabinet.

4. When the posts are aligned with that of the adjacent cabinet retighten the

grub screw on the foot of the rear post.

Adjusting the glass

1. The glass can be moved laterally to even out the gaps between each piece

of glass.

2. Lift the glass to the fully open position

3. Loosen the grub screw on the locking plates at each hinge.

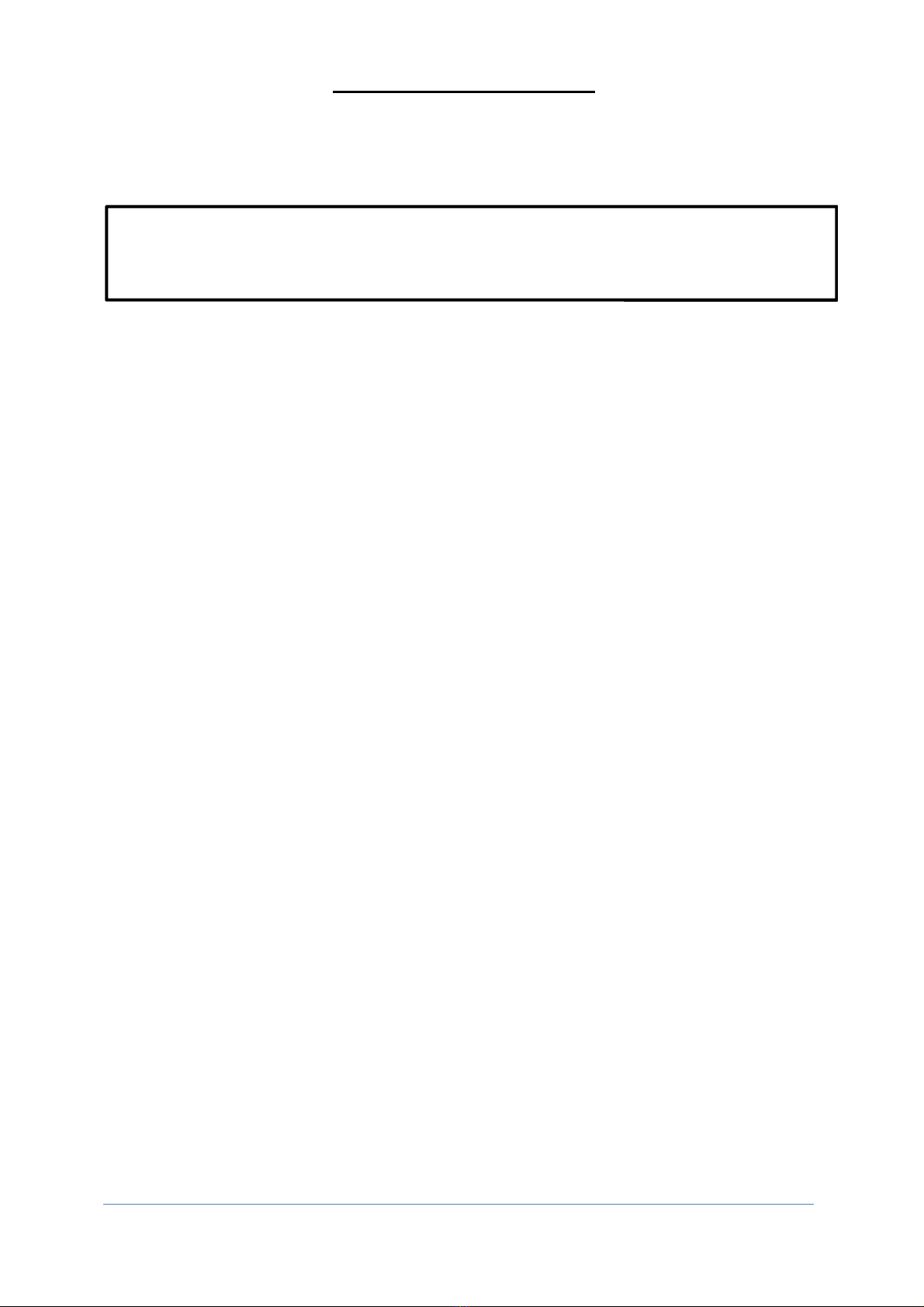

Hinge attachment screws

Locking plate grub screw

4. Loosen the hinge attachment screws on each hinge. This will allow the

glass clamp to be moved.

5. Tighten the hinge attachment screws on the hinges before lowering the

glass to check the new position.

6. When the new position is attained check again that the hinge attachment

screws are tight. If they are not the glass will sit at different heights and the

glass clamp extrusion could be damaged.

7. Tighten the locking plate grub screws.

Page 12

ELECTRICAL INSTALLATIONS

The electrical installation shall:

•

Meet existing regulations and safety codes,

•

Have an electrical supply to the cabinet that is independent of other supplies,

•

Be individually isolated,

There is a wiring diagram in the electric box of each cabinet.

If you require a replacement wiring diagram, please contact McAlpine Hussmann.

Please supply cabinet serial number with the request.

DRAIN INSTALLATIONS

Points to be aware of for cabinet drain installation:

•

The cabinet should be correctly leveled,

•

Water traps are factory fitted to the case,

•

The installer should ensure that the drain then slopes to the drainage point,

•

Drains may need insulating to prevent condensation dripping onto the floor,

PRE-START CHECK LIST

It is suggested that the following items be included but not limited to any pre-start

check of this cabinet.

•

All electrical connections are secure and electrical tests completed.

•

Refrigeration system has been pressure tested.

•

Drain traps have been primed with water to seal and drain screens are fitted

where provided.

•

Any loose material created during installation has been cleaned from the

cabinet. Pay particular attention to filings that may be caught under the

evaporator and fan panel seal. These could cause rust spots and pitting that

could permanently damage the stainless steel.

•

All electrical, refrigeration and sensor penetrations have been sealed inside

and outside the cabinet. Including any penetrations through baffles or other

internal panels

•

Fan panels seal correctly

Page 13

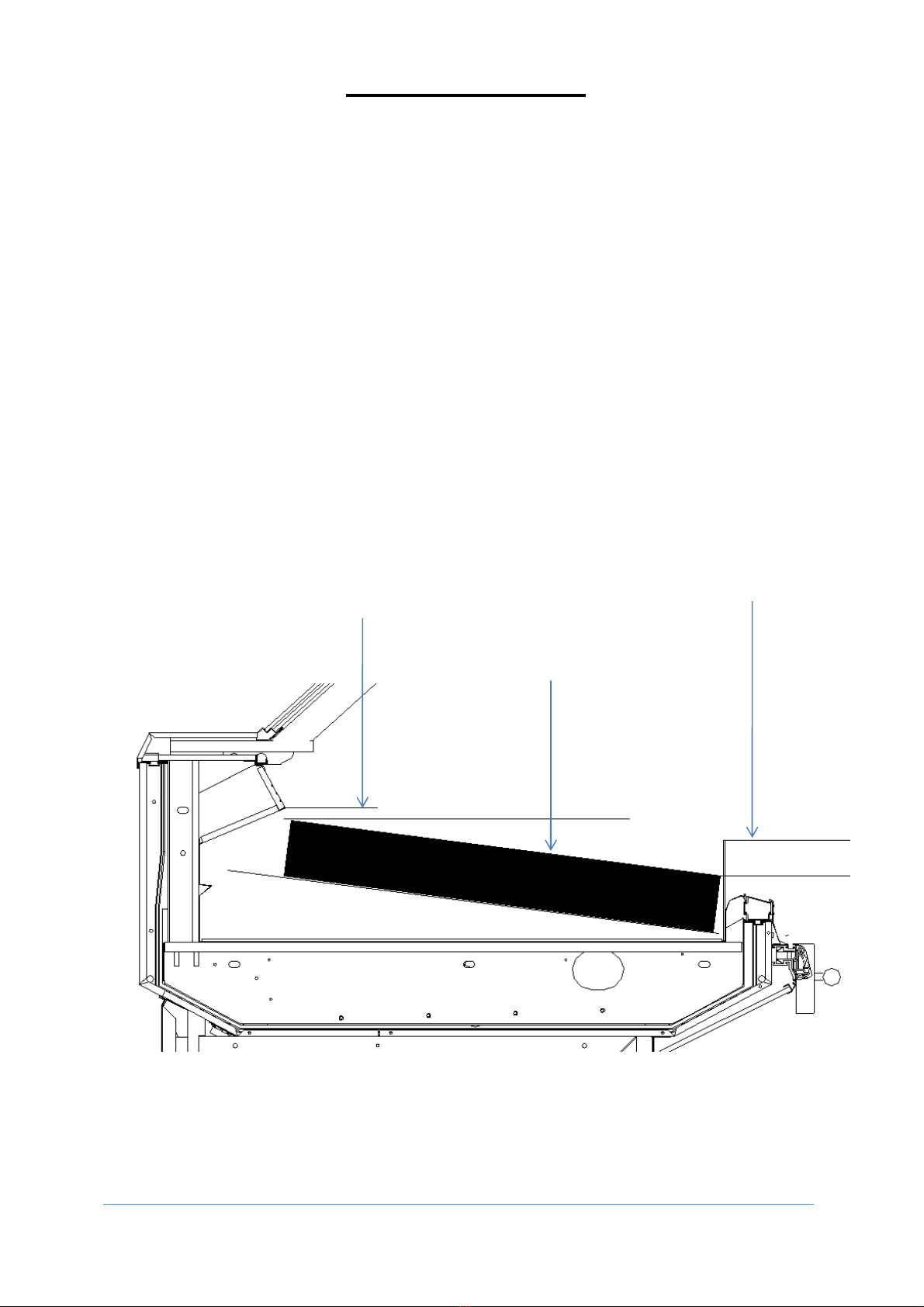

TOP OF

PRODUCT 50mm

BELOW TOP OF PRODUCT STOP

CABINET OPERATION

LOADING LIMITS

VLL726E – VLL726BL – VSS726E

These refrigerated display cabinets are not designed to cool down perishable food

products but to maintain them at the temperature which they are introduced to the

cabinet. For non-meat product this should be between -1°C and +5°C.

These cabinets have a load limit of 100mm above the storage surface. Product shall

be kept at least 20mm below the bottom of the air delivery vents. Food products

stored within the load limits are properly refrigerated. Food products stored outside

the load limits may not be properly refrigerated, and disturb the airflow with the result

that cabinet performance is compromisedand food products may be damaged.

VLL726E

VLL726BL

TOP OF PRODUCT

20mm

BELOW

AIR DELIVERY VENTS

100mm PRODUCT DEPTH

Page 14

VSS726E

VSS726E cabinets are available with curved or straight front glass

TOP OF

PRODUCT 20mm

BELOW

AIR DELIVERY VENTS

100mm PRODUCT

DEPTH

PRODUCT SHALL BE 50mm

BELOW PRODUCT STOP

Page 15

VLL727BL

This refrigerated display cabinet is not designed to cool down perishable food

products but to maintain the temperature at which they are introduced to the cabinet.

Ice should not be stacked more than 20mm above the Ice tray. Product should be at

least 20mm below the rear air delivery vents.

ICE LOAD LIMIT: 20mm ABOVE ICE TRAY.

PRODUCT HEIGHT LOAD LIMIT: 20mm

BELOW REAR AIR DELIVERY VENTS &

FRONT ICE STOPS.

ALWAYS FIT ICE STOPS ADJACENT TO

PATCH ENDS. THESE WILL PREVENT

CONDENSATION

20mm

20mm

20mm

Page 16

VVS727E

This refrigerated display cabinet is not designed to cool down perishable food

products but to maintain the temperature at which they are introduced to the cabinet.

This cabinet has a load limit of 100mm above the shelves and the deck rack. Food

products stored within the load limits are properly refrigerated. Food products

stored outside the load limits may not be properly refrigerated, this may disturb the

airflow with the result that cabinet performance is compromised and food products

may be damaged.

VVS727E cabinets are available with curved or straight front glass.

100mm PRODUCT DEPTH

Page 17

FITTINGS AND ACCESSORIES

Only fittings and accessories supplied with the cabinet should be used. Any

other additions may cause the cabinet to not work in its intended fashion.

VLL726E and VLL726BL fittings and accessories may include:

•

Front product stops

•

Display racks

•

Bag holders

•

Glove dispensers

•

Scale mounting frames

VSS726E fittings and accessories include:

•

Front product stops

•

Bag holders

•

Glove dispensers

VLL727BL fittings and accessories include:

•

Ice trays

•

Front ice stops.

•

Product dividers

•

Bag holders

•

Glove dispensers

•

Scale mounting frames

•

Patch end ice stops – These fit inside the ice tray adjacent to the patch end.

Bank ice against them to hold in place

It is very important that the patch end ice stops are fitted. They prevent

condensation from forming on the outside of the cabinet

VVS727E fittings and accessories include

•

Shelf fences, wire or perspex

•

Product dividers

•

Olive bar canopy kit

•

Canopy light shield*.

The canopy light shield is a standard perspex part that is sent as a loose item

to prevent transport damage. This must be fitted to protect light tubes and

help with cabinet operation.

The following are general examples of things to avoid:

•

The use of large merchandising signage inside the cabinet as these may

disturb air flow

•

Product stands that elevate product above the stated load limits

•

Manufacturer supplied ice trays turned upside down to elevate product.

•

Display decorations, product and price tickets over the air return

vents

Page 18

TEMPERATURE CHECKING

The air delivery temperature in this case should be checked at least once a

day.

The temperature should be below 1°C.

Checking should be done systematicallyand the temperature

recorded

Page 19

MAINTENANCE

CLEANING

To maximize efficiency and durability, It is suggested that your cleaning and

maintenance program include a deep clean weekly and a maintenance clean daily

•

Deep cleaning should include:

oRemoval of all food products.

oRemoval of all removable panels.

oRemove all food scraps.

oSanitizing wash.

oRinsing with clean water.

•

Maintenance clean should include:

oRemoval of all food products.

oWipe down of all exposed panels.

Do not pour water or cleaning solutions into the cabinet

oInspect for spills that may require deeper cleaning.

NOTE: if a liquid spill should occur, the spill should be cleaned as soon as

practicable. Liquids in pickled product can be particularly acetic, and if left will

risk damage to some components in the cabinet. Fresh water can be used to

dilute the liquid spill until the first opportunity for a deep clean to be carried

out.

Cleaning instructions can be found on the rear of case.

IMPORTANT! Always isolate the cabinet from the mains power supply before

deep cleaning.

For cleaning use: Warm water

Water based solutions

Soft cloths

Do not use: Abrasive products

Solvent based products

•

The front glass can be removed for cleaning (VSS726E, VVS727E).

•

Keep water away from electrical components.

•

Do not flood the tub area (below the deck display area) as electrical components

and penetration seals may be compromised causing damage and water leaks

•

Check drain traps are clear of obstructions.

oVLL727BLdrains are at the rear of the tub area.

oVSS726E,VLL726E,VLL726BLdrains are under the cover behind the

evaporator.

oVVS727Edrains are under the Evaporator fan panel. The rear deck rack

support panel will have to be removed first to allow the fan panel to be

lifted. It is important to replace the fan panel so it seals to the tub.

Page 20

Stainless steel is used inside the cabinet to give a strong corrosion resistant finish that

maximizes the cabinets service life.

It is not rustproof, particularly in the harsh environment of Food Display cabinets.

Chlorine and bromine, commonly used for sanitisation are highly caustic chemicals for

stainless steel and heat and humidity enhance the corrosiveness of these chemicals.

Regular cleaning is the best way to prevent corrosion and add to the service life for

your stainless steel product. The goal of your cleaning and maintenance program

should be to keep the stainless steel's protective chromium oxide layer intact. This is

what prevents corrosion

REGULAR INSPECTION

To ensure reliability of the cabinet and leak tightness of the refrigerant circuit, it is

advisable that trained personnel carry out periodic maintenance.

It is recommended that a check be made 3 months after commissioningof the

cabinet and then every 6 months.

The maintenance check should include:

Leak testing of the cabinet refrigerant circuit,

Ensuring no damage has occurred to any electrical components,

Cleaning the evaporator coil,

Particular attention should be given to the operation of any

safety devices.

Checking lift glass to ensure it has not moved in the glass clamp and

that it operates correctly (VLL726E, VLL726BL, VLL727BL).

Ensure front and end ice stops are in good order and being used

(VLL727BL)

Damage to cabinet components that need to be replaced to ensure

proper cabinet operation.

These checks will ensure the best possible performance of the cabinet over its

service life.

DISPOSAL OF THE CABINET

It is encouraged that the cabinet be refurbished if practical.

If disposal is necessary, please be aware that the foam-insulatedpanels incorporate

cyclo-pentane as the blowing agent and will require the cabinet to be disposed of in

accordance with local authority guidelines.

REPLACEMENT PARTS

All parts that may fail during the life of the cabinet are available from McAlpine

Hussmann.

When ordering replacement parts please quote the serial number of the

cabinet to ensure correct replacement.

This manual suits for next models

4

Table of contents