McConnel ROBOPOWER 111300001 User manual

Publication 811

August 2015

Part No. 23671.11

Revision: 26.01.17

McCONNEL

ROBOPOWER

140HP UNMANNED TRACTOR

Operator Manual

Machines from Serial No. 111300001 ►

IMPORTANT

VERIFICATION OF WARRANTY REGISTRATION

DEALER WARRANTY INFORMATION & REGISTRATION VERIFICATION

It is imperative that the selling dealer registers this machine with McConnel Limited before

delivery to the end user – failure to do so may affect the validity of the machine warranty.

To register machines go to the McConnel Limited web site at www.mcconnel.com, log

onto ‘Dealer Inside’ and select the ‘Machine Registration button’ which can be found in

the Service Section of the site. Confirm to the customer that the machine has been

registered in the section below.

Should you experience any problems registering a machine in this manner please contact

the McConnel Service Department on 01584 875848.

Registration Verification

Dealer Name:

……………………..…………………………………………………………….

Dealer Address:

…….………………………………………………………………………….

Customer Name:

……………………..…………………………………………………………

Date of Warranty Registration:

……/……/...…… Dealer Signature: ………………..……

NOTE TO CUSTOMER / OWNER

Please ensure that the above section above has been completed and signed by the selling

dealer to verify that your machine has been registered with McConnel Limited.

IMPORTANT: During the initial ‘bedding in’ period of a new machine it is the customer’s responsibility

to regularly inspect all nuts, bolts and hose connections for tightness and re-tighten if required. New

hydraulic connections occasionally weep small amounts of oil as the seals and joints settle in – where

this occurs it can be cured by re-tightening the connection – refer to torque settings chart below.The

tasks stated above should be performed on an hourly basis during the first day of work and at least

daily thereafter as part of the machines generalmaintenance procedure.

CAUTION: DO NOT OVER TORQUE HYDRAULIC FITTINGS AND HOSES

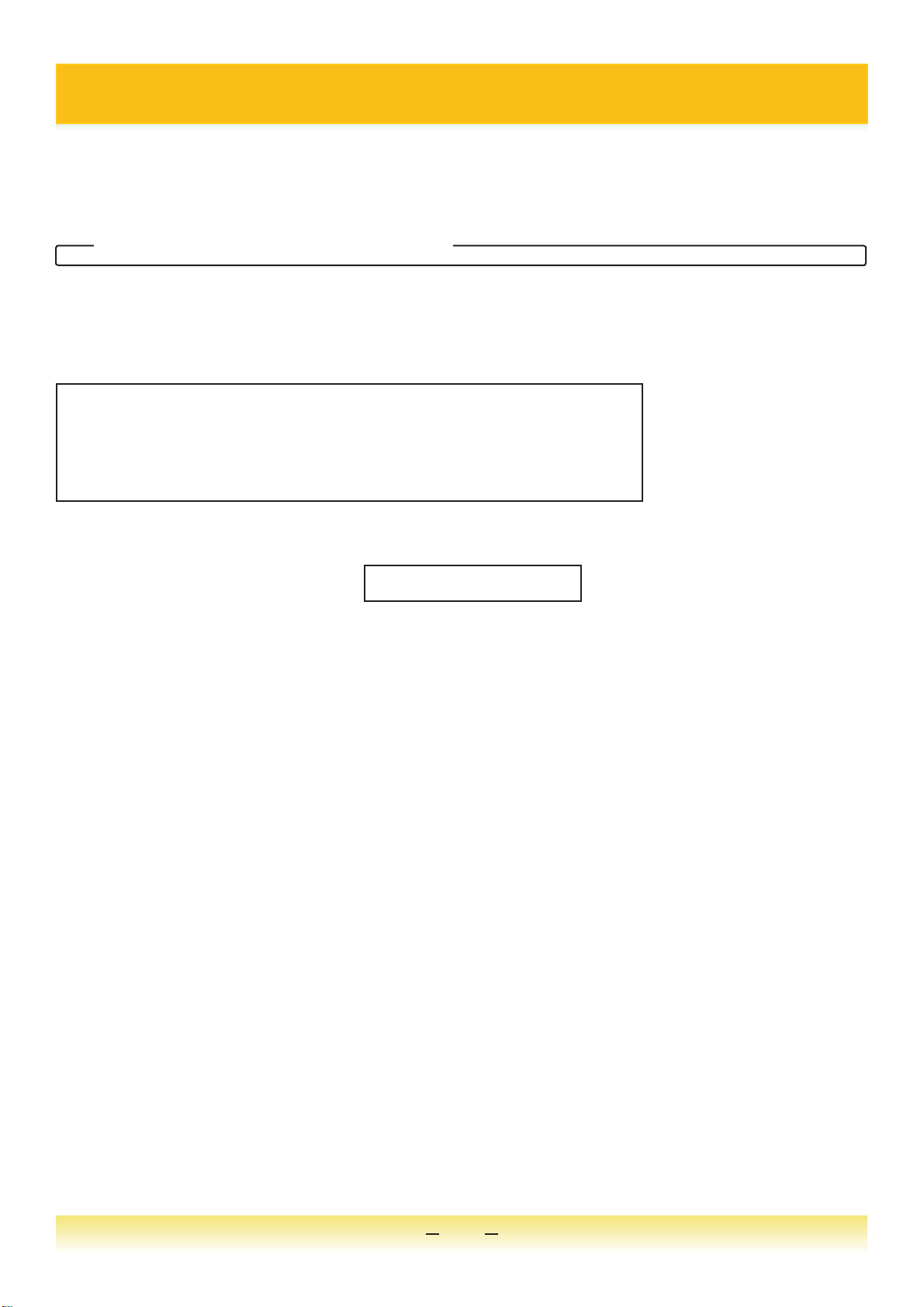

TORQUE SETTINGS FOR HYDRAULIC FITTINGS

HYDRAULIC HOSE ENDS PORT ADAPTORS WITH BONDED SEALS

BSP

Setting

Metric

BSP

Setting

Metric

1/4” 18 Nm 19 mm 1/4” 34 Nm

19 mm

3/8” 31 Nm 22 mm 3/8” 47 Nm

22 mm

1/2” 49 Nm 27 mm 1/2” 102 Nm

27 mm

5/8” 60 Nm 30 mm 5/8” 122 Nm

30 mm

3/4” 80 Nm 32 mm 3/4” 149 Nm

32 mm

1” 125 Nm 41 mm 1” 203 Nm

41 mm

1.1/4”

190 Nm

50 mm

1.1/4”

305 Nm

50 mm

1.1/2” 250 Nm 55 mm 1.1/2” 305 Nm

55 mm

2” 420 Nm 70 mm 2” 400 Nm

70 mm

Warranty Policy (page 1 of 3)

WARRANTY POLICY

WARRANTY REGISTRATION

All machines must be registered, by the selling dealer with McConnel Ltd, before delivery to the end user.

On receipt of the goods it is the buyer’s responsibility to check that the Verification of Warranty

Registration in the Operator’s Manual has been completed by the selling dealer.

1. LIMITED WARRANTIES

1.01. All mounted machines supplied by McConnel Ltd are warranted to be free from defects in material

and workmanship from the date of sale to the original purchaser for a period of 12 months, unless a

different period is specified.

All Self Propelled Machines supplied by McConnel Ltd are warranted to be free from defects in

material and workmanship from the date of sale to the original purchaser for a period of 12 months

or 1500 hours. Engine warranty will be specific to the Manufacturer of that unit.

1.02. All spare parts supplied by McConnel Ltd and purchased by the end user are warranted to be free from

defects in material and workmanship from the date of sale to the original purchaser for a period of 6

months. All parts warranty claims must be supported by a copy of the failed part invoice to the end

user. We cannot consider claims for which sales invoices are not available.

1.03. The warranty offered by McConnel Ltd is limited to the making good by repair or replacement for the

purchaser any part or parts found, upon examination at its factory, to be defective under normal use

and service due to defects in material or workmanship. Returned parts must be complete and

unexamined. Pack the component(s) carefully so that any transit damage is avoided. All ports on

hydraulic items should be drained of oil and securely plugged to prevent seepage and foreign body

ingress. Certain other components, electrical items for example, may require particular care when

packing to avoid damage in transit.

1.04. This warranty does not extend to any product from which McConnel Ltd’s serial number plate has

been removed or altered.

1.05. The warranty policy is valid for machines registered in line with the terms and conditions detailed and

on the basis that the machines do not extend a period of 24 months or greater since their original

purchase date, that is the original invoice date from McConnel Limited.

Machines that are held in stock for more than 24 months cannot be registered for warranty.

1.06. This warranty does not apply to any part of the goods, which has been subjected to improper or

abnormal use, negligence, alteration, modification, fitment of non-genuine parts, accident damage,

or damage resulting from contact with overhead power lines, damage caused by foreign objects (e.g.

stones, iron, material other than vegetation), failure due to lack of maintenance, use of incorrect oil or

lubricants, contamination of the oil, or which has served its normal life. This warranty does not apply

to any expendable items such as blades, belts, clutch linings, filter elements, flails, flap kits, skids, soil

engaging parts, shields, guards, wear pads, pneumatic tyres or tracks.

1.07. Temporary repairs and consequential loss - i.e. oil, downtime and associated parts are specifically

excluded from the warranty.

1.08. Warranty on hoses is limited to 12 months and does not include hoses which have suffered external

damage. Only complete hoses may be returned under warranty, any which have been cut or repaired

will be rejected.

1.09. Machines must be repaired immediately a problem arises. Continued use of the machine after a

problem has occurred can result in further component failures, for which McConnel Ltd cannot be held

liable, and may have safety implications.

1.10. If in exceptional circumstances a non McConnel Ltd part is used to effect a repair, warranty

reimbursement will be at no more than McConnel Ltd’s standard dealer cost for the genuine part.

Warranty Policy (page 2 of 3)

1.11. Except as provided herein, no employee, agent, dealer or other person is authorised to give any

warranties of any nature on behalf of McConnel Ltd.

1.12. For machine warranty periods in excess of 12 months the following additional exclusions shall apply:

1.12.1. Hoses, exposed pipes and hydraulic tank breathers.

1.12.2. Filters.

1.12.3. Rubber mountings.

1.12.4. External electric wiring.

1.12.5. Bearings and seals

1.12.6. External Cables, Linkages

1.12.7. Loose/Corroded Connections, Light Units, LED’s

1.12.8. Comfort items such as Operator Seat, Ventilation, Audio Equipment

1.13. All service work, particularly filter changes, must be carried out in accordance with the manufacturer’s

service schedule. Failure to comply will invalidate the warranty. In the event of a claim, proof of the

service work being carried out may be required.

1.14. Repeat or additional repairs resulting from incorrect diagnosis or poor quality previous repair work

are excluded from warranty.

NB Warranty cover will be invalid if any non-genuine parts have been fitted or used. Use of non-genuine

parts may seriously affect the machine’s performance and safety. McConnel Ltd cannot be held

responsible for any failures or safety implications that arise due to the use of non-genuine parts.

2. REMEDIES AND PROCEDURES

2.01. The warranty is not effective unless the Selling Dealer registers the machine, via the McConnel web

site and confirms the registration to the purchaser by completing the confirmation form in the

operator’s manual.

2.02. Any fault must be reported to an authorised McConnel Ltd dealer as soon as it occurs. Continued use

of a machine, after a fault has occurred, can result in further component failure for which McConnel

Ltd cannot be held liable.

2.03. Repairs should be undertaken within two days of the failure. Claims submitted for repairs undertaken

more than 2 weeks after a failure has occurred, or 2 days after the parts were supplied will be

rejected, unless the delay has been authorised by McConnel Ltd. Please note that failure by the

customer to release the machine for repair will not be accepted as a reason for delay in repair or

submitting warranty claims.

2.04. All claims must be submitted, by an authorised McConnel Ltd Service Dealer, within 30 days of the

date of repair.

2.05. Following examination of the claim and parts, McConnel Ltd will pay, at their discretion, for any valid

claim the invoiced cost of any parts supplied by McConnel Ltd and appropriate labour and mileage

allowances if applicable.

2.06. The submission of a claim is not a guarantee of payment.

2.07. Any decision reached by McConnel Ltd. is final.

3. LIMITATION OF LIABILITY

3.01. McConnel Ltd disclaims any express (except as set forth herein) and implied warranties with respect to

the goods including, but not limited to, merchantability and fitness for a particular purpose.

3.02. McConnel Ltd makes no warranty as to the design, capability, capacity or suitability for use of the

goods.

3.03. Except as provided herein, McConnel Ltd shall have no liability or responsibility to the purchaser or

any other person or entity with respect to any liability, loss, or damage caused or alleged to be caused

directly or indirectly by the goods including, but not limited to, any indirect, special, consequential, or

incidental damages resulting from the use or operation of the goods or any breach of this warranty.

Notwithstanding the above limitations and warranties, the manufacturer’s liability hereunder for

damages incurred by the purchaser or others shall not exceed the price of the goods.

3.04. No action arising out of any claimed breach of this warranty or transactions under this warranty may

be brought more than one (1) year after the cause of the action has occurred.

Warranty Policy (page 3 of 3)

4. MISCELLANEOUS

4.01. McConnel Ltd may waive compliance with any of the terms of this limited warranty, but no waiver of

any terms shall be deemed to be a waiver of any other term.

4.02. If any provision of this limited warranty shall violate any applicable law and is held to be

unenforceable, then the invalidity of such provision shall not invalidate any other provisions herein.

4.03. Applicable law may provide rights and benefits to the purchaser in addition to those provided herein.

McConnel Limited

3

INDEX

CHAPTER 1 - GENERLA DESCRIPTION

1.1 Background information 9

1.2 Training requested to the operator 10

1.3 Warning for use 10

1.4 Premise 11

1.4.1 Manual update

1.4.2 Copyright

1.5 Guarantee 12

1.6 Responsability 12

1.7 Permitted use 13

1.8 Misuse or not permitted 13

1.9 Running and testing of the machine 13

CHAPTER 2 - DESCRIPTION OF THE MACHINE

2.1 Description of the machine 14

2.2 Norms 14

CHAPTER 3 - SAFETY SECTION

3.1 General safety instructions 17

3.1.1 Know the machine 18

3.1.2 Wear protective clothing 18

3.1.3 Warning for the maintenace 18

3.1.4 Operating safely 19

3.2 General Precautions 20

3.2.1 Safety warnings 21

3.2.2 Safety instructions 21

3.2.3 Safety instructions - standard use 21

3.2.5 Work safety instruction 22

3.2.6 Hyd. system safety instructions 23

3.2.7 Decal location 24

3.2.8 Decal description 24

3.3 General safety rules

3.3.1 Care and maintenance 26

3.3.2 Safety during the refueling and topping up 27

- McCONNEL ROBOPOWER

-

4

3.4 Practice safe maintenance 28

3.4.1 Warning signs 28

3.4.2 Equipment 28

3.4.3 Personnel 28

3.4.4 Working under the machine 29

3.4.5 Keep clean the machine 29

3.4.6 Periodical replacing of main parts for safety 29

CHAPTER 4 - TECHNICAL DATA

4.1 Technical characteristics 30

4.2 Dimension 32

4.2.1 Machine 32

4.3 Parts of machine 33

CHAPTER 5 - TERMINOLOGY

5.1 Terms 35

CHAPTER 6 - OPERATING CONTROL

6.1 Check up 36

6.2 Checks before every working day 36

6.2.1 Check-up oil leaks 36

6.2.2 Oil level check up 37

6.3 ASSEMBLY 38

6.3.1 Dash panel 39

6.4 Operating 40

6.4.1 Starting the engine 40

6.4.2 Forwards & backwards travel 41

6.4.3 Forwards & backwards travel (swap mode) 41

6.4.4 Bias poty 42

6.4.5 Steering direction control 42

6.4.6 Steering bias 42

6.4.7 Flail head hieght control 43

6.4.8 Flail head rotor control 43

6.4.9 Rotor stop 44

6.4.10 Engine speed control 44

6.4.11 Mower front hood 44

- McCONNEL ROBOPOWER

-

5

6.4.13 Optional 46

6.4.14 Optional 46

6.4.15 Engine Shutdown 46

6.4.16 S-KEY 47

6.5 Display LCD

6.5.1 Description 48

6.5.2 Service menu 49

6.5.3 Service Code 49

6.5.4 Warning 50

6.5.5 Allarm 51

6.6 TROUBLESHOOTING

6.6.1 Diesel engine 52

6.6.2 Electrical loom 53

6.6.3 Hydraulic system 53

6.7 Fuses and relays 54

6.7.1 Fuses and relays box 55

6.8 How to plug an equipment 56

6.9.Driving and maneuvering the machine 57

CHAPTER 7 - TRANSPORT AND MOVEMENT

7.1 Lorry loading and unloading 59

7.2 Towing of the machine 60

7.3 Wiring remote controL 61

7.4 Using booster battery 62

CHAPTER 8 - STORAGE 63

8.1 Disposal and putting out of service 64

CHAPTER 9 - SERVICE

9.1 Premise 65

9.2 General norms 65

9.3 No-ordinary maintenance 66

9.4 Recommended oils and grease 66

9.4.1 Fuel 67

9.5 Engine maintenance

9.5.1 Engine oil 67

9.5.2 Coolant 67

9.5.3 Fuel 68

- McCONNEL ROBOPOWER

-

6

9.6 Maintenance of hyd. plant 68

9.7 Maintenance of electric plant 69

9.8 Periodic replacement of safety devices 70

9.9 Maintenance as required

9.9.1 Check,cleaning or replacing air cartridge 70

9.9.3 Replacing tracks 72

9.10 Checks before every working day 73

9.10.1 Coolant level 73

9.10.2 Fuel level 74

9.10.3 Engine oil 75

9.10.4 Hyd. oil level 75

9.10.5 Drenage water/fuel separator 76

9.11 Service every 50 hours

9.11.1 Check pressure tensioner tracks

77

9.11.2 Electrical plant 77

9.12 Service after initial 50 hours

9.13 Service every 250 hours

9.14 Service every 500 hours

9.15 Service every 1000 hours

9.15.1 Coolant replacemenent 82

- McCONNEL ROBOPOWER

-

7

CHAPTER 10 - INSTRUCTIONS FOR EMERGENCY SITUATION

10.1 Fire 83

CHAPTER 11 - NOTES

- McCONNEL ROBOPOWER

-

8

This is the operator’s manual of the construction in the meaning of the the Machinery Directive

Do not destroy, do not modify, integrate only with additional papers.

Manual Code: EENUM11000

Review n°: 00 Edition: 11/2013

Type of machine: Mower selfpropelled

Model: RoboPOWER

This manual is valid from S/N: ROBOP111300001

1.1– BACKGROUND INFORMATION

1 – GENERAL DESCRIPTION

- McCONNEL ROBOPOWER

-

9

1.2 - TRAINING REQUESTED TO THE OPERATOR

Attentive reading of this manual:

- Every operator and personnel responsible for the maintenance of the machine must read enti-

rely with the maximum attention this manual and respect the contents herein.

- the employer has the obligation of ascertaining that the operator possesses the requisite aptitu-

de tests for the driving of the machine and has taken attentive vision of the manual.

WARNING:

In reference to integrations or suggestions for the correct use of the machine.

ATTENTION :

In reference to situations of danger that, if not avoided

0$<UHVXOWLQ0,125,1-85<

DANGER:

In reference to situations of danger that, if not avoided

:,//UHVXOWLQ'($7+RUVERY SERIOUS INJURY

The norms of functioning contained in this manual are valid exclusively for the machine

0F&211(/ RoboPOWER.

The operator’s manual must be read and utilized in the following mode:

- Read attentively the instruction manual and consider it an integral part of the machine;

- The instruction manual must be easily within reach of the personnel responsible for the driving

and for the maintenance;

- Look after the manual for all the duration of the machine;

- Ensure that any update is incorporated in the text;

- Supply the manual to any other user or successive owner of the machine;

- Use the manual in mode such so as not to damage all or in part the contents;

- Do not remove, tear up or rewrite for any motive parts of the manual;

- Conserve the manual in zone protected from damp and heat;

- In case the manual is lost or partially ruined and therefore it is not possible to read the contents

completely, request a new manual from the manufacturer.

Pay the maximum attention to the following symbols and to their meaning. Their function is

highlight to information particular such as:

1.3 - WARNINGS FOR USE

- McCONNEL ROBOPOWER

-

10

The machine shown in this manual may differ slightly from your machine, but will be similar enou-

gh to help you understand our instructions.

The norms of service described in this manual, constitute part integral of the delivery of the machi-

ne. These norms, furthermore, are meant for the operator already expressly taught for drive this

type of machine and contain all the information necessary and indispensable for the safety of fun-

ctioning and the optimal use, not incorrect, of the machine. Hurried and incomplete preparations

cause improvisation and this causes many accidents; before initiating work, read attentively and

respect scrupulously the following suggestions:

-

tion of functioning;

2) The operator must always have the instruction manual available at any moment;

3) Schedule every service with care;

4) Know in detail where and how is foreseen the use of the machine: use on the ground, time ta-

ken, limitation of the movements caused by the presence of buildings, electric lines and similar;

5) Before work ensure that the measures of safety function correctly and have no doubts on their

functioning; in case of the contrary do not utilize in any case the machine;

6) Observe accurately the warnings relating to special dangers contained in this manual;

7) Constant preventive and accurate maintenance always guarantees elevated safety of functio-

ning of the machine. Never delay necessary repairs and carry them out only and exclusively with

specialized personnel, and use only original spare.

1.4 - PREMISE

1.4.1 - MANUAL UPDATE

the time of sale of the machine.

The Manufacturer reserves the right to make, at any time, any changes to the machines for tech-

nical or commercial reasons. In the event that such changes do not require (for security reasons)

the manufacturer to act on the machines sold so far, will not be sent updates of the same manual

or the information contained herein is considered inadequate. Any additions that the manufacturer

deems appropriate to provide below will need to be kept with the manual and considered an inte-

gral part of it.

The copyright of this manual belongs to the Manufacturer. This manual contains text, illustrations

and drawings of a technical nature that can not be disclosed or transmitted to third parties, in who-

le or in part, without the written permission of the manufacturer of the machine.

1.4.2 - COPYRIGHT

- McCONNEL ROBOPOWER

-

11

P QXI FWXUHU

from the putting into service, proven by the documentation delivered to the customer.

7KHP QXI FWXUHUV UWV V

defective by it during the period of guarantee.

P QXI FWXUHU

from any other costs sustained by the concessionary and by the customer of the

concessionary such as damage presumed, present or future, such as lost earnings, penalty, etc...

The ordinary and extraordinary maintenance must occur following the instructions contained

in this manual. For all cases not included and for every type of assistance contact 0F&RQQHO/WG

by email or fax, even in the case of agreement taken telephonically.

0F&RQQHO/LPLWHGassumes no responsibility for eventual delays or lack of interventions.

0F&RQQHO/LPLWHG does not retain itself responsible for eventual damage or malfunctioning due

to technical interventions carried out on the machine by non-authorized personnel.

1.5 - GUARANTEE

0F&RQQHO/LPLWHG

accident to persons or things that can occur caused by:

- Lacking observance of the instructions contained in this manual regarding the driving, the use

and the maintenance of the machine;

- Violent actions or erroneous manoeuvres in the use and in the maintenance of the machine;

IURP0F&RQQHO/LPLWHG

- Occurrences however foreign to the normal and correct use of the machine.

In any case, whenever the user blames the accident to a defect of the machine, they must

demonstrate that the damage occurred was a principal and direct consequence of such “defect”.

1.6 - RESPONSABILITY

ATTENTION :

For the repairs of maintenance or repairs carried out always use exclusive

pieces of spare original parts.

0F&RQQHO/LPLWHG

the above.

The machine is guaranteed according to the contract stipulated in the sale.

The guarantee nevertheless expires whenever the norms and instructions of use.

- McCONNEL ROBOPOWER

-

12

The RoboPOWER is a machine constructed to be used by professional personnel, principally

LQVEXVKHV QGKHGJHV

ZLWK maximum diameter RI3 cm. The appropriate utilization foresees not workingZLWKWKHFXWWLQJ

cuttinghead lifted from the ground. Every other utilization is not appropriate and the maQXI FWXUHU

declines any responsibility for eventual damage to persons, things or the machine that F QGHULYH

from it. The machine is suitable for machining QG chopping up to a speed of 4-5 km/h GHSHQGLQJ

RQWKH soil conditions in which it works and the Q WXUHof material (LHlength, wheWKHULWLV wetRU

dry, density, etc..) and on slope WRmaximum 45°. This machine is usually used during the day

if UHTXLUHGIRUXVHat night or in conditions of reduced visibility, WKHP FKLQHshould be used with

QJLYHVRI WOH VW

100mHWUHV

1.7 - PERMITTED USED

&ategorically YRLGthe following uses:

• Use of the machine by minors, LQH[SHULHQFHGpersons, and persons not licensed.

• Use of the machine for the lifting of persons or things.

• Use of the mower as pile driver.

• Use of the machine for towingSXUSRVHV.

• Use of the machine for cXWWLQJ of ZRRGP WHUL OV and hedges with diameter LQH[FHVVRI 3cm.

• It should not be used on surfaces contaminated by glass, loose stones, pieces of iron or other

foreign objects that could be HMHFWHG by the blades or F XVHdamagHthe mower

• 2SHU WLQJthe machine QGaccessories QH URURQP WHUL OV physical and chemicalWK WK YH

FK U FWHULVWLFVWK W

• Overloading the machine beyond the limits allowed;

• Increase the length of WKHP FKLQHV arms without the authorization of WKHP QXI FWXUHU;

• It is forbidden to GULYHRUP QRHXYUHWKHP FKLQH on public roads.

1.8 - MISUSE OR NOT PERMITTED

ATTENTION :

In this paragraph are indicated some of the improper or not consented uses;

being impossible to foresee all the possible improper uses, if particular

occasions for the use of the machine present themselves, before carrying out

0F&RQQHO/LPLWHG

WARNING:

The instructions regarding V IHW\XVH QGP LQWHQ QFH UHVXSSOLHGLQWKLVP QX OLWLVYLW O

WK W WKHRZQHUWKHRSHU WRU QGVHUYLFHHQJLQQHUVUH GWKLVP QX OIXOO\EHIRUHRSHU WLQJRU

maLQW LQLQJWKHP FKLQH

,WLVUHFRPPHQGHGWK W OOXVHUVSU FWLFHRSHU WLQJWKHP FKLQHLQ V IHRSHQORF WLRQVRWK W

WKH\aUHIXOO\I PLOL UZLWKFRQWUROVIXQFWLRQV QG OO VSHFWVRIP FKLQHRSHU WLRQEHIRUHWKH\

WWHPSWWRXVHWKHP FKLQHLQ ZRUNLQJHQYLURQPHQW

- McCONNEL ROBOPOWER

-

13

1.9 - RUNNING AND TESTING OF THE MACHINE

DANGER:

UsHRI the machine LQVRPH the LQVW QFHV mentioned above risk tipping or strucWXU O

failure of the P FKLQHWK WF QUHVXOWin a risk of injury or death to the operator.

Every machine is scrupulously checked and tested before delivery. A new machine must however

sedprovided a ''period for components.

If the machine is placed under to an excessive workload during the initial phase of functioning, its

potential performance will be prematurely compromised and its functionality reduced in a short

period of time.

In the running in period pay great attention to the following points:

- After starting, allow the engine to run at low revs for 5-6 minutes.

its maximum and Q\

VXGGHQ cceleration or deceleration.

RIXVHSUHYHQW WLYHP LQWHQ QFHPXVWEHF UULHGRXW

- (ngine RLOreplacement

(RLO

- *earbox RLOreplacement.

ATTENTION :

UHSO FHPHQWWKH

presence of deposits; iIGHSRVLWV UHSUHVHQW verify the possible cause before\RX

WWHPSWWRUHVW UWRUXVHWhe machine.

- McCONNEL ROBOPOWER

-

14

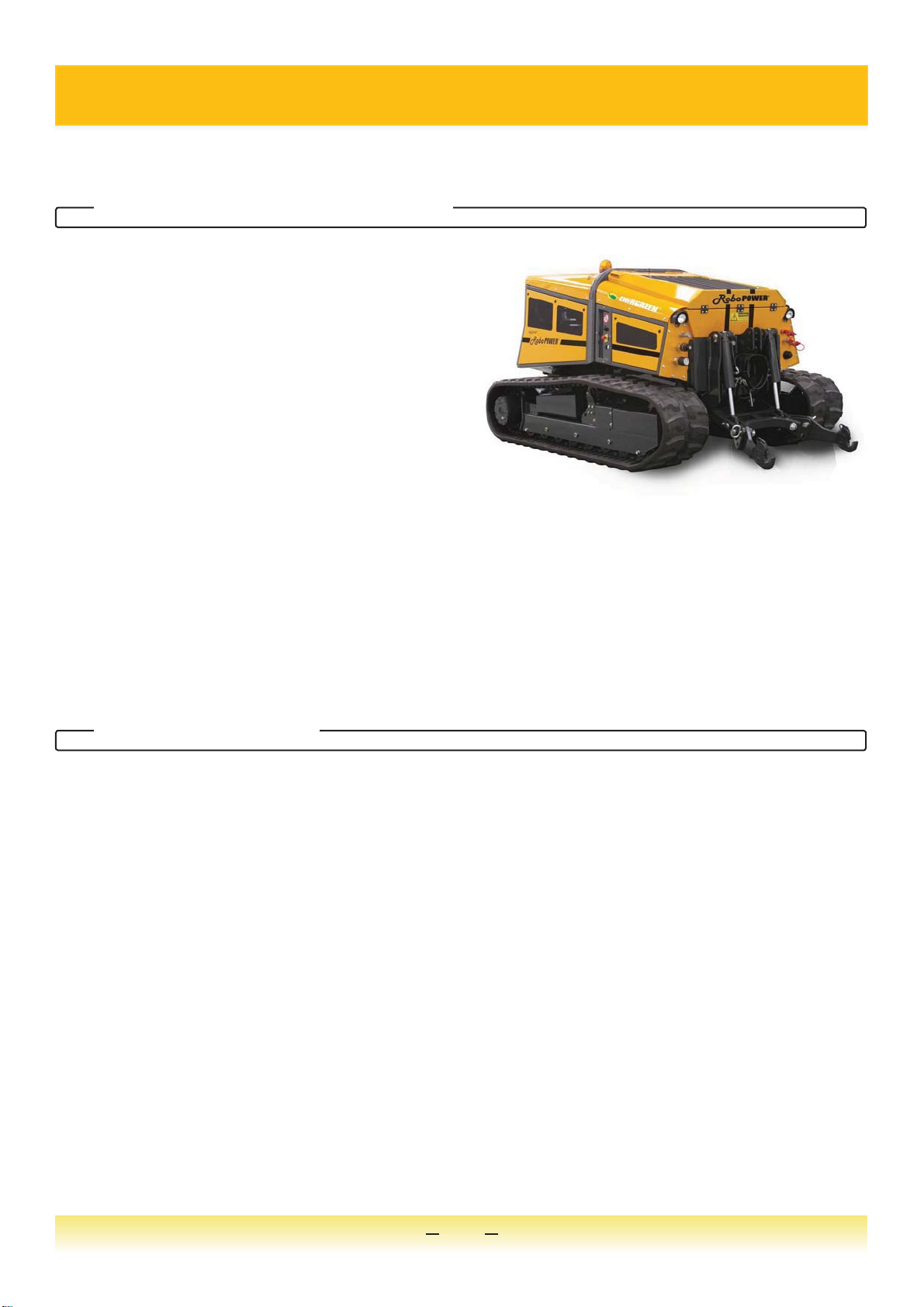

grass, shrubs, maintenance the green roadsiGHV

QG embankments etc. ..

Equipped with quick release hydraulic conQHFWLRQ

allowLQJ the TXLFNreplacement of variousW\SHVRI

HTXLSPHQWWRVXLWoperational needs.

Equipment permitted:

- mower

- snow blower

- PTO driven mulching heads

- hydraulic sweeper

- agricXltural equipment (Cat. II)

0F&RQQHOGeclines any responsibility for damage of any nature caused by incorrect use andRU

XVH RI Q\HTXLSPHQWQRWstated ERYH.

2.1 - DESCRIPTION OF THE MACHINE

2 - DESCRIPTION OF THE MACHINE

The machine has been designed and constructed in the respect of the directive CE in merit for

the safety and to the approximation of the legislations of the states member; in the case

In the design have been furthermore taken in consideration the following norms:

- UNI EN ISO 12100:2010 “safety of the machinery”

- EN 60204 “safety of the machinery” (equipment electric)

- ISO 11684:1995

- UNI EN ISO 3767-2 : 1998

2.2 - NORMS FOLLOWED

- McCONNEL ROBOPOWER

-

DECLARATION OF CONFORMITY

Conforming to EU Machinery Directive 2006/42/EC

We,

McCONNEL LIMITED, Temeside Works, Ludlow, Shropshire SY8 1JL, UK

Hereby declare that:

The Product; Radio Controlled Tracked Mower

Product Code; RMOW

Serial No. & Date ………………………………… Type …………………………

Manufactured in; Italy

Complies with the required provisions of the Machinery Directive 2006/42/EC

The machinery directive is supported by the following harmonized standards;

■BS EN ISO 12100 (2010) Safety of machinery –General principles for design –Risk

assessment and risk reduction.

■BS EN 349 (1993) + A1 (2008) Safety of machinery - Minimum distances to avoid the

entrapment with human body parts.

■BS EN ISO 14120 (2015) Safety of machinery - Guards general requirements for the

design and construction of fixed and movable guards.

■BS EN 4413 (2010) Hydraulic fluid power. Safety requirements for systems and their

components.

McCONNEL LIMITED operates an ISO 9001:2008 quality management system,

certificate number: FM25970.

This system is continually assessed by the;

British Standards Institution (BSI), Beech House, Milton Keynes, MK14 6ES, UK

BSI is accredited by UK Accreditation Service, accreditation number: UKAS 003.

The EC declaration only applies if the machine stated above is used in

accordance with the operating instructions.

Signed …………………................ Responsible Person

CHRISTIAN DAVIES on behalf of McCONNEL LIMITED

Status: General Manager Date: January 2018

16

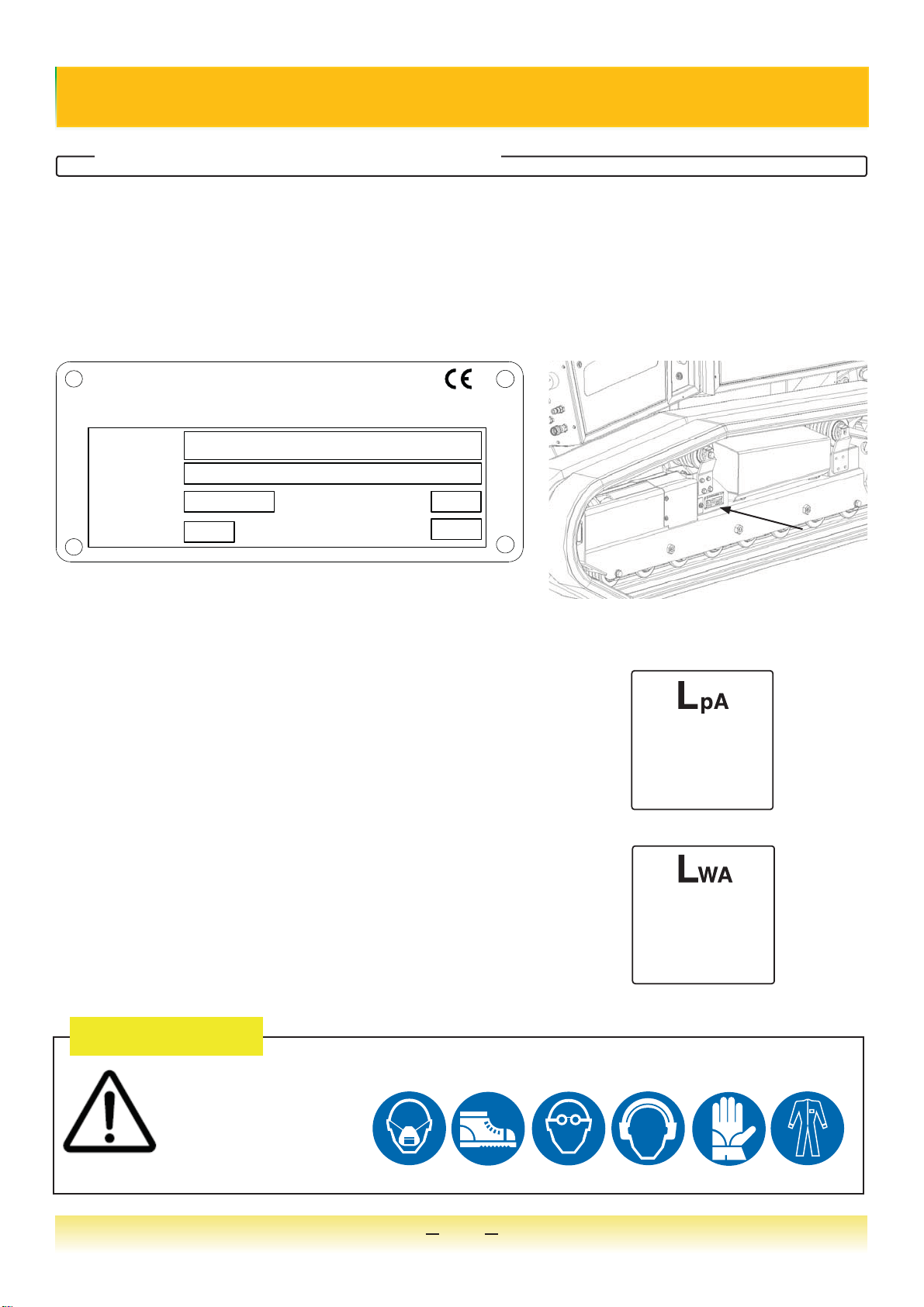

ORF WHGRIWKHP FKLQH

ATTENTION: 1RWH P FKLQHS/NRand XVHhours before contactLQJWKH0F&RQQHO Service 'ept.

MANUFACTURED BY LASERJET SRL

36026 VIA PIETRE 73 CAGNANO DI POJANA MAGGIORE (VI) - ITALY -

DENOMINAZIONE-FUNZIONE

DENOMINATION-FUNCTION

PORTATTREZZI RADIOCOMANDATO

REMOTE CONTROL EQUIPMENT CARRIER MACHINE

NUMERO DI SERIE

SERIAL NUMBER

ROBO

POTENZA MOTORE

ENGINE POWER

28.2

kW

ANNO FABBRICAZIONE

MANUFACTURE YEAR

201

MODELLO/TIPO

MODEL/TYPE

MASSA

WEIGHT

kg

E13010913158

NOISE LEVEL

LpA = the value indicates the maximum sound level percei-

ved by the operator at 1 meter away from the machine.

LwA = the value indicates the sound level outside of the

machine and refers to the perceived noise by those who are

close to the work area.

Standards ISO 3744:2010, ISO 11201:2010

105

99

ATTENTION :

Always wear personal protective equipment when operating the machine.

2.3 - IDENTIFICATION OF THE MACHINE

- McCONNEL ROBOPOWER

-

Table of contents

Other McConnel Tractor manuals

Popular Tractor manuals by other brands

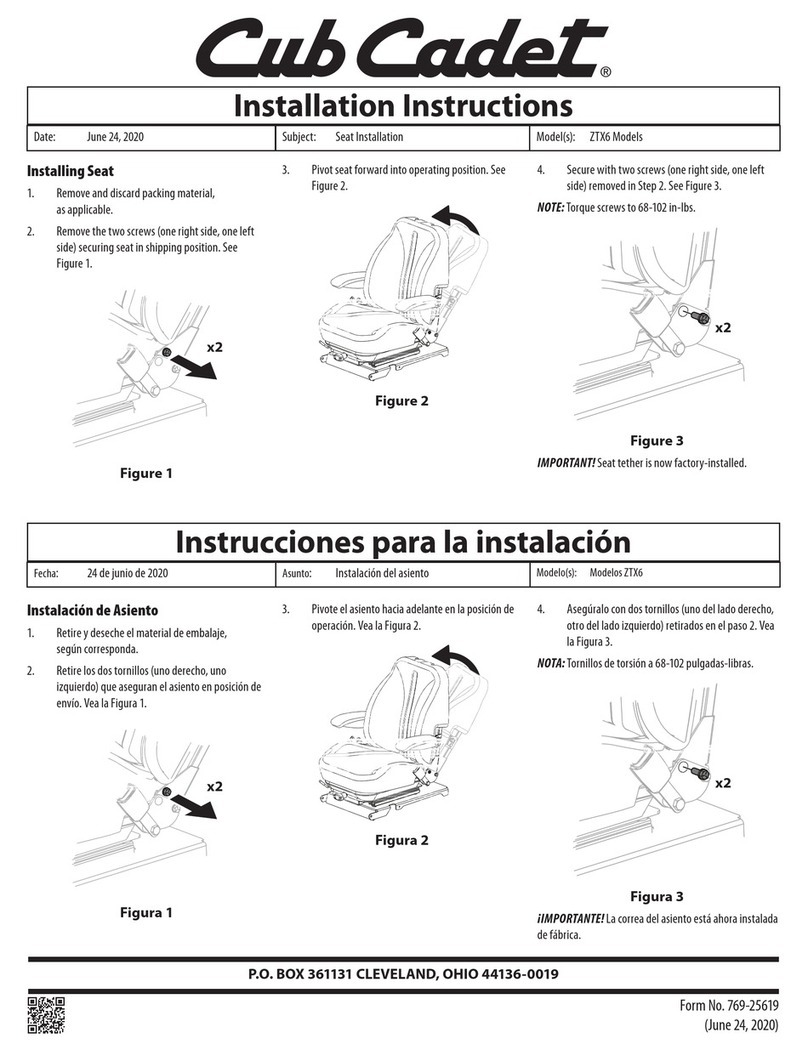

Cub Cadet

Cub Cadet Ultima ZTX6 54 installation instructions

Taylor-Dunn

Taylor-Dunn Tiger TC-030-60 Operation, Maintenance, and Replacement Parts Manual

MacDon

MacDon M Series Unloading and assembly instructions

Valtra

Valtra A75n Operator's manual

New Holland

New Holland Boomer 3040 Service manual

New Holland

New Holland 8010 Operator's manual