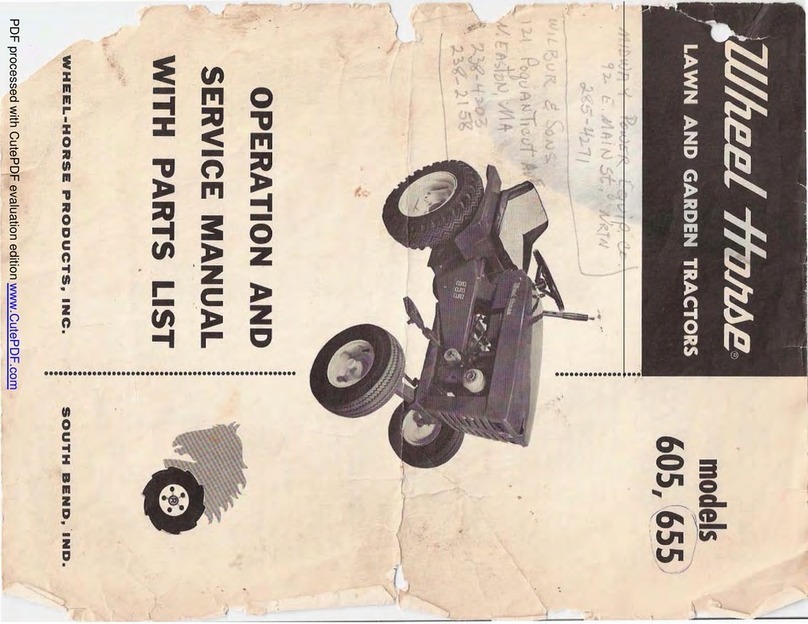

Wheel Horse 1067 User manual

Other Wheel Horse Tractor manuals

Wheel Horse

Wheel Horse 605 Troubleshooting guide

Wheel Horse

Wheel Horse B-81 Reference manual

Wheel Horse

Wheel Horse B Series User manual

Wheel Horse

Wheel Horse 1-7441 User manual

Wheel Horse

Wheel Horse 867 User manual

Wheel Horse

Wheel Horse B-81 User manual

Wheel Horse

Wheel Horse 200 Series User manual

Wheel Horse

Wheel Horse 854 Troubleshooting guide

Wheel Horse

Wheel Horse B-81 User manual

Wheel Horse

Wheel Horse D-250 Operating instructions