2

6. The Tundish (E), which shows visible

discharge from the Relief Valves, is to

be in a prominent, visible and safe

position away from any electrical

devices (likewise with the drain

connection) and within 500mm of the

Temperature & Pressure Relief Valve

(D). Pipework from the Tundish (E)

must initially be vertical for a minimum

of 300mm where possible and then

have a continuous fall in excess of 1

in 200. Pipework away from the

Tundish (E) should be in a minimum of

22mm, of material suitable for

temperatures of 95°C and have a

resistance to flow of water not greater

than that of a straight pipe of 9 metres

(each bend or elbow is equal to 0.8

metre of resistance). See BBA

Information. Sheet No 33:1989 for

further details - available from the

manufacturer. Also note page 9 of

these instructions.

7. The Expansion Vessel (F) charged at

2.1 Bar, should either be fitted directly

to connection (M) on the cylinder, or if

space dictates, securely to the wall

with the optional remote fixing kit and

the hose fitted between the vessel and

connection (M).

8. Connect the 3kW 11” 240V Immersion

Heater/s BSEN 60335/2/73 (with

manual re-set cut out at 80°C) to the

power supply and earth them in

accordance with the current IEE wiring

regulations. The fuse rating should be

13 Amps. Do not at any time fit

Immersion Heaters without a thermal

cut-out.

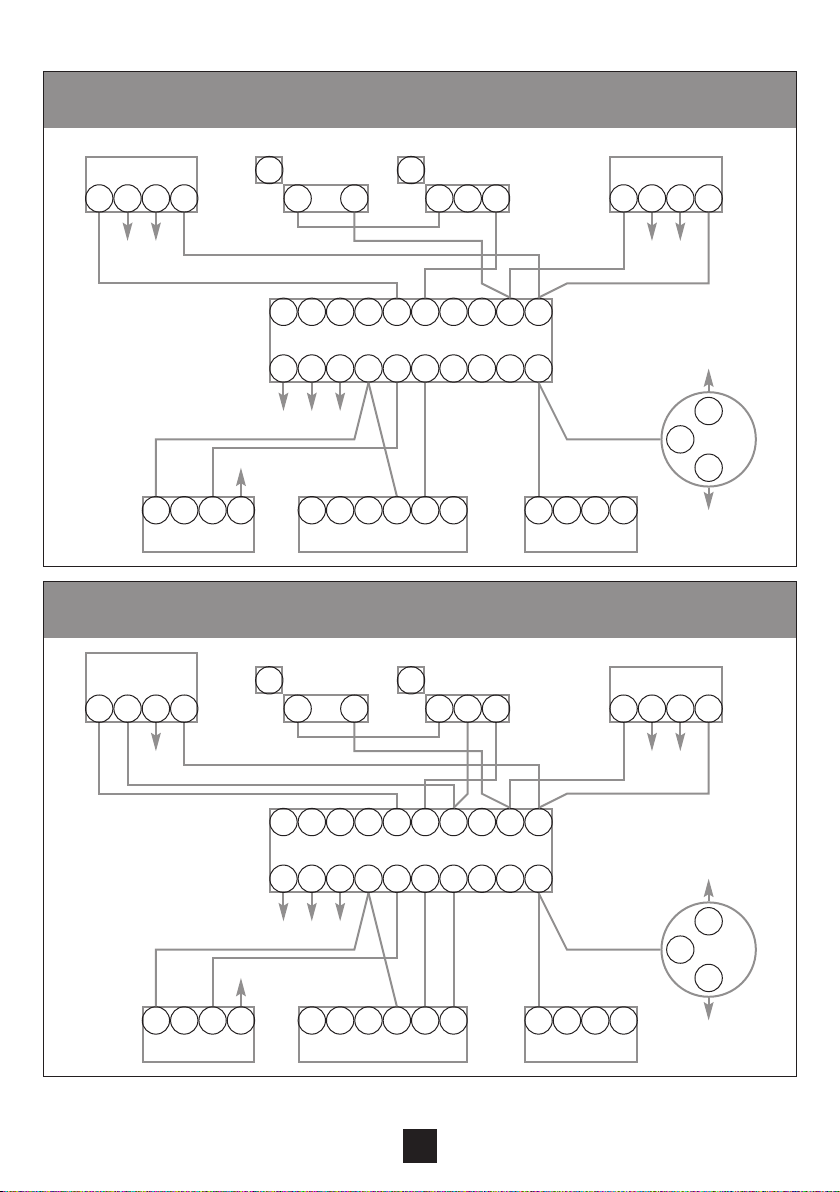

9. On Indirect Units where a Coil is fitted

to the cylinder, the supplied Two Port

Motorised Zone Valve and Dual

Thermostat Controller (J) must be

fitted in accordance with the

instruction details supplied with them

for the appropriate installation.

N.B. Indirects, are suitable for oil,

gas and electric fired boilers on a

pumped, gravity or sealed system.

(We would however recommend

28mm Coil connections with a 28mm

Zone Valve on gravity systems).

Maximum working pressure of the

coil is 3.5 Bar. All electrical wiring to

thermostats, zone valve and

immersion heaters must be earthed

and to current IEE Wiring Regulations.

The fuse should generally be 3 Amps

but refer to appliance instructions to

confirm this.

10. The SecondaryReturn (L) if supplied,

should be plugged if not required. If

the Secondary System pipe-work is

greater than 15% of the unit capacity,

alarger Expansion Vessel may need

to be fitted - contact McDonald

Engineers.

11. Immersion Heaters (H) and the Dual

Aquastat Controller (J) supplied with

the Indirect units should be set to no

greater than 60°C and the internal

High Limit Thermostats are factory set

no higher than 85°C. Always check

this before switching on power.

Please see the checklist on page 4

to ensure all controls are present

and correct.