8

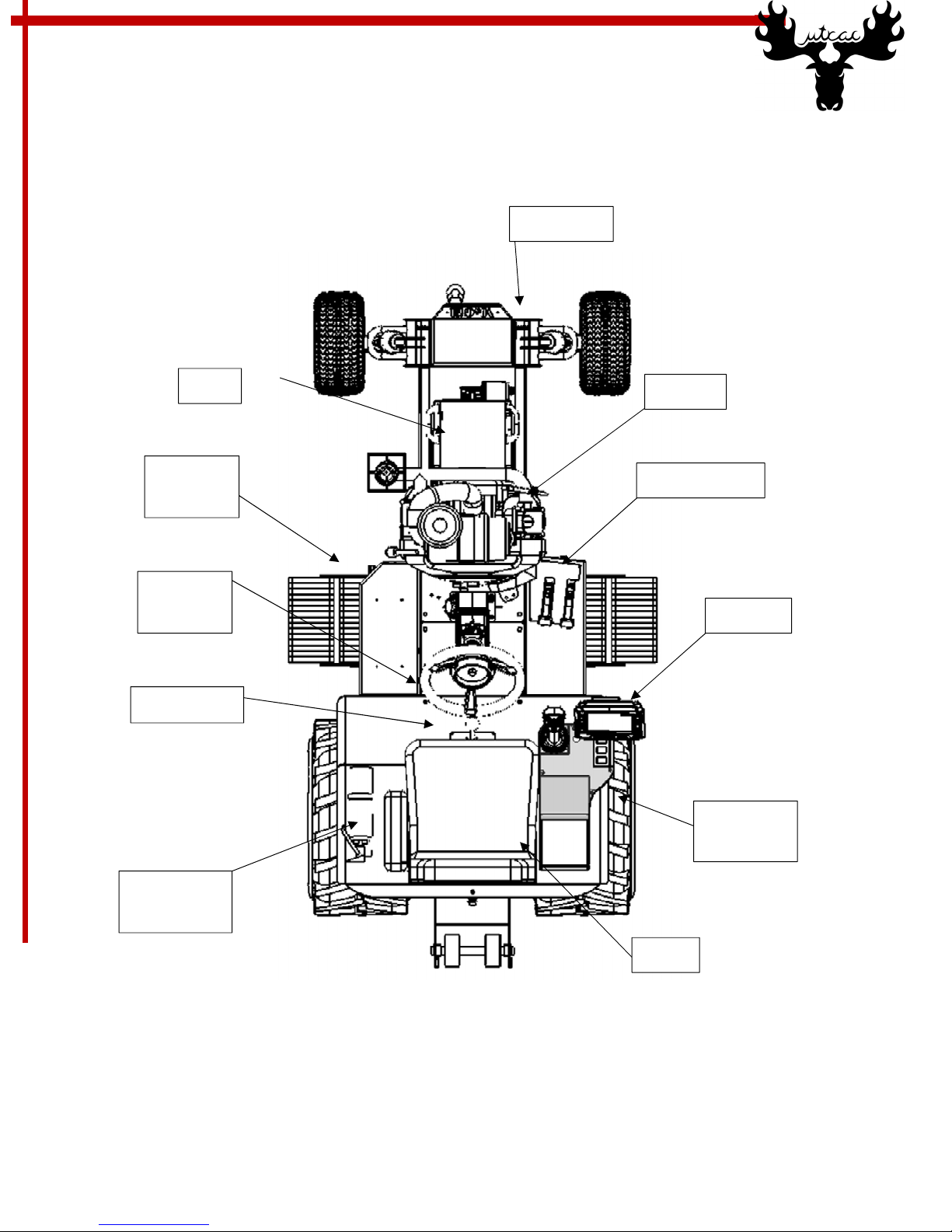

Protecting your MR18

Pre-Operation Safe Use Checklist

●Clothing: Full coverage

o Long sleeves and pants or full-body suit

o Full-closed shoes

●Helmet: Approved DOT and/or CSA tested helmets

●ye protection: If helmet does not have visor use goggles or safety glasses

●Visual inspection must include, but is not limited to:

o Making sure all components look in proper condition

o Making sure that there are not any obstructing objects in the

wheels/axles/exhaust

o Check for proper levels of gasoline and oil, as well as secure tightening of the

caps

●Check that the belt is not visually worn out at any place

●Check proper working of the kill switch

Operations Safe Use Guidelines

●

Be aware of the location of the fire extinguisher and driving controls

●

Remain seated while driving the MR18

●

Always drive at a safe and prudent speed

o

Slow down before turning and avoid erratic operation

o

Operator must never drive at any speed at which there are difficulties in

maneuvering, stopping, or possible danger to observers or other personnel

o

Do not operate under the influence of alcohol or drugs

●

Never carry passengers

●

Turn off the engine beforehand if getting off the machine

●

Avoid contact with spinning parts and hot components

o

Shields and safety devices should not be removed during operation of the MR17

●

MR18 is not provided with any type of lights, use only during day or fully lit areas

●

Never use indoors or in poorly ventilated areas