Section 5: Specifications & Capacities . . . .

Section 6: Troubleshooting . . . . . . . . . . . . . .

Section 7: Appendix . . . . . . . . . . . . . . . . . . .

Bolt Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

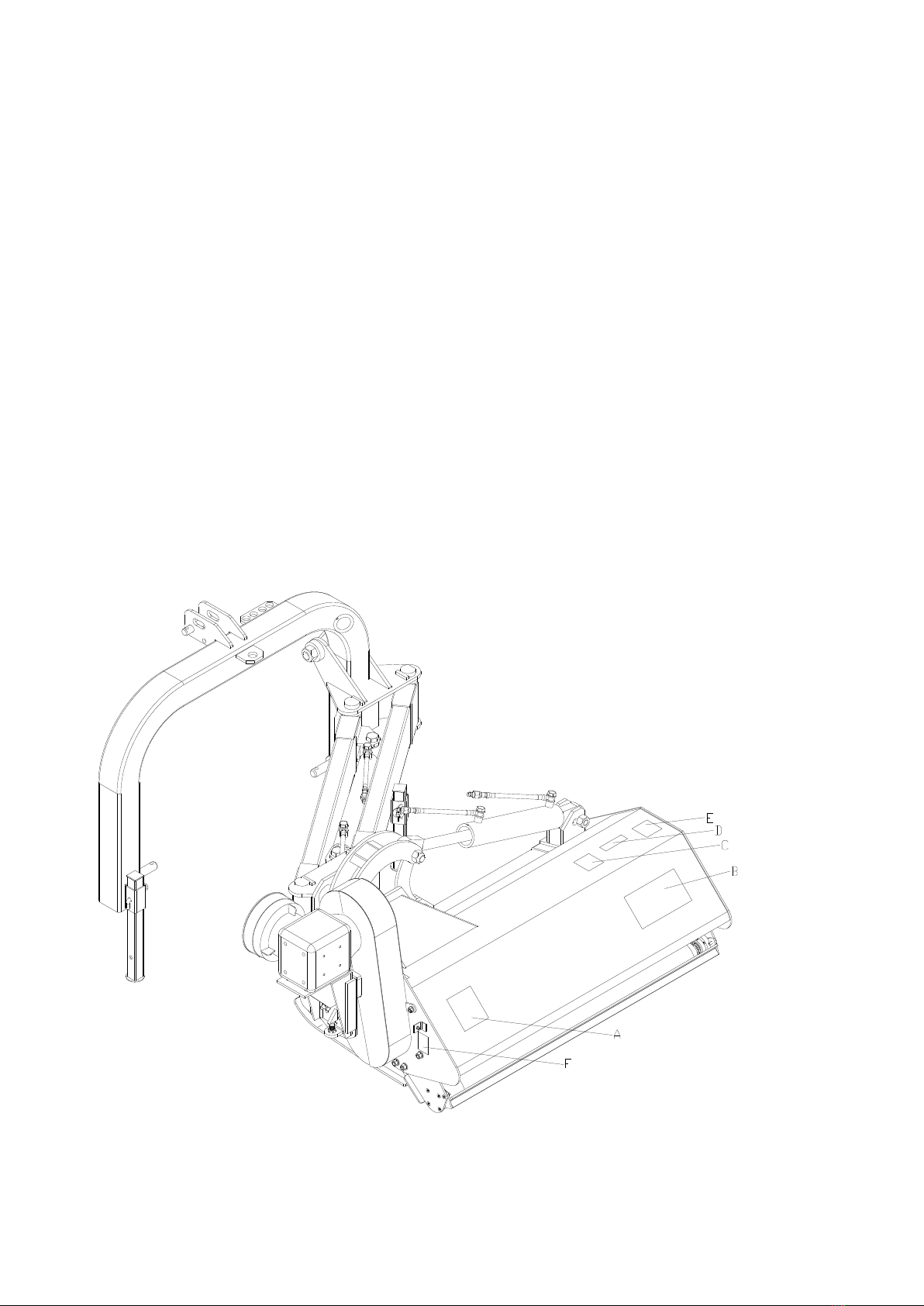

Section 8: Parts illustration . . . . . . . . . . . . .

Important Safety information

Safety at all times

Thoroughly read and understand the instructions given in this manual before operation. Refer

to the “Safety Decal”, read all instructions noted on them.

Do not allow anyone to operate this equipment who has not fully read and comprehended this

manual and who has not been properly trained in the safe operation of the equipment.

Operator should be familiar with all functions of the unit.

Operate implement from the driver’s seat only.

Make sure all guards and shields are in place and secured before operating the implement.

Do not leave tractor or implement unattended with engine running.

Dismounting from a moving tractor could cause serious injury or death.

Do not stand between tractor and implement during hitching.

Keep hands, feet, and clothing away from power-driven parts.

Wear snug fitting clothing to avoid entanglement with moving parts.

Watch out for wires, trees, etc., when raising implement. Make sure all persons are clear of

working area.

Turning tractor too tight may cause implement to ride up on wheels. This could result in injury or

equipment damage.

Look For The Safety Alert Symbol

The SAFETY ALERT SYMBOL indicates there is a potential hazard to personal safety involved

and extra safety precaution must be taken. When you see this symbol, be alert and carefully read

the message that follows it. In addition to design and configuration of equipment, hazard control

and accident prevention are dependent upon the awareness, concern, prudence and proper

training of personnel involved in the operation, transport, maintenance and storage of

equipment.

Be aware of signal words

A signal word designates a degree or level of hazard seriousness. The signal words are:

DANGER

Indicates an imminently hazardous situation which, if not avoids, will result in death or serious injury.

This signal word is limited to the most extreme situations, typically for machine components that, for

functional purpose, cannot be guarded.

3