www.SteamPoweredRadio.Com

The

BF-SK

utilizes

the Model

8-910

solid-state

FM

exciter.

Full

technical

details

pertaining

to

the

8-910

operation are contained in Appendix A ot

this

manual.

The

RF

output

of

the

exciter

is

used to

drive

an

inter-

mediate power

amplifier

(IPA)

stage wl'lic:h employs

paral-

lel-connected type 4CX2508 radial

beam

power tetrode

tubes.

This

stage in tum provides

RF

excitation

to a

single

type

3CX3000/A7

high-mu, zero-bias triode tube

in

the power

amplifier

(PA)

stage. The

PA

stage oper-

ates

as

a

Class

C

ampllfler,

in a grounded-grid configura-

tion.

A low.-pass

AF

filter

mounted

within

the cabinet

enclosure attenuates hannonicaily-f'elated frequencies

at

the

transmitter

output termination.

A

single

high-voltage

power supply provides

plate

vol•

tage for the

PA

and

IPA

stages.A

sei,arate power supply

provides

IPA

screen voltage

which

is

adjustable

by

means

of

a

motor~riven

power

output

control from the

front

panel. Independent transfonners provide fl lament

voltages

to

the

PA

and

IPA

tubes,

with

a front panel

FlLAMENT ADJUST

control.

lnasmucn as the

PA

tube

is

a

high-mu power triode spe-

ciflcally

designed tor zero grid bias,

its

operation in a

grounded-grid mode

eliminates

the need tor screen grid

and grid bias power

supplies.

This

permits great

sim-

plification

of

circuitry.

Interlocked

control

logic

permits straightforward push-

button CQntrol

at

all

start-stop

functions.

These, plus

telemetering

sampl~

are terminated tor interconnection

to remote control systems.

Automatic

recycling

and a memory-type

LEO

status

i

ndlcator

assembly

senses

and

indicates

the cause ot

carrier

interruptions.

speciflc:ally

in

the event

of

exciter

RF

output.

IPA

or

PA

failure,

high

voltage

overload

or

or

excessive

VSWR.

The

automatic

recycling

sequence

~nsists

of two pulses spaced approximately one-second

apart. followed

by

an

adjustable

time

interval

from 3

to

20

sectlnds

after

which the two

pulses

are repeated.

It

the

fault

still

persists.

the

recycling

sequence

is

termina-

ted.

An

"overcount"

.

as

well

as the soun:e

of

the

fault

is

shown

on

the

indicator

panel

LED.

If anywhere in the

recycling

sequence, the

transmitter

is

restored to normal

operation, the

LEO

indicator

associated

witn

the

fault

remains

on

until

the manual

RESET

switch

is depressed.

Adequate

cooling

is

provided

oy

maintenance of

positive

cabinet

pressure. The

airflow

routing

is

through

the

shielded

IPA

compartment and upward through the PA

shielded

e:,ctosure. The

airtlow

Is provided

by

means

of

a rugged, permanently-lubricated.

centrifugal

blower,

shock-mounted on the base

of

the

transmitter

cabinet. Its

outlet

is

ducted to the bottom

of

the I

PA

enclosure.

Supplemental

cooling

tor power supply components

is

provided

by

a small exhaust

tan

located in the top

of

the

~

cabinet.

Air

entering the

transmitter

is

filtered

by

dual,

maintainable

fl

lters

mounted

0:1

the rear door

of

the

cabinet.

The

rear door opening

is

prote<:ted

with

dual mechanical

intertocl<

switches.

one

ot

which

defeats

the

high-voltage

2

control

circuitry.

The other shorts the hiqh-vnltage plate

power

supply to ground.

An

insulated "grounair.g

stic,c".

located

just

inside

the cabinet

at

the door openmg

is

also

provided.

111.

INSTALl.ATlON

3.1

PLAHHING

It

is

recommended tnat the manual

be

studied in

its

en-

tirety

prior

to

final

instattatio~

ot

the

8F-5K

. A

full

understanding

of

the

controls,

c2rcuI try and input

and

out-

put

terminations 'Nill

assist

in the preplanning stage.

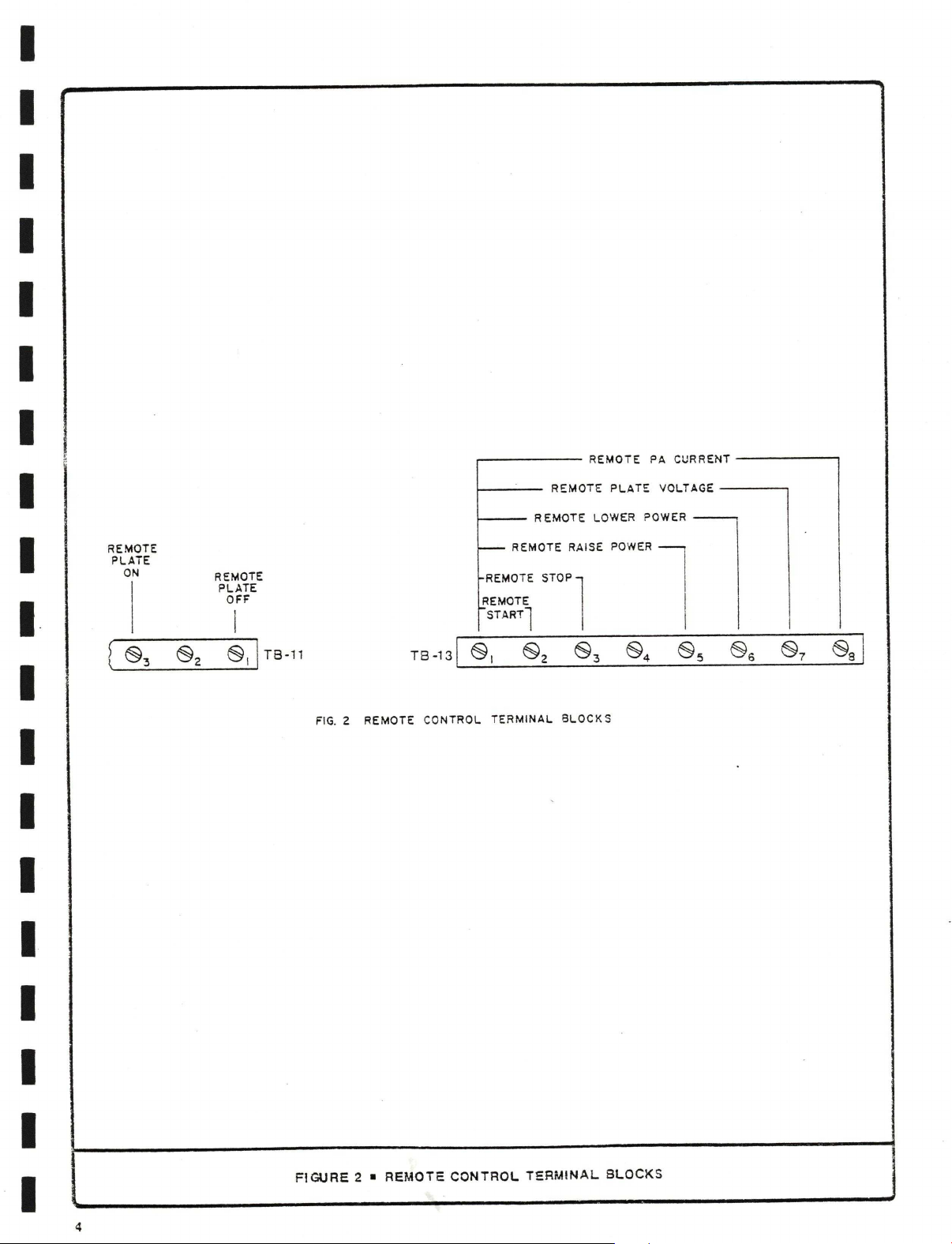

Figure

1

is

an

outline

dlmensional drawing of the trans-

mitter.

Provide

adequate clearances tor access to the

transmitter

through the rear. Preplan the location

of

the

entrances for power,

audio/remote

control cable harnes-

sing,

external monitoring

coaxial

cable

teed and the

RF

output connection to the

coaxial

transmission

line.

The

BF-SK ·

output termination

is

by .means

of

an

EIA

1

·5/8"

flange.

This

flange

with

a short

section

of

1-5/8"

rigid

line

mates

with

an

ungassed

field

coui,ling

clamped to

the

output

of

the harmonic

filter.

These

coaxial

line

com-

ponents are

pacl<ed

separately and should be assembled

to

ascertain

the

precise

physical

location

ot

the output

termination.

AI

though cable entrances

may

be

made through ei

mer

the top

or

bottom

of

the cabinet, the preferred arrange-

ment tor

ease

ot

installation

is

through the bottom ~n-

trances to the

cabinet

for

all

interconnections except

the

output

coaxial

transmission

line.

3.2 UNPACKING

Inspect

the

unit

for damage which might be incurred dur•

ing

shipment.

Particularly

note

condition

of

knobs, .

meters and ceramic

insulators.

Inspect

painted surfaces

for

dents

or

scratches.

If

damage is detected, immedi-

ately

notify

the

earner

and

advise

McMartin ot steps you

have taken.

The tubes

will

normally

be

packed separately.

Install

these in

their

respective

sockets.

3.3

EXTERNAL

CONNECTIONS

A

11

external connections are made from the rear

at

the

cabinet.

(Directions

given below,

right

or

left,

are

based

on

rear

view

access.)

3.3•1

RF

Output

The

RF

output termination

is

an

EIA

standard

1·5/8"

coaxial

end flange located at the top

of

the RF harmonic

tiIter. The external coaxial Iine

run

should be terminated

to

this

coupling.

The external

line

should be secured so

tnat

excessive

lateral or

vertical

pressure is not exerted

on

tne output termination. The

coaxial

line

output com-

ponents are .packaged separately

and

should

be

assem-

bled

prior

to connection

of

the external transmission

line.

3.3-2

Audio Input

The audio input termination

strip

is located

at

t~e lower

left

of

the cabinet. Jacketed, two-conducter shielded

cable

should

be

used. Monaural

or

lett-cnanne! stereo

input

should

be

connected

to

TS-12(3

&

4),

Right-cnannel

, audio input should

be

ccnnected

to

T8•3

(6

&

7).

If

SCA

operation

is

used, tne SCA audio input should

be

connec•

ted

to

TB-3 (1

&

2). Shield grounds should

be

made to

T8•3

(5

or

8.)

3..3-3 Monitor C<lnnectlons

The RF

drive

tor

FM

frequency

and/or

modulation moni•

taring equipment

may

be

taken

from

either

of

two tennina-

tions.

each of which are of the

BNC

type. One

ot

these

is

located

directly

above

the main housing

ot

the RF

output

tilter.

This

is

a fixed-probe type

pIck~it

point.

The other

is

located

on

the le

!t

side

ot

tne

PA

enclo•

sure adjacent to the coaxial leed to the RF harmonic

tilter

input

port. This

is

the termination of a pickup loop

wnich

may

be

mechanically

orier

,ted in relation to the

PA output connection

to

tne

ti

Iter.

This

loop is readily

accessible

tor adjustment

by

opening the rear door ot

ttie PA stage compartment.

The

coaxial

cable

rrom

the

pick

up

point

is

terminated

on

TS-2 (5

&

6).,

#5

ground. The external cable should

be

of

the

flexible

coaxial type.