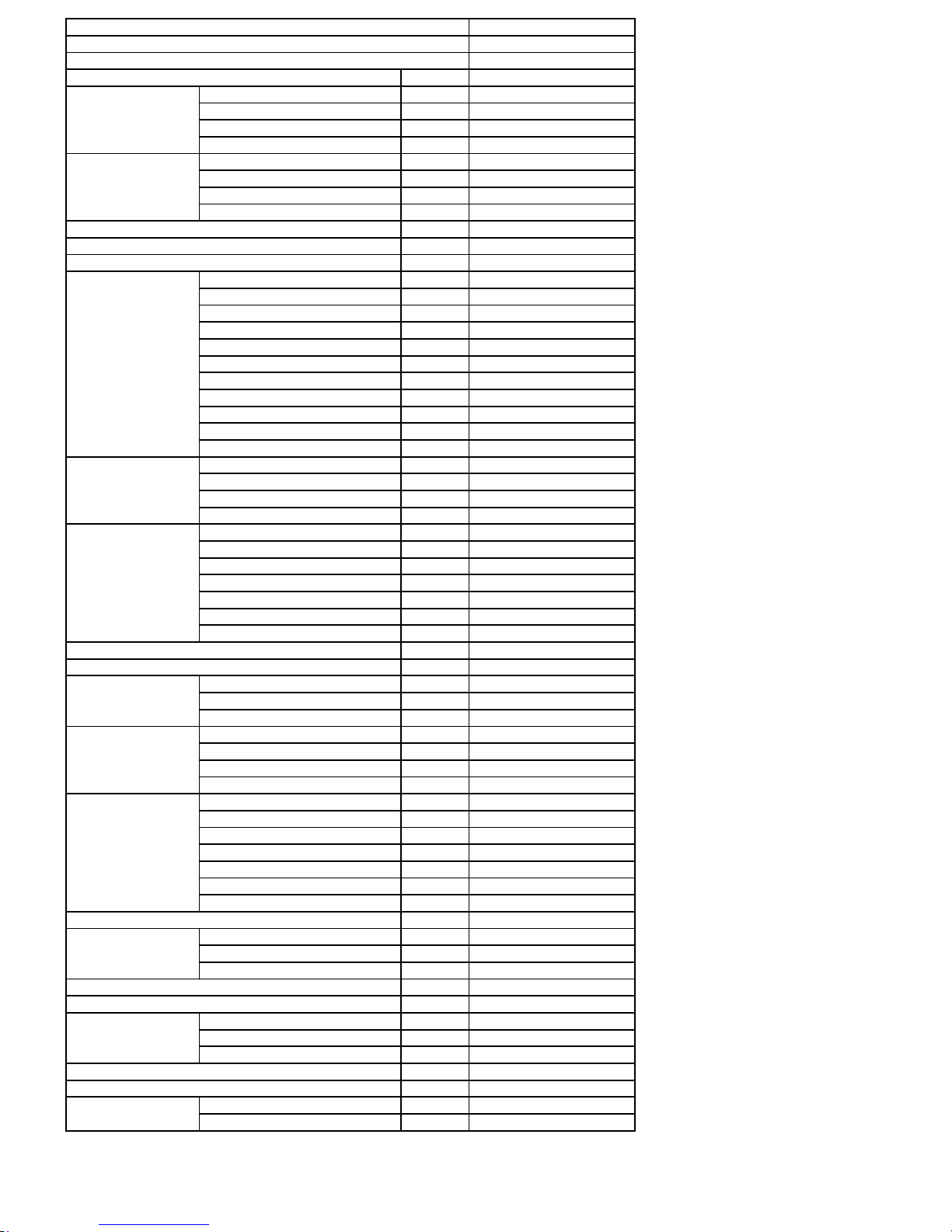

CONTENTS

1. Precaution.................................................................................................................................................... 3

1.1 Safety Precaution ........................................................................................................................3

1.2 Warning .......................................................................................................................................3

2. Function........................................................................................................................................................ 7

3. Dimension .................................................................................................................................................... 9

3.1 Indoor Unit...................................................................................................................................9

3.2 Outdoor Unit ..............................................................................................................................14

4. Refrigerant Cycle Diagram ....................................................................................................................... 16

5. Wiring Diagram.......................................................................................................................................... 18

5.1 Indoor Unit.................................................................................................................................18

5.2 Outdoor Unit ..............................................................................................................................28

6 Installation Details...................................................................................................................................... 40

6.1 Wrench torque sheet for installation ..........................................................................................40

6.2 Connecting the cables...............................................................................................................40

6.3 Pipe length and the elevation ....................................................................................................41

6.4 Installation for the first time........................................................................................................44

6.5 Adding the refrigerant after running the system for many years ................................................48

6.6 Re-installation while the indoor unit need to be repaired...........................................................49

6.7 Re-installation while the outdoor unit need to be repaired.........................................................51

7. Operation Characteristics......................................................................................................................... 54

8. Electronic function.................................................................................................................................... 55

8.1 Abbreviation ..............................................................................................................................55

8.2 Display function.........................................................................................................................55

8.3 Main Protection .........................................................................................................................56

8.4 Operation Modes and Functions ...............................................................................................57

9. Troubleshooting......................................................................................................................................... 73

9.1 Indoor Unit Error Display ...........................................................................................................73

9.2 Diagnosis and Solution..............................................................................................................74