SAFETY PRECAUTION

Read the following "SAFETY PRECAUTIONS" carefully before installation.

The caution items stated here must be followed because these important contents are related

to safety. The meaning of each indication used is as below.

Incorrect installation due to ignoring of the instruction will cause harm or damage, and the

seriousness is classified by the following indications.

!

!

This indication shows the possibility of causing death or serious injury.

This indication shows the possibility of causing injury or damage to

properties only.

1. Injury means causing harmed, burned, electrical shocked, but not serious for hospitalization.

2. Damage of property means disrepair of property, material.

Carry out test running to confirm that no abnormality occurs after the installation. Then, expl-

ain to user the operation, care and maintenance as stated in instructions. Please remind the

customer to keep the operating instructions for future reference.

Engage dealer or specialist for installation. If installation done by the user is defective, it

will cause water leakage, electrical shock or fire.

Install according to this installation instructions strictly. If installation is defective, it will

cause water leakage, electrical shock or fire.

Use the attached accessories parts and specified parts for installation. Otherwise, it will

cause the set to fall, water leakage, fire or electrical shock.

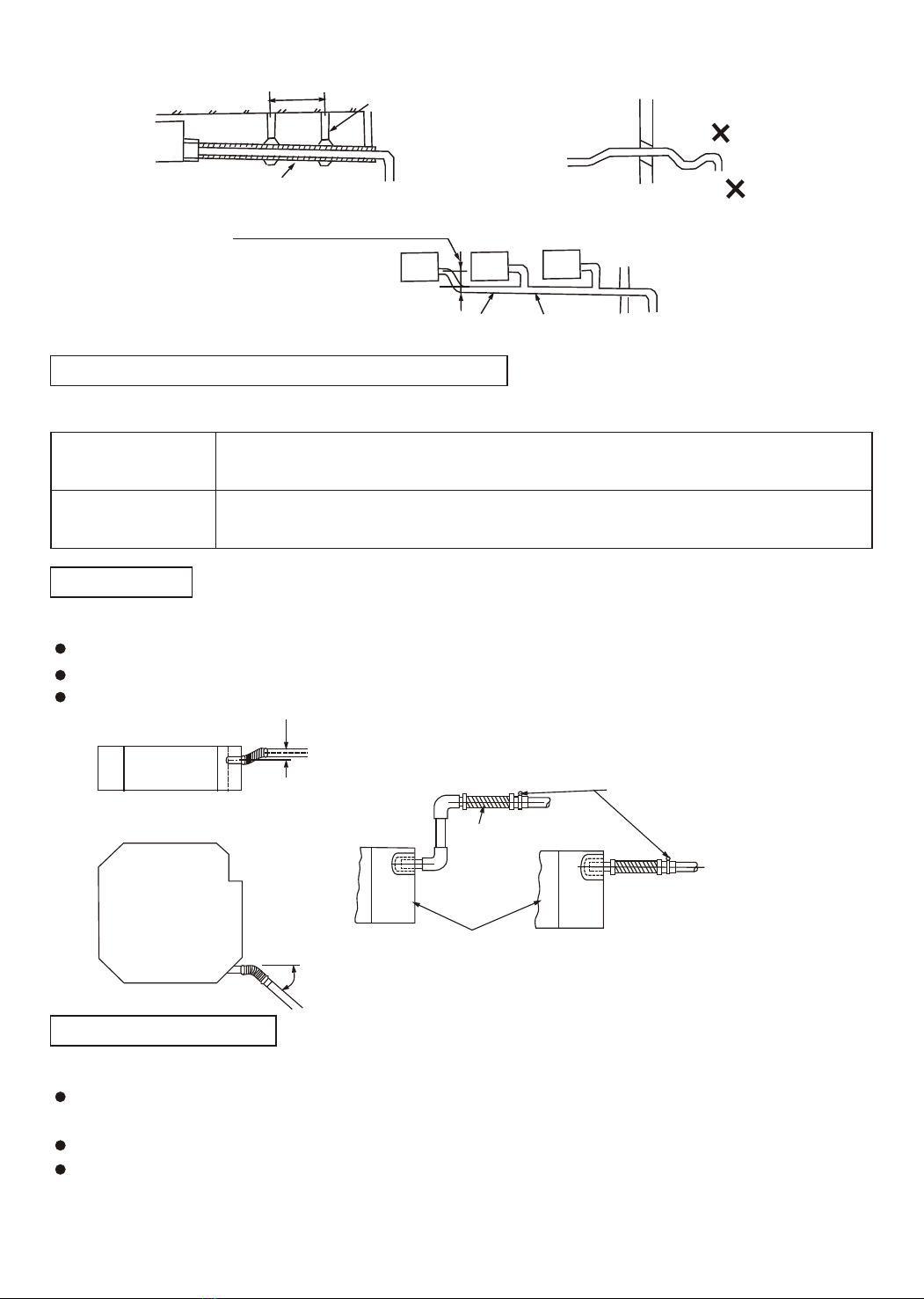

Install at a strong and firm location which is able to withstand the set's weight. If the stren-

gth is not enough or installation is not properly done, the set will drop and cause injury.

For electrical work, follow the local national wiring standard, regulation and this installa-

tion instructions. An independent circuit and single outlet must be used. If electrical circuit

capacity is not enough or defect found in electrical work, it will cause electrical shock or fire.

When carrying out piping connection, take care not to let air or other substances other

than the specified refrigerant go into refrigeration cycle. Otherwise, it will cause lower

capacity, abnormal high pressure in the refrigeration cycle, explosion and injury.

Grounding is necessary. It may cause electrical shock if grounding is not perfect.

Do not install the unit at place where leakage of flammable gas may occur. In case gas

leaks and accumulates at surrounding of the unit, it may cause fire.

WARNING

!WARNING

CAUTION

NOTE :

2