CONTENTS

1.

General information of Outdoor Units..................................2

2.

Features..................................................................................3

3.

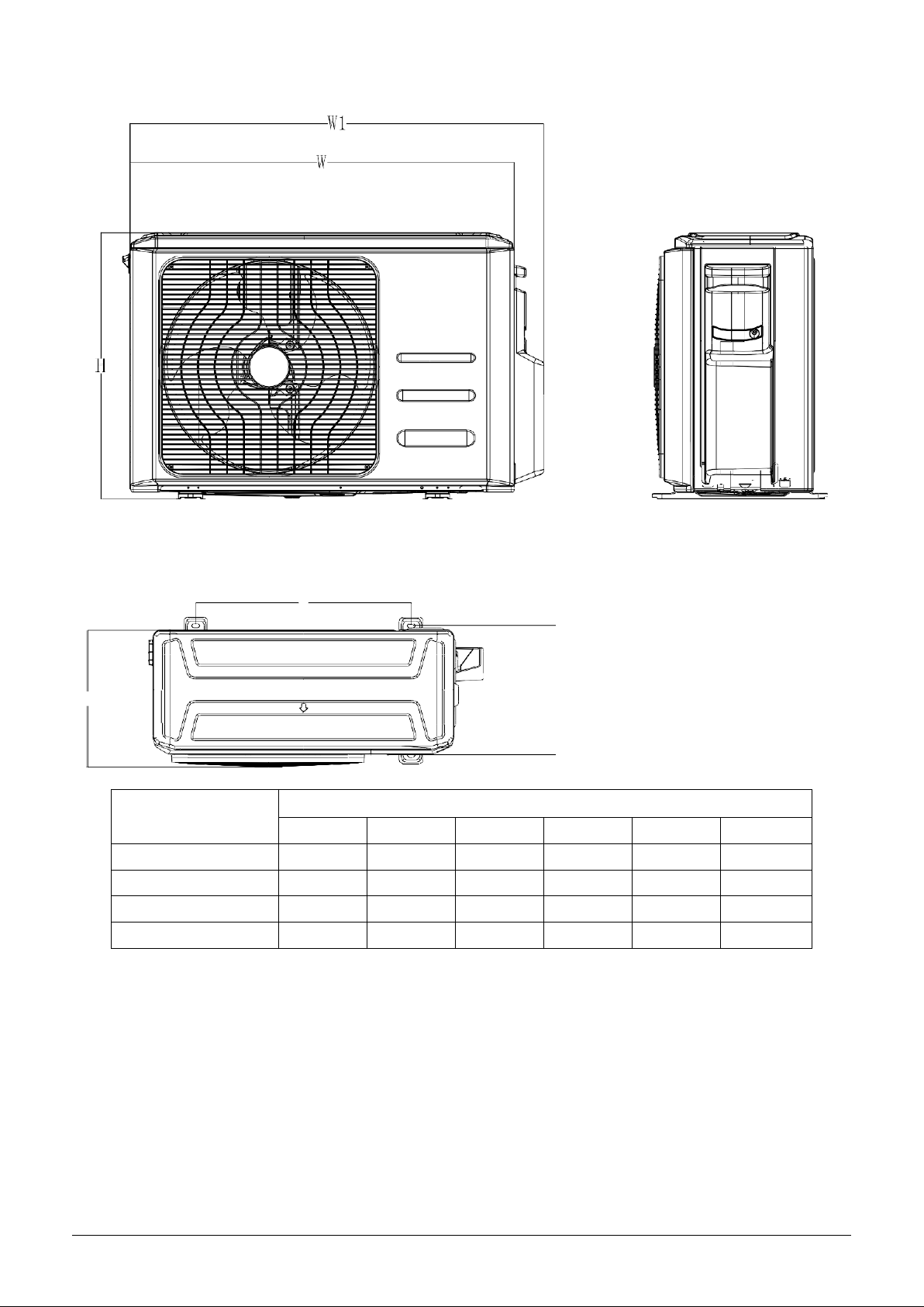

Dimensions.............................................................................4

4.

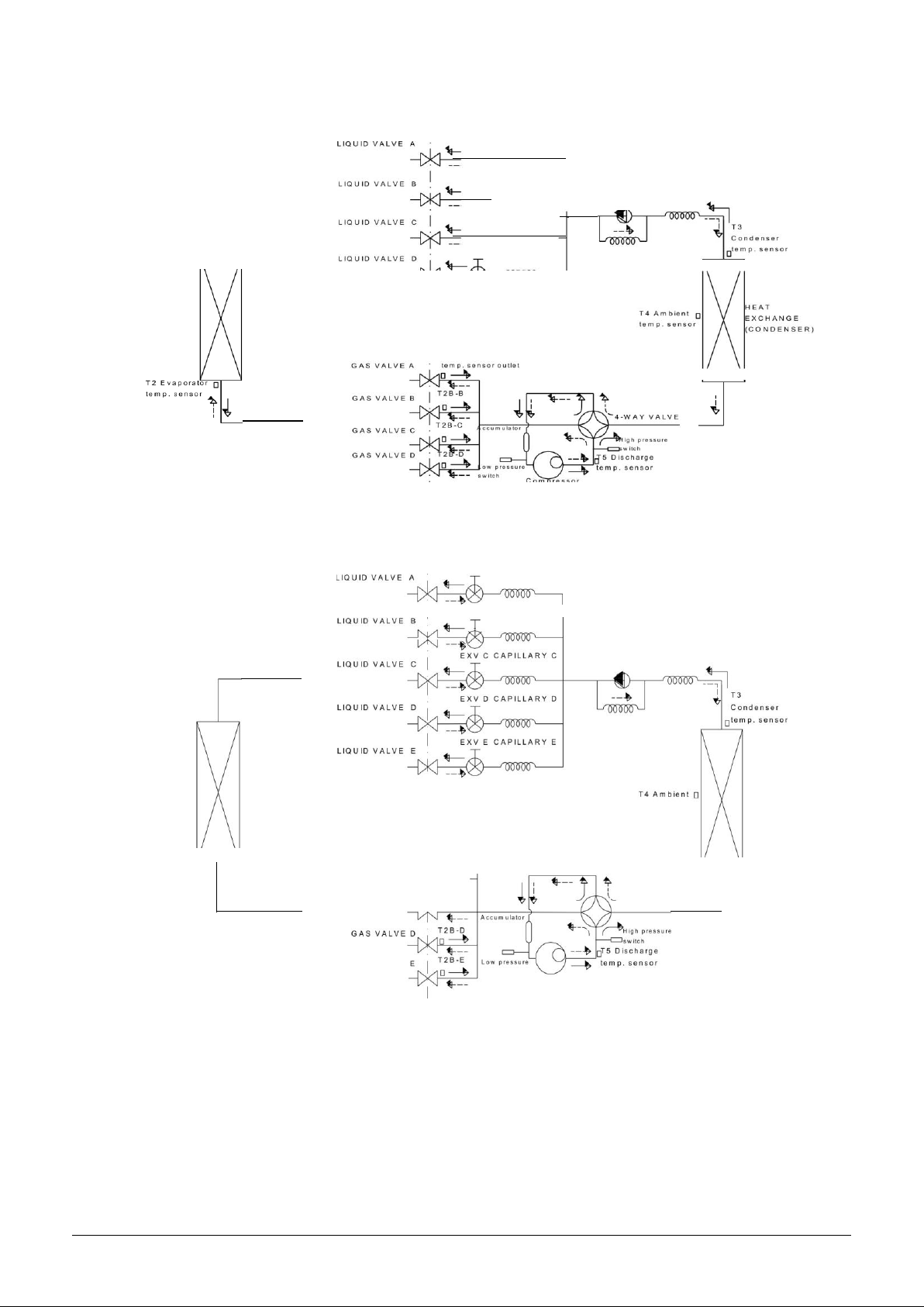

Refrigeration Cycle Diagram.................................................5

5.

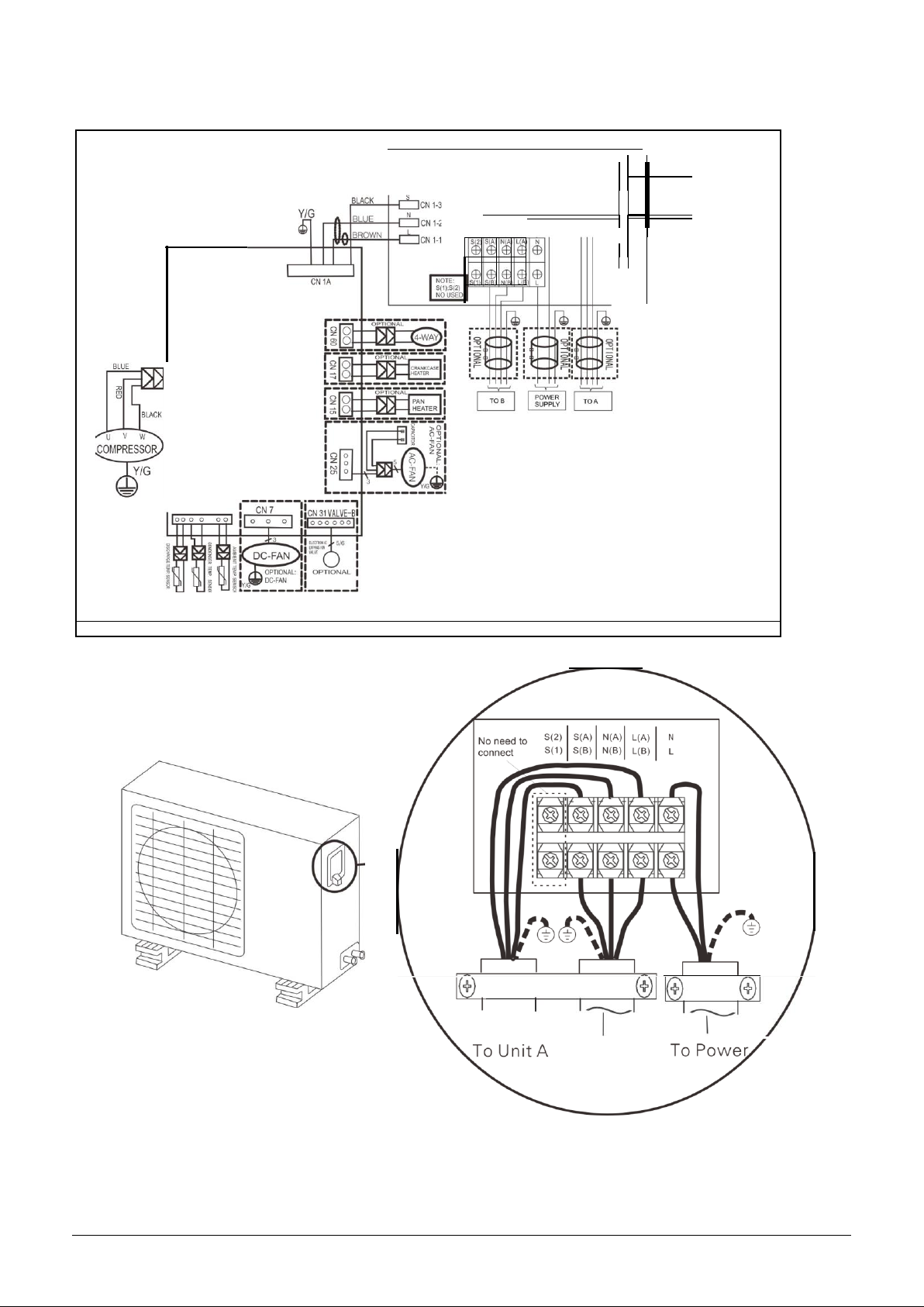

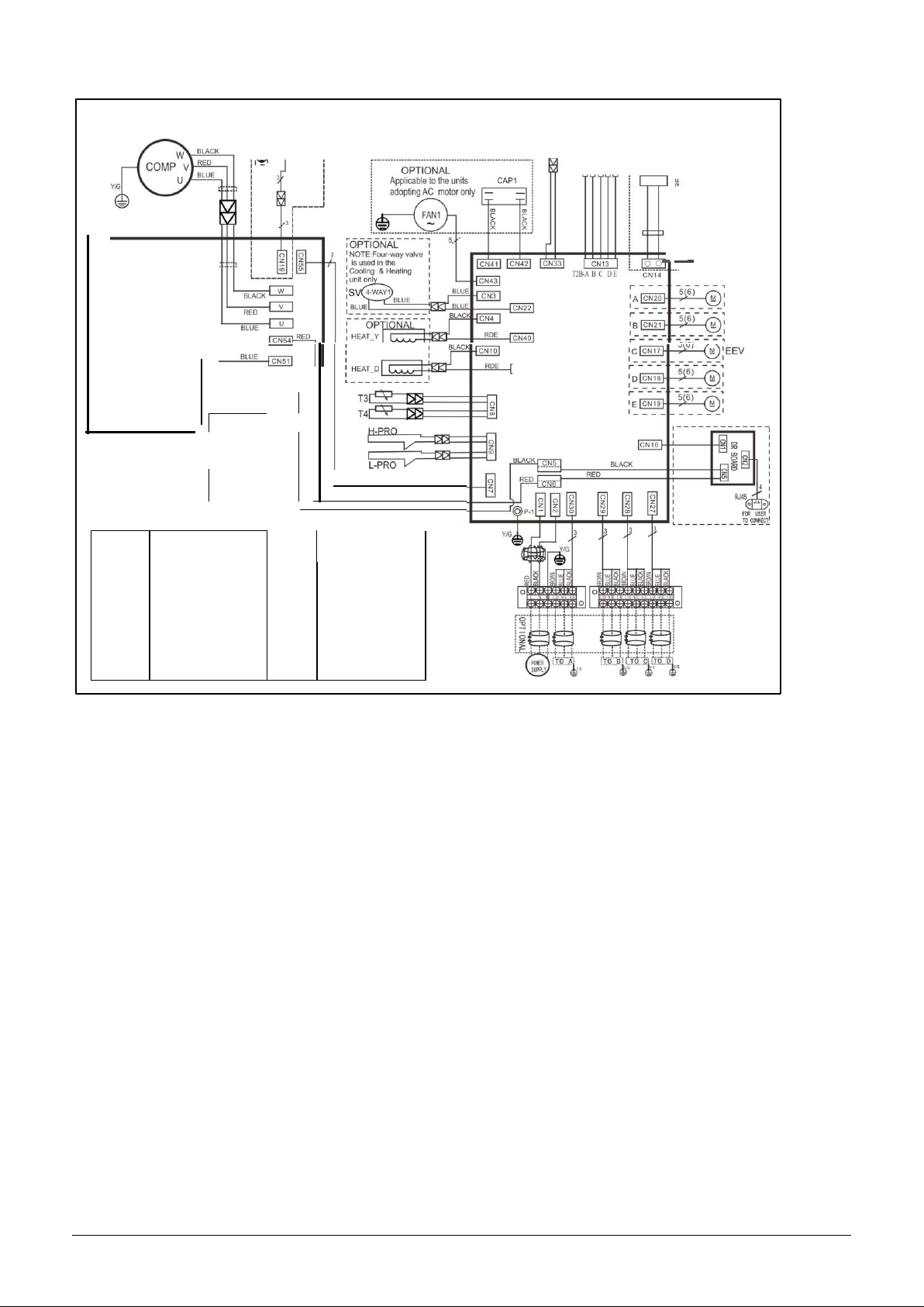

Wiring diagram.......................................................................7

6.

Indoor units combination....................................................11

7.

Sound Levels........................................................................13

8.

Installation Details ...............................................................14

8.1 Wrench torque sheet for installation........................................................................... 14

8.2 Connecting the cables................................................................................................ 14

8.3 Pipe length and the elevation..................................................................................... 14

8.4 Installation for the first time......................................................................................... 15

8.5 Adding the refrigerant after running the system formany years ................................ 18

8.6 Re-installation while the indoor unit need to be repaired........................................... 19

8.7 Re-installation while the outdoor unit need to be repaired......................................... 21

9.

Electronic control function .................................................23

10.

Troubleshooting.................................................................28

Caution: Risk of fire/flammable materials