ACC5703

Contents

1. Safety ........................................................................................................................................ 5

1.1 Symbols Used ................................................................................................................................................. 5

1.2 Warnings.......................................................................................................................................................... 5

1.3 Notes on CE Marking ...................................................................................................................................... 6

1.4 Intended Use ................................................................................................................................................... 6

1.5 Proper Environment......................................................................................................................................... 7

2. Functional Principle, Technical Data ...................................................................................... 8

2.1 Functional Principle ........................................................................................................................................ 8

2.2 Structure and Electrical Connection................................................................................................................ 8

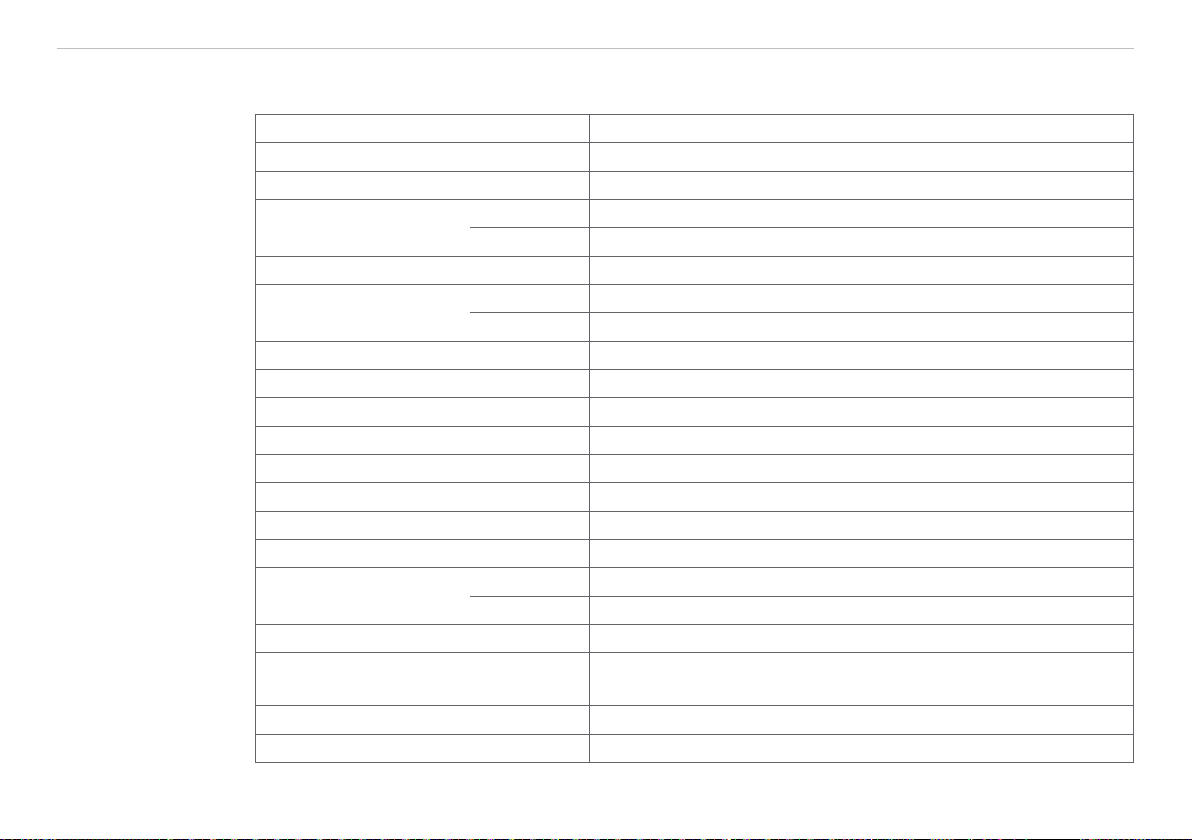

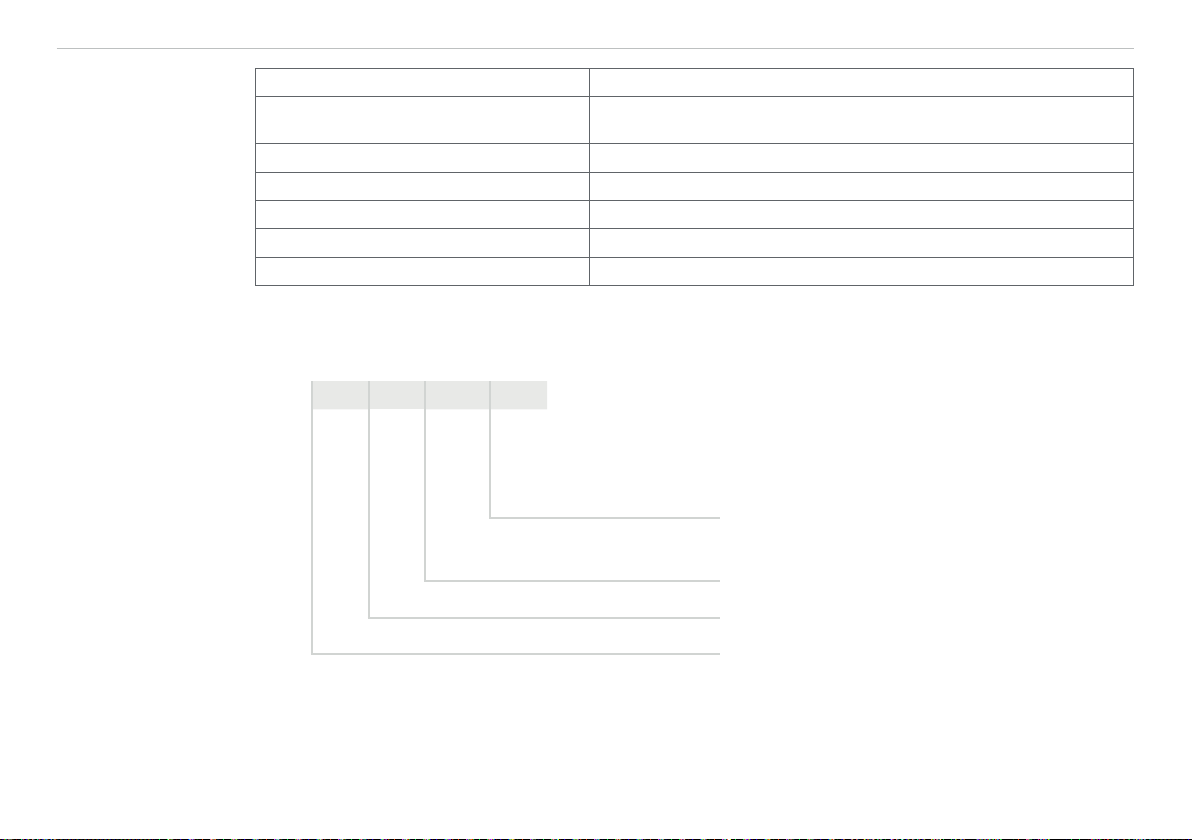

2.3 Technical Data ................................................................................................................................................. 9

3. Delivery .................................................................................................................................. 12

3.1 Unpacking, Included in Delivery.................................................................................................................... 12

3.2 Storage ......................................................................................................................................................... 12

4. Installation and Assembly...................................................................................................... 13

4.1 Sensor Cable Assembly ................................................................................................................................ 13

4.2 Sensor Assembly........................................................................................................................................... 13

4.3 Pin Assignment.............................................................................................................................................. 15

4.4 Current and Voltage Output .......................................................................................................................... 15

4.4.1 Continuous Operation Mode........................................................................................................ 16

4.4.2 Switching Operation Mode........................................................................................................... 17

4.5 Configuration of Sampling Rate and Low- and High-pass Filter .................................................................. 19

4.6 Digital Output RS485 ..................................................................................................................................... 20

5. Operation ................................................................................................................................ 21

6. Liability for Material Defects ................................................................................................. 21

7. Service, Repair ...................................................................................................................... 22

8. Decommissioning, Disposal ................................................................................................. 22