Mecal CDA10 User manual

TRASLATION OF ORIGINAL INSTRUCTIONS

CRIMP DATA ANALYZER

CDA10

USE AND MAINTENANCE MANUAL

Model: CDA10

Serial number:

Revision: 01

Customer:

Year of manufacturer: 2019

CRIMP DATA ANALYZER

CDA10

REV.01

2

REVISION

REVISION

MODEL

LINGUA

DATE

REVISION

NOTES

CDA10

English

10/08/2019

00

Release

CDA10

English

10/01/2020

01

Update

The information contained in this manual is the property of Mecal S.r.l.

The drawings and other documents accompanying the machine are the property of Mecal S.r.l.

Distributing and/or duplicating this manual in any form, whole or partially, without written

authorisation from Mecal S.r.l. is prohibited.

Mecal S.r.l. reserves the right to modify the characteristics of the product described in this manual

without notice.

In case of doubts or difficulties in understanding or interpreting this manual, the original/official

version indicated as "ORIGINAL INSTRUCTIONS" on the cover must be considered as the valid

version.

All of the images included in this manual should be considered as examples only, as they may not

refer to the machine described here.

The

Crimp Data Analyser – CDA10 addressed by this manual will hereinafter

be referred to as "interchangeable equipment" or "equipment".

The

Crimp Data Analyser – CDA10 is an interchangeable device which,

assembled with a main system called "machine," adds a new function to the

latter.

CRIMP DATA ANALYZER

CDA10

REV.01

3

STRUCTURE OF THE MANUAL

The manual is divided into 9 chapters, the last of are the attachments.

CHAPTER 1 - GENERAL INFORMATION

This chapter contains general descriptions regarding the structure of the manual.

CHAPTER 2 - SAFETY

This chapter contains a description of the standards, the environmental operating conditions,

ergonomics, the accident prevention devices used, the residual risks and the monitoring plates

applied to the machine.

CHAPTER 3 - GENERAL DESCRIPTION

This chapter contains a description of the operating principles of the machine, the work cycle, the

general technical data and the description of the mechanical, electrical and fluidic units making up

the machine itself.

CHAPTER 4 - PACKAGING AND TRANSPORT

This chapter contains instructions for correctly packaging, handling, transport and unloading at the

user facility.

CHAPTER 5 - INSTALLATION

This chapter contains instructions for correctly carrying out installation at the user facility,

connections to the facility's power supplies, verifications, checks and any adjustments to be carried

out before start-up.

CHAPTER 6 - USE

This chapter, intended for operators and maintenance personnel, contains instructions for starting

and using the machine in its various operating cycles, with descriptions of the controls available to

the operator, the most important operating sequences and use of the diagnostic systems.

CHAPTER 7 - DISMANTLING

This chapter contains warnings and instructions for correctly performing decommissioning and

dismantling of the machine at the end of its operational life.

CHAPTER 8 - MAINTENANCE

This chapter, intended for maintenance technicians, contains the machine maintenance plan. It

provides warnings, precautions and instructions for properly performing maintenance operations

on the machine.

CHAPTER 9 - ATTACHED DOCUMENTATION

CRIMP DATA ANALYZER

CDA10

REV.01

4

CONTENTS

1. GENERAL INFORMATION..................................................................................................................... 10

1.1 INTRODUCTION .........................................................................................................................................10

1.2 SUPPORT ...................................................................................................................................................10

1.3 GLOSSARY..................................................................................................................................................11

1.4 SIMBOLS ....................................................................................................................................................13

1.5 MANUFACTURER’S INFORMATION...........................................................................................................14

1.6 SAFETY STANDARDS ..................................................................................................................................15

1.7 MANUFACTURER’S RESPONSIBILITIES ......................................................................................................15

1.8 MACHINE MANAGEMENT .........................................................................................................................16

1.9 CONDITIONS CHECK ..................................................................................................................................16

1.10 WARRANTY..............................................................................................................................................17

2. SAFETY ............................................................................................................................................................21

2.1 GENERAL INFORMATION...........................................................................................................................21

2.1.1 Machine certification .........................................................................................................................22

2.1.2 Intended and improper uses..............................................................................................................23

2.2 ENVIRONMENTAL OPERATING CONDITIONS............................................................................................24

2.2.1 Fire protection installation.................................................................................................................24

2.2.2 Explosive atmosphere........................................................................................................................24

2.2.3 Lighting...............................................................................................................................................24

2.2.4 Ergonomics.........................................................................................................................................24

2.2.5 Vibrations...........................................................................................................................................25

2.2.6 Noise ..................................................................................................................................................25

2.2.7 Electromagnetic emissions ................................................................................................................25

2.3 DISPOSAL OF EXHAUSTED MATERIALS......................................................................................................26

2.4 DANGER ZONES.........................................................................................................................................26

2.5 SAFETY DEVICES APPLIED TO THE MACHINE ............................................................................................26

2.6 RESIDUAL RISKS.........................................................................................................................................27

2.6.1 General information...........................................................................................................................27

2.6.2 Residual risks......................................................................................................................................27

2.6.3 Plates present on the machine ..........................................................................................................28

CRIMP DATA ANALYZER

CDA10

REV.01

5

3. GENERAL DESCRIPTION ..................................................................................................................................32

3.1 LAYOUT......................................................................................................................................................32

3.2 TECHNICAL INFOMATION..........................................................................................................................35

3.3 DESCRIPTION OF UNITS.............................................................................................................................36

3.3.1 Adjustable support.............................................................................................................................36

3.3.2 Control unit ........................................................................................................................................36

3.3.3 Force cell sensor ................................................................................................................................37

3.3.4 Encoder ..............................................................................................................................................38

4. PACKAGING AND TRASPORT..........................................................................................................................42

4.1 PACKAGING ...............................................................................................................................................42

4.2 TRASPORT..................................................................................................................................................43

4.3 LIFTING AND HANDLING ...........................................................................................................................44

4.3.1 Weight of packages ...........................................................................................................................45

5. INSTALLATION ................................................................................................................................................49

5.1 MACHINE INSTALLATION ..........................................................................................................................49

5.1.1 General safety precautions................................................................................................................49

5.1.2 Choosing the site and verifying installation requirements................................................................50

5.1.3 Positioning and assembling the equipment ......................................................................................50

5.1.4 Positioning and assembling the force cell sensor on TT and P107 presses.......................................51

5.1.5 Positioning and assembling the force cell sensor on P040 and P080 presses...................................52

5.1.6 Positioning and assembling the encoder...........................................................................................53

5.2 CONNECTIONS...........................................................................................................................................54

5.2.1 Connecting to electrical mains on TT and P107 presses....................................................................54

5.2.2 Connecting to electrical mains on P040 presses................................................................................55

5.2.3 Connecting to electrical mains on P080 and P120 presses ...............................................................56

5.2.4 Replacing the force cell TT1000 with CDA10 .....................................................................................57

5.2.5 Auxiliary connecting...........................................................................................................................58

5.3 CHECKS AND VERIFICATIONS ....................................................................................................................59

5.3.1 General checks on the mechanical units ...........................................................................................59

5.3.2 Electrical system check ......................................................................................................................60

5.4 UNIVERSAL INTERNATIONAL RECYCLING CODES......................................................................................61

6. USE ..................................................................................................................................................................67

6.1 SWITCH......................................................................................................................................................67

6.2 ELECTRICAL CIRCUIT..................................................................................................................................67

CRIMP DATA ANALYZER

CDA10

REV.01

6

6.3 CONTROL AND SENSOR SYSTEMS .............................................................................................................68

6.4 MACHINE ARRANGEMENT ........................................................................................................................69

6.4.1 Encoder configuration........................................................................................................................69

6.4.2 Acoustic signal setting........................................................................................................................70

6.4.3 Web connection.................................................................................................................................71

6.4.4 Network setting .................................................................................................................................73

6.4.5 Software update ................................................................................................................................74

6.4.6 Sensor calibration ..............................................................................................................................76

6.4.7 Crimp force detection history ............................................................................................................77

6.4.8 Operating password setting...............................................................................................................79

6.5 MACHINE USE PROCEDURES.....................................................................................................................80

6.5.1 Initial checks.......................................................................................................................................80

6.5.2 Connecting power..............................................................................................................................80

6.5.3 Operating mode .................................................................................................................................80

6.5.4 Switching off the machine .................................................................................................................80

6.6 USE ............................................................................................................................................................81

6.6.1 Learning..............................................................................................................................................81

6.6.2 Production..........................................................................................................................................83

6.6.3 How crimp force curve mismatch is calculated .................................................................................84

6.6.4 Crimp fail............................................................................................................................................86

6.6.5 Parameters setting (Analysis Menu)..................................................................................................87

6.6.6 Error messages...................................................................................................................................88

6.7 UNLOADING THE MACHINE ......................................................................................................................90

6.7.1 Reel unloading procedure..................................................................................................................90

6.8 FAULTS.......................................................................................................................................................91

7. DISMANTLING.................................................................................................................................................94

7.1 DISPOSAL...................................................................................................................................................95

8. MAINTENANCE ...............................................................................................................................................99

8.1 GENERAL SAFETY PRECAUTIONS...............................................................................................................99

8.1.1 General hazard notes.......................................................................................................................100

8.1.2 General warnings .............................................................................................................................101

8.2 QUALIFICATION OF MAINTENANCE PERSONNEL....................................................................................103

8.2.1 General skills ....................................................................................................................................103

8.2.2 Skills related to qualified personnel.................................................................................................103

CRIMP DATA ANALYZER

CDA10

REV.01

7

8.3 SAFETY CONTROL PLAN...........................................................................................................................107

8.3.1 Functional checks and tests on safety devices ................................................................................107

8.4 MACHINE STOP PROCEDURE ..................................................................................................................108

8.5 MAINTENANCE SHEETS ...........................................................................................................................109

8.6 SPARE PARTS ...........................................................................................................................................111

8.6.1 Mechanical spare parts....................................................................................................................111

8.6.2 Electrical spare parts........................................................................................................................111

9. ATTACHED DOCUMENTATION .....................................................................................................................115

9.1 LAYOUT....................................................................................................................................................116

CRIMP DATA ANALYZER

CDA10

REV.01

8

GENERAL INFORMATION 1

SAFETY 2

GENERAL DESCRIPTION 3

PACKAGING AND TRANSPORT 4

INSTALLATION 5

USE 6

DISMANTLING 7

MAINTENANCE 8

ATTACHMENTS 9

CRIMP DATA ANALYZER

CDA10

REV.01

9

CRIMP DATA ANALYZER

CDA10

REV.01

10

1. GENERAL INFORMATION

1.1 INTRODUCTION

This manual contains all the information necessary for correct installation, regular use and suitable

maintenance of the machine.

This document is the use and maintenance manual for the machine:

CRIMP DATA ANALYZER - CDA10

and has been compiled in compliance with Machinery Directive 2006/42/CE.

The Use and Maintenance manual is to be considered an integral part of the machine and must be

kept until its final disposal. It must be kept by the person in charge of the machine after final

installation.

1.2 SUPPORT

For technical support, contact:

MECAL S.r.l.

Registered and production office: Strada per Felizzano, 18 - 15043 Fubine (AL) - Italy

Tel. +39 (0)131 792792 - Fax (0)131 792733 / 792734 Fully paid share cap. € 500.000

Register of Alessandria Companies n. 11690 - CCIAA Alessandria - REA N. 153887 - N. IEC AL002563

Tax Code 01328270069 – ISO Code: IT – VAT n.01328270069

Mecal S.r.l., manufacturer of the equipment in question, will hereafter be

referred to as “Manufacturer”.

The company that purchased the equipment will hereinafter be referred to as

"Client".

The Manufacturer requires that personnel in charge of running and maintaining the machine,

as well as personnel in charge of transport and assembly operations, read this document.

CRIMP DATA ANALYZER

CDA10

REV.01

11

1.3 GLOSSARY

Component: constitutive part of the electrical equipment, usually specified by its function, but

used in various applications.

Contact: person responsible for conducting certain operations or assessments that may occur

during work or maintenance.

Control circuit (of a machine): circuit used to control the operation of the machine and for

protecting power circuits.

Control device: device inserted in a control circuit used for use of the machine.

Danger zone: area inside or near the machine where the presence of an exposed person

constitutes a risk to his/her health and/or his/her safety.

Emergency situation: dangerous situation that needs to be urgently interrupted or avoided.

Emergency stop – emergency stop function: function that is provided:

- To avert arising or reduce existing hazard to person, damage to machinery or to work in progress

and

- To be initiated by a single human action

Exposed person: any person who has their body or any part of their body in a danger zone.

Failure: failure: the end of an element's ability to execute a required function.

Fixed guard: guard affixed in such a manner (for example by screws, nuts and welding) that it can

only be opened or removed by the use of tools or by destruction of the means to which the guard

is affixed.

Guard: physical barrier, designed as part of the machine (for example: using screws, nuts, welds),

to provide protection.

Hazard: potential source of harm.

Improper use: use of the machine outside the limits specified in the technical documentation.

Information for use: Protective measure consisting of communication links (for example, text,

words, signs, signals, symbols, diagrams) used separately or in combination, to convey information

to the user.

Intended use: the use of machinery in accordance with the information provided in the

instructions for use.

Machine: set of pieces or components, of which at least one is mobile, connected to each other,

and possibly with actuators, with control and power circuits, etc., connected for a well-defined

application, particularly for the transformation, treatment, displacement and conditioning of a

material. Interchangeable equipment modifying the function of a machine, which is placed on the

market for the purpose of being assembled with a machine or a series of different machines or

with a tractor by the operator himself in so far as this equipment is not a spare part or a tool.

Machinery Directive: DIRECTIVE 2006/42/EC OF THE EUROPEAN PARLIAMENT AND OF THE

COUNCIL on the approximation of the laws of the Member States relating to machinery.

Malfunction: inability of a machine to perform its intended function.

Marking: symbol and writings for identification of the machine, affixed by the Manufacturer.

Movable guard: guard that can be opened without the use of tools.

Operator: person qualified to install, operate, adjust, clean and maintain the machine.

PLC: Programmable Logic Control able to manage and control all machine movements. Equipped

with electronic boards to control the various devices and to receive the relative control signals.

protection of persons from a present or latent hazard.

Protections (protection criteria): means of protection that uses measures to protect persons

against hazards that cannot be rationally eliminated, against risks that cannot be sufficiently

reduced by protection measures integrated in the design..

CRIMP DATA ANALYZER

CDA10

REV.01

12

Protective device: means of protection other than a guard.

Protective means: guard or protection device.

Qualified personnel or qualified maintenance personnel:those persons who have attended

specialisation courses, training, etc. and have experience in the installation, commissioning and

maintenance, repair, transport and handling of the machine.

Residual risk: risk that remains after taking protective measures.

Risk: combination of probability of occurrence of harm and the severity of that harm.

Safe operating procedure: a work method that reduces risks.

Safety measure: means that eliminates or reduces a hazard.

Safety protections: guard or protective device used as a safety measure for the

Supplier: Supplier: entity (Manufacturer, installer, systems integrator) that supplies the equipment

or services associated with the machine (the user can also act as a Manufacturer for himself).

Transport: set of operations to transfer the machine from the manufacturer's assembly site to the

Client's final work site.

User: entity that uses the machine and associated electrical equipment.

Work Area: volume delimited by accident prevention guards and intended for machine operation.

CRIMP DATA ANALYZER

CDA10

REV.01

13

1.4 SYMBOLS

The manual uses some symbols that are intended to draw the attention of the reader and

highlight some particularly important aspects.

SYMBOL MEANING NOTE

HAZARD

Indicates a hazard with risk of injury or even

death for the user.

Pay close attention to text blocks

indicated by this symbol.

CAUTION

Represents a warning of possible

deterioration or damage to the machine and/or

equipment.

Pay attention to the text blocks indicated by

this symbol.

WARNING NOTE

Indicates a warning or a note of key

features or of useful information.

Pay attention to the text blocks indicated by

this symbol.

ADDITIONAL

INFORMATION

Text blocks that contain complementary

information are introduced by this symbol.

This information has no direct relation to the

description of a function or the development of a

procedure. It may be references to other

complementary documentation, such as instruction

manuals for the use of attachments, technical

documents or other sections of this manual.

CRIMP DATA ANALYZER

CDA10

REV.01

14

1.5 MANUFACTURER CONTACTS

The Manufacturer's Technical Department is always available to Clients for any type of information

or clarification concerning use, maintenance, installation, etc.

The latter should always put the questions in clear terms, with references to this manual, always

indicating the data shown on the identification plate of the machine in question.

Any requests for support at the Customer’s site, or for clarification regarding the technical aspects

of this document, must be addressed to:

Mecal S.r.l.

Registered office and plant: Strada per Felizzano, 18 - 15043 Fubine (AL)

Tel. (0131) 792792 - Fax (0131) 792733/792734 Fully paid share cap. € 500.000

Register of Alessandria Companies n. 11690 - CCIAA Alessandria - REA N.

153887 - N. IEC AL002563

Tax Code 01328270069 – ISO Code: IT - VAT: 01328270069

CRIMP DATA ANALYZER

CDA10

REV.01

15

1.6 SAFETY STANDARDS

The requirements, indications, standards and related safety notes described in the various chapters

of the manual are intended to define a series of behaviours and obligations which must be followed

when performing the various activities that constitute the intended use of the machine, aimed at

operations that are safe for personnel, equipment and the surrounding environment.

The safety standards listed are intended for all authorised personnel, instructed and delegated to

perform the various activities and operations of:

•Transport

•Installation

•Operation

•Use

•Management

•Maintenance

•Cleaning

•Decommissioning and dismantling

1.7 MANUFACTURER’S RESPONSIBILITIES

The Manufacturer declines all responsibility deriving from incorrect or improper use of the machine

in question and from any damage caused by the use of non-prescribed spare parts, from

maintenance operations not carried out correctly or from tampering with circuits, components and

system software.

The responsibility concerning the application of safety requirements, reported as follows, is at the

expense of the technical personnel responsible for activities foreseen on the machine. Technical

personnel must ensure that the operators authorised to carry out the required activities are

qualified, that they comply with and are aware of the provisions contained in this document and of

the general safety standards applied to the machine.

Failure to comply with safety standards may result in injury to personnel and damage to equipment.

CRIMP DATA ANALYZER

CDA10

REV.01

16

1.8 MACHINE MANAGEMENT

Machine management is only allowed to be performed by authorised and appropriately trained

operators, or operators with at least sufficient technical experience.

Operators in charge of machine use and maintenance must be aware that the knowledge and

application of safety regulations is an integral part of their work.

Operators not authorised to work on the machine must not have access to their control panels.

Perform the following operations before starting the machine:

•Read this manual carefully;

•Be familiar with which protections and emergency stop devices are present on the machine,

where they are located and how they work;

Removing or even partially removing the protections, safety devices or monitoring plates affixed on

the machine is prohibited. In the event of malfunction or failure of these devices, immediately

repair or replace them.

1.9 CONDITIONS CHECK

Check that machine has not been damaged during transport. Please therefore report any accidents

or presence of visible damage (signs or traces of impact) as follows:

•With a written note on the Transport Document.

•Communicating the damage detected by registered letter to the carrier and to Mecal S.r.l.,

within 48 hours of receipt of the machine.

CRIMP DATA ANALYZER

CDA10

REV.01

17

1.10 WARRANTY

Mecal S.r.l. guarantees that its machines are free from manufacturing defects for the period of time

indicated in the stipulated contractual conditions.

The purchaser is only entitled to the replacement of parts recognised as defective: the costs of

packaging and transport, as well as any installation, are at the purchaser’s expense. In this case, the

following must be specified:

•Date and number of the purchase document.

•Machine model.

•Serial number.

No claims for damages for production losses caused by any periods of machine downtime will be

recognised.

The warranty does not cover damages due to use that does not comply with the contents of this

"Use and Maintenance Manual," which is an integral part of the machine, including any

maintenance that does not comply with the instructions provided.

La garanzia non sarà riconosciuta per la macchina sulla quale sono state eseguite modifiche non

autorizzate.

The warranty will not be recognised if any unauthorised modifications have been made to the

machine.

Modifications to or tampering with safety devices are strictly prohibited.

In the event of breakages during the warranty period, original spare parts must be used for the

warranty to be valid.

Repair work must only be carried out by specialised operators who are familiar with the machine.

CRIMP DATA ANALYZER

CDA10

REV.01

18

Table of contents

Other Mecal Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

sauter

sauter FP Series instruction manual

berlinger

berlinger Freeze-tag user manual

Siemens

Siemens Milltronics C-40 instruction manual

Changzhou Tonghui Electronic

Changzhou Tonghui Electronic TH2638/A Operation manual

Hanna Instruments

Hanna Instruments HI 83141 instruction manual

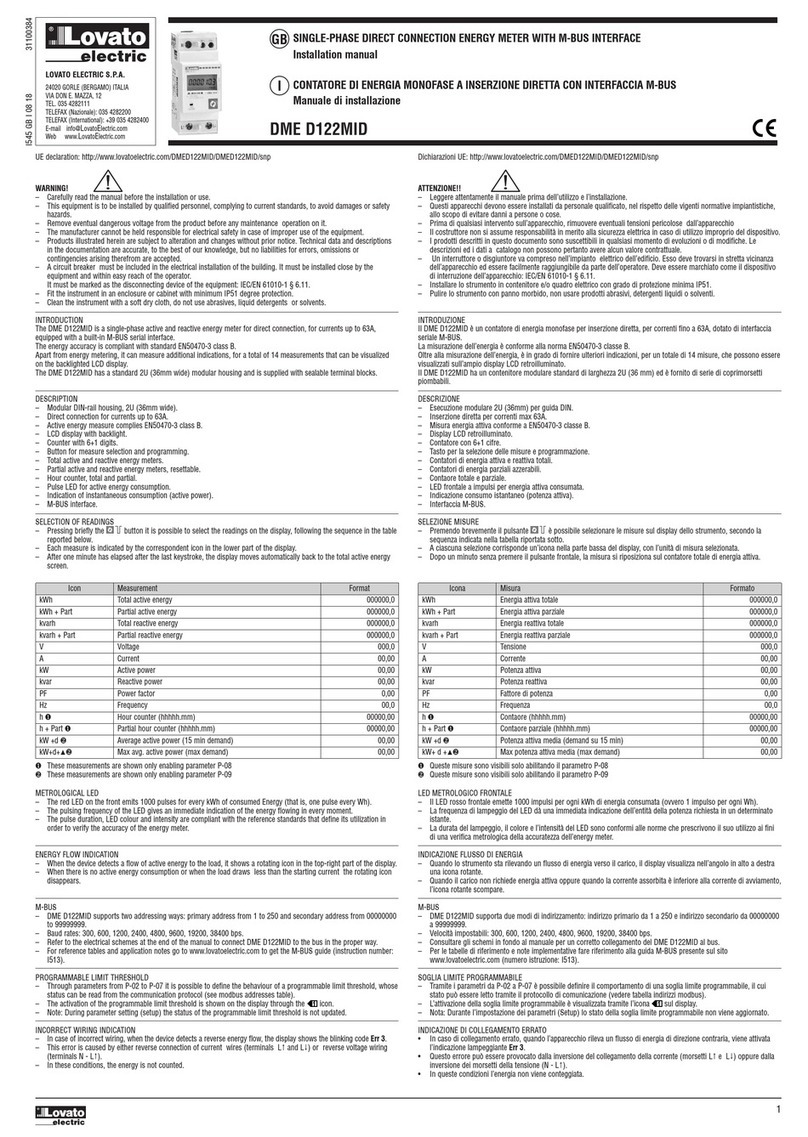

Lovato

Lovato DME D122MID installation manual