eurosensDizzi

Installationmanual.Version2

www.mechatronics.by 9

4.2.5.ConnectsensortothePCandrunthesoftware"CAY_Oscilloscope".

4.2.6.Prepareaglue.

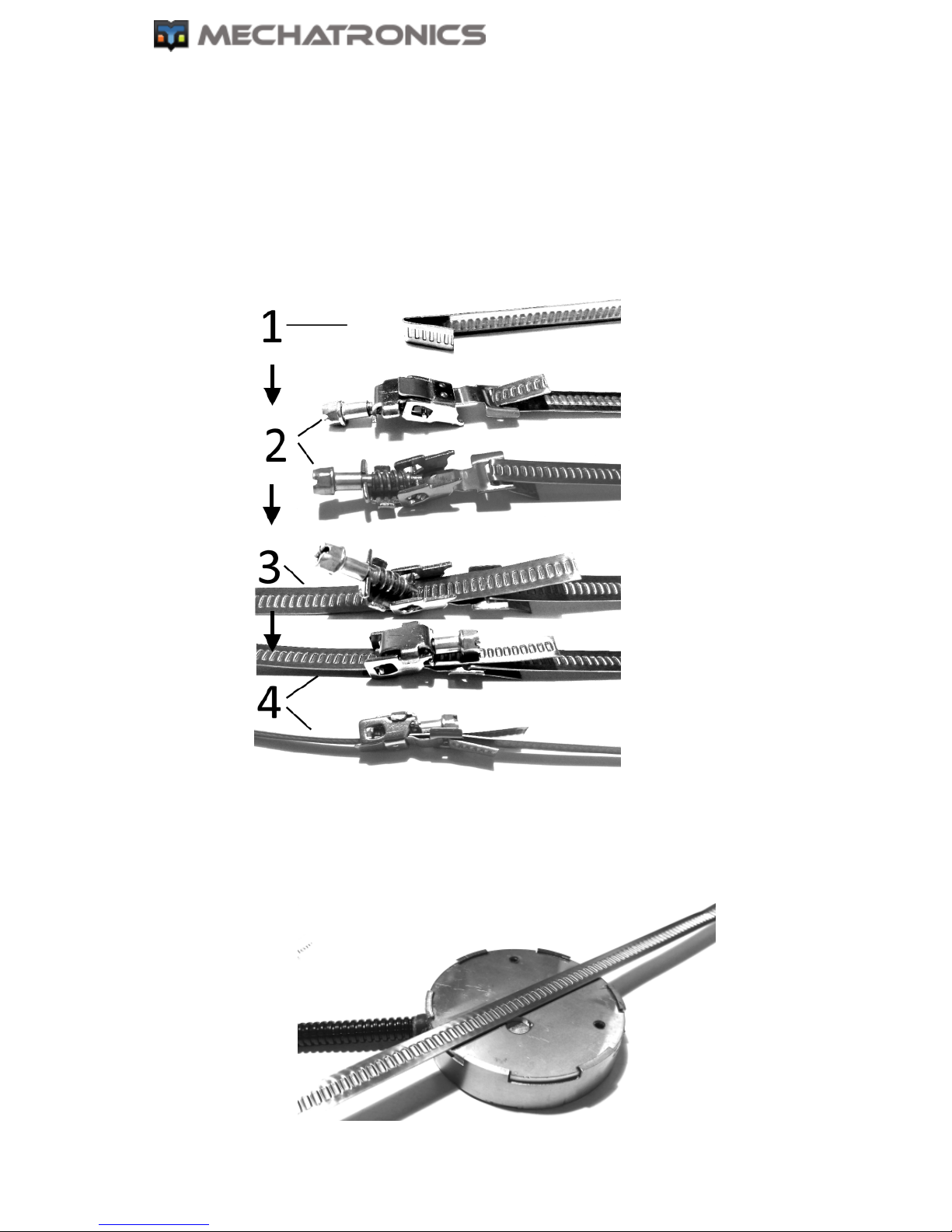

4.2.7.Attachthemetalbandtothemagnetsandputthenutson.

4.2.8.Addgluetothemagnetsandinstallthemtothetank.

4.2.9.Addgluetothecenterofsensorsurface.

4.2.10.Gentlypressthesensortotank,bubblesanddirtintheareaofinstallation

arenotallowed.

4.2.11.Whilemonitoringthesignalquality,tightenthenuts.Whentighteningthe

nutsexcludedetachingofmagnetsfromthetank.

4.2.12.Sealthenuts.

4.2.13.Fullbygluethegapbetweenthetopofthesensorandbottomofthetank.

5. Electricconnection

ATTENTION!

1.BeforeinstallationitisnecessarytopowerOFFtheelectriccircuit

ofthevehicle.Todothis,usethebatterycircuitbreaker(ground

switch)ordisconnectthebatteryconnectors.

2.ItisrecommendedtoclampDizzicabletogetherwithstandardwir‐

ingtothevehiclechassis.

3.RememberthatcasingoftheDizzihaselectricconnectionwith

“ground”wire.Directconnectiontothevehiclebatteryatthevehicles

withbatterycircuitbreaker(groundswitch)isNOTrecommended.

Connect“ground”wireaftergroundswitch.

6. Sensorconfiguration

6.1. Measurethedistancefromthebottomofthetanktothemaximumlev‐

el.

6.2. Runtheprogram"CAY_Configuration"andmakenecessarysettings.

Please,refertotheDizziConfigurationmanual.