EUROSENSFuelflowmeters.Operationmanual.ver.1.6

www.mechatronics.by Page9|30

Eurosens

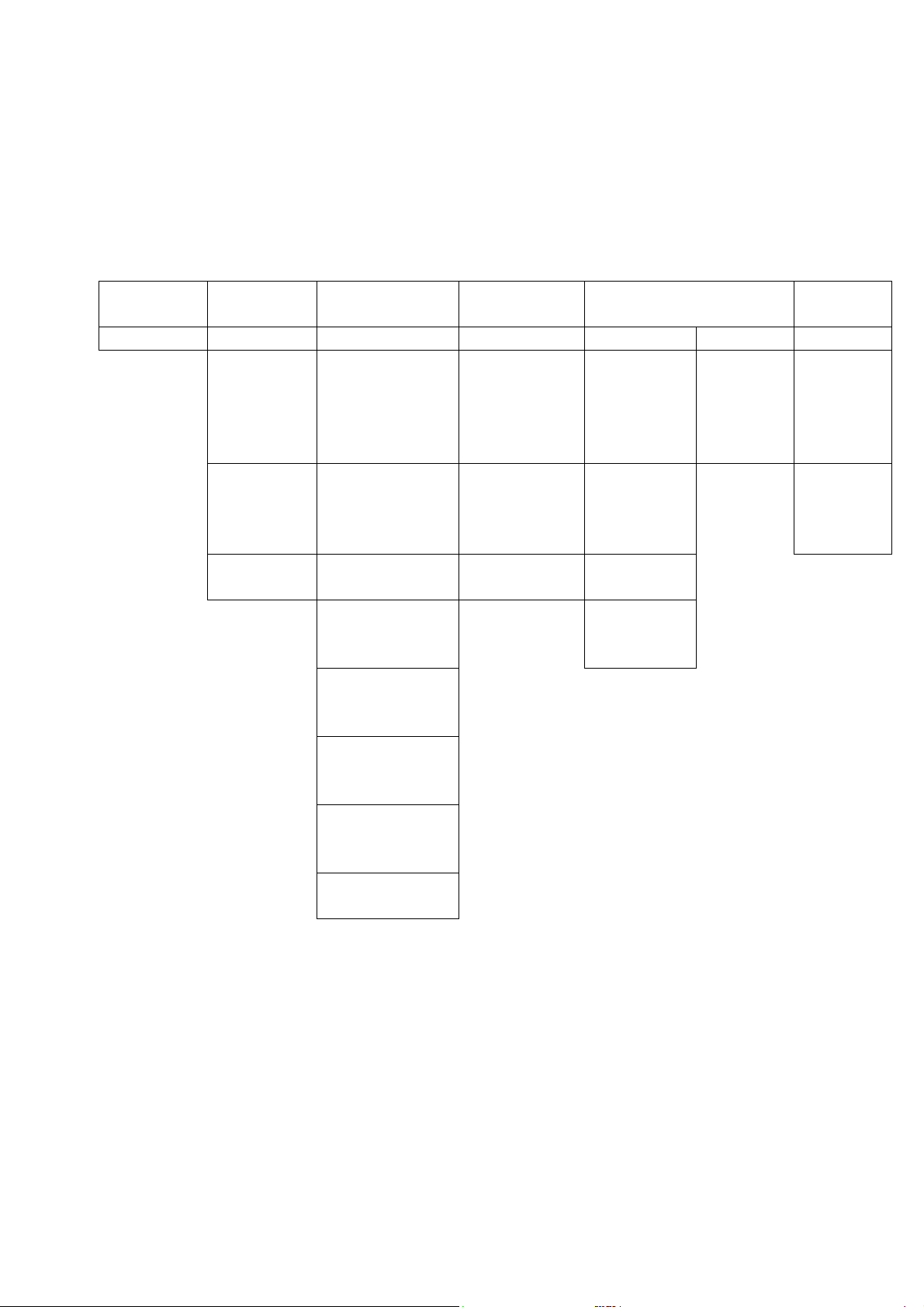

flowmeters

Qstart,

liters/hour

Qmin,

liters/hour

Qnom,

liters/hour

Qmax,

liters/hour

Amount

pulses/literAccuracy

DirectCAN500.051,0525050050±0,5%

DirectRS100I0,5150100200±1%

DirectRS250I0,52125250100±1%

DirectRS500I1,0525050050±1%

DirectCAN100I0,5150100200±0,5%

DirectCAN250I0,52125250100±0,5%

DirectCAN500I1,0525050050±0,5%

DeltaRS100 0,51050100200±1,2%*

DeltaRS250 0,520125250100±1,2%**

DeltaRS5001,04025050050±1,5%***

DeltaRS100I0,51050100200±1,2%*

DeltaRS250I0,520125250100±1,2%**

DeltaRS500I1,04025050050±1,5%***

DeltaCAN100 0,51050100200±1,2%*

DeltaCAN250 0,520125250100±1,2%**

DeltaCAN500 1,04025050050±1,5%***

DeltaCAN100I0,51050100200±1,2%*

DeltaCAN250I0,520125250100±1,2%**

DeltaCAN500I1,04025050050±1,5%***

Flowstosupply/consumptioninliters/hour:*45/10**90/20***160/30

I‐CANLCDintegrateddisplay‐CANinterfaceRS‐RS232/RS485interface

EurosensflowmeterscanalsohaveaseriesofRS232/RS485datainterfaces,aswellas

theCANinterfacebyRS232/RS485operationofthedatainterfaceprotocolispossibleEurosens

DeltaorMODBUS.CANinterfaceisinaccordancewiththeSAEJ1939specification.

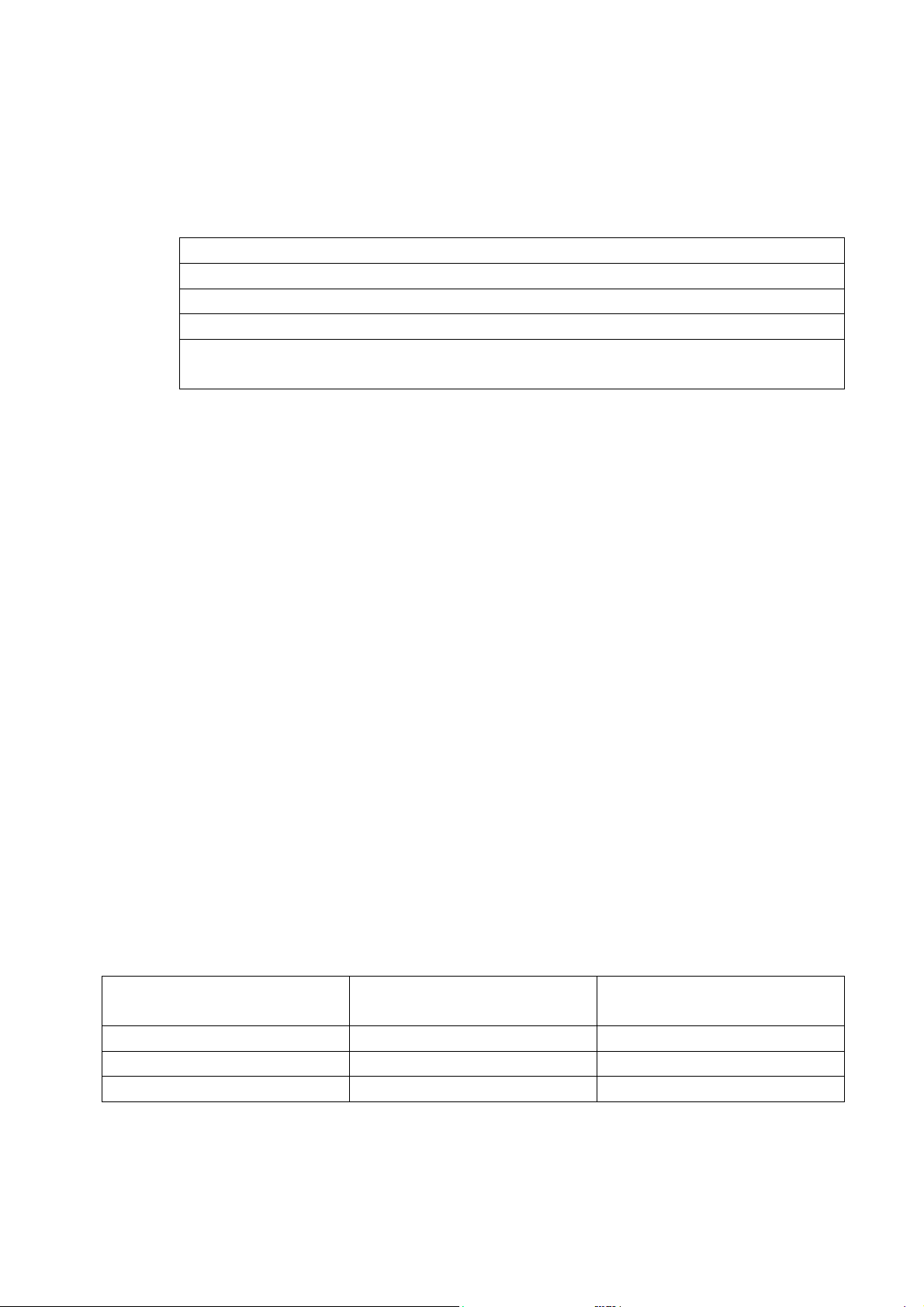

Table.6.Mainspecifications

Parameter,measurementunitsValue

Maxpressure,MPa2.5

Nominalpressure,MPa0.2

Filteringdegreeofmeasuredfluid,mm,notmore

than

0.08

ConnectionthreadM14x1.5M16x1.5

Pressuredropatmaximumflowrate,nominal

pressure,dieselfuelat20°С,MPa,notmorethan

0.02

Supplyvoltagerange,Vfrom10to50(from9to32)*