GA 5752 4981 GB 15 3

Table of contents

Table of contents

1 Introduction ..............................................................................................................................................5

1.1 Foreword ....................................................................................................................................................5

1.2 How to use these operating instructions .................................................................................................... 5

1.2.1 Abbreviations ............................................................................................................................... 5

1.2.2 Symbols ....................................................................................................................................... 5

1.2.2.1 Cross-references ....................................................................................................... 5

1.2.2.2 Actions and responses .............................................................................................. 5

1.2.3 Definitions .................................................................................................................................... 6

1.2.3.1 Design of safety notes ............................................................................................... 6

1.2.3.2 Structure of notes ...................................................................................................... 6

1.2.4 Symbols used .............................................................................................................................. 6

1.3 Disposal......................................................................................................................................................7

1.3.1 ATMOS products.......................................................................................................................... 8

1.3.2 Packaging .................................................................................................................................... 8

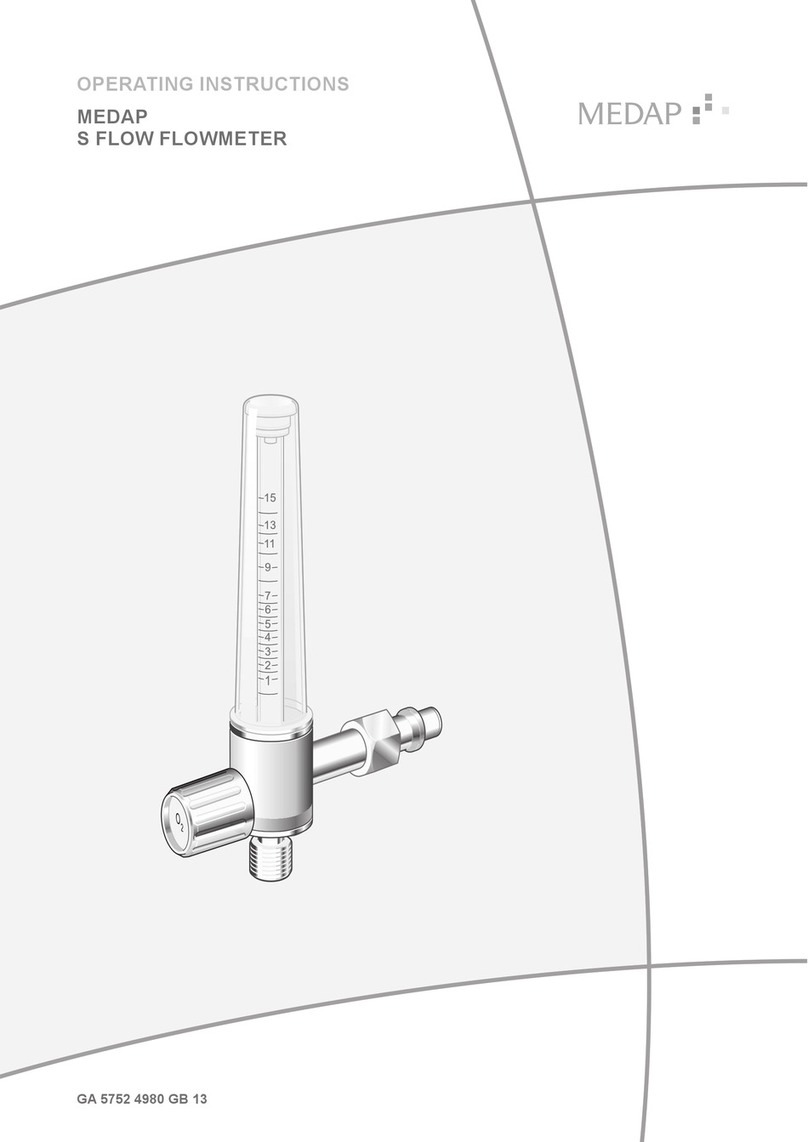

1.4 Overview of LS FLOW flowmeter............................................................................................................... 8

1.5 Basic requirements.....................................................................................................................................8

1.5.1 Use in accordance with the intended purpose ............................................................................. 8

1.5.2 Applicable standards.................................................................................................................... 9

1.5.3 Intended purpose ......................................................................................................................... 9

1.5.3.1 Possible applications ............................................................................................... 10

1.5.4 Versions of LS FLOW / LS DFLOW flowmeter .......................................................................... 10

1.5.5 Interface description................................................................................................................... 11

1.5.5.1 Approved interface for compressed gas supply ...................................................... 11

1.5.5.2 Flowmeter outlet ...................................................................................................... 11

1.5.5.3 Connection tube ...................................................................................................... 12

1.5.5.4 Tube adapter for Air and O2 .................................................................................... 12

2 Safety notes............................................................................................................................................13

2.1 General safety notes ................................................................................................................................ 13

2.2 Product safety notes.................................................................................................................................13

3 Initial operation.......................................................................................................................................15

3.1 Equipment inspection...............................................................................................................................15

3.2 Connection to the terminal unit.................................................................................................................15

3.2.1 General ...................................................................................................................................... 15

3.2.2 Version A.................................................................................................................................... 15

3.2.3 Version B.................................................................................................................................... 16

3.2.4 Version C ................................................................................................................................... 16

3.3 Mounting accessories...............................................................................................................................16

3.3.1 General ...................................................................................................................................... 16