Medclair MDU User manual

MDU - Mobile Destruction Unit

User’s manual

DU2100-M2 Revision: A5

2020-08-28

DU2100-M2 User’s manual –Revision: A5

2(14)

Content

1. General 3

1.1. Definition 3

1.2. Overview 3

1.3. Safety information 4

2. Installation, service & daily care 5

2.1. Installation 5

2.2. Service 5

2.3. Daily care 5

3. Product overview 6

3.1. Front 6

3.2. Back 7

3.3. Dimension sketch 7

4. Preparation, start and shut down 8

4.1. Preparation 8

4.2. Start of the MDU 8

4.3. Shut down 9

5. Summary of possible indications 10

5.1. Indications for operationel status 10

5.2. Indications for fault status 12

6. Environment and recycling 13

6.1. Terms of Use 13

6.2. Worn-out equipment 13

DU2100-M2 User’s manual –Revision: A5

3(14)

1. General

1.1. Definition

This document is a user’s manual for the mobile N2O destruction unit DU2100-M2.

For a technical overview see document ”Technical Brief DU2100-M2”.

When the acronym MDU is used within the document it refers to DU2100-M2.

1.2. Overview

The mobile unit MDU is a smart solution that can easily be moved anywhere where nitrous oxide is

needed for pain relief. This unit is a total solution for administrating nitrous oxide to the patient and

collecting residual nitrous oxide from exhaled air and destruct it. The MDU can easily be moved

between treatment rooms and is quiet, efficacious and reliable.

The mobile unit purifies more than 99 % of the nitrous oxide entering the unit. This facilitates a

healthy working environment for healthcare professionals and a minimal impact on the external

environment.

The MDU is specially adapted to suit the mobile needs of healthcare professionals allowing them to

use it in an easy and reliable manner. The unit accommodates a nitrous oxide cylinder (either pre-

mixed or concentrated) as well as an oxygen tube, and if needed an associated mixing unit (titration

unit. The latter is used to set different nitrous oxide concentrations, where varied treatment levels are

required.

The face mask with an accompanying tube for the administration of nitrous oxide is attached to the

unit, and a suction tube for exhalation is fitted using a standard connection to the MDU.

All required tubes, gas cylinders and valves are kept in the MDU, making it easy to transport as a

complete unit.

The MDU is constructed with few moving parts and components, which all have a high degree of

reliability and long product lifespan.

The MDU has an integrated control system that continuously monitors a number of parameters,

including temperature and gas flows, and stops automatically when overloaded. On delivery, the

device is already set up with an Ethernet connection for remote monitoring, and it is easy to connect a

modem to the unit for remote monitoring by MedClair’s technician.

DU2100-M2 User’s manual –Revision: A5

4(14)

1.3. Safety information

The user’s manual shall always be available for users.

MDU may only be used by trained personnel.

Nitrous concentration of up to 70 % is allowed to be connected to the unit.

MDU is designed to be used for pain treatment.

MDU shall not be placed within reach for the patient.

MDU is only allowed to be used in environments where concentration of VOC (volatile organic

compound), is below 100 ppm and the concentration of halogenated hydrocarbons of the type

other anaesthesia gases is below 1 ppm.

Only approved gas tubes can be connected to the MDU.

To avoid the possibility for foreign object to come into the unit the incoming air/nitrous ports

shall always be connected to an exhaust tube or protected with the provided rubber cap.

Air supply towards the MDU is never allowed to be closed, if this is done the MDU will trigger a

Malfunction alarm.

The MDU is designed for having two demand valves connected (one for nitrous and one for

oxygen).

If only one demand valve is used the buffer tube (delivered with the MDU) shall be connected to

the free gas inlet to avoid that the demand valve is opened because of the negative pressure

generated.

Inside the chassis there is a risk for lethal voltage.

The chassis may only be opened by authorized personnel..

The MDU shall be sorted as electronic waste. Included battery, placed on the

circuit board, shall be sorted separately.

Read the completet user’s manual before use!

DU2100-M2 User’s manual –Revision: A5

5(14)

2. Installation, service & daily care

2.1. Installation

As the MDU is an independent and movable unit there are no need for any installation. The unit is

ready for use after connection to 230V wall socket and applicable tubes for the N2O exhaust (and O2

exhaust when used).

2.2. Service

Contact Medclair in case of need for service.

During service a full check-up of the functionality as well as preventive actions like change of filter

and battery (if needed) will be performed.

2.3. Daily care

When needed the unit shall be cleaned using a light detergent.

DU2100-M2 User’s manual –Revision: A5

6(14)

3. Product overview

3.1. Front

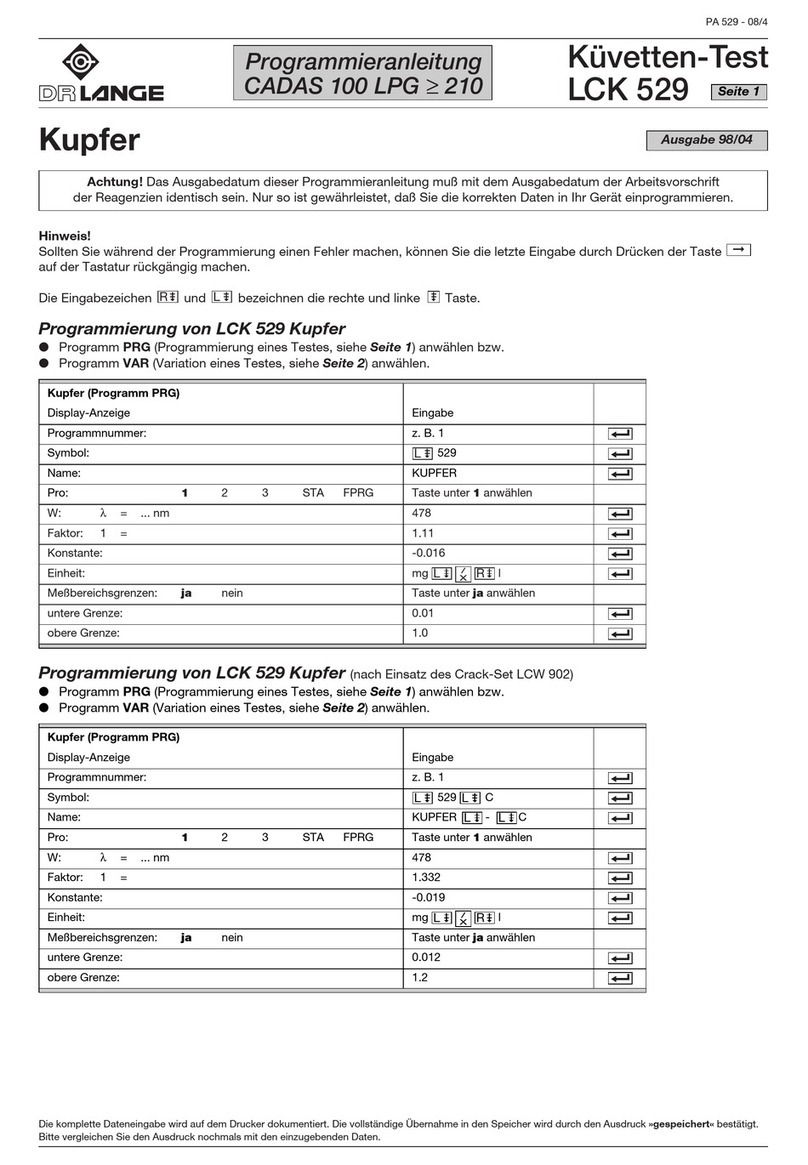

On the front there are two tube connection ports for exhaust air. Normally the exhaust air containing

N2O is connected to gas inlet #1 (blue) and exhaust air containing normal air only or O2to gas inlet

#2 (white). Technically there are no difference between the two ports since they are connected on the

inside. If only one port is used, the provided plug shall be connected to the port not used.

MDU is equipped with a handle and wheels to be easily moved (the front wheels are possible to lock

for a stable placement during treatment).

At the bottom of the unit there is an impact protection bumper to prohibit damages when hitting e.g. a

doorframe when moving the unit between wards.

Gas cylinders is placed at their intended place (Gas bottle stand) and shall be fixed with the flexible

bracket so they are securely anchored to the MDU. Different sizes of gas cylinders can be used.

MDU is provided with a washable operator panel with buttons for start (ON), stop (OFF), indications

for operating status and possible fault situations. See separate chapter in this manual for detailed

information of the use of the unit and explanation of the different indications on the panel.

Operator panel

Accessory attachments

Handle/

Protection rim

Flexible bracket

Gas bottle stand

Impact protection

Gas inlet #1

Gas inlet #2

Lockable wheel

DU2100-M2 User’s manual –Revision: A5

7(14)

3.2. Back

On the back there is a drawer where user manual, plug and other miscellaneous items can be placed.

At the bottom of the unit there is a particle filter where the purified air is let out, this filter is changed

at the yearly service. In addition there is a separate exhaust for the air from the cooling system.

3.3. Dimension sketch

Below is the dimensions of the MDU in mm.

Storage box

230 V electrical

connection

Underneath: emission

of cooled and cleaned

air

DU2100-M2 User’s manual –Revision: A5

8(14)

4. Preparation, start and shut down

4.1. Preparation

Use the handle to move the unit in position

Lock the wheels to avoid that the unit is unintentionally moved

Place the gas cylinder/cylinders on the unit and fix them to the unit with the straps

Connect exhaust tube/tubes to the unit (if only one tube is connected the connection not used

shall have the supplied rubber plug attached to avoid that foreign objects find its way in to the

unit).

NOTE: Demand valve, the MDU is designed for having two demand valves connected (one for

nitrous and one for oxygen).

If only one demand valve is used the buffer tube (delivered with the MDU) shall be connected to

the free gas inlet to avoid that the demand valve is opened because of the negative pressure

generated.

NOTE: When using the MDU together with a gas mixer there might be needed to connect an

exhaust tube to the free inlet, this tube will in this case act as a buffer.

Connect the unit to the wall socket 230 VAC.

The operator panel shall now indicate that the unit has electric connection, “Initiated” blinks

4.2. Start of the MDU

Press ”ON” button

”Initiated” is lit to indicate that the unit has started the heating phase (< 30 min)

”50%” is lit when the heating has reached half way (”Initiated” is turned off)

”READY” is lit when the unit is ready for use (”50%” is turned off)

NOTE: If the unit have been in operation recently there will be heat remaining in the unit and

therefore the indications ”50%” or ”READY” may be lit directly at start of the unit – this is the case

after a short move of a unit that have been in operation.

NOTE: The unit may never be started with caps on both its connections. “Malfunction” will in this

case be lit because of blockage of incoming air flow.

DU2100-M2 User’s manual –Revision: A5

9(14)

4.3. Shut down

Press “OFF” button

The unit now starts the cooling phase and the ”READY” indication will blink for one minute

”Initiated” will blink to indicate that the power cord can be disconnected

NOTE: The unit will continue cooling down after that the power is disconnected

NOTE: If the unit has been used for N2O treatment it shall be left running for 5 minutes after

completed treatment to empty the unit from N2O residuals.

DU2100-M2 User’s manual –Revision: A5

10(14)

5. Summary of possible indications

5.1. Indications for operationel status

Indication

Status/button pressed

Description

The unit is not connected to 230V

No indications

230V power connected to MDU

“Initiated”blinks with short

interval

”ON” button has been pressed and the

preheating phase has been started

”Initiated” is lit

DU2100-M2 User’s manual –Revision: A5

11(14)

Indication

Status/button pressed

Description

The unit has reached 50% of the

operating temperature

”50 %” is lit

The unit has reached the operating

temperature and MDU is now ready

for use

”READY” is lit

”OFF” button has been pressed and

the cooling down phase has been

started

”READY” blinks

The power connection can be

disconnected without disturbing the

cooling down phase

”Initiated” blinks with short

interval

DU2100-M2 User’s manual –Revision: A5

12(14)

5.2. Indications for fault status

MDU has a built-in control system to monitor temperatures and gas flows and the unit will stop

automatically in the case of problems.

Indication: ”Overheated” alternatively ”Malfunction” is indicated on the operator panel.

NOTE: Indication ”Malfunction” can be lit if caps are mounted on both the inlets due to blockage of

air flow.

If ”Overheated”is lit it means that too high temperature has been

reached within the catalytic reactor (this can happen when the unit has

been exposed with high load e.g. a concentration higher than 70%

nitrous has been connected to the unit).

The MDU will rectify this automatically i.e. heating will be stopped and

the MDU starts up again when the temperature has fallen below the

limit.

If the fault indication hasn’t disappeared after 30 minutes, contact

Medclair.

If ”Malfunction” is lit perform the following steps:

Step 1: Restart the unit by disconnecting the power cord.

Wait 15 minutes

Step 2: Connect the power cord

The indication should now show that power is connected by

a blinking ”Initiated” indication.

Step 3: Press ”ON”

The heating phase will now start.

If the fault indication remains, contact Medclair.

DU2100-M2 User’s manual –Revision: A5

13(14)

6. Environment and recycling

6.1. Terms of Use

MDU shall only be used in controlled inhouse environment with for the operation approved

ventilation.

6.2. Worn-out equipment

When worn-out the equipment will be taken back by MedClair for dismantling and then left for

recycling.

Battery, DU2100-M2 contains a lithium battery which shall be left for battery recycling.

Electric components, to be dismanteled and left as electronic waste

Catalytic mass, will be send back to the supplier for recovery of metal components

Mechanics, divided into platis and metall and then sent for recycling.

DU2100-M2 User’s manual –Revision: A5

14(14)

This manual suits for next models

1

Table of contents

Popular Laboratory Equipment manuals by other brands

Okolab

Okolab H301-OLYMPUS-IX3-SVR user manual

Koehler

Koehler K1798 Series Operation and instruction manual

Solaxx

Solaxx RetroJet troubleshooting guide

Master

Master MWC Series Installation and operation manual

Pfeiffer Vacuum

Pfeiffer Vacuum PRISMAPRO QMG 250 quick start guide

Hach

Hach sensION+ EC7 user manual

Hand Held Products

Hand Held Products IMAGETEAM 4200 quick start guide

socorex

socorex Acura electro 925 operating instructions

Leica

Leica CM3600 XP instruction manual

ADInstruments

ADInstruments PowerLab owner's manual

Metrohm

Metrohm 942 Extension Module Vario ChS-PP manual

strex

strex STB-1400-10 user manual