MEDICOP 1300008 User manual

WARRANTY

The product will operate correctly, if it will be used in

accordance with these instructions.

Manufacturer assures the service.

In case of troubles on product by normal use, manufacturer

assured, that troubles will be abolish in 45 days, starting

with day, when product will be taken in hand of

manufacturer. When repair will not be possible, user will

receive new product.

Parts of the product, which can be wear down by normal

use are not included under the warranty.

Warranty is valid, if the date of purchase, signature and

stamp of seller are documented.

If the product will be send back to manufacturer, it shall be

together with this warranty sheet.

The manufacturer is response for transport-costs by

warranty-procedure, if suitable documents are available.

If only one part of product will be replaced, new warranty

will be valid in full-duration only for that part.

In case, that a repair was done by not competent personnel,

the warranty will not be valid any more.

The Warranty is valid 1 year, starting with a date of

purchase.

Date of Production: Date of Sale:

Manufacturer: Sales Agent:

Serial Number:

01230123

Dear costumer,

We would like to thank you, that you are choosing our

product. It is recommended that it will be used in accordance

with these instructions for use.

The product has a marking:

The product is made and tested in accordance with following

European standards:

EN ISO 10524-1, DIN 477, BS 341, EN ISO 407 and MDD

93/42/EEC (annex I).

The product meets the requirements as regards hazard analysis

for medical instruments in accordance with standard ISO

14971.

Address of the manufacturer:

Medicop d.o.o.

Obrtna ulica 43

9000 Murska Sobota

Slovenija

tel:++386 (0)2 531 12 03, 526 82 22

fax: ++386 (0)2 531 17 26

www.medicop.eu

- July 2006 -

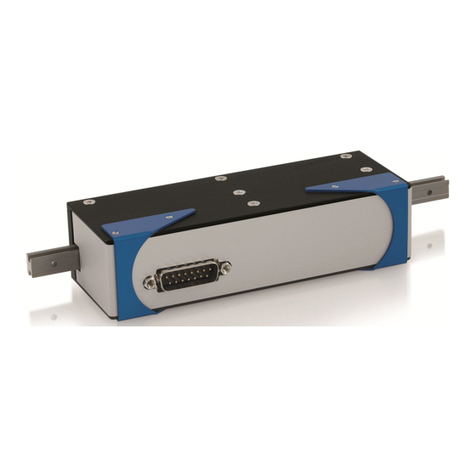

AGA CLUTCH

Setting up the gas flow:Hold the connector with

your hand and push it into the outlet as indicated by an

arrow until it stops and locks in the outlet.

Interruption of gas-flow: Push with one hand

upon the releasing ring of the outlet and pull the

connector from the outlet.

CONTROL SHEET

Name

Pressure reducer for medical gases

Mark.

Ser.No

No.

Description Of Repair

Date

Response

Replacing of the washer

1. Remove the washer by use an appropriate dry

and clean screwdriver.

2. Carefully place the new washer in to the seat.

Outlet connections

Accessory for tube

The tube shall be placed to the accessory and

fixed by clamp. The washer 11 shall be replaced

every 4 years.

Clutch for medical gas

Setting up the gas flow:Hold the connector

with your hand and push it into the outlet as

indicated by an arrow until it stops and locks in the

outlet.

Interruption of gas-flow: Push with one hand

upon the releasing ring of the outlet and pull the

connector from the outlet.

We recommend replacing the washer every 5 years.

Disassembling of the clutch:

1 –Remove the safety ring (1) from clutch casing (3a)

with an appropriate tool

2 –Unscrew clutch casing (3a) of the clutch casing

(3b). No tools are required.

3 –Remove plain washer (4) from it’s place with a

sharpen screwdriver

To assembly the clutch the reversible

procedure should be done.

1-Safety ring, 2-Releasing ring, 3a-Clutch casing, 3b-body of the clutch,

4-Plain washer, 5-valve, 6-spring

INSTRUCTIONS FOR USE

1. Description:

1.1 Purpose

The main purpose of pressure regulators is reducing high pressure of

gases in cylinders (to 20 000kPa = 200 bar) to an appropriate lower

working level (usually from 3 to 5 bar) which is used for various

medical and therapeutic devices.

1.2 Function

During use, the oxygen (medical gas) from the cylinder is entering through

the cylinder valve and connecting yoke 3into the casing of the regulator 4.

The pressure in the cylinder can be read on the manometer 1. Sinter filter

10 built into the connecting yoke remove the dirtiness from the cylinder.

Mechanism built into the casing of the regulator 4is reducing the inlet

pressure to the working pressure which can be constant or adjustable from

0,5 to 5 bar append from the type of the regulator. Each pressure regulator

is equipped with a manometer that shows the current pressure in the

cylinder, a connecting yoke for a cylinder, a safety valve 5and an outlet

accessory.

1.3 Models of pressure regulators

1300008 –Pressure regulator with direct outlet-flow

Pressure regulator is made as one-stage

regulator. The regulator reduces inlet pressure

(10-200 bar) to the outlet pressure 5+0.5 bar.

The pressure regulators are different regarding

of the type of the connecting yoke and outlet

connection.

This pressure reducer can be used for O2, Air,

CO2

1300009 –Pressure regulator with direct outlet-flow and non-return valve

Pressure regulator is made as one-stage

regulator. The regulator reduces inlet pressure

(10-200 bar) to the outlet pressure 5+0.5 bar.

The none return valve built into the outlet

connection prevent the back flow.

The pressure regulators are different regarding

of the type of the connecting yoke.

This pressure reducer can be used for O2, Air,

CO2

7. Maintenance

On the pressure reducer must be carried out follow maintenance work:

PRESCRIBED CONTROL:

No.

Description

Ident. Nr.

Period

1

Manometer 0 to 315bar

1052140

1 year

2.1

Flow meter 0 to 15 l/min

1052102

1 year

2.2

Manometer 0 to 15 bar

1052108

1 year

Technical Inspection

1 years

after every work

3

Complete service kit replacement by Medicop

5 years

PRESCRIBED REPLACEMENT:

No.

Description

Ident. Nr.

Period

10

Sinter filter DIN connector yoke

1052015

1 year

10

Sinter filter BS connector yoke

1052015

1 year

10

Sinter filter PIN-INDEX connector yoke

1052064

1 year

Washer DIN connector yoke, Ø10.78x2.62

1052026

1 year

Washer BS connector yoke, Ø10.78x2.62

1052026

1 year

Washer PIN-INDEX connector yoke, Ø16/Ø6,5

1052052

1 year

Replacing of the sinter filter

1. With an appropriate screwdriver unscrew

the sinter filter by turning it to the left.

2. During the procedure it is recommended

the pressure regulator is turned up side-

down, so that dirtiness can not enter into

the regulator when it is without filter.

3. Fix the new sinter filter by turning it with a

screwdriver to the right.

Checking the system for leaks

1. Close the system behind the pressure

reducer by switching off devices

connected to the pressure reducer.

2. Check if the connection is tightly

attached. If necessary tight them by

hands only.

3. Open slowly the cylinder valve. The

pressure in the cylinder can be read on

the manometer 1.

4. Close the shut-off valve of the cylinder.

5. Observe the needle of the manometer

app. 1 minute. If the needle is staying

constant the system is free from

leakage. And if the needle falls the

system has a leakage.

Prepare of the leakages

1. Prepare a soapy solution using unparfumed soap.

With the soapy solution wet the screwed unions. At the leakages

bubbles will be form.

2. Perform decompression of the system by turning on and than off

the pressure reducer or device connected to the pressure

reducer. Exchange the faulty seals at the leaks.

3. Check the system for leaks again.

If the leaks can not be tightened up the unit must be repaired.

1300001 –Pressure regulator with adjustable outlet flow

1300030 –Pressure regulator with adjustable outlet pressure

Pressure regulator is made as two-stage

regulator. In the first stage the inlet pressure

(200 bar) is reduced to app. 15 bar and in the

second stage the pressure can be adjustable

from 0 to max 5 bar (1300030) or 0-15l/min

(1300001).

The valve is equipped with two manometers.

First manometer 1 shows the pressure in the

cylinder. The second flow meter 2.1 shows the

adjusted outlet flow or manometer 2.2 adjusted

outlet pressure.

The outlet-flow or outlet-pressure could be

adjusted by screw 6.

The pressure regulators are different regarding

of the type of the connecting yoke and outlet

connection.

This pressure reducer can be used for O2, Air,

CO2

1300007 –Pressure regulator with fixed outlet-flow

The regulator is designed as two-step reducer.

First reduction is done from max. 200 bar to 10

bar and the second reduction from 10 bar to 5

bar. The outlet pressure could be also adjusted

from 0 to 5.5 bar, but only by the manufacturer.

The outlet flow is fixed at 4 l/min.

The pressure regulators are different regarding

of the type of the connecting yoke.

This pressure reducer can be used for O2, Air,

CO2

1300011, 1300018 –Pressure regulator with stepwise adjustable outlet-flow

Pressure regulator is made as one-stage

regulator. The regulator reduces inlet pressure

(10-200 bar) to the outlet pressure 5+0.5 bar.

Manometer 1 shows the pressure in the cylinder

Pressure regulator makes it possible to set

different outlet flows by turning of the

regulating screw 6. Flow setting is indicated on

the scale 7. You can simultaneously use the

direct fixed outlet flow and different stepwise

adjusted outlet flow.

The pressure regulators are different regarding

of the type of the connecting yoke and outlet

connection.

This pressure reducer can be used for O2, Air,

CO2

1.4 Technical Data

Model

1300008

(standard)

1300009

(standard)

1300001

(standard)

1300030

(standard)

1300007

(standard)

1300011,

1300018

(standard)

Description

Middle dimensions in

mm

100x100x110 mm

Connecting yoke

(DIN 477), PIN-INDEX, BS (341),

or other specific connections

Middle weight in kg

0,8

Inlet pressure

200

Outlet working pressure

5±0,5

5±0,5

-

0-5

-

5±0,5

Flow at the working

pressure l/min

120*

120*

0-15

-

4

0-25

0-15

Safety valve set

pressure in bar

7,5

7,5

7,5

7,5

7,5

7,5

Temperature:

- operation

- storage

-20°C to + 60°C

-20°C to + 70°C

Classification

IIb

Standard

EN 738-1

*at 150 bar

4.5 Storage

In case that the device is not in use we recommend followed:

1. Clean up the device (»Cleaning«)

2. Pressure regulator shall be store in the dry place

5. Cleaning

The pressure regulator shall be dry cleaned only.

No liquid must be entered in to the pressure reducer.

Parts which are in contact with oxygen are prohibited to cleaning

with liquids.

6. Troubleshooting

Fault

Cause

Mending

Leakage on the connecting

yoke

Damaged sealing

Replace sealing

Leakage on the outlet

accessory

Damaged sealing

Replace sealing

Leakage at safety valve

Prohibited pressure

increase in the

pressure reducer

Repair by manufacturer

or trained authorized

person only.

Mechanical damage

(manometer, sealing

surface, surface damages)

4.3 Adjusting of the outlet flow

1300008, 1300009, 1300007 –

Pressure regulator with direct

outlet-flow

Outlet flow is fixed and can not be

changed.

1300001 –Pressure regulator with

adjustable outlet flow

The outlet flow can be adjusted by

regulating screw 6.

The flowmeter 2.1 indicated the adjusted

outlet flow 0- 15l/min.

1300011 (0-25), 1300018 (0-15) –

Pressure regulator with stepwise

adjustable outlet-flow

Direct flow at the outlet 8is fixed.

The flow at the outlet 9can be set by

regulating screw 6. Adjusted value is

indicated on the scale 7. Outlet flow

(stepwise):

0,1,2,3,4,5,6,7,10,15

or

0,1,2,3,4,7,10,15,20,25 l/min

4.4 After operation

1. Don’t ever let to get the cylinder completely empty because the

ambient air can be entering in to the cylinder and causing

corrosion.

2. On the manometer of the pressure reducer check the remaining capacity

of gas. You should change the cylinder when the pressure drops app.

below 50bar.

3. Shut down the cylinder valve.

Set the flow and the pressure at the pressure regulators with adjustable

outlet flow and adjustable outlet pressure to „0“.

2. Warnings

!

The oiling of the regulator parts is strongly prohibited!

Don’t ever let to get the cylinder completely empty but it

should be refilled when there is still app. 10-50 bar of

pressure inside!

At the operating with pressure regulator pay attention to

cleanness of your hands, tools and environment!

The shut-off valve of the cylinder shall be closed and

opened slowly, because there is the danger of the

pressure push.

The settings of the safety valve shall not be changed!

The shut-off valve of the cylinder shall be closed after the

use!

The cylinder shall be insured against overthrowing!

Smoking and use of the open fire nearby the unit is

strongly prohibited!

Before use read also the enclosed user manuals, and

user manuals of the devices supplied to the pressure

regulator!

Maintenance works shall be carried out by trained

person only!

Never use tools to tighten or unscrew the connecting

yoke!

Before use and maintenance wash your hand toughly!

Screwed unions shall be tightened by hands only.

3. Preparing for operating

3.1 Connecting of the pressure regulator to the gas

cylinder

To blow away the particles of dirtiness briefly open the valve of the cylinder

and then tight it again.

At the procedure the outlet of the cylinder valve shall be pointed to the floor

so that the particles do not get in to the eye or not cause other damage. The

oxygen shall not get in to the clothing.

1. Pressure reducer shall be screwed and tightened to the cylinder by

coupling nut without any tools.

2. Open the cylinder valve by one slowly turns of the cylinder valve to the

left. The pressure in the cylinder is indicated on the manometer 1.

Pressure reducer with

coupling nut

Pressure regulator with PIN

INDEX connecting yoke

By coupling of the

regulator with PIN-

INDEX yoke to the

make sure that the

pins of the yoke are

correctly inserted in to

the cylinder valve.

3.2 Removing of the pressure reducer

1. Shut the cylinder valve by turning the cylinder valve to the right.

2. Perform decompression of the system by turning on and than off

the pressure reducer or device connected to the pressure reducer.

If the reducer is under the pressure it is impossible to remove

them.

3. Unscrew the coupling yoke from the cylinder valve.

4. Operating

4.1 Start operating

By one slowly turn open the cylinder valve. Gas supply is established.

Manometer indicated the pressure in the cylinder.

4.2 Adjusting of the outlet pressure

1300030 –Pressure regulator

with adjustable outlet pressure

The outlet pressure can be adjusted

with regulating screw 6. The

manometer 2.2 indicated the adjusted

pressure.

This manual suits for next models

1

Table of contents