Medisafe SI PCF User manual

SI PCF

User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 2 of 81

Intentionally blank

Table of Contents SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 3 of 81

Table of Contents

1. INTRODUCTION ............................................................................................................................................ 7

Medisafe Contact Details......................................................................................................................... 8

Independent Monitoring.......................................................................................................................... 9

Memorandum of Registration ............................................................................................................... 10

SI PCF Warranty Registration................................................................................................................. 11

Safety Precautions ................................................................................................................................. 13

Training Personnel ................................................................................................................................. 16

Compliance ............................................................................................................................................ 17

Product Identity ..................................................................................................................................... 17

Manufacturer Information..................................................................................................................... 17

Intended Use........................................................................................................................................ 18

Performance ........................................................................................................................................ 18

Cycle Record......................................................................................................................................... 18

Cycle Failure ......................................................................................................................................... 18

Concept Summary................................................................................................................................ 18

General Safety...................................................................................................................................... 19

Chemicals ....................................................................................................................................................... 19

Decontamination ........................................................................................................................................... 19

Heat................................................................................................................................................................ 19

Electrical Safety.................................................................................................................................... 19

Service Contracts & Warranty.............................................................................................................. 19

Validation Option................................................................................................................................. 19

2. INSTALLATION ............................................................................................................................................ 21

Transport and Storage ........................................................................................................................... 22

Marking............................................................................................................................................................ 22

Environmental.................................................................................................................................................. 22

Lifting ..................................................................................................................................................... 22

Unpacking .............................................................................................................................................. 22

Returns................................................................................................................................................... 22

Enclosures Check List ............................................................................................................................. 23

Standard PCF S ................................................................................................................................................. 23

Robotic PCF S ................................................................................................................................................... 23

Standard Accessory Kit (MP21424).................................................................................................................. 24

Additional Accessories ........................................................................................................................... 25

Baskets ............................................................................................................................................................. 25

Printer .............................................................................................................................................................. 25

Approved Chemicals ........................................................................................................................................ 25

Installation Requirements...................................................................................................................... 26

Connecting the SI PCF ............................................................................................................................ 28

Installation Drawings............................................................................................................................. 29

Front View........................................................................................................................................................ 29

Rear View Showing Services............................................................................................................................. 30

Right Side View Lid Closed ............................................................................................................................... 31

Right Side View Lid Open ................................................................................................................................. 32

Rear View Alternative Drain Connection ......................................................................................................... 33

Right Side View Alternative Drain Connection ................................................................................................. 34

CONNECTING TO THE RS232 PORT........................................................................................................................... 35

Table of Contents SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 4 of 81

Thermal Printer.................................................................................................................................... 35

Data Logging PC................................................................................................................................... 35

3. OPERATION ................................................................................................................................................ 37

Menu...................................................................................................................................................... 38

Power Up ............................................................................................................................................... 39

Authorisation code................................................................................................................................. 39

Setting Time & Date............................................................................................................................... 39

Set Time ........................................................................................................................................................... 39

Set Date............................................................................................................................................................ 39

Selecting a program............................................................................................................................... 40

Standard Program Parameters......................................................................................................................... 40

Robotic Program Parameters........................................................................................................................... 41

Chemical Handling ................................................................................................................................. 42

Chemical Consumption .................................................................................................................................... 43

Chemical Replacement .................................................................................................................................... 43

Disposal of chemical containers....................................................................................................................... 43

Chemical Priming ............................................................................................................................................. 43

Baskets................................................................................................................................................... 44

Basket Removal................................................................................................................................................ 44

Basket Insertion ............................................................................................................................................... 44

Instruments............................................................................................................................................ 44

Instrument Loading Precautions ...................................................................................................................... 44

Starting a Standard Instrument Cycle.................................................................................................... 45

Starting a Robotic Instrument Cycle .................................................................................................... 46

Manual Pre Wash........................................................................................................................................... 46

Instrument Loading ........................................................................................................................................ 46

Automated Wash Cycle........................................................................................................................ 48

Cycle Process.................................................................................................................................................. 48

Pre-wash ........................................................................................................................................................ 49

Wash .............................................................................................................................................................. 49

Rinse............................................................................................................................................................... 50

Final Rinse/Disinfection ................................................................................................................................. 50

Cooling ........................................................................................................................................................... 51

Cycle Complete .............................................................................................................................................. 51

Unload............................................................................................................................................................ 51

Robotic Instrument Preparation .................................................................................................................... 51

Re-Wash Cycle ............................................................................................................................................. 52

Cycle Errors .......................................................................................................................................... 53

Aborting a Cycle................................................................................................................................... 53

Downloading the Cycle Log.................................................................................................................. 54

Download Logs............................................................................................................................................... 54

Routine Maintenance........................................................................................................................... 55

Before Every Cycle ......................................................................................................................................... 56

Daily Checks ................................................................................................................................................... 56

Weekly checks................................................................................................................................................ 56

Decontamination Guide....................................................................................................................... 57

Daily Cleaning/ Procedure.............................................................................................................................. 57

Full Decontamination..................................................................................................................................... 57

Pre Transport Procedure................................................................................................................................ 57

Decontamination Certificate.......................................................................................................................... 58

4. TROUBLESHOOTING ................................................................................................................................... 59

Table of Contents SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 5 of 81

Error Messages ...................................................................................................................................... 60

Other Faults ........................................................................................................................................... 62

5. TECHNICAL ................................................................................................................................................. 65

General Specifications............................................................................................................................ 66

Applied Standards.................................................................................................................................. 70

6. APPENDICES ............................................................................................................................................... 71

EMC .................................................................................................................................................................. 72

EMC & Electromagnetic Compatibility Data.......................................................................................... 72

Electromagnetic Emissions .................................................................................................................... 73

Electromagnetic Immunity..................................................................................................................... 74

Separation Distances Between SI PCF and Mobile RF Equipment.......................................................... 76

Warranty................................................................................................................................................ 77

Service Record........................................................................................................................................ 78

Operator PIN Number Codes.................................................................................................................. 79

Symbols Glossary ................................................................................................................................... 81

Table of Contents SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 6 of 81

Intentionally blank

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 7 of 81

1. Introduction

1. Introduction

User Manual

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 8 of 81

Medisafe Contact Details

United Kingdom

(Manufacturing, Sales, Customer Service & Technical Support)

Medisafe UK Ltd

Unit 1 Twyford Industrial Estate

Twyford Road

Bishop’s Stortford

Hertfordshire CM23 3LJ

England

Tel: +44 (0) 1279 461641

Fax: +44 (0) 1279 461643

E-mail [email protected]om

www.medisafeinternational.com

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 9 of 81

Introduction

Important

Read this entire manual before attempting to install, operate or perform any

maintenance on the Sonic Irrigator Parametric Controlled Flow (SI PCF) Ultrasonic

Cleaning System. Ensure all appropriate personnel understand the contents of this

manual.

This Operating Manual contains important information on proper use and maintenance of the SI PCF

Ultrasonic Cleaning System. All personnel involved in the use and maintenance of this equipment

must carefully review and comply with the warnings, cautions and instructions contained in this

manual. These instructions are important to protect the health and safety of personnel operating the

Ultrasonic Cleaning System and should be retained in a conveniently accessible area for quick

reference.

Advisory

A listing of the Safety Precautions to be observed when operating the SI PCF Ultrasonic Cleaning

System is found in Section 1-5 of this manual. Do not operate the equipment until you have become

familiar with this information.

Independent Monitoring

Important Note for the Product Owner

It is advised that an independent monitoring system is fitted in accordance with ISO 15883-1:2009 -

Washer-disinfectors.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 10 of 81

Memorandum of Registration

Important

The person undertaking the installation must complete this Memorandum of Registration. In the event

of a Warranty Claim, the information contained within this Registration is your evidence that the

product has been correctly installed.

Important Note for the Installer

This Memorandum of Registration MUST be completed by the person undertaking installation and

witnessed by the owner of the product. For installation instructions and contact information for

qualified personnel who can perform the installation, please contact Medisafe (see section 1-1).

Failure to provide this evidence in the event of a warranty claim may result in the claim being rejected

(this does not affect your statutory rights as a customer).

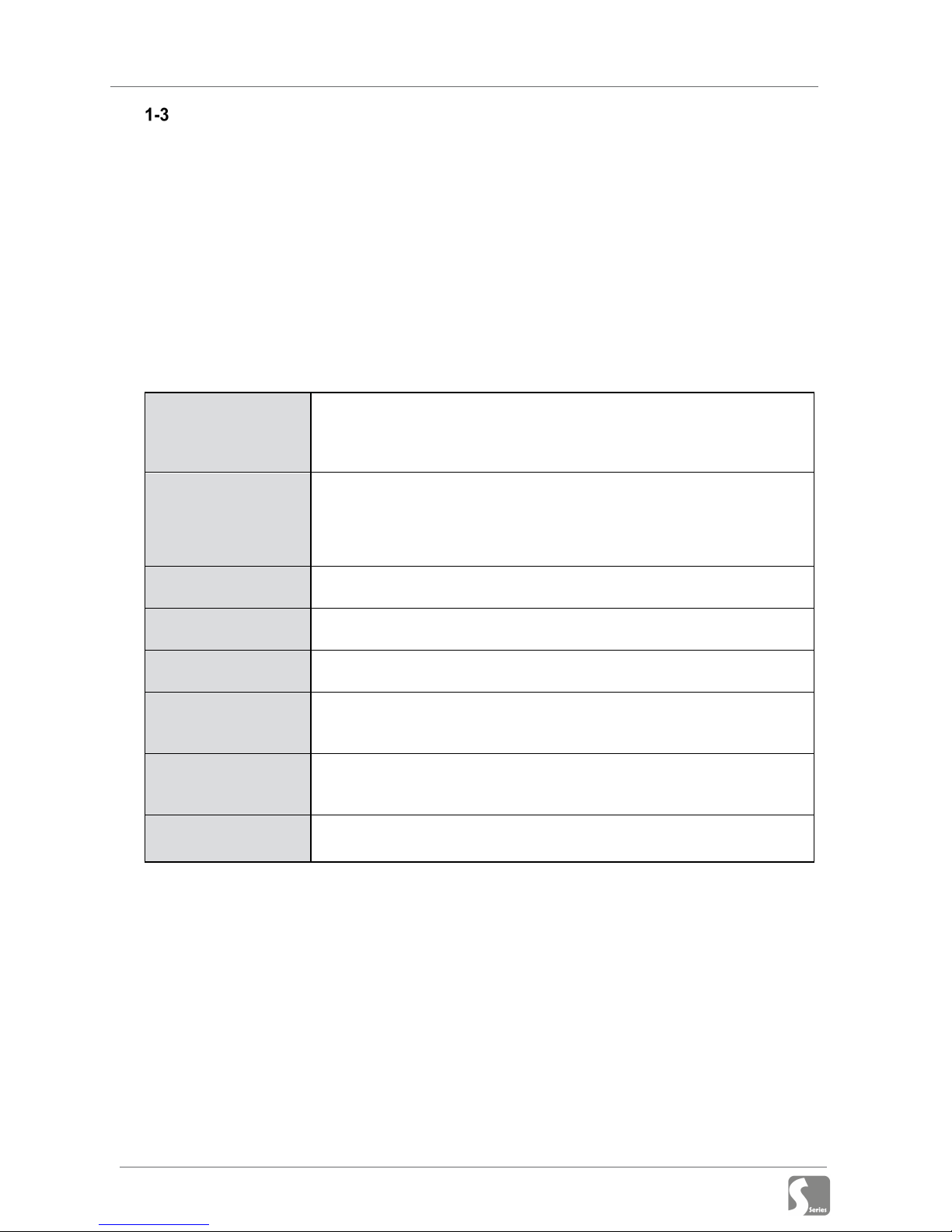

Owner Name:

Installation Address:

Installation Date:

Model No.:

Serial No.:

Software Version:

Installed by:

Witnessed by:

Service and Maintenance Requirements

The SI PCF should be serviced on a regular basis to ensure that the product continues to perform in

accordance with its design parameter, see section 6-7 for more information.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 11 of 81

SI PCF Warranty Registration

Important Note for the Installer

This Registration Form MUST be completed by the person undertaking installation and witnessed by

the owner of the product. In the event of a Warranty Claim, the information contained within this

Registration is your evidence that the product has been correctly installed. Failure to provide this

evidence in the event of a warranty claim may result in the claim being rejected (this does not affect

your statutory rights as a customer). A copy of this form must be sent to your local Medisafe

authorised distributor to validate the warranty.

Tests parts one and two must be completed by the engineer commissioning the SI PCF for warranty

registration purposes. Where no value is required write pass or fail with a comment if necessary.

For installation instructions and contact information for qualified personnel who can perform the

installation, please contact Medisafe (see section 1-1).

Owner Name:

Installation Address:

Installation Date:

Model No:

Serial No:

Software Version:

Installed by:

Witnessed by:

Position:

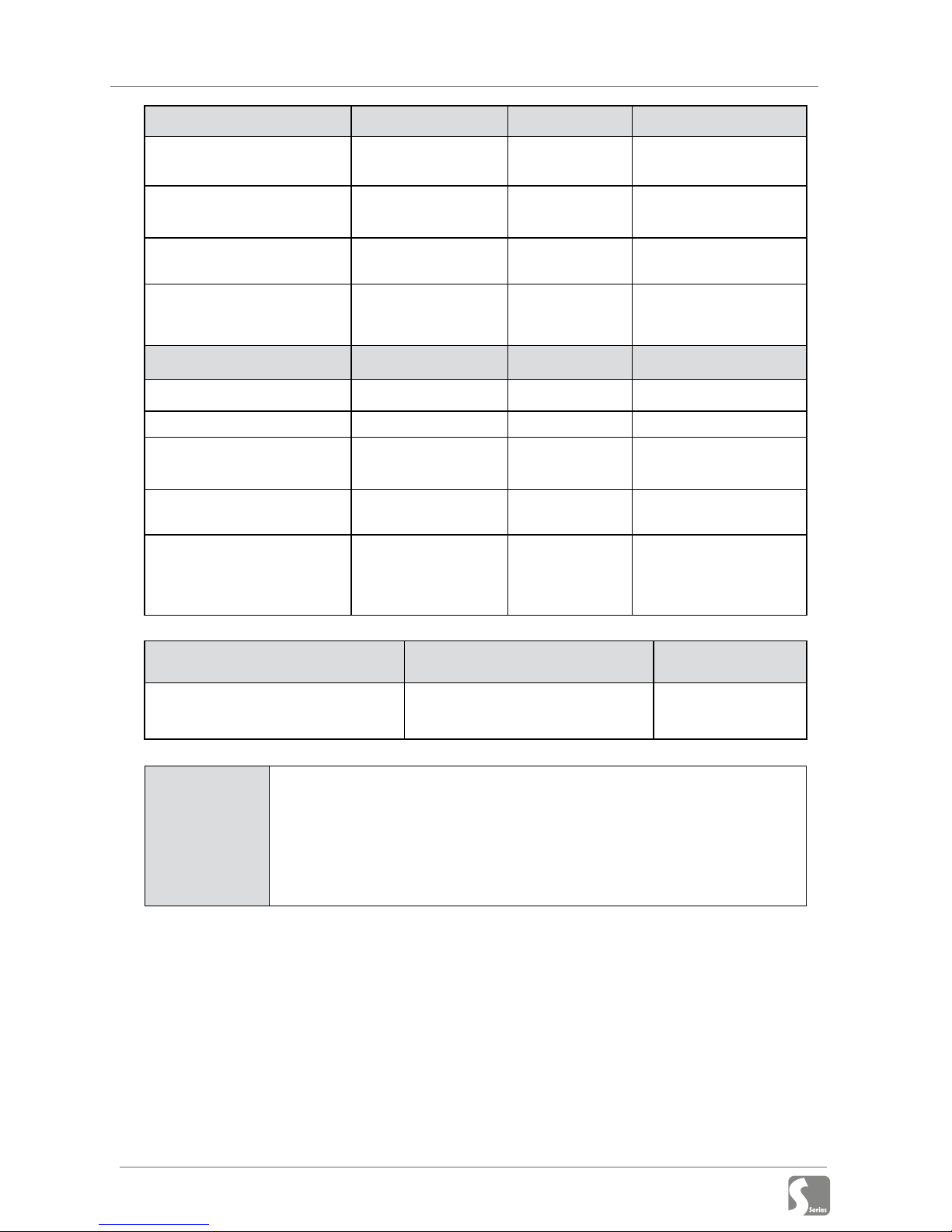

Part 1, Test Type Acceptable Value Result Comments

Drains remove effluent effectively

-

Phase sequence, Pump Rotation -

Support bases secure -

There is no evidence of

interference to or from other

equipment connected to the

same services

-

Hot Water Hardness (As

specified by WD Manufacturer) 125 ppm (max)

Cold Water Hardness (As

specified by WD Manufacturer) 125 ppm (max)

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 12 of 81

Part 1, Test Type Acceptable Value Result Comments

Hot Water Temperature 50°C (122°F) min

80°C (176°F) max

Cold Water Temperature 5°C (41°F) min

30°C (86°F) max

Hot Water Pressure

2 - 5 bar

(30 – 70 psi)

Cold Water Pressure

2 – 5 bar

(30 - 70 psi)

Part 2, Final rinse water Acceptable Value Result Comments

Rinse water supply Type RO, DI, Softened

If softened, Hardness < 125 ppm

Water Pressure

2 – 5 bar

(30 – 70 psi)

Temperature 5°C (41°F) min

80°C (176°F) max

Electrical conductivity

<30µS/cm (RO)

<10µS/cm (DI)

<300µS/cm (Soft)

Signed Name Date

Comments /

remedial work

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 13 of 81

Safety Precautions

The following Safety Precautions must be observed when operating or servicing the SI PCF.

WARNING indicates the potential for personal injury and CAUTION indicates the potential for damage

to equipment. For emphasis, certain Safety Precautions are repeated throughout the manual. It is

important to review ALL Safety Precautions before operating or servicing the unit.

Warning – Breathing Hazard

Some cleaning solutions emit harmful vapours. Only use cleaning solutions in well-

ventilated areas. Do not inhale vapours. Do not permit solution vapours to exceed

maximum allowable concentrations in the work area. Ensure adequate ventilation.

Warning – Chemical Burn and/or Eye Injury Hazard

•Detergents are caustic and can cause adverse effects to exposed tissues. Do

not get in eyes, on skin or attempt to ingest by mouth.

•Read and follow precautions and instructions on detergent label and in the

Material Safety Data Sheet (MSDS) prior to handling chemical, refilling chemical

containers or servicing chemical injection pumps and lines.

•Wear appropriate Personal Protective Equipment (PPE) whenever handling

chemicals or servicing chemical injection pumps and lines. This should include

plastic gloves, goggles or full-face visor, and disposable plastic apron.

•Wear appropriate Personal Protective Equipment (PPE) whenever removing

baskets or parts from cleaning chamber.

•In case of body contact with chemical, always follow emergency procedure given

in that chemical’s MSDS or call emergency services.

•Use a funnel when transferring any chemical from one container to another.

Warning – Burn Hazard

•

Since temperatures within the unit can reach 92°C (198°F) during and after

operation, take care when opening lid at the end of a cycle. Allow sufficient time

for items to cool before handling, cleaning or maintenance procedures.

•Wear appropriate Personal Protective Equipment (PPE) whenever reaching into

Chamber after a thermal disinfection operation.

•Under no circumstances attempt to forcibly open the lid during operation.

•During reloading of instruments in the re-wash program the water temperature

within the unit can reach 60°C (140°F), take care when opening lid and

reloading the instruments.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 14 of 81

Warning – Explosion Hazard

Use only water or water-detergent mix in cleaning chamber. Never use

flammable or combustible cleaning liquids. Fire or explosion could result.

Warning – Electric Shock Hazard

•

To prevent the risk of fire or electric shock, do not expose equipment to

unnecessary moisture. Always ensure that all external surfaces are dried after

each cycle.

•When removing a basket, allow to drain into the chamber before moving to the

next cleaning station. Excess water spillage may cause electrical shock and

serious injury.

•Since dangerous high voltages are present inside the unit, keep

the left

cabinet door closed and locked at all times.

•Disconnect all utilities to unit before servicing. Do not service unit unless all

utilities have been properly locked out. Always follow local occupational health

and safety regulations, as well as electric and plumbing codes.

•

Isolate electrical supply by turning the buildings disconnect switch to OFF

before checking or replacing any parts. Electrical shock can cause serious

injury.

Warning – Slipping Hazard

To avoid slippery floor conditions,

immediately wipe up any spilled liquid or

condensation. If spills or leaks could contain detergents or other chemicals,

follow safety precautions and handling procedures set forth on detergen

t or

chemical label and/or MSDS.

Warning – Personal Injury and/or Equipment Damage Hazard

•Only Medisafe or Medisafe-trained service personnel must make repairs and

adjustments to this equipment

. Maintenance performed by unqualified

personnel or installation of unauthorized parts could cause personal injury,

result in improper equipment performance, invalidate the warranty, or result in

costly damage. Contact Medisafe regarding service options.

•

Regularly scheduled preventive maintenance, in addition to the faithful

performance of routine maintenance described within the service manual, is

required for safe and reliable operation of this equipment. Contact Medisafe to

schedule preventive maintenance.

•Failure to perform periodic service inspections of the machine could result in

serious personal injury or equipment damage.

•Do not wear loose fitting clothing, neckties or jewellery that could become

entangled in moving parts.

•Never reach into a chamber when unit is in operation.

•Always use a basket to reprocess instruments within the unit.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 15 of 81

Caution – Possible Equipment Damage

Caution

•Never place items or person(s) on the lid.

•Do not drop items into the wash tank as this could damage the ultrasonic

transducers.

•Do not place items directly into the wash tank or allow them to make contact

with the tank sides.

•Never scratch chamber walls. This can increase cavitation erosion.

•Do not load basket with instruments pointing at the lid.

•Do not overload the basket, maximum load of 10kg (22lbs).

•Do not allow Luer pipes to protrude from the basket.

•When

choosing a detergent, select one with a low chloride content.

Detergents with a high chloride content can be harmful to stainless steel.

•Repeated fuse blows or circuit breaker trips indicate a short circuit or overload.

Have a fully trained technician locate and correct situation.

•Use nonabrasive cleaners when cleaning unit. Follow directions on container

and rub in a back-

and forth motion, in same direction as surface grain.

Abrasive cleaners damage stainless steel. Cleaner rubbed in a circular motion

or applied with a wire brush or steel wool will scratch and dull stainless steel.

•Avoid running equipment into the Control Panel or Touch Screen to prevent

damage to controls.

Caution – Chemical

Caution

•

Chemical bottles must be connected to the correct port. Otherwise, wash

efficiency and/or rinsing will be compromised.

•Check chemical bottles are in date before use

Caution – Instrument Care

Caution

•Always confirm compatibility with the instrument manufacturer.

•Always follow the manufacturer’s instructions if processing instruments with

special characteristics e.g. fibre optics or rigid optics.

•Whether pre or post processing instruments, always follow the manufacturer’s

instructions.

•Always attach tubing to a suitable size distal connector for instruments being

cleaned or to a quick connect port if the instrument has one.

•Always open box jointed instruments.

•Always ensure taps are open on cannulated instruments.

•Always dissemble instruments that are designed to be taken apart.

•Always attach at least one Luer pipe to each basket manifold if cannulated

instruments are not being cleaned, this will aid water circulation.

•Visually inspect instruments after reprocessing

•I

f any instruments became detached from the Medisafe connection tubing

during processing, they should be reprocessed after ensuring that the Luer

connection is firmly seated.

•Do not connect more than ten instruments to the Si Robotic Basket as this will

reduce the water pressure and compromise effective cleaning.

•Do not connect more than six instruments to the Xi Robotic Basket as this will

reduce the water pressure and compromise effective cleaning.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 16 of 81

Training Personnel

The owner of this equipment has the responsibility for training the users and keeping the appropriate

records.

There should be regular training of all personnel concerned with the operation and

maintenance of the equipment. The training schedule shall include:

•Operation of the machine (see section 2-10, 3-1, 3-4-1, 3-4-2, 3-5, 3-7, 3-8, 3-9, 3-10

and 3-11).

•Safe use of machine (see section 1-5)

•Chemical handing (see section 3-6)

•Emergency Procedures e.g. how to handle the load in case of aborted cycle (see

section 3-12 and 3-13)

•Regular maintenance procedures (see section 3-15 and 3-16)

•Troubleshooting (see section 4)

The following table can be used for keeping training records.

Date Name Title of Training Signature of Trainer

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 17 of 81

Compliance

The SI PCF has been designed to perform

within the guidelines recommended by

international decontamination Standards. A

stringent quality control program ensures that

every unit is manufactured and tested under

controlled conditions to ensure that all

products perform identically.

Commitment to RoHS and WEEE

Requirements

Medisafe is committed to meeting or

exceeding the requirements of the RoHS CE

Marking directive (2011/65/EC) (Restriction of

the Use of Certain Hazardous Substances in

Electrical and Electronic Equipment).

Medisafe is also committed to meeting all

requirements of the WEEE directive

(2012/16/EU) (Waste Electrical and Electronic

Equipment).

WEEE and Battery Disposal

Waste electrical and electronic

products must not be placed in the

general refuse but collected

separately. Separately collected

WEEE products are to be sent to an approved

recycling or disposal operators for safe

recycling, recovery or reuse.

Medisafe UK Ltd is registered with the "B2B

Compliance" Scheme. B2B Compliance on

behalf of Medisafe, takes on the legal

responsibilities of the reporting, collection and

treatment of, all WEEE that Medisafe UK Ltd is

obligated for - and ensures that the

appropriate recycling targets are met. .For

independent confirmation of Medisafe UK Ltd

status can call B2B Compliance on 0845 680

9829 or visit www.b2bcompliance.org.uk.

To fulfil our B2B WEEE take-back obligations,

B2B Compliance will undertake the

appropriate collection and disposal of

obligated products of Medisafe UK Ltd.

If a Medisafe Product has reached its end of

life, please contact B2B Compliance

collections team on 0845 680 9829 or

collections@b2bcompliance.org.uk to arrange

collection and treatment.

Otherwise, please recycle where facilities

exist. Check with your Local Authority or

Distributor for recycling advice.

Declaration of CE Conformity

The SI PCF is designed and manufactured in

the UK by Medisafe UK Ltd. and complies with

the essential requirements of the Medical

Devices Directive 93/42/ EEC (where

appropriate). All products are CE compliant

and are registered as Class IIb devices

through the application of rule 15 within Annex

IX of the Medical Devices Directive 93/42/

EEC.

Product Identity

The model and serial number label are located

on the inside panel of the chemical

compartment.

Example of serial number label:

The software version is shown on the front

panel display when the unit is first switched on.

Manufacturer Information

Medisafe UK Ltd

Unit 1 Twyford Industrial Estate

Twyford Road

Bishop’s Stortford

Hertfordshire CM23 3LJ

England

Tel.: +44 (0) 1279 461641

Fax: +44 (0) 1279 461643

E-mail info@medisafeinternational.com

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 18 of 81

Intended Use

The Medisafe Sonic Irrigator PCF is a High-

Pressure, Ultrasonic, Flushing Washer

Disinfector for the medical market. It is

intended to provide cleaning and low-level

thermal disinfection of surgical instruments,

including complex lumen/cannulated devices,

such as robotic surgical instruments.

This is achieved through a combination of

ultrasonics and a flushing action to remove

debris from both the outside and inside (hollow

instruments only) of items placed within the

wash tank.

Note: The SI PCF Washer has been validated for

the cleaning and low-level thermal disinfection of

surgical instruments and devices, including complex

lumen/cannulated surgical instruments and devices

such as robotic surgical instruments. Testing to

validate cleaning and disinfection efficacy for a

specific instrument is the responsibility of the

instrument manufacturer. Consult the instrument

manufacturer’s instructions regarding cleaning and

disinfection.

Note: If the equipment is used in a manner not

specified by the manufacturer, the effectiveness

and protection provided by the equipment may be

impaired.

Performance

Washing is achieved using a unique, specially

formulated and clinically validated

decontamination fluid (EDA+ or 3E-Zyme®),

which is introduced into the machine during

the cycle.

This machine has a class AB weir incorporated

into the tank design to comply with most water

authority regulations.

A stringent quality control program ensures

that every unit is manufactured and tested

under controlled conditions to ensure that all

units perform identically.

Cycle Record

During the cycle, parameters are reported at

key stages of the process as an ASCII serial

data steam via the RS232 port. This can then

be logged either on a printer (see section 2-6-2

and 2-10) or on a PC (see section 2-11).

The on-board cycle log can be download via a

USB flash drive (see section 3-14).

Cycle Failure

The SI PCF is designed to perform within strict

and carefully controlled tolerances. If an

unexpected condition occurs during a wash

cycle, the system will abort the cycle and

report an error, see section 3-12 for more

details.

Concept Summary

The SI PCF has the ability to wash up to

twenty instruments.

There are six pre-defined user selectable

programs with Pre-wash, Wash, Rinse and

Disinfection stages tailored to clean a

multitude of different loads.

The program parameters can also be changed

within specified limits by an engineer during

installation or service.

The SI PCF has an interlock system that

prevents a cycle being started with the lid up.

Load Instruments

The user loads the instruments into the basket,

places it into the machine and presses the

touch screen to lock the lid.

Prewash

The cycle begins with a cold-water fill to the

mid-level; the spray and irrigation valves are

opened alternately with the pump running for

the specified time. The water is then drained.

Wash

At the main wash stage, the tank is filled to the

top level with a cold and hot water mix to attain

a set temperature. Detergent is also added at

this point. The pump is pulsed on and off, to

even out the temperature, fill all cavities, and

to mix the chemical thoroughly. Once the tank

is full the ultrasonics degas the tank by pulsing

on and off to remove any dissolved air. A

period of irrigation follows in order to flush any

material from inside the instruments. The

ultrasonics then alternate with irrigation for the

set period of time. The water is then drained.

Rinse

The tank is filled to the mid-level; and heated

to the set point. The machine then alternates

between the spray and irrigation for the pre-

defined time. The water is then drained.

For some programs this stage is repeated.

Disinfection

If disinfection is required, the machine is then

filled to the minimum level with hot water and

heated up to the pre-set temperature (91°C /

196°F) for 3 minutes. The water is then

drained.

Cooling

To disperse the vapour in the chamber, the

machine opens the drain valve and fills with

cold water for several minutes.

Unload

The user touches the screen to acknowledge

the end of the cycle, which unlocks the lid and

allows the basket to be removed.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 19 of 81

General Safety

This equipment is not suitable for use with

flammable materials or gases, and should not

be used for any purpose other than that

defined by the manufacturer as a high

pressure sonic irrigation washer disinfector.

Chemicals

Since this equipment contains a high power

heating device, the use of substances or

chemicals, other than those specified by

Medisafe, may be hazardous. Therefore,

always read the manufacturer’s chemical

safety information before use and never use

toxic, corrosive, or flammable liquids.

Using non-approved chemicals may cause

damage to your machine and could void your

warranty and guarantee of performance.

Decontamination

In the event that this product needs to be

returned to the supplier, it MUST first be fully

decontaminated before transporting. The

Decontamination Certificate (see section 3-16-

4) must also be completed and displayed in a

prominent position when returned with the

product.

Heat

Since temperatures within the

unit can reach 92°C (198°F)

during and after operation, take

care when opening lid at the

end of a cycle. Allow sufficient

time for items to cool before

handling.

Electrical Safety

Dangerously high voltages are

present inside the machine. Do

not remove any panelling, or

attempt to gain access to the

inside of the machine, keep the

left cabinet door closed and

locked at all times. Refer

servicing and repair to qualified

personnel only.

It is expected that any person servicing or

repairing the SI PCF will be a competent

engineer with an understanding of electrical

safety, and knowledge of three phase power. It

is also crucial to understand the risks of

working with electrical appliances that use

water. Caution must be taken at all times to

ensure a safe environment.

To avoid risk of electric shock, this equipment

must only be connected by a fully qualified

electrician and to a mains supply with a

protective earth.

To prevent the risk of fire or electric shock, do

not expose equipment to unnecessary

moisture. Always ensure that all external

surfaces are dried after each cycle.

The key must only be available to a

Responsible Body.

Service Contracts & Warranty

Your SI PCF is supplied with a conditional 12-

month parts warranty, which is effective from

the date of installation.

Medisafe (UK) offers a range of Service

Contracts and Extended Warranty Packages

to provide continuous maintenance and

breakdown cover once the original warranty

has expired.

Hazards can result from

unauthorized modification of the

machine. No modification of this

equipment is allowed. Any

modification to this equipment will

void the warranty.

Validation Option

Medisafe (UK) can also provide a Validation

Service to address the essential local

regulation requirement. The work will be

carried out by authorised Medisafe engineers

to ensure your SI PCF continues to conform to

local and national guidelines.

For more information on service or any of

these options, please contact Medisafe or your

regional distributor.

Introduction SI PCF User Manual

Ref: DOC03148 Issue 1 Friday, 06 January 2017 Page 20 of 81

Intentionally blank

Table of contents