Contents

Contents

1 General guidelines ...............................................................................................................................................................4

Symbols used.......................................................................................................................................................................4

Formatting rules ...................................................................................................................................................................4

Disposal ...............................................................................................................................................................................4

2 Safety.....................................................................................................................................................................................5

3 Description of the device.....................................................................................................................................................6

Intended use ........................................................................................................................................................................6

Functional principle ..............................................................................................................................................................6

Scope of delivery..................................................................................................................................................................6

Views of the device ..............................................................................................................................................................7

4 Commissioning.....................................................................................................................................................................8

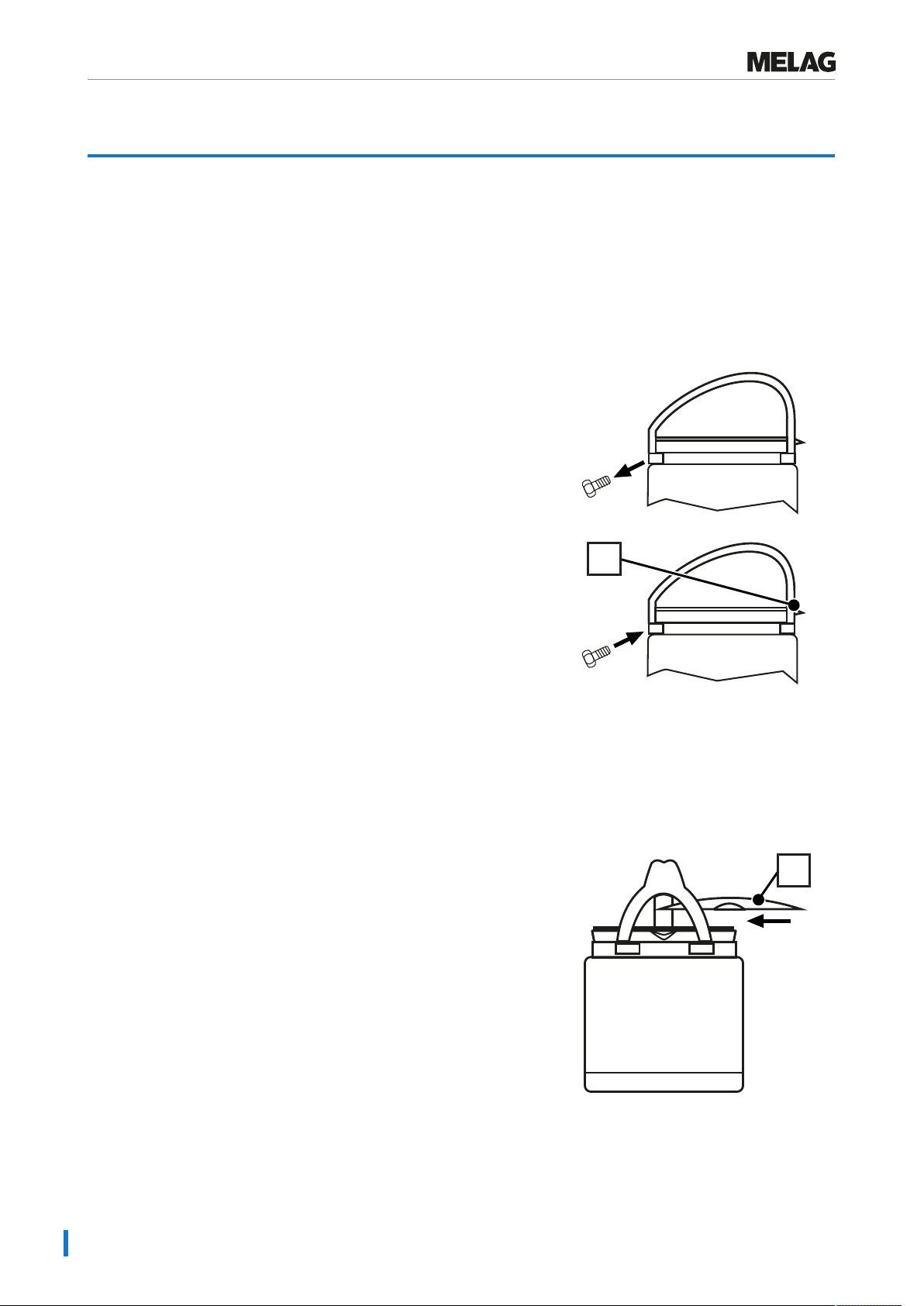

Fitting the glass flask............................................................................................................................................................8

Before commissioning..........................................................................................................................................................9

5 Operation ............................................................................................................................................................................11

Producing distilled water ....................................................................................................................................................11

6 Maintenance........................................................................................................................................................................12

Cleaning the distilling chamber ..........................................................................................................................................12

7 Malfunctions .......................................................................................................................................................................13

8 Technical data ....................................................................................................................................................................14

9 Accessories and spare parts ............................................................................................................................................15

Glossary .................................................................................................................................................................................16