1-1

MPT12 Manual

24 May 2017

SECTION 1

Definitions and Abbreviations

Contents

MANUAL USAGE

This technical manual only contains information

required to safely operate and maintain the Mega

Portable Tank. If your system is not covered in this

manual please contact MEGA Corp. Product Support

at: 1-800-345-8889 or visit our website at

www.megacorpinc.com for more detailed

information.

The exact location of the hazards and description of

the hazards are reviewed in this section. All personnel

working on or operating the machine must become

familiarized with all the safety messages.

Due to the nature of these processes, ensure that all

safety information, warnings and instructions are

read and understood before any operation or any

maintenance procedures are performed. Some

procedures take place with heavy components and

at moderate heights, ensure proper safety

procedures are maintained when performing these

actions. Failure to use and maintain proper safety

equipment and procedures will cause injury, death or

damage to equipment.

WARNING, CAUTION AND NOTES

The following definitions are found throughout the

manual and apply as follows:

Operating procedures and techniques, which could

result in personal injury and/or loss of life if not

carefully followed.

Operating procedures and techniques, which could

result in damage to equipment if not carefully

followed.

Operating procedures and techniques that are

considered essential to emphasize.

USE OF SHALL, WILL, SHOULD AND MAY

Shall and Will – Used when application of a

procedure is mandatory.

Should – Used when application of a procedure is

recommended.

May - Used to indicate an acceptable or suggested

means of accomplishment.

Manual Usage ...................................................................1-1

Warning, Caution And Notes ......................................1-1

Use Of Shall, Will, Should And May ...........................1-1

Safety Messages ..............................................................1-2

Abbreviations ...................................................................1-3

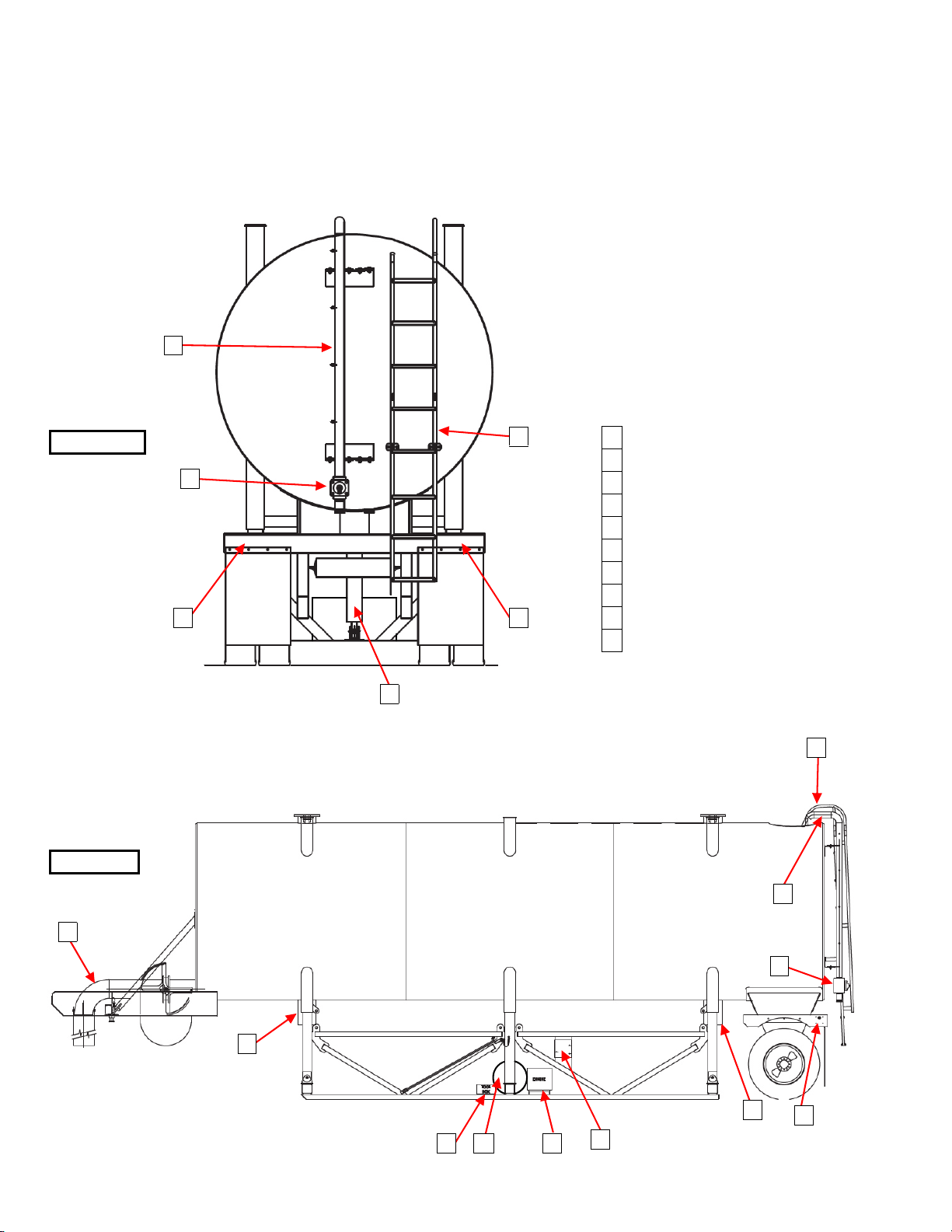

MPT Overview (Typical) ................................................1-4