Megmeet MV300 Series User manual

1

MV300 Series Universal Vector Control Variable

Speed Drive

User Manual

Document Version: V1.0

Archive Date: 2015/07/29

BOM Code: R33010207

Shenzhen Megmeet Drive Technology Co., Ltd. provides full technical support for our

customers. Customers can contact local Megmeet offices or customer services centers, or

directly contact Megmeet headquarters.

Shenzhen Megmeet Drive Technology Co., Ltd.

All rights reserved. The contents in this document are subject to change without notice.

Shenzhen Megmeet Drive Technology Co., Ltd.

Address: 5th Floor, Block B, Unisplendor Information Harbor, Langshan Rd., Science &

Technology Park, Nanshan District, Shenzhen, 518057, China

Website: www.megmeet-drivetech.com

Tel: +86-755-86600500

Fax: +86-755-86600562

Service email: driveservice@megmeet.com

2

Foreword

Thank you for using the MV300 series universal vector control variable speed drive of Shenzhen

Megmeet Drive Technology Co., Ltd.

As new generation of integrated vector control platform, MV300 adopts the advanced integrated drive solution,

realizing the integration of asynchronous motor driving and the integration of torque control and speed control,

all driving indexes reach industry-leading level. MV300 can meet the high performance requirement of various

complex applications of customers. It has perfect anti-tripping ability and adjustability to the poor grid,

temperature, humidity and dust conditions, remarkably improving its reliability and adaptability.

MV300 adopts the modular extension design. It can not only meet the general requirements of the customer,

but also satisfy the industry and customized requirements through flexible extension. With the process

close-loop control, multi-functional input/output terminals, pulse frequency reference, simple PLC and

main/auxiliary reference control, MV300 can fully meet the requirements of complicated and high-precision

drive, which is of great value for reducing the system cost and improving the system reliability.

The MV300 can meet the requirements of the users for low noise and low EMI by adopting the integrated

EMC design and optimized PWM control technology.

The relevant precautions during the installation, wiring, parameter setting, troubleshooting and daily

maintenance will be detailed in this manual. To ensure the correct installation and operation of the MV300

series drive as well as its high performance, please read carefully this user manual before installing the

equipment. This manual shall be kept properly and delivered to the actual users of the drive.

Precautions for unpacking inspection

Please check carefully when unpacking the product:

·Whether the product has the damage signs;

·Whether the rated value in the nameplate is consistent with your order requirement.

We have implemented strict inspection on the manufacturing, package and delivery of the product. If there is

any error, please contact us or your distributor immediately.

We are engaged in the continuous improvement of drive. The relevant manuals provided by us are subject to

change without prior notice.

3

Safety Precaution

Operation without following instructions can cause death or severe personal injury.

Operation without following instructions can cause medium or slight personal injury or

damage to product and other equipment.

·Please install the product on the incombustible materials (e.g., metal), otherwise, fire may be caused.

·Do not place any combustible material near the product, otherwise, fire may be caused.

·Do not install the product in the environment with explosive gas, otherwise, explosion may be caused.

·Only qualified personnel can wire the drive, otherwise, electric shock may be caused.

·

Never wire the drive unless the input AC supply is completely disconnected, otherwise, electric shock may

be caused.

·The grounding terminal of the drive must be reliably grounded, otherwise, electric shock may be caused.

·The cover must be properly closed before power-up, otherwise, electric shock and explosion may be

caused.

·When powering up the drive that has been stored for over 2 years, the input voltage must be gradually

increased with the voltage regulator, otherwise, electric shock and explosion may be caused.

·Do not touch the terminals when the product is powered up, otherwise, electric shock may be caused.

·Do not operate the drive with wet hands, otherwise, electric shock may be caused.

·Maintaince operation can not be conducted until 10 minutes has passed after disconnecting the power

supply. Meanwhile, be sure to confirm that the chage LED is completely off and the DC bus voltage is

below 36V, otherwise, electric shock may be caused.

·Only qualified personnel can replace the components. Do not leave any wire or metal parts inside the

drive, otherwise, fire may be caused.

·After changing the control board, the parameters must be properly set before operating the drive,

otherwise, property damage may be caused.

·The bare parts of the terminal lugs in the main circuit must be wrapped with insulation tape, otherwise,

electric shock may be caused.

·

When carrying the drive, protect the operation panel and the cover against any stress, otherwise, the drive

may drop and cause human injury or property damage.

·Please install the drive on the place that can withstand the weight of the drive, otherwise, the drive may

drop and cause human injury or property damage.

·Do not install the drive in the environment with water splash (e.g., near the water pipe), otherwise, you

may suffer the property loss.

4

·Take care not to drop any foreign objects, such as the screws, gaskets and metal bars, into the drive,

otherwise, fire and property damage may be caused.

·

Do not install and operate the drive if it is damaged or its components are not complete, otherwise, fire and

human injury may be caused.

·Do not install the product in the place exposed to direct sunlight, otherwise, property damage may be

caused.

·Do not short circuit terminal P/B1 and terminal -DC, otherwise, fire and property damage may be caused.

·Cable lugs must be firmly connected to the terminals of main circuit, otherwise, property damage may be

caused.

·Do not connect AC 220V input to the control terminals other than terminal TA, TB and TC, otherwise,

property damage may be caused.

5

Contents

MV300 Series Universal Vector Control Variable Speed Drive ............................................ 1

Chapter 1 Introduction of MV300 Series Drive .................................................................... 7

1.1 Product model .....................................................................................................................................7

1.2 Product nameplate ..............................................................................................................................7

1.3 Product series......................................................................................................................................8

1.4 Technical specifications of product ......................................................................................................9

1.5 Drive structure ...................................................................................................................................11

1.6 Outline, mounting dimensions and gross weight of drive...................................................................11

1.7 Outline and mounting dimensions of operation panel........................................................................15

1.8 Outline and mounting dimensions of operation panel box.................................................................15

1.9 Options ..............................................................................................................................................16

Chapter 2 Drive Installation ............................................................................................... 18

2.1 Removal and installation of drive components ..................................................................................18

2.2 Installation environment.....................................................................................................................19

2.3 Mounting direction and space............................................................................................................19

Chapter 3 Wiring of Drive .................................................................................................. 21

3.1 Wiring and configuration of main circuit terminals .............................................................................22

3.2 Wiring and configuration of control circuit..........................................................................................30

3.3 Installation method for EMC requirements.........................................................................................41

Chapter 4 Quick Operation Guide for Drive....................................................................... 52

4.1 Drive operation panel ........................................................................................................................52

4.2 Drive running mode ...........................................................................................................................61

4.3 Initial power-up ..................................................................................................................................64

Chapter 5 Parameter List .................................................................................................. 66

5.1 Basic menu function code parameter table........................................................................................66

Chapter 6 Parameter Description .................................................................................... 114

6.1 System management parameters (Group P00)...............................................................................114

6.2 Status display parameters (Group P01)...........................................................................................118

6.3 Basic parameters (Group P02)........................................................................................................121

6.4 Motor parameters (Group P03)........................................................................................................130

6.5 Speed control parameters (Group P05)...........................................................................................135

6.6 Torque control parameters (Group P06) ..........................................................................................140

6.7 VF control parameters (Group P07) ................................................................................................145

6.8 Start and stop control parameters (Group P08) ...............................................................................148

6.9 Digital input/output parameters (Group P09) ...................................................................................152

6.10 Analog input/output terminal parameters (Group P10) ..................................................................170

6

6.11 Auxiliary function parameters (Group P11) ....................................................................................179

6.12 Advanced function parameters (Group P12) .................................................................................185

6.13 Multi-stage reference and simple PLC parameters (Group P13)...................................................188

6.14 Process PID parameters (Group P14)...........................................................................................194

6.15 Communication parameters (Group P15)......................................................................................201

6.16 Keyboard display setting parameters (Group P16)........................................................................202

6.17 Fieldbus option parameters (Group P40) ......................................................................................204

6.18 Protection and fault parameters (Group P97)................................................................................205

6.19 Drive parameters (Group P98) ......................................................................................................212

Chapter 7 Troubleshooting .............................................................................................. 214

7.1 Displaying exception and solutions..................................................................................................214

7.2 Operation exception and solutions ..................................................................................................221

Chapter 8 Maintenance ................................................................................................... 225

8.1 Daily maintenance...........................................................................................................................225

8.2 Periodical maintenance ...................................................................................................................226

8.3 Replacing wearing parts ..................................................................................................................226

8.4 Storage of drive ...............................................................................................................................227

Appendix 1 Modbus Communication Protocol................................................................. 228

1. Networking mode...............................................................................................................................228

2. Interface mode ..................................................................................................................................228

3. Communication mode........................................................................................................................228

4. Protocol format ..................................................................................................................................228

5. Protocol functions..............................................................................................................................230

6. Control parameters and status parameters of drive...........................................................................237

7. Expand access mode ........................................................................................................................244

8. Cautions ............................................................................................................................................249

9. CRC verification.................................................................................................................................251

10. Application example.........................................................................................................................253

11. Scaling of drive parameters .............................................................................................................255

Appendix 2 Braking Components .................................................................................... 256

Appendix 3 Warranty and Service ................................................................................... 259

Parameter record table..........................................................................................................................261

Wring diagram .......................................................................................................................................262

7

Chapter 1 Introduction of MV300 Series Drive

1.1 Product model

The description of the drive model on the nameplate indicates the information of the product series, such as

voltage class of power supply, power class, the software/hardware code of customized product, etc.

MV300 X - 4 T 0.75 - XX - XX

Product Series

G

1

1

P

General

Pump/Fan

0.75kW~400kW

Rated output power

00~ZZ:Software code

for customized product

00~ZZ:Hardware code

for customized product

S: Single-phase

T: Three-phase

2: 220V

4: 380V

1.2 Product nameplate

8

1.3 Product series

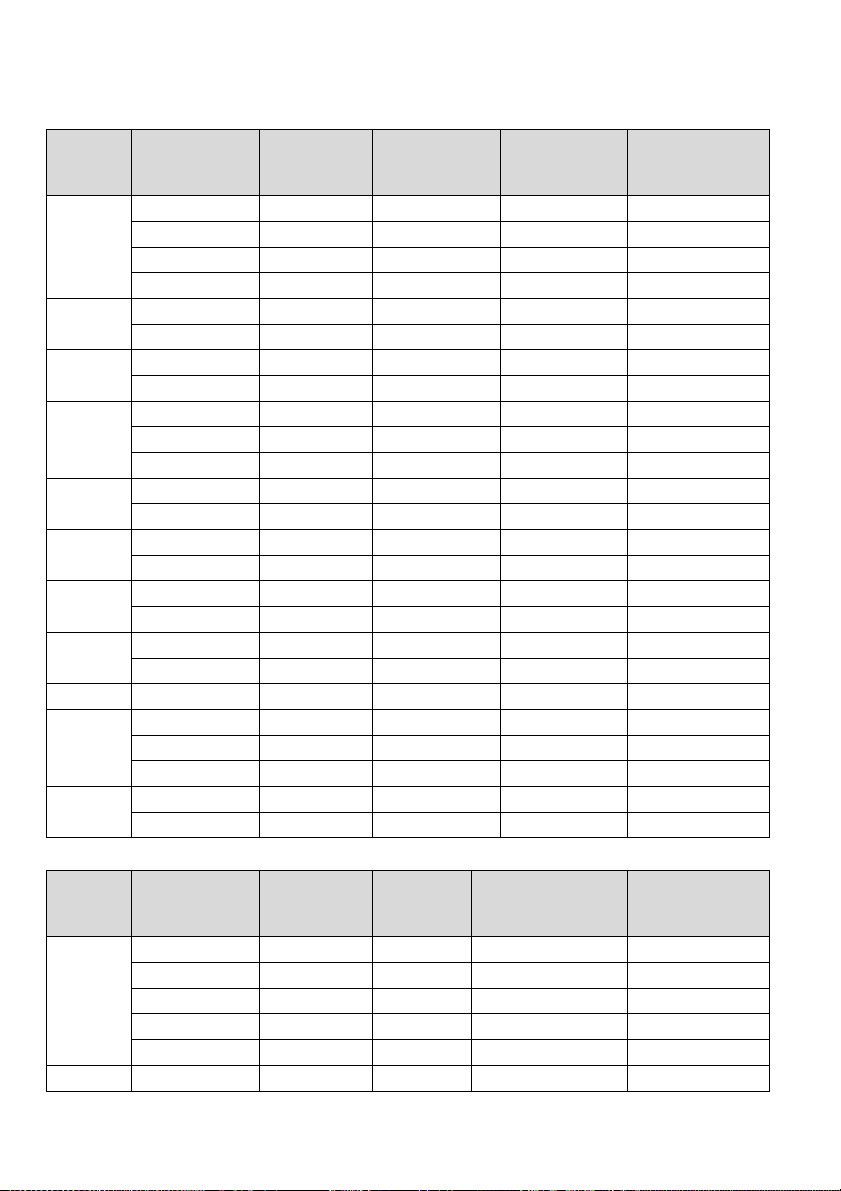

Table 1-1 Name and model of MV300G

Enclosure

mode Product model Rated capacity

(kVA)

Rated input

current

(A)

Rated output

current

(A)

Rated output power

(kW)

R2

MV300G-4T0.75 1.5 3.5 2.3 0.75

MV300G-4T1.5 3.0 5.1 3.7 1.5

MV300G-4T2.2 4.0 5.8 5.5 2.2

MV300G-4T3.7 5.9 10.5 8.8 3.7

R3

MV300G-4T5.5 8.5 14.5 13.0 5.5

MV300G-4T7.5 11.0 20.5 17.0 7.5

R4

MV300G-4T11 17.0 26.0 25.0 11

MV300G-4T15 21.0 35.0 32.0 15

R5

MV300G-4T18.5 24.0 38.5 37.0 18.5

MV300G-4T22 30.0 46.5 45.0 22

MV300G-4T30 40.0 62.0 60.0 30

R6

MV300G-4T37 50.0 76.0 75.0 37

MV300G-4T45 60.0 92.0 90.0 45

R7

MV300G-4T55 72.0 113.0 110.0 55

MV300G-4T75 100.0 157.0 152.0 75

R8

MV300G-4T90 116.0 180.0 176.0 90

MV300G-4T110 138.0 214.0 210.0 110

R9

MV300G-4T132 167.0 256.0 253.0 132

MV300G-4T160 200.0 307.0 304.0 160

R9P MV300G-4T200 250.0 385.0 380.0 200

R10

MV300G-4T220 280.0 430.0 426.0 220

MV300G-4T280 355.0 525.0 495.0 280

MV300G-4T315 445.0 590.0 585.0 315

R11

MV300G-4T355 500.0 665.0 650.0 355

MV300G-4T400 565.0 785.0 725.0 400

Table 1-2 Name and model of MV300P

Enclosure

mode Product model Rated capacity

(kVA)

Rated input

current

(A)

Rated output current

(A)

Rated output power

(kW)

R2

MV300P-4T0.75 1.5 3.5 2.3 0.75

MV300P-4T1.5 3.0 5.1 3.7 1.5

MV300P-4T2.2 4.0 5.8 5.5 2.2

MV300P-4T3.7 5.9 10.5 8.8 3.7

MV300P-4T5.5 8.5 14.5 13.0 5.5

R3 MV300P-4T7.5 11.0 20.5 17.0 7.5

9

R4

MV300P-4T11 17.0 26.0 25.0 11

MV300P-4T15 21.0 35.0 32.0 15

MV300P-4T18.5 24.0 38.5 37.0 18.5

R5

MV300P-4T22 30.0 46.5 45.0 22

MV300P-4T30 40.0 62.0 60.0 30

MV300P-4T37 50.0 76.0 75.0 37

R6

MV300P-4T45 60.0 92.0 90.0 45

MV300P-4T55 72.0 113.0 110.0 55

R7

MV300P-4T75 100.0 157.0 152.0 75

MV300P-4T90 116.0 180.0 176.0 90

R8

MV300P-4T110 138.0 214.0 210.0 110

MV300P-4T132 167.0 256.0 253.0 132

R9

MV300P-4T160 200.0 307.0 304.0 160

MV300P-4T200 250.0 385.0 380.0 200

R9P MV300P-4T220 280.0 430.0 426.0 220

R10

MV300P-4T280 355.0 525.0 495.0 280

MV300P-4T315 445.0 590.0 585.0 315

R11

MV300P-4T355 500.0 665.0 650.0 355

MV300P-4T400 565.0 785.0 725.0 400

1.4 Technical specifications of product

Table 1-3 Technical specifications of drive

Input power

Rated voltage (V)

Three-phase: 380V~480V; continuous fluctuation of voltage:

±10%, transient fluctuation of voltage: -15%~+10% (i.e. the

range is 323V~528V); Voltage unbalance rate: <3%, the

distortion rate complying with IEC61800-2

Rated input current (A) Please refer to Table 1-1 and Table 1-2.

Rated frequency (Hz) 50Hz/60Hz, fluctuation range: ±5%

Output power

Standard applicative motor (kW)

Please refer to Table 1-1 and Table 1-2.

Rated capacity (kVA)

Rated current (A)

Output voltage (V) Output with three-phase under rated input conditions: 0 ~ rated

input voltage, the error is less than ±3%

Output frequency (Hz) V/F: 0.00~3000.0Hz (unit: 0.01Hz); vector control: 0~650.00Hz

Overload capacity G: 1 min for 150% rated current, 0.5 s for 200% rated current

P: 1 min for 110% rated current, 1 s for 150% rated current

Operation control

features

Control mode Vector control without PG, V/F control without PG

Maximum output frequency 3000Hz for V/F control, 650Hz for vector control

Speed adjusting range 1: 200 (vector control without PG)

10

Speed control precision ±0.2% (vector control without PG)

Speed fluctuation ±0.3% (vector control without PG)

Torque response <10ms (vector control without PG)

Torque control The torque control precision is 7.5% when vector control without

PG

Startup torque 150% @ 0Hz (vector control without PG)

Product functions

Key functions

Fast tracking, over-torque/under-torque detection, torque limit,

multi-stage speed operation, multiple acceleration/deceleration

time switching, auto-tuning, S curve acceleration/deceleration,

slip compensation, fan speed control, skip frequency operation,

energy saving operation, PID adjustment (sleep function),

non-stop upon instantaneous power interruption, switching of

multi-command, MODBUS communication, Fieldbus

communication, drooping control, torque control, torque and

speed control mode switching, automatic restart, DC braking,

dynamic braking; simple PLC, dwell function, two sets of motor

parameters switching

Basic frequency 0.01Hz~3000.0Hz

Startup frequency 0.00Hz~60.00Hz

Frequency setting mode

Digital panel setting, terminal UP/DN setting, host device

communication setting, analog setting (AI1/AI2), terminal pulse

setting, fieldbus communication setting

Acceleration/deceleration time 0.1~3600.0 (unit can be selected among 0.1s, s and min)

Dynamic braking capacity Braking rate is 0.0~100.0%. Please refer to Table 1-7.

DC braking capacity

G:15kW and below have built-in braking unit as standard,

18.5kW~75kW can customize built-in braking unit,braking rate:

0.0~100.0%

P:18.5kW and below have built-in braking unit as standard,

22kW~90kW can customize built-in braking unit,braking rate:

0.0~100.0%

Terminal functions Please refer to the introduction of terminal functions for details.

Protection

function Refer to “Protection function” section for details.

Others

Efficiency ≥93% (7.5kW and below); ≥95% (45kW and below); ≥98%

(55kW and above)

Installation method Wall-mounted

Protection degree IP20

Cooling mode Air cooling with fan control

Environment

Operating site Indoor, away from direct sunlight, free from dust, corrosive gas,

combustible gas, oil mist, water vapor, water dripping or salt

Altitude Used at the place lower than 1000m, (derated at the place

above 1000m, derated 1% for every increase of 100m)

Ambient temperature -10℃~+40℃(derated when used in the ambient temperature of

40℃~50℃)

11

Humidity 5%~95%RH, non-condensing

Vibration less than 5.9m/s2(0.6g)

Storage temperature -40℃~+70℃

1.5 Drive structure

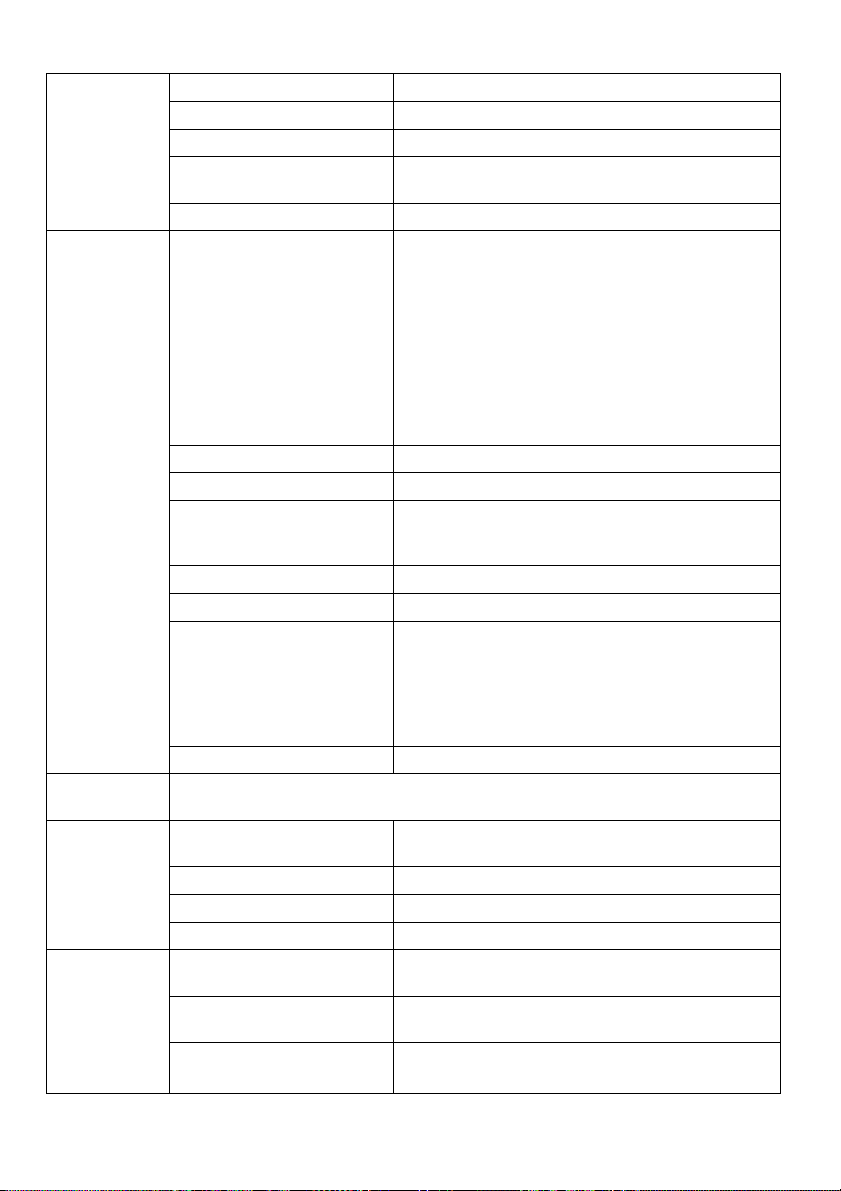

1. Mid-enclosure 2. Main control board 3. Upper cover 4. Operation panel 5. Main circuit wiring terminal

6. Lower cover 7. Fan guard 8. Fan 9. Mounting holes for complete unit 10. Bottom enclosure 11. Dustproof plate

12. Nameplate 13. Connector 14. Bottom plate 15. Mid-enclosure 16. Control terminal 17. Wiring plate

Fig. 1-1 Drive structure (taking R4 as an example)

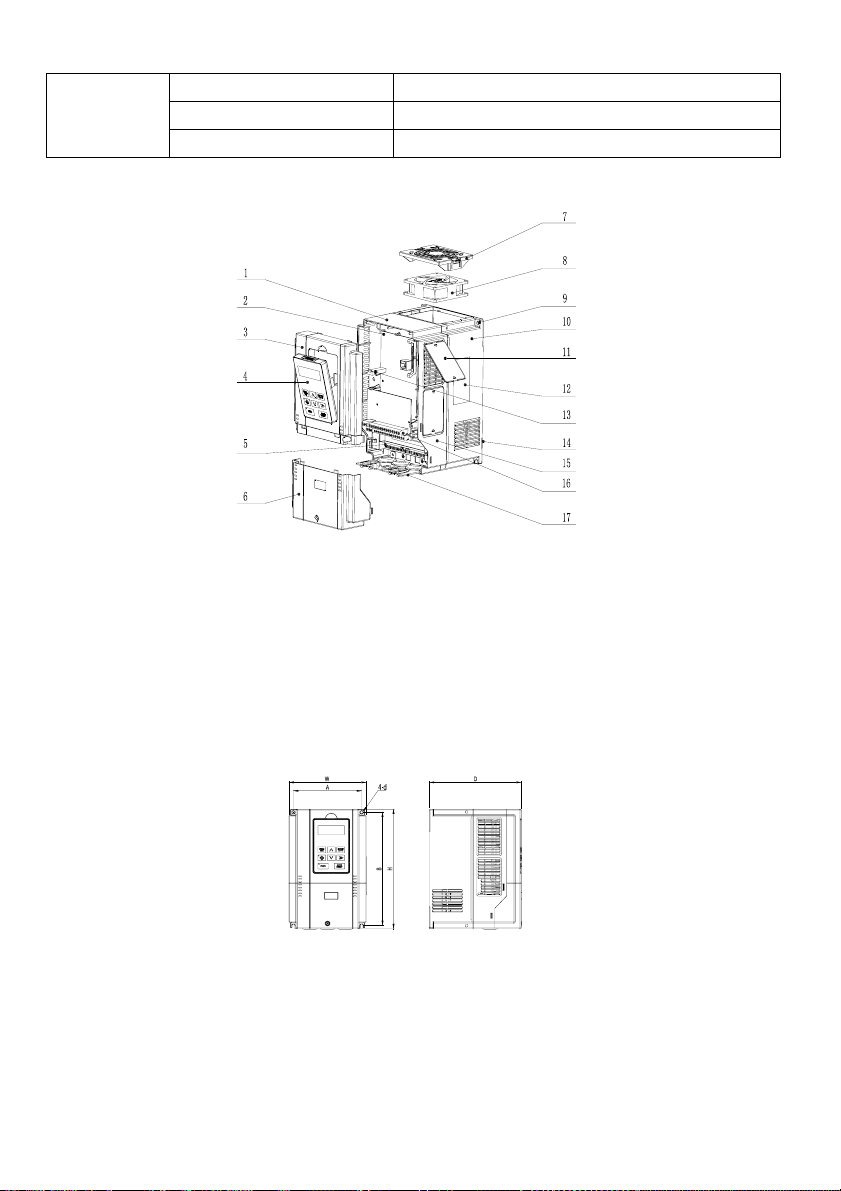

1.6 Outline, mounting dimensions and gross weight of drive

There are four types of outlines as shown in Fig.1-2, Fig.1-3, Fig.1-4 and Fig.1-5. The outline, mounting

dimensions and gross weight are as shown in Table 1-4 and Table 1-5.

1. Enclosure R2~R4 ( G: 0.75kW-15kW; P:0.75kW-18.5kW)

Fig. 1-2 Outline, mounting dimensions for products of R2~R4

2. Enclosure R5~R8 (G: 18.5kW-110kW; P: 22kW-132kW)

12

Fig. 1-3 Outline, mounting dimensions for products of R5~R8

3. Enclosure R9~R10 (G: 132kW-315kW; P: 160kW-315kW)

Fig. 1-4 Outline, mounting dimensions for products of R9~R10

4. Enclosure R11 (G: 355kW-400kW; P: 355kW-400kW)

Fig. 1-5 Outline, mounting dimensions for products of R11

Table 1-4 Outline, mounting dimensions and gross weight of MV300G

Enclosure

model Drive model A(mm)B(mm)H(mm)W(mm)D(mm)

Diameter of

mounting

aperture

(mm)

Gross weight

±0.5 (kg)

R2

MV300G-4T0.75 115 218 229 126 174 5.5 4

MV300G-4T1.5

MV300G-4T2.2 115 218 229 126 174 5.5 4

13

MV300G-4T3.7 4

R3 MV300G-4T5.5 137 236 249 155 198 5.5 4

MV300G-4T7.5

R4 MV300G-4T11 186 314.5 330 209 206 6.5 9

MV300G-4T15

R5

MV300G-4T18.5

220 437.5 451.5 284.5 213 6.5 19MV300G-4T22

MV300G-4T30

R6 MV300G-4T37 270 549 570 335 267 7 41

MV300G-4T45

R7 MV300G-4T55 270 579 600 335 292 7 49

MV300G-4T75

R8 MV300G-4T90 350 705 726.5 452 328.5 12 87

MV300G-4T110

R9 MV300G-4T132 350 827.5 849.5 500 350 12 154

MV300G-4T160

R9P MV300G-4T200 370 827.5 849.5 530 350 12 154

R10

MV300G-4T220

500 932 956 700 361.5 14 216MV300G-4T280

MV300G-4T315

R11 MV300G-4T355 --1624 710 610 -250

MV300G-4T400

Table 1-5 Outline, mounting dimensions and gross weight of MV300P

Enclosure

model Drive model A(mm)B(mm)H(mm)W(mm)D(mm)

Diameter of

mounting

aperture

(mm)

Gross weight

±0.5 (kg)

R2

MV300P-4T0.75 115 218 229 126 174 5.5 4

MV300P-4T1.5

MV300P-4T2.2

115 218 229 126 174 5.5 4

MV300P-4T3.7

MV300P-4T5.5

R3 MV300P-4T7.5 137 236 249 155 198 5.5 4

R4

MV300P-4T11

186 314.5 330 209 206 6.5 9MV300P-4T15

MV300P-4T18.5

R5

MV300P-4T22

220 437.5 451.5 284.5 213 6.5 19MV300P-4T30

MV300P-4T37

R6 MV300P-4T45 270 549 570 335 267 7 41

MV300P-4T55

R7 MV300P-4T75 270 579 600 335 292 7 49

MV300P-4T90

R8 MV300P-4T110 350 705 726.5 452 328.5 12 87

MV300P-4T132

R9 MV300P-4T160 350 827.5 849.5 500 350 12 154

MV300P-4T200

R9P MV300P-4T220 370 827.5 849.5 530 350 12 154

R10 MV300P-4T280 500 932 956 700 361.5 14 216

MV300P-4T315

R11 MV300P-4T355 --1624 710 609 -250

MV300P-4T400

14

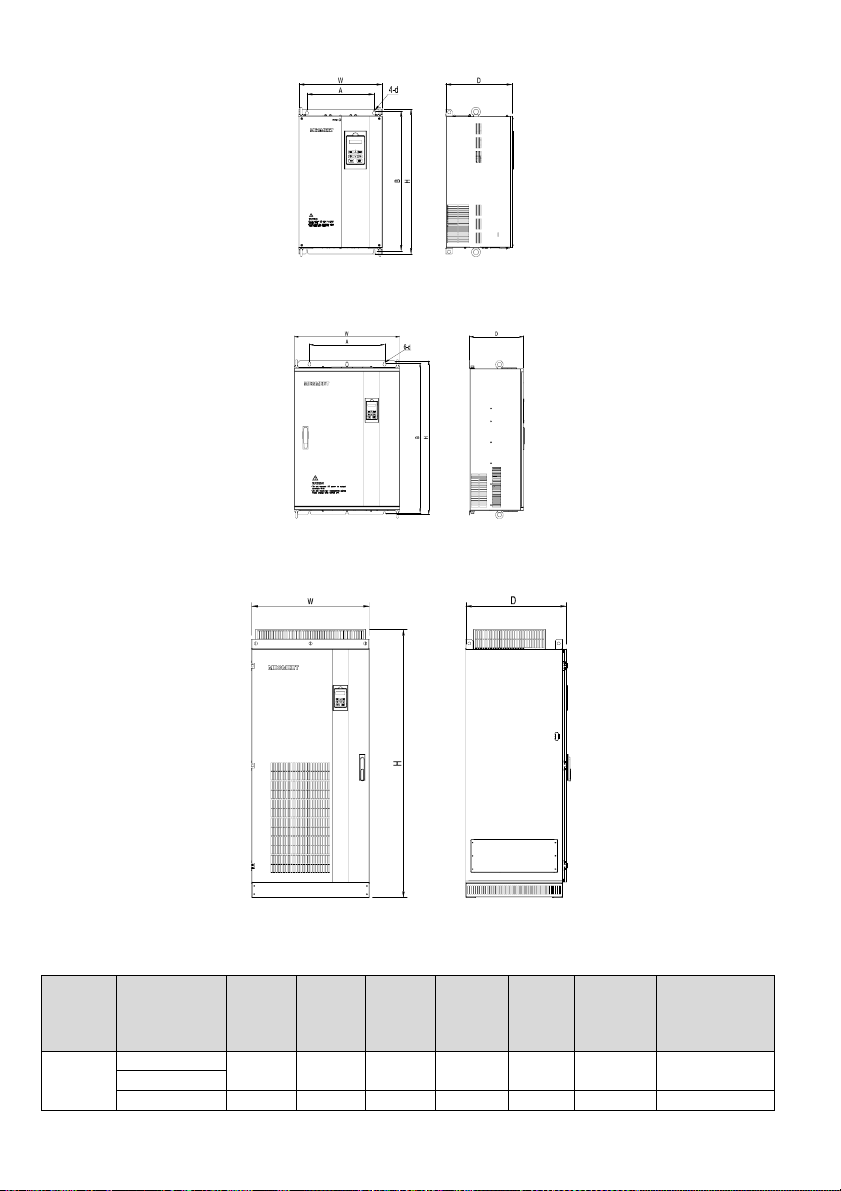

Note: For 75kWG drive or above, DC reactor is included in its standard configuration. The weight of DC

reactor is not included in the gross weight of the Table 1-4 and Table 1-5. Outline and dimensions of DC

reactor are shown below. For the drive of 355kWG/355kWP and above, DC reactor is included in its standard

configuration.

Diameter of terminal

Enlarged view of terminal

Mounting

hole

Mounting

hole

Fig. 1-6 Dimensions of DC reactor

Table 1-6 Mechanical Parameters of DC Reactor

Applicable

drive(kW)Model of DC reactor

Recommended

size of copper

(mm2)

Size(mm)Gross

weight

(kg)

A B C D E F G H I J

Diameter

of

terminal

75G DCL-0160-UIDH-7908

60 160 100 98 130 95 65 9 215

/

20

Ф8 14.5

90G/90P DCL-0180-UIDH-7908 Ф10 16

110G/110P DCL-0250-UIDH-7908 100 210 176 115 150 125 84 11 255 30 Ф12 25.5

132G/132P JSY-3674

150

200 170

135 171

120

85

10 260 280

30 Ф12

28

160G/160P JSY-3449 210 180 130 12 280 320 32

200G/200P

JSY-3066-1

200

220 190

135 171 150 90

12 315 340 40 Ф15

40

220G/220P 250

280G/280P

JSY-3067-1 325 145 181 160 95 45

315G/315P

Note

1.Columns B and C in Table 1-6 are the sizes of mounting holes of DC reactor.

15

2.For the drive of 75kWG~110kWG/110kWP, the DC reactor is packed separately with a wooden box, so the

gross weight includes the weight of the DC reactor and the wooden box.

3.DC reactor should be installed at the bottom of the cabinet if it is to be installed inside a cabinet. The

clearance between reactor and the drive should be at least 35cm, and the reactor should be as far away from

the air inlet port of the drive as possible. If ventilation is poor in the cabinet, it is recommended to increase fan

forced air cooling for the reactor to avoid high ambient temperature.

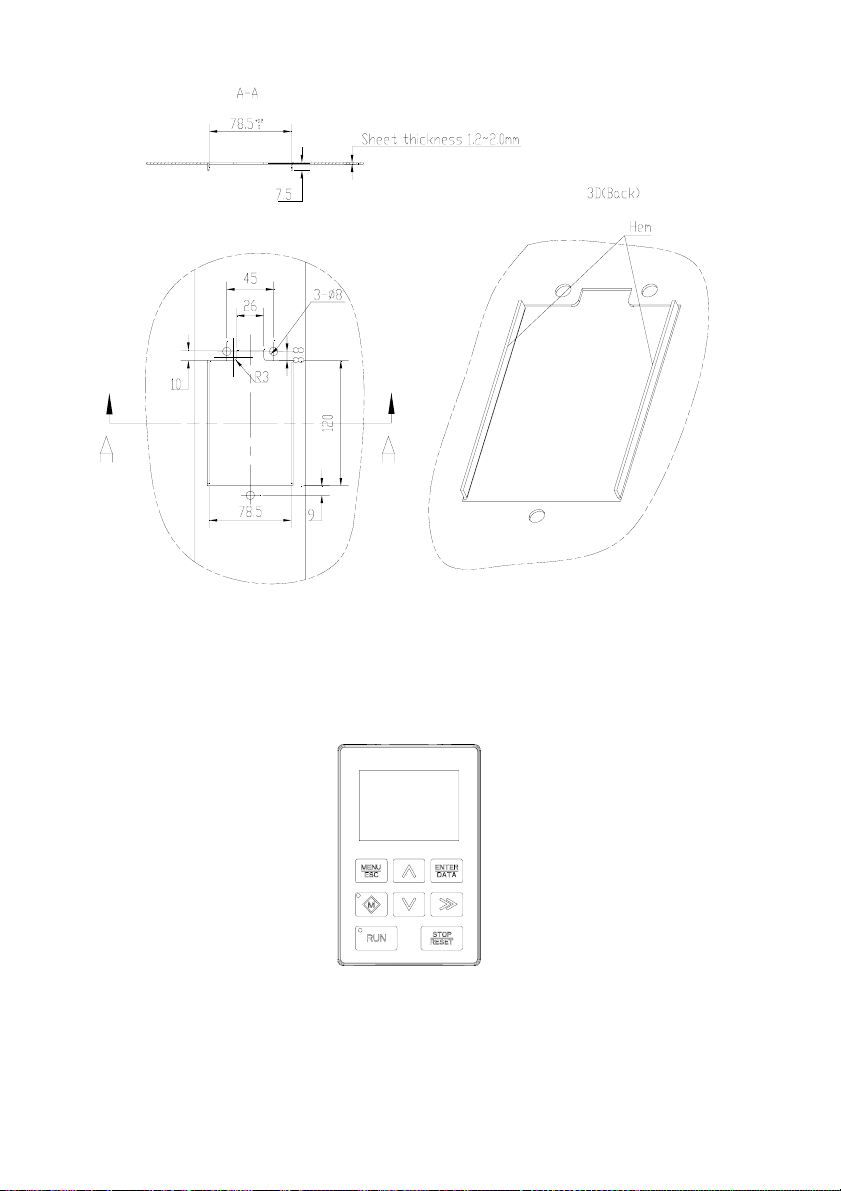

1.7 Outline and mounting dimensions of operation panel

Fig. 1-7 Outline and mounting dimensions of operation panel

1.8 Outline and mounting dimensions of operation panel box

The outline dimensions of the box used for mounting operation panel is as shown in Fig. 1-8.

Fig. 1-8 Outline dimensions of operation panel box

The mounting dimensions of the operation panel box is as shown in Fig. 1-9.

16

Fig. 1-9 Mounting dimensions of operation panel box

1.9 Options

1.9.1 LCD operation panel (reserved)

Fig. 1-10 LCD operation panel

1.9.2 Braking components

The information of braking components is as shown in Table 1-7.

17

Table 1-7 Braking components of MV300

Model Braking components

G

15kW and below Built-in braking unit.

18.5kW ~ 75kW Built-in braking unit, need

customization.

90kW and above Separate braking unit, see

Appendix 2.

P

18.5kW and below Built-in braking unit.

22kW ~ 90kW Built-in braking unit, need

customization.

110kW and above Separate braking unit, see

Appendix 2.

18

Chapter 2 Drive Installation

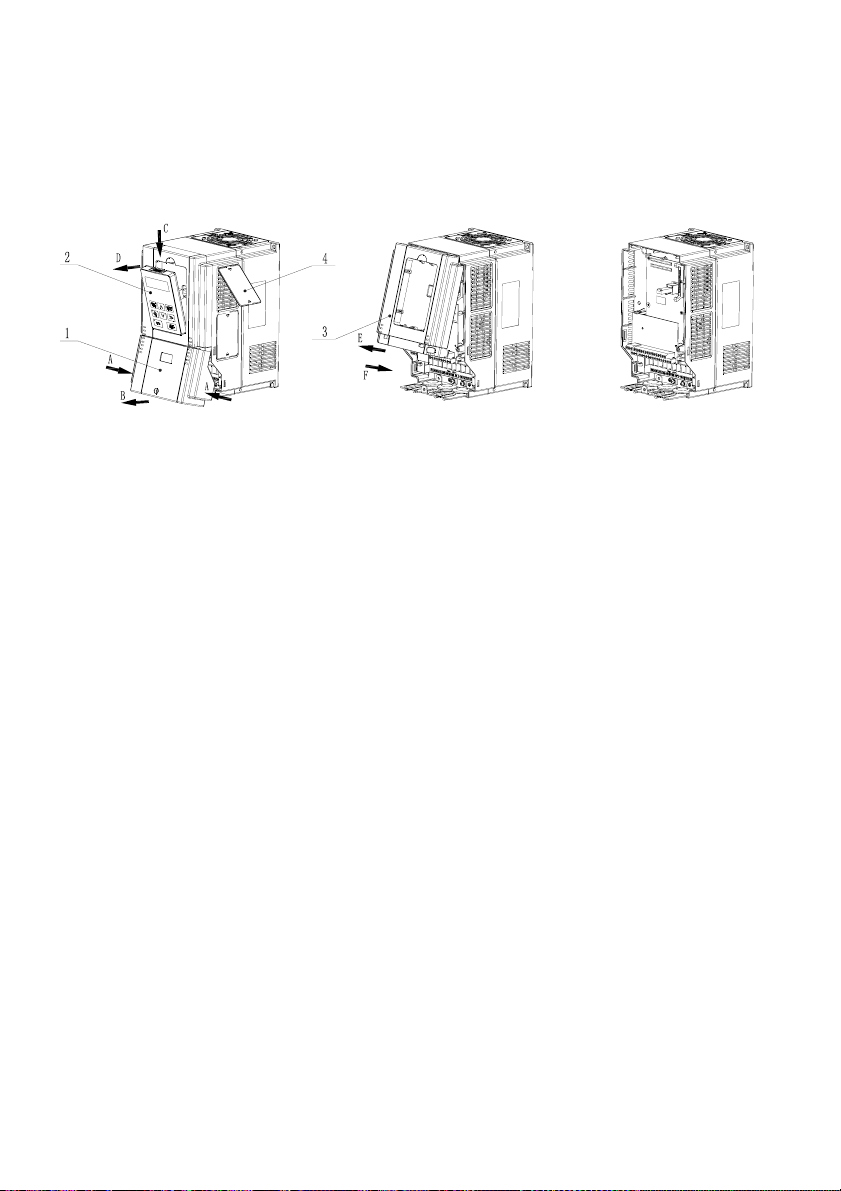

2.1 Removal and installation of drive components

1. Lower cover 2. Operation panel 3. Upper cover 4. Dustproof plate

Fig. 2-1 Removal and installation of drive components (taking R4 as an example)

1. Removal and installation of lower cover

Removal: Loosen the fixing bolts of the lower cover with the screwdriver, press the snap-fits on both sides in

direction A, make snap-fits off with the mid-enclosure and then lift the lower cover in direction B. Now, the

lower cover is removed.

Installation: Insert the insertion piece at the top of the lower cover into the upper cover, press both sides of the

lower cover with both hands in direction A so that the snap-fits can enter into the mid-enclosure, then tighten

the fixing bolts of the lower cover with the screwdriver. Now, the lower cover is installed.

2. Removal and installation of operation panel

Removal: Insert your finger into the square hole above the operation panel, press the clip in direction C and

then separate the upper section of the operation panel with the upper cover in direction D, then separate the

connector with the operation panel. Now, the operation panel is removed.

Installation: Ensure the display of the operation panel face upwards, press the operation panel into its

box while keeping them parallel. Now, the operation panel is installed.

3. Removal and installation of upper cover

Removal: Loosen the fixing bolts of the upper cover with the screwdriver, pull in direction E to separate the

upper cover from the mid-enclosure (if necessary, press the snap-fits of the upper cover from its side with the

straight screwdriver). Now, the upper cover is removed.

Note: Do not directly remove the upper cover with the operation panel on it. The operation panel should be

removed before removing the upper cover to avoid damages to the connecting base between the operation

panel and control board, which may cause unreliable contact between the operation panel and the control

board.

Installation: Press the lower part of the upper cover in direction F so that its snap-fits can enter into the

mid-enclosure, and then tighten the fixing bolts of the upper cover with the screwdriver. Now, the upper cover

is installed.

4. Removal and installation of dustproof plate

19

Removal: It is recommended to push both snap-fits of the dustproof plate from the inside of the enclosure with

tools, so that the snap-fits can be separated from the mid-enclosure. Now, the dustproof plate is removed.

Note: Removing the dustproof plate from the outside of the enclosure directly may damage it or the

mid-enclosure.

Installation: Place the snap-fit on one end of the dustproof plate into the mid-enclosure, move the dustproof

plate to another end while pressing it till the snap-fit on another end also enters into the mid-enclosure. Now,

the dustproof plate is installed.

Note: Do not press the dustproof plate forcibly if it is deformed, otherwise, it may be damaged.

2.2 Installation environment

When selecting the installation environment, the following issues should be taken into account:

·The ambient temperature should be within -10 ~40 . If the temperature is between 40 ~50 , derating℃℃ ℃℃ is

required.

·The humidity should be within 5%~95%RH, non-condensing.

·The vibration at the installation place should be less than 5.9m/s2(0.6g).

·The device should be protected from the direct sunlight.

·The device should be mounted in the location free of dust and metal powder.

·Do not install the device in the place with corrosive gas and explosive gas.

If there is any special installation requirement, please consult our company.

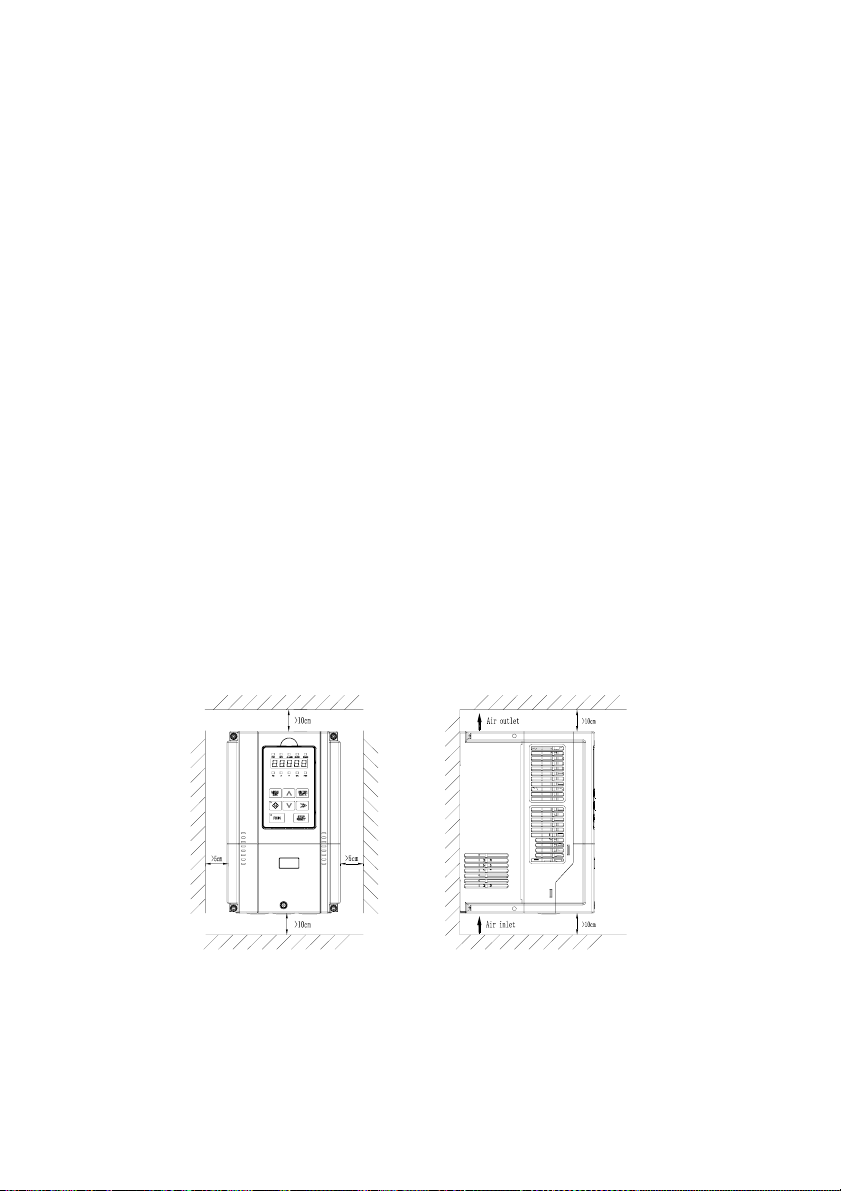

2.3 Mounting direction and space

In general, the drive shall be installed vertically to avoid poor heat dissipation.

For the installation spacing and distance requirement, please refer to Fig.2-2 and Fig.2-3.

Fig. 2-2 Installation spacing for models of 45kWG/55kWP and below

20

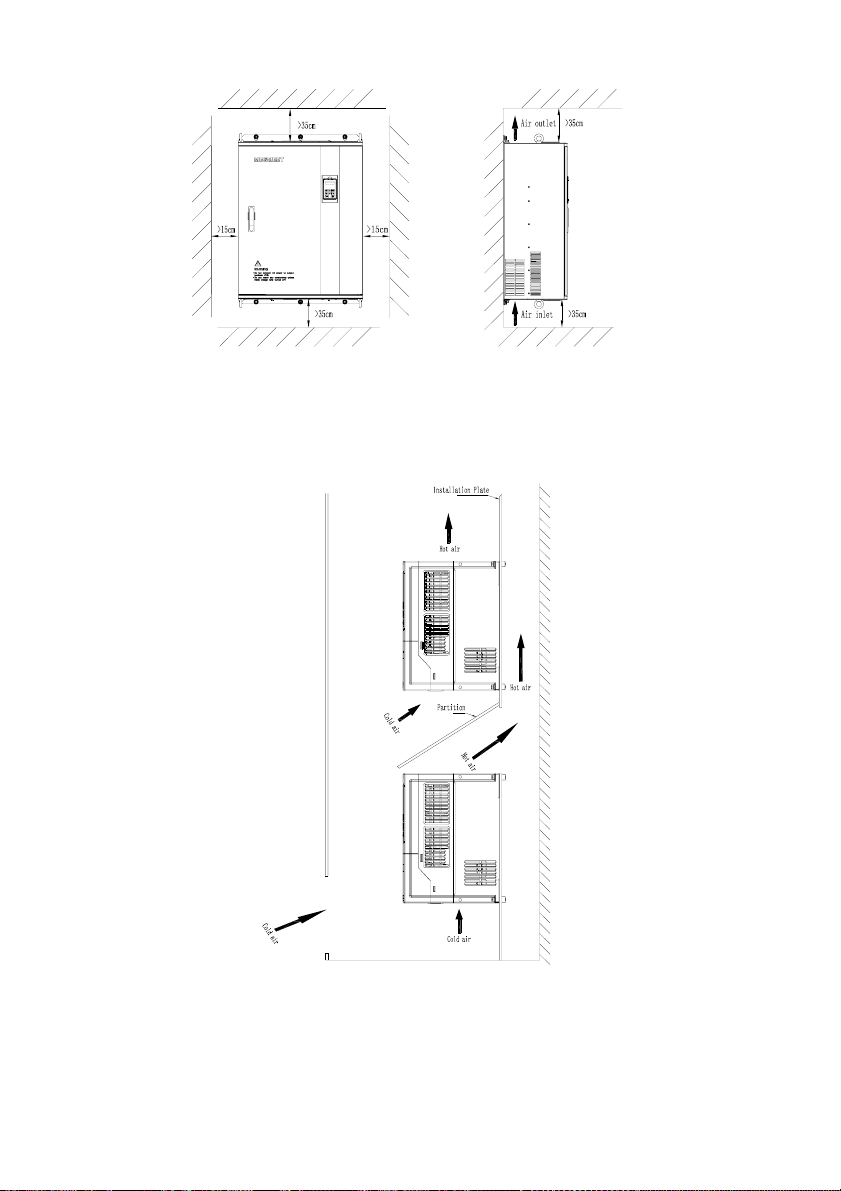

Fig. 2-3 Installation spacing for models of 55kWG/75kWP and above

When more than two drives are mounted in the up-down installation mode, the partition plate should be

installed between them, so as to avoid the influence of the heat dissipation from the bottom drive on the top

one, as shown in Fig.2-4.

Fig. 2-4 Installation of multiple drives

This manual suits for next models

40

Table of contents

Other Megmeet DC Drive manuals