Meiji FINER-CORE-13 User manual

INSTRUCTION MANUAL

FINER CORE

Hand Spray Gun

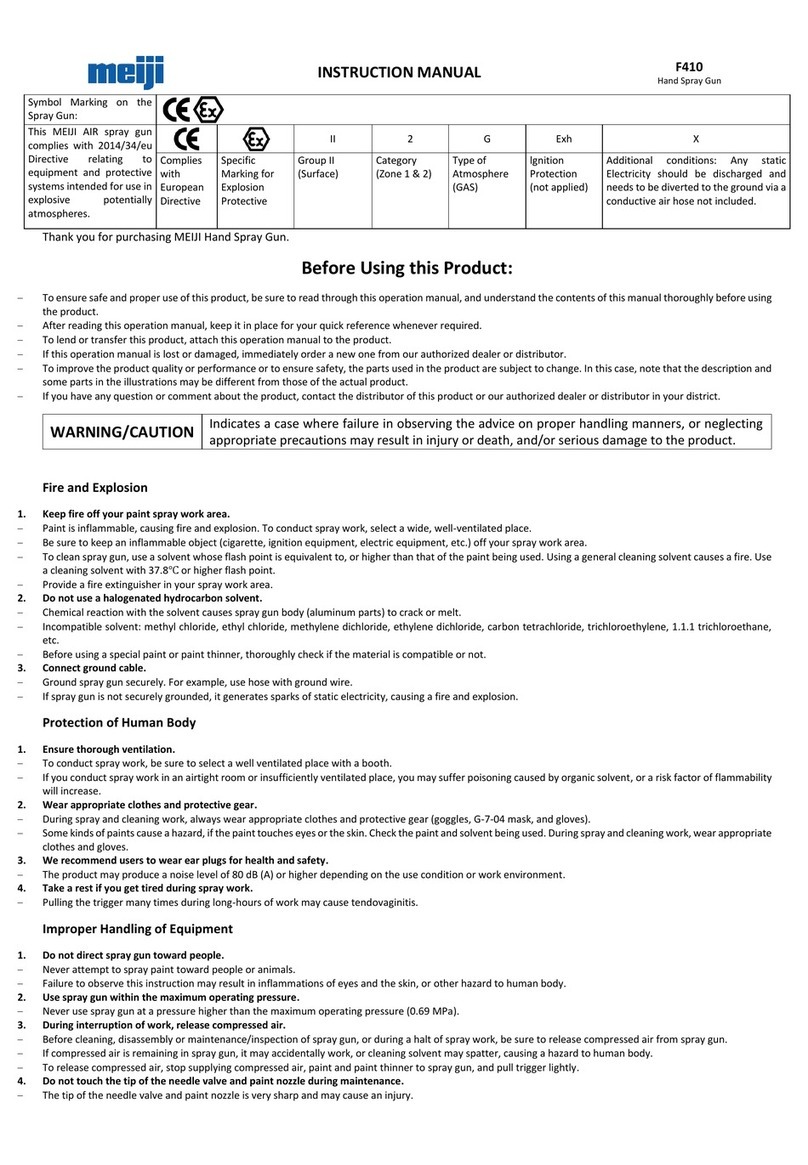

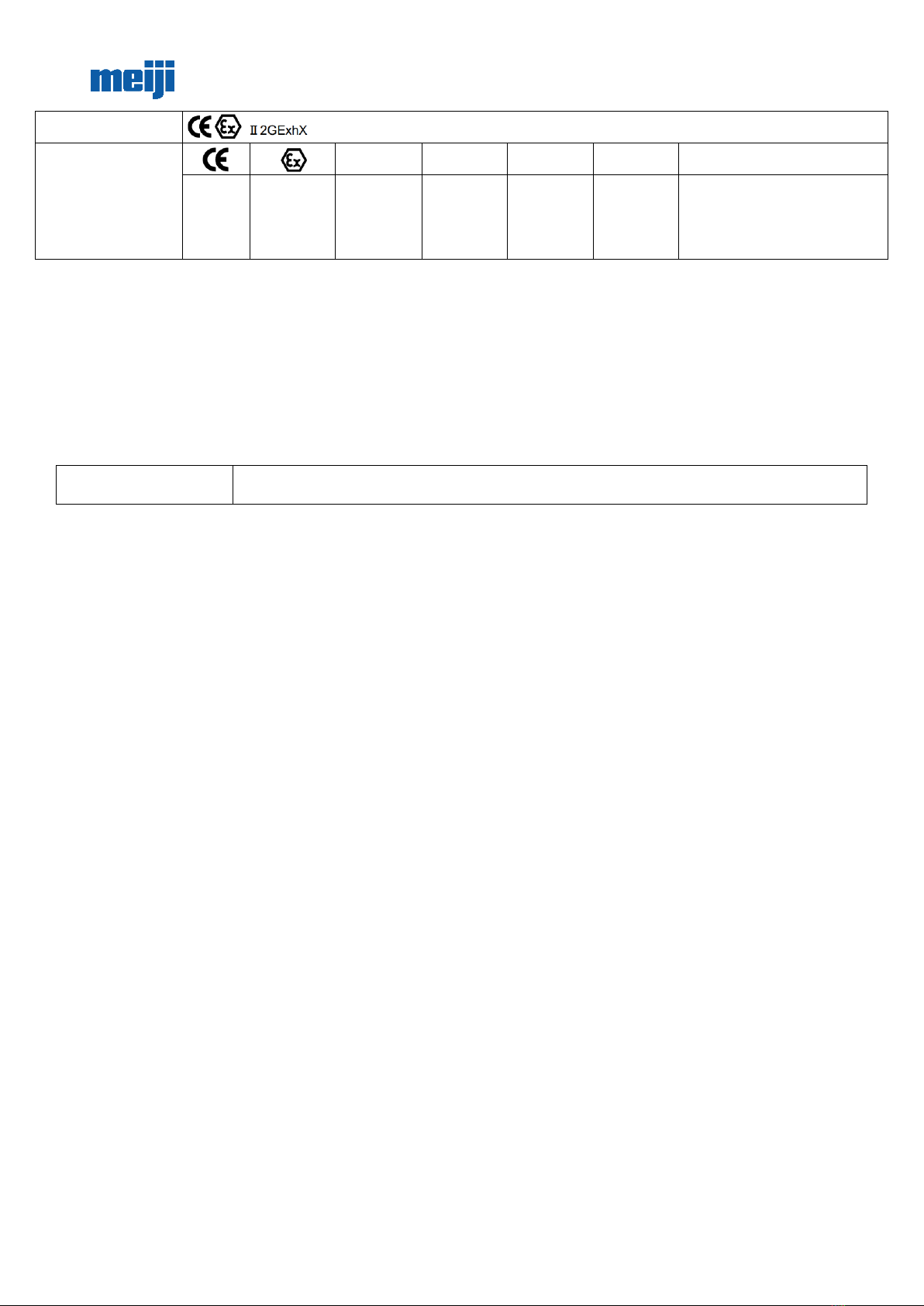

Symbol Marking on the

Spray Gun:

This MEIJI AIR spray gun

complies with 2014/34/eu

Directive relating to

equipment and protective

systems intended for use in

explosive potentially

atmospheres.

II

2

G

Exh

X

Complies

with

European

Directive

Specific

Marking for

Explosion

Protective

Group II

(Surface)

Category

(Zone 1 & 2)

Type of

Atmosphere

(GAS)

lgnition

Protection

(not applied)

Additional conditions: Any static

Electricity should be discharged and

needs to be diverted to the ground via a

conductive air hose not included.

Thank you for purchasing MEIJI Hand Spray Gun.

Before Using this Product:

−To ensure safe and proper use of this product, be sure to read through this operation manual, and understand the contents of this manual thoroughly before using

the product.

−After reading this operation manual, keep it in place for your quick reference whenever required.

−To lend or transfer this product, attach this operation manual to the product.

−If this operation manual is lost or damaged, immediately order a new one from our authorized dealer or distributor.

−To improve the product quality or performance or to ensure safety, the parts used in the product are subject to change. In this case, note that the description and

some parts in the illustrations may be different from those of the actual product.

−If you have any question or comment about the product, contact the distributor of this product or our authorized dealer or distributor in your district.

WARNING/CAUTION

Indicates a case where failure in observing the advice on proper handling manners, or neglecting

appropriate precautions may result in injury or death, and/or serious damage to the product.

Fire and Explosion

1. Keep fire off your paint spray work area.

−Paint is inflammable, causing fire and explosion. To conduct spray work, select a wide, well-ventilated place.

−Be sure to keep an inflammable object (cigarette, ignition equipment, electric equipment, etc.) off your spray work area.

−To clean spray gun, use a solvent whose flash point is equivalent to, or higher than that of the paint being used. Using a general cleaning solvent causes a fire. Use

a cleaning solvent with 37.8℃or higher flash point.

−Provide a fire extinguisher in your spray work area.

2. Do not use a halogenated hydrocarbon solvent.

−Chemical reaction with the solvent causes spray gun body (aluminum parts) to crack or melt.

−Incompatible solvent: methyl chloride, ethyl chloride, methylene dichloride, ethylene dichloride, carbon tetrachloride, trichloroethylene, 1.1.1 trichloroethane,

etc.

−Before using a special paint or paint thinner, thoroughly check if the material is compatible or not.

3. Connect ground cable.

−Ground spray gun securely. For example, use hose with ground wire.

−If spray gun is not securely grounded, it generates sparks of static electricity, causing a fire and explosion.

Protection of Human Body

1. Ensure thorough ventilation.

−To conduct spray work, be sure to select a well ventilated place with a booth.

−If you conduct spray work in an airtight room or insufficiently ventilated place, you may suffer poisoning caused by organic solvent, or a risk factor of flammability

will increase.

2. Wear appropriate clothes and protective gear.

−During spray and cleaning work, always wear appropriate clothes and protective gear (goggles, G-7-04 mask, and gloves).

−Some kinds of paints cause a hazard, if the paint touches eyes or the skin. Check the paint and solvent being used. During sprayand cleaning work, wear appropriate

clothes and gloves.

3. We recommend users to wear ear plugs for health and safety.

−The product may produce a noise level of 80 dB (A) or higher depending on the use condition or work environment.

4. Take a rest if you get tired during spray work.

−Pulling the trigger many times during long-hours of work may cause tendovaginitis.

Improper Handling of Equipment

1. Do not direct spray gun toward people.

−Never attempt to spray paint toward people or animals.

−Failure to observe this instruction may result in inflammations of eyes and the skin, or other hazard to human body.

2. Use spray gun within the maximum operating pressure.

−Never use spray gun at a pressure higher than the maximum operating pressure (0.69 MPa).

3. During interruption of work, release compressed air.

−Before cleaning, disassembly or maintenance/inspection of spray gun, or during a halt of spray work, be sure to release compressed air from spray gun.

−If compressed air is remaining in spray gun, it may accidentally work, or cleaning solvent may spatter, causing a hazard to human body.

−To release compressed air, stop supplying compressed air, paint and paint thinner to spray gun, and pull trigger lightly.

4. Do not touch the tip of the needle valve and paint nozzle during maintenance.

−The tip of the needle valve and paint nozzle is very sharp and may cause an injury.

Other Precautions

1. Do not modify the product.

−Do not modify spray gun.

−If you modify spray gun, it cannot provide sufficient performance. Also, a failure of the machine may result.

2. Stop other equipment.

−To conduct spray work in an operating area of other equipment (robot, reciprocating equipment, etc.), confirm that the equipment has stopped first.

−If you touch a robot or reciprocating equipment, you may get injury.

3. Do not use spray gun for food and chemicals.

−Do not apply spray gun to food or chemicals.

−Corrosion of paint circuit may result in an accident. Also, mixture of foreign substances may result in health disorder.

4. If an abnormal condition occurs, immediately stop spray gun.

−If you find a problem, immediately stop spray gun, and examine the cause of the problem. Do not use gun until the problem can be solved.

Installation

1. Use clean compressed air.

−Use clean compressed air that has passed through an air dryer or air filter. If contaminated air is used, it results in a failure in spray work.

2. Ensure tight connections.

−When connecting paint cup and air hose to spray gun, tighten them securely by using spanner. If the connection is loose, compressed air, paint and other liquids

may spatter over human body, painted work pieces and peripheral equipment, resulting in damage.

3. Conform to the rated withstand pressure of hose.

−Make sure that the air pressure supplied to air hose does not exceed the rated withstand pressure of hose. Do not use an old or damaged hose.

1. Operating Procedure

1. Mount a paint cup and air hose securely to the spray gun by using a spanner or other tool.

2. Although it varies depending on the paint viscosity, property, and operating conditions, a recommended spraying pressure is between 0.15 to 0.25 MPa. Never

use spray gun at a pressure higher than the maximum operating pressure (0.69 MPa).

3. Recommended spraying distance is 150 to 250 mm. If spray gun is too close to a target work piece or it swings like an arc, good finished quality cannot be obtained.

4. To obtain a uniformly finished condition, always hold spray gun at a right angle to the spraying surface.

5. Tightening the air volume adjusting screw clockwise will decrease the air volume, and loosening the air volume adjusting screw counterclockwise will increase

the air volume.

6. If you tighten the pattern adjusting screw by turning it clockwise completely, paint is sprayed in a spot pattern. As you loosen the pattern adjusting screw by

turning it counterclockwise, spray pattern area gradually increases. When you rotate the screw approximately three times, the pattern area becomes the

maximum. Adjust the spray pattern depending on the spray work step and the type of paint being used.

7. If you tighten the paint adjusting screw by turning it clockwise, spray volume decreases. As you loosen the screw by turning it counterclockwise, spray volume

gradually increases. When you rotate the screw three to four times, spray volume becomes the maximum. Set paint volume depending on spray work

conditions.

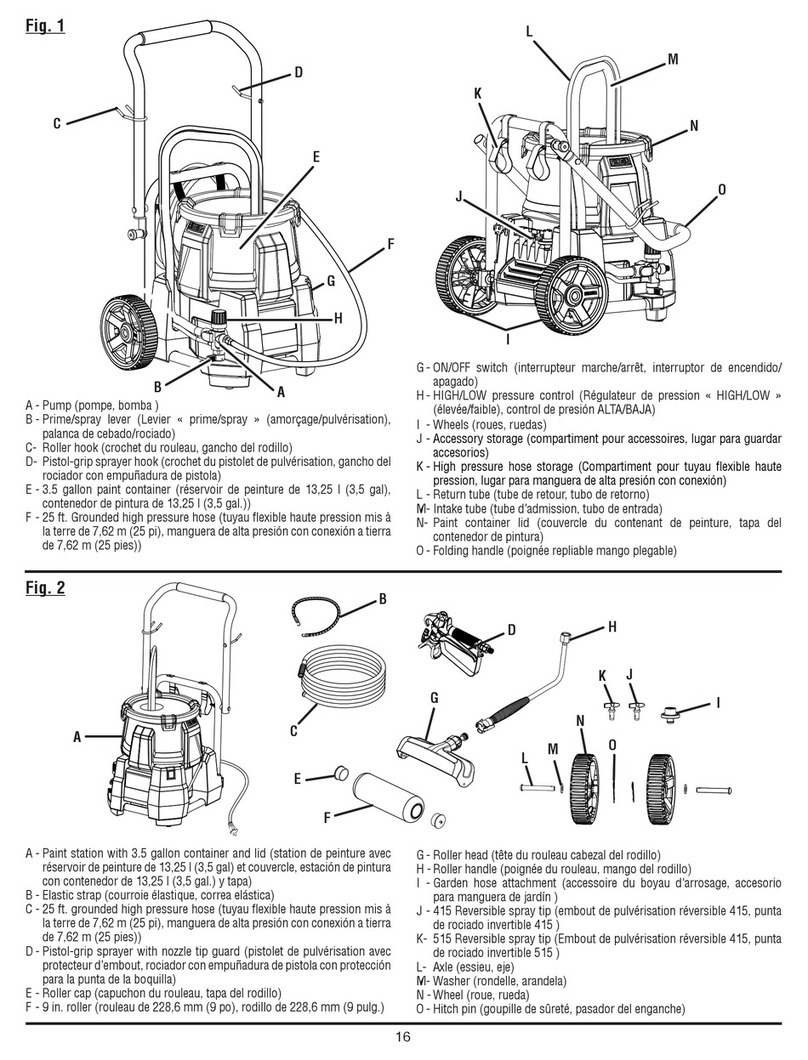

Pattern adjusting screw

Paint adjusting screw

Clockwise (Spot

pattern)

Counterclockwise (Flat

pattern)

Air volume

adjusting screw

Counterclock wise

Clockwise

Rotation direction of paint adjusting screw

Max. Mín.

Rotation direction of

pattern adjusting screw

2. Maintenance and Inspection

1. Clean and lubricate spray gun everyday to maintain it in the best operating condition.

2. To clean spray gun body, wipe dust off body with a cloth damped with a solvent. If spray gun is soaked in a solvent, lubricant is removed, and an adhering substance

enters air circuit, causing a trouble in spay work.

We shall not be liable for any trouble resulting from use of gun cleaner that causes dust or paint waste to enter paint nozzle air circuit.

3. After using spray gun, be sure to clean spray gun with a clean solvent, and leave cup empty.

4. To clean cup, remove surplus paint from cup first, and then pour an appropriate solvent into cup, to wash off residual paint completely.

5. If spray gun is used with a cleaning solvent remaining in gun and cup, and with paint waste or dust adhering to paint circuit, it causes a failure in spray work.

6. After disassembling air cap (3) and fluid nozzle (2), clean them with a brush. When disassembling fluid nozzle (2), be careful not to damage it.

7. To clean paint circuit, spray a small quantity of solvent as in the same manner as spray work.

8. Be sure not to damage each hole of air cap (3), and center hole and tip periphery of fluid nozzle (2).

9. If needle valve set (6) or air valve (26) malfunctions, apply a small quantity of oil (non-silicone oil) to sliding part from the outside.

10. After cleaning the equipment with water, be sure to eliminate water. Residual water causes the equipment to rust away.

11. Soaking whole spray gun in solvent may cause spray gun malfunction. Also soaking air cap assy. itself for extended period may cause a defective spray pattern.

3. Specifications

Model

Paint feed system

Paint

nozzle

bore

(mm)

Applicable air

cap

Spraying

distance

(mm)

Spraying air

pressure (mPa)

Air

consumption

(L/min)

Paint spraying

volume

(mL/min)

Maximum

effective

pattern

width (mm)

Connection

diameter

Weight

(g)

FINER-CORE-13

Gravity

1.3

FINER CORE

200

0.20

300

170

280

G1/4 (air)

G3/8 (paint)

340

FINER-CORE-15

1.5

200

300

FINER-CORE-

HVLP-13

1.3

FINER CORE

HVLP

0.18 (0.07)

380

135

280

FINER-CORE-

HVLP-15

1.5

155

300

* The paint viscosity values are equivalent to 20 seconds for the lacquer enamel paint using Meiji V-1 viscosity cup.

4. Parts List

N.

Name

Qnt.

1

Body

1

2

Paint nozzle

1

3

Air cap set

1

6

Needle valve ass'y

1

9

Needle Spring

1

10

Spring insert

1

11

Trigger

1

12

Trigger pin

1

13

Trigger screw

1

16

Air volume adjusting valve ass'y

1

17

Pattern adjusting valve ass'y

1

20

U-packing P5

2

22

Trigger presser

1

23

Needle packing screw

1

24

Sleeve

1

25

Packing presser spring

1

26

Air valve

1

27

Valve spring

1

28

Packing guide

1

29

O-ring presser

2

30

Valve seat

1

31

O-ring S10

1

32

Hexagon nipple 1/4×M11

1

34

Needle cylinder

1

35

Paint adjusting screw

1

36

Paint adjusting screw cover

1

37

Adjusting screw cover

2

38

Hexagon socket set screw

3

39

Head base (with parallel pin)

1

5. Parts Replacement

Before replacing spray gun parts, remove residual paint, and clean spray gun. Then, release air pressure from spray gun, and remove the air hose and paint cup.

To repair spray gun, place it in a clean level place, and wear protective goggles. For parts replacement, use the specified appropriate tools.

−Replacement of paint nozzle and needle valve ass’y (It is recommended that these parts should be simultaneously replaced).

1. Remove paint adjusting screw (35) and needle spring (9), and pull out needle valve ass'y (6) from the spray gun body.

2. Remove air cap set (3).

3. Remove paint nozzle (2) by using a spanner 17 or socket wrench 17.

4. Tighten paint nozzle (2) at a tightening torque of 10 N・m by using a torque wrench.

−Replacement of air volume adjusting valve ass'y and pattern adjusting valve ass'y

1. Before assembling or disassembling air volume adjusting valve ass'y (16) and pattern adjusting valve ass'y (17), turn the knob counterclockwise completely to

loosen it.

−Replacement of valve seat, air valve, valve spring, O-ring presser, and needle cylinder

1. Remove paint adjusting screw (35) and needle spring (9), and pull out needle valve ass'y (6) from the spray gun body.

2. Remove needle cylinder (34) using socket wrench 14.

3. Remove O-ring presser (29), valve spring (27), and air valve (26) from the spray gun body.

4. Remove valve seat (30) by using hexagon wrench 10, so that seat surface on the mounting part will not be damaged.

5. Tighten valve seat (30) by using hexagon wrench 10 until the seat touches the spray gun body. Then, re-tighten the seat lightly.

6. Insert air valve (26) until it reaches the innermost end so as not to damage seat surface. Then, insert valve spring (27) and O-ring presser (29).

7. Tighten needle cylinder (34) using socket wrench 14.

−Replacement of packing presser spring, O-ring presser, packing guide, and O-ring S10 perfluor

1. Following the procedure for “Replacement of valve seat, air valve, valve spring, O-ring presser, and needle cylinder”, remove the relevant parts.

2. Remove packing presser spring (25), O-ring presser (29), packing guide (28), and O-ring S10 (31).

3. If packing guide (28) and O-ring S10 (31) are hard to remove, vibrate spray gun.

4. Insert O-ring S10 (31), packing guide (28), O-ring presser (29), and packing presser spring (25) in this order.

−Replacement of sleeve

1. Remove needle packing screw (23) with spanner 10.

2. Remove sleeve (24).

3. Insert sleeve (24).

4. Tighten needle packing screw (23) with spanner 10.

6. Troubleshooting

Trouble condition

Cause

Corrective Action

Paint breaking

Lack of paint in paint cup.

Refill paint

The paint circuit is clogged.

Clean paint circuit with a solvent.

A screw of the paint circuit connecting part, or paint nozzle (2), is

loose, or the tapered seat is damaged.

Tightening or replacement

Sleeve (24) has been worn out, or the needle packing screw (23) is

loose.

Replace sleeve (24) or re-tighten needle packing screw

(23) securely.

One-sided

pattern

Part of the square hole of air cap (3) has been clogged or

damaged.

Cleaning or replacement.

Paint or dust is adhering to the tip periphery of paint nozzle (2)

Cleaning or replacement.

Crescent

pattern

Part of the square hole of air cap (3) has been clogged or

damaged, or paint or dust is adhering to inside of the center hole,

or the center hole has been damaged

Cleaning or replacement.

Paint or dust is adhering to the tip periphery of paint nozzle (2)

Cleaning or replacement.

Thick in middle

Paint nozzle (2) has been worn out, and nozzle bore diameter

increased.

Replacement.

Spraying air pressure is too low.

Increase spraying air volume and pressure.

Paint viscosity is too high.

Reduce paint viscosity.

Narrow in

middle

Spraying air pressure is too high

Reduce spraying air volume and pressure.

Dust or paint is adhering to the gap between the center hole of air

cap (3) and the periphery of paint nozzle (2).

Cleaning.

Paint leak from needle packing

screw

Needle packing screw (23) is loose.

Adjust needle packing screw (22).

Sleeve (24) has been worn out.

Tighten or replace needle packing.

Liquid leak from the tip of paint

nozzle

Paint nozzle (2) or needle valve ass'y (6) has been worn out or

damaged.

Replacement.

Sleeve (24) or needle valve ass'y (6) is stuck.

Lubrication.

mproper adjustment of needle packing screw (23)

Adjustment.

Head Office 3-14, 2-chome, Tagawa, Yodogawa-ku Osaka 532-0027, Japan

Tel:+81-6-6309-1227 Fax:+81-6-6309-0157

MEIJI AIR COMPRESSOR MFG. CO., LTD

MEIJI AIR COMPRESSOR MFG.CO.,LTD.

3-14,2-chome,Tagawa,Yodogawa-ku,Osaka,532-0027,Japan

Phone : +81-6-6309-1227

Fax : +81-6-6309-0157

E-mail:export1@meijiair.co.jp

URL,:http//www.meijiair.co.jp/

We, MEIJI AIR COMPRESSOR MFG.CO.,LTD. 3-14,2-chome,Tagawa,Yodogawa-ku,Osaka, 532-0027, Japan,

declare, under our sole responsibility, that the product

DECLARATION OF CONFORMITY

model:

Finer-core SPRAY GUN

on which a plate is affixed, stating :

for use in Group Ⅱand Category 2 ;

are in conformity with European ATEX Directive 2014/34/EU Directive relating to equipment and protective

systems intended for use in explosive potentially atmospheres.

Name and position of issuer: Koji Fukuda, Director and Factory Manager

Signature of issuer: Koji Fukuda

Place and date of issue: Osaka, Japan

This is a translation of the CE declaration of conformity issued by MEIJI AIR COMPRESSOR MFG.CO.,LTD.

Other copies are considered not valid.

2020-08-07

II 2G Ex h X

This manual suits for next models

3

Table of contents

Other Meiji Paint Sprayer manuals