MEKANIKA Evo-S User manual

EVO CNC MILLING MACHINE

USER MANUAL

www.mekanika.io

MAINTENANCE

Prior to commissioning the Evo CNC Milling Machine, it has to be ensured that the machine is in a technically

perfect and well-maintained condition. Always ensure that the machine is not powered if you want to perform

adjustment or maintenance works. For this purpose, disconnect the power plug.

Sharp-edged cutting tools must also be dismounted prior any maintenance work to avoid a risk of injury.

Remove workpieces you have clamped onto the machine table, including the clamping system.

Only use high quality tools during your maintenance work.

The Evo CNC machine is, to a good extent, maintenance-free. Handle your CNC system with

care in order to ensure a long service life. Regular maintenance has a substantial impact on the service life of

your machine. Frequently clean the CNC system with a cloth.

Often inspect the slots of the aluminium proles, where the wheels are moving, for any debris, dust or stuck

chips.

Clean the electronic devices, including the screen and keyboard from dust and impurities.

Regularly clean the fan lter of the control unit. A clogged lter might result in overheating inside the box, po-

tentially leading to permanent damage to the electronic components.

All parts of the machine and of the control unit can be purchased individually as spare parts.

Please contact us directly about this.

When ordering spare parts, please provided the information on the machine model, size and part number avail-

able in accordance with the building instructions.

GENERAL INFORMATION

RECOMMENDED MAINTENANCE WORK

SPARE PARTS

19

TABLE OF CONTENT

GENERAL INFORMATION

Contact for Customer Information

Notice

Meaning of Terms Used

GENERAL INSTRUCTIONS

Foreword

General Safety Warnings for the Use of Machines

Protective Measures

Personal Protective Equipment

Emergency Stop Button

Residual Risk

Check-list for Safety When Using the Machine

Safety Symbols

MACHINE DESCRIPTION

Workplace

Intended Use of the Machine

ASSEMBLY & SYSTEM SETUP

Environmental Conditions

Machine Positioning

Machine Assembly

Machine References

Recommended Workplace Layout

OPERATION

Commissioning and Safe Operation

Machine Work Surface

Clamping the Workpiece

Operation of the CNC System

TECHNICAL DATA

Dimensions and Weight

Technical Specications

TRANSPORTATION AND STORAGE

Transport

Packaging

Storage

MAINTENANCE

General information

Recommended Maintenance Work

Spare Parts

4

4

4

4

5

5

5

8

9

9

9

10

10

11

12

12

13

13

13

13

14

15

16

16

16

16

16

17

17

17

18

18

18

18

19

19

19

19

TRANSPORTATION & STORAGE

If you want to transport the machine, please pay special attention to its dimensions. You might need additional

people for transportation. Never lift heavy loads above people!

Avoid a unilateral load of the machine frame!

If you do not want to reuse the packaging material of the machine and its components, please separate it

according to the disposal conditions on site and take it to a collection center for recycling or dispose of it.

If the machine or its components is not used for a longer period of time, please observe the following points

regarding storage:

• Only store the machine and the components in closed rooms.

• Protect the machine and the components against humidity, wetness, cold, heat and direct sun radiation.

• Store the machine and its components dust-free and cover it if necessary.

• The storage place must not be subjected to vibrations.

TRANSPORT

PACKAGING

STORAGE

18 3

GENERAL INFORMATION

CONTACT FOR CUSTOMER INFORMATION

NOTICE

MEANING OF TERMS USED

All instructions, warranties and other collateral documents are subject to change at the sole discretion of

Mekanika SRL.

Please visit www.mekanika.io on your product page to access up-to-date informations and documents.

The following terms are used throughout this operating manual to indicate various levels of potential harm

when operating this machine. The safety symbols, and their explanations, deserve your careful attention and

understanding.

The safety warnings themselves do not eliminate any danger. The instructions or warnings they give are not

substitutes for proper accident prevention measures.

NOTICE

Procedures which, if not properly followed, create a possibility of physical property damage and a little or no

possibility of injury.

CAUTION

Procedures which, if not properly followed, create a probability of physical property damage and a possibility

of serious injury.

WARNING

Procedures which, if not properly followed, create a probability of property damage, collateral damage, serious

injury or death or create a high probability of supercial injury.

Read the entire operating manual in order to become familiar with the features of the machine and how to

operate them. Failure to operate the machine correctly can result in damage to the machine, personal property

and cause serious injury, electric shock and/or re.

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE REFERENCE.

Mekanika SRL

Rue de Birmingham, 102

1070 Anderlecht

Belgium

E-mail: help@mekanika.io

If you encounter any issue or have any question regarding your machine, contact us and we’ll get back to you

within 24 hours.

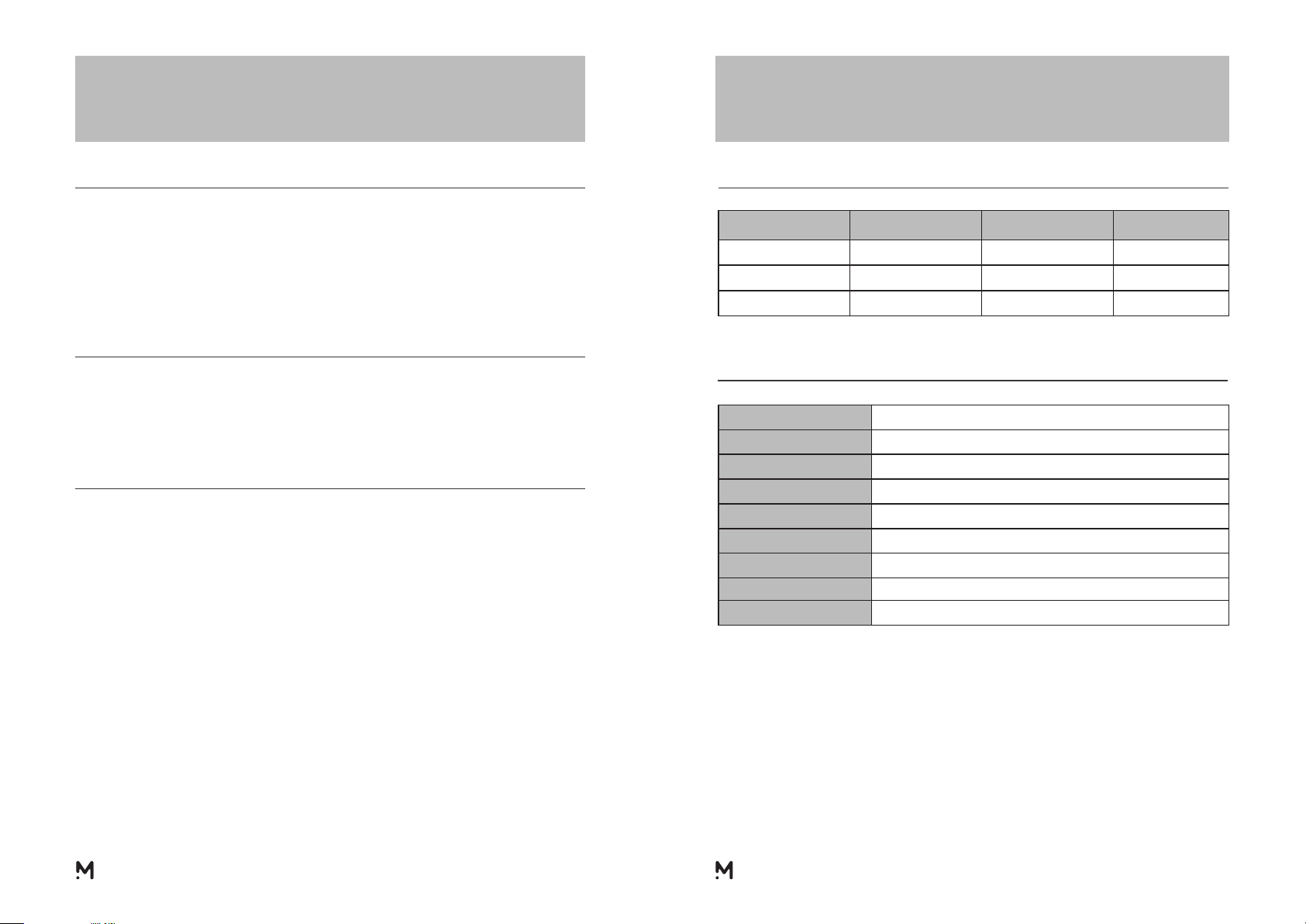

TECHNICAL DATA

Model Dimensions Working Area Weight

Evo-S 850x1250 mm 650x650 mm 37 kg

Evo-M 850x1250 mm 650x1050 mm 42 kg

Evo-L 1250x1250 mm 1050x1050 mm 48 kg

DIMENSIONS & WEIGHT

TECHNICAL SPECIFICATIONS

Working area 650 x 650mm | 650 x 1050mm | 1050 x 1050mm

Z clearance height 90mm with a travel distance of 75mm

Linear Guides Custom v-slot aluminium proles

Drive system Pulleys & PU GT2 timing belts with steel core

Accuracy 0.05mm

Maximal travel speed 20,000mm/min

Motors (X, Y1, Y2, Z) 4 High-torque Nema23 stepper motors

Structure High quality aluminium proles and digitally manufactured steel plates

Controller & Software PlanetCNC software installed and pre-congured on a Raspberry Pi 4B

4 17

GENERAL INSTRUCTIONS

These operating instructions explain how the Evo CNC Milling Machine works and inform you about the correct

handling of the machine.

Please read these operating instructions as well as all accompanying documents in their entirety before

commissioning of the system.

It is imperative to adhere to the safety instructions listed in these operating instructions at all times.

Should any doubts or the need for further information arise, do not hesitate to contact us prior to the use of the

machine.

GENERAL SAFETY WARNINGS FOR THE USE OF MACHINES

PERSONAL SAFETY

NOTICE

All persons who operate the machine must have read and fully understood

all relevant safety and operating instructions. Misunderstanding may re-

sult in personal injury.

CAUTION

Dress properly. Do not wear loose clothing or jewellery. Pin your hair above

your shoulders so that it cannot get caught in the linear guides or moving

parts.

CAUTION

Stay alert, watch what you are doing and use common sense when operat-

ing a machine. Do not use a machine while you are tired and/or under the

inuence of drugs, alcohol or medication. A moment of inattention while

operating a machine may result in serious personal injury.

CAUTION

Use personal protective equipment. Always wear eye protection. Protec-

tive equipment, such as a suitable dust mask or ear protection, reduces

the risk of injuries.

CAUTION

This tool is controlled by a computer. During operation, it cannot be con-

trolled directly. Lack of caution or expertise as well as program errors can

lead to unexpected movements.

CAUTION Do not touch the motors as they can heat up signicantly during opera-

tion.

CAUTION Never place any parts of the tool or accessories in your mouth as this can

lead to serious injuries.

FOREWORD

OPERATION

The machine and all connected components have to be wired correctly and be in perfect condition.

The operator must have completely read and understood the entire documentation of the relevant machine

model and its corresponding instructions. Furthermore, he must have been trained in operating the machine as

well as its accessories and has to be familiar with the use of CNC Milling Machine and CNC software in general.

The workplace needs to be compliant with the applicable regulations and provisions of the respective industry.

The operator must use the provided dust shoe to prevent access to the cutting tool and be protected from

ejection of chips while machining.

COMMISSIONING AND SAFE OPERATION

The workpiece must be secured directly on the machine table using clamping devices.

If you want to mill through the material and produce cutouts, we recommend the use of suitable material as

spoilerboard. It is placed under the workpiece and protects the machine table from potential damage.

The workpiece should be suciently clamped in order to prevent it from unintentional shifting during process-

ing.

Never hold the workpiece with your hands during the operating process. There is a high risk of serious injury!

The entire CNC system is controlled and operated via a Raspberry Pi, using a touch screen and a custom key-

board as a user interface.

The operator must have completely read and understood the entire documentation of the CNC control software

before commissioning the CNC system.

For further questions regarding the applied control software, please contact the respective software manufac-

turer at https://planet-cnc.com/

There is no spoilerboard included in our kit. At rst, a simple MDF wood panel is enough to get a grasp on CNC

machining. When being more experienced, we suggest building a threaded insert grid on a surfaced spoiler-

board. If you intend to machine hard material and use a lubrication system on the machine, we suggest you

purchase an aluminium T-slot proles worktable, as MDF will swell in contact with water.

MACHINE WORK SURFACE

CLAMPING THE WORKPIECE

OPERATION OF THE CNC SYSTEM

16 5

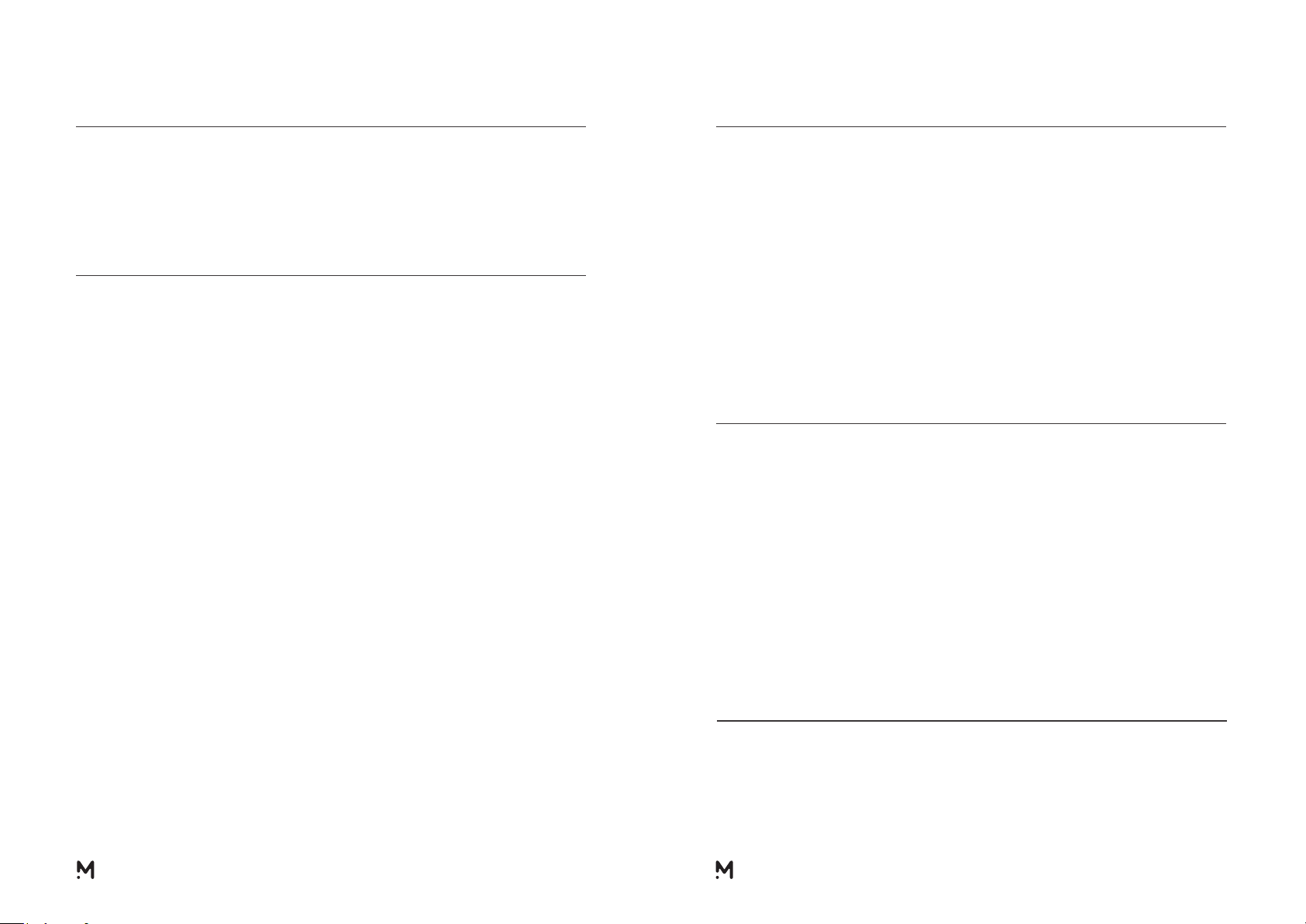

RECOMMENDED WORKPLACE LAYOUT

ELECTRICAL

SAFETY

NOTICE Do not expose the machine to moisture. The machine is only suitable for

indoor use.

WARNING

Machine plugs must match the outlet. Never modify the plug in any way.

Do not use any adapter plugs with grounded machines. Unmodied plugs

and matching outlets will reduce the risk of electric defects and malfunc-

tions

WORK AREA SAFETY

NOTICE Keep work area clean and well lit. Cluttered or dark areas are prone to ac-

cidents.

NOTICE Operate the machine only in interior spaces on a solid, horizontal table or

workbench.

CAUTION Keep children and bystanders at a distance while operating a power tool.

Distractions can cause you to lose control and can result in accidents.

CAUTION

Do not operate the machine in explosive atmospheres, such as in the

presence of ammable liquids, gases or dust. Machines can create sparks

which may ignite the dust or fumes.

USE OF THE MACHINE

NOTICE Do not leave a running tool unattended, turn power o. Only when tool

comes to a complete stop and is disconnected from the mains it is safe.

NOTICE

Use the machine and accessories in accordance with these instructions,

taking into account the working conditions and the work to be performed.

Use of the machine for operations dierent from those intended could re-

sult in a hazardous situation with high probability of supercial injury.

NOTICE

Never use dull or damaged end mills. Sharp end mills must be handled

with care. Damaged end mills can snap during use. Dull end mills require

more force to cut the tool, possibly causing the end mill to break.

NOTICE

The speed and feed of the end mill when carving, routing or cutting is very

important. Always observe the speed and feed for the particular end mill

recommended.

NOTICE

Do not allow familiarity gained from frequent use of your rotary tool to be-

come commonplace. Always remember that a careless fraction of a second

is sucient to inict severe injury.

6 15

OPERATING

AREA LOADING AREA

0.5 meter MAINTENANCE & SECURITY

AREA

MAINTENANCE & SECURITY

AREA

1 meter

MAINTENANCE & SECURITY

AREA

14 7

Z-AXIS

X-AXIS

Y-AXIS

MACHINE REFERENCES

AXES TERMINOLOGY

CONTROL UNIT

USE OF THE MACHINE

NOTICE

Clean the tool’s air vents every four hours by using compressed air. Exces-

sive accumulation of powdered metal inside the motor housing may cause

electrical failures.

CAUTION Do not reach in the area of the rotating tool. The proximity of the rotating

tool to your hand may not always be obvious.

CAUTION Never try to reach the limit sensors while the machine is moving, it could

lead to the crushing of your hand or ngers.

CAUTION Do not alter or misuse the tool. Any alteration or modication is a misuse

and may result in serious personal injury.

CAUTION

Disconnect the plug from the power source before you make any adjust-

ments, change accessories, or store the tool. Such preventive safety meas-

ures reduce the risk of starting the power tool accidentally.

CAUTION

Store the machine out of the reach of children and do not allow persons

unfamiliar with these instructions to operate the machine. Machines are

dangerous in the hands of untrained users.

CAUTION

If the workpiece or end mill gets jammed, immediately press the emergen-

cy stop button. Wait for all moving parts to stop and turn o the spindle

with the power switch, then free the jammed material. Do not try to do this

with the spindle turned on.

CAUTION Do not touch the end mill or collet after use. After usage they are too hot to

be touched with bare hands.

CAUTION

Before starting any machining operation, always have the workpiece se-

curely clamped. Never attempt to hold the workpiece with your hands or

using any accessories. These tools can jam easily in the material, and can

kickback, causing loss of control resulting in serious injury.

CARE OF THE TOOLS

NOTICE

Properly maintain the tools you use. Check for misalignment or binding of

moving parts, breakage of parts and any other conditions that may aect

the machine’s operation. If damaged, have the machine repaired before

use. Many accidents are caused by poorly maintained machines.

NOTICE Have your machine serviced by a qualied repair person using only identi-

cal replacement parts.

1 2

MOTORS

FAN & DUST

FILTER

LIMIT

SWITCHES PROBE Z

HDMI ETHERNET

POWER SUPPLY

EMERGENCY STOP

USB

X

X

Z

Z

Y Y

2

Y

1

Y

8 13

PROTECTIVE MEASURES

ADDITIONNAL SAFETY MEASURES

CAUTION

Depending on the application eld of the machine (private or commer-

cial), observe the applicable occupational safety and health, safety and

accident prevention and environmental regulations.

WARNING

Some dust created while machining certain types of material can

contain chemicals known to cause cancer, birth defects or other re-

productive harm. Always inform yourself on the material you have

at hand before machining it. Some examples of these chemicals are:

lead from nonferrous metals with lead content, carbonate from car-

bon ber, arsenic and chromium from chemically-treated lumber.

Your risk from exposures to these varies, depending on how often you per-

form this type of work. To reduce your exposure to these chemicals: work

in a well ventilated area, and work with approved safety equipment, such

as those dust masks that are specially designed to lter out microscopic

particles.

The Evo CNC Machine has been designed for advanced users and is only to be operated by technically skilled

persons above the age of 18.

The machine is only to be used in a technically perfect condition, which is to be ensured by the user prior to

each operation.

The emergency switch as well as, if applicable, additional safety devices, always need to be easily accessible and

fully functional.

The use of lubrication systems is allowed. Please take into consideration that if you are using a MDF spoilerboard

(machine worktable), the MDF panel will swell and be damaged by the water.

ASSEMBLY & SYSTEM SETUP

The machine is solely suitable for the operation in dry, interior spaces.

Keep the environmental temperature of the machine dust-free. High dust exposure can cause damages to the

system.

The humidity should be within normal limits for humidity indoors (40 to 60 %). Protect the machine against

wetness and humidity.

The ideal environmental temperature for the system lies between 18°C to 25°C, respectively from 64°F to 77°F.

Particularly protect the electronics against overheating by avoiding direct sun radiation or indirect heating up

nearby a radiator.

Place the machine on a suitable table or on a machine stand. In order to provide a comfortable working height,

we recommend a working height of approx. 840 mm. For a torsion-free stand, the surface of the machine stand

needs to be solid and even. The machine is to be secured in a way that it cannot shift or fall down.

All movable parts of the machine must be able to operate collision-free.

The routing of the tool´s cables, such as with the milling motor, has to be eected in a way that the cable cannot

be clamped between the guide ways of the machine. For this purpose, use the cable chains we have set up for

the dierent axis.

The machine has to be easily accessible and operable. Especially the emergency switch has to be easily acces-

sible at all times.

Take care to ensure a sucient illumination of the machine`s location and the workplace surrounding the ma-

chine.

The control unit has to be ideally placed under the work area of the machine and the interface unit has to be

placed in the vicinity of the machine.

Please follow carefully our attached mounting guide and datasheet in order to properly mount your Mekanika

CNC machine.

If you have any questions, please do not hesitate to contact us!

ENVIRONMENTAL CONDITIONS

MACHINE POSITIONING

MACHINE ASSEMBLY

12 9

The Evo CNC Milling Machine is constructed for a permanent and regular application for professionals and hob-

byists. Due to the machine stiness, a variety of dierent materials, such as wood and non-ferrous metals, can

be processed.

The plausible and reasonable scope of uses include:

• Manual movement mode, using a digital“jog”to move the machine along its 3 axes independently.

• Automatic Homing procedure, operated by the user by clicking on a button. This procedure moves the ma-

chine sequentially on each of its axes in the following order: Z, X, Y, until it encounters the limit switches.

• Automatic Square Gantry procedure, operated by the user by clicking on a button. This procedure moves the

machine along its Y axis towards the front until it reaches its limit switches on both sides of the axis.

• Measure Tool Length procedure, activated by the user by clicking on a numerical button. This procedure

makes the machine descend at reduced speed along its Z axis until its tool comes into contact with a remov-

able sensor previously placed by the user.

• Normal operating mode, where the machine moves automatically according to a machine code, called

G-code, previously loaded by the user.

• Manual control mode using a terminal, the machine moves according to a machine code, called G-code,

entered directly by the user.

The plausible and reasonable scope of interventions include:

• Manual movement of the machine to access certain zones.

• Adjustment of the belts tightening.

• Adjustment of the wheels tightening;

• Changing the cutting tool on the milling spindle.

• Attachment/removal of the dust shoe.

• Attachment/removal of the raw material to be machined on the work surface.

• Switching on, pausing and stopping a machine code (G-code).

• Connection/disconnection of external machine cables.

• Opening of the cable entry chains to access the cables.

The workplace needs to provide enough space around the CNC Milling Machine in order for the machine to

work comfortably and to be able to fully use its traveling paths. Additionally, a safe distance to possibly nearby

positioned machines is to be maintained.

The location of the machine as well as the workplace surrounding the machine has to be suciently illuminated.

WORKPLACE

INTENDED USE OF THE MACHINE

PERSONAL PROTECTIVE EQUIPMENT

EMERGENCY STOP BUTTON

When working with the Mekanika CNC Machine, the operator has to wear at least the following personal protec-

tive equipment and has to be compliant with the below-mentioned safety aspects:

• Safety glasses to protect the eyes against ying chips and other projections.

• Ear protection to protect the ears against noise.

• Safety shoes to protect the feet against falling objects.

• No wearing of clothes which can get caught in the machine, such as ties, scarves, wide sleeves. Roll up

sleeves to prevent caught in moving parts. Additionally, jewellery, watches, rings and especially long neck-

laces and rings are to be dispensed with.

• Shoulder-length or longer hair must be secured with a hairnet or a hat in order to prevent it from getting

caught in the linear guides and / or rotating tools.

Prior to all adjustments to the machine, such as to the milling motor and to the control box, its control or sys-

tem-guided tools have to be disconnected from the power source.

Never hold the workpiece with your hands. It is mandatory to secure the workpiece on the worktable. Otherwise,

there exists a high risk of injuries!

The emergency stop is located in a separate housing with a magnetic disk and is securely connected with the

machine. In order to be able to intervene at all times, the emergency stop has to be positioned at a suitable

place.

By pressing the emergency stop switch, the emergency stop is triggered. The control of the machine is immedi-

ately interrupted. Additionally, the control software receives the signal to stop the operating process, freezing

the user interface. The machine stops moving immediately.

ATTENTION! The emergency stop switch can only eect the stop of all components if these components are

electronically connected with the emergency stop switch. The spindle motor, that features a separate ON /

OFF switch, is NOT controlled via the Raspberry Pi and the USB controller. The milling tool will continue to run

although you have activated the emergency stop switch, leading to a risk of personal injury and damage to

property if you don’t act with caution.

If you want to deactivate the emergency stop status, reactivate the control by turning the emergency stop

switch to the right. The operating process has to be restarted.

If you have any questions on this matter, please do not hesitate to contact us.

RESIDUAL RISK

Despite all safety precautions against the contact with rotating or hot tools and the protection from crushes, a

residual risk remains due to a careless handling and automatic movements of the CNC system.

10 11

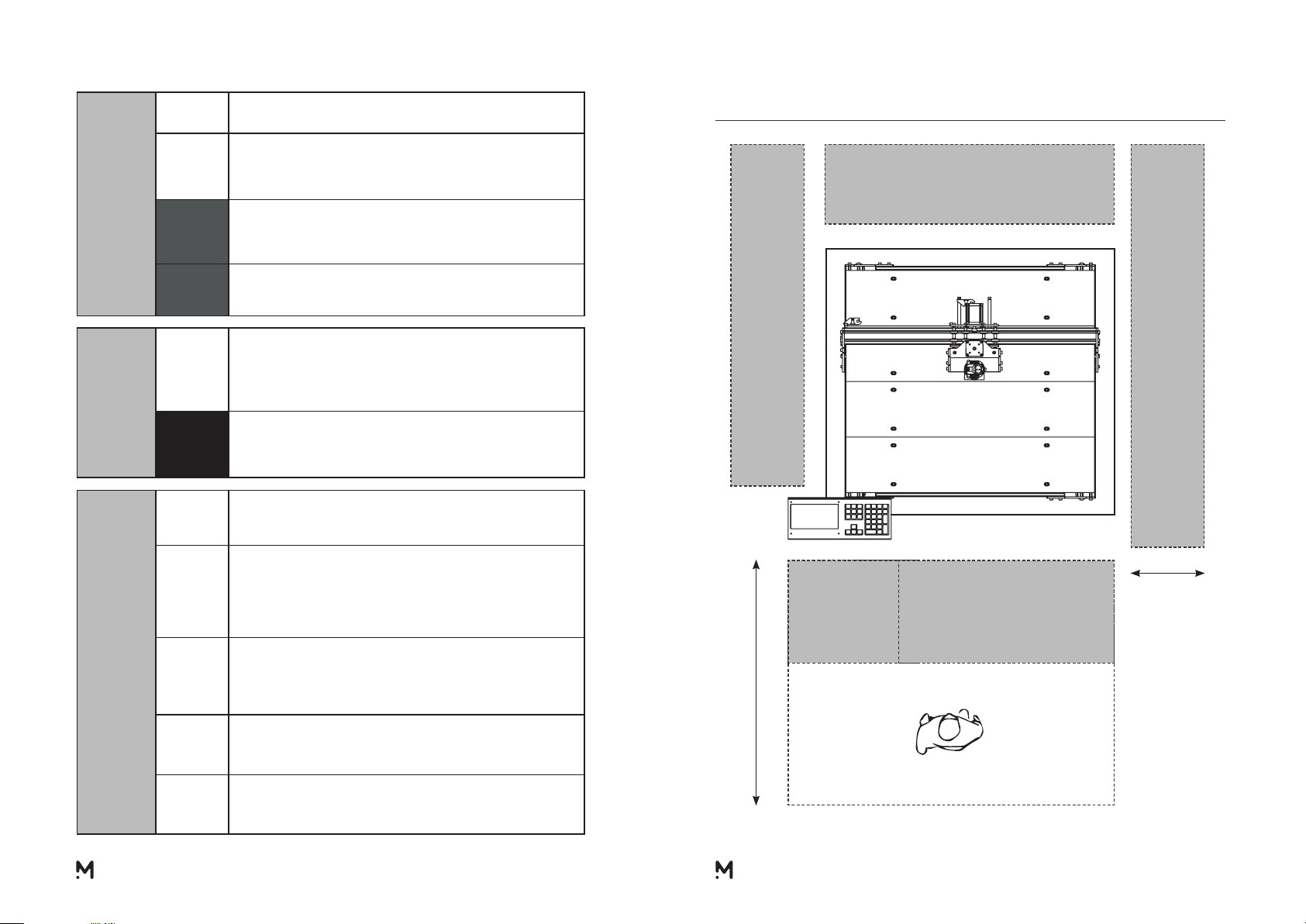

BE PREPARED WORK SAFE FINISH RIGHT

• Use appropriate personal

protective equipment :

- Safety Glasses

- Hearing

protection

- Safety Shoes

• Remove rings, bracelets,

watches and necklaces

before work.

• Tie and conne long hair.

• Wear tight tting clothing

and roll up sleeves to

prevent snagging.

• Inspect the equipment to

ensure there are no obvious

defects, damaged chucks ,

dull or cracked tools.

• Ensure you have the

required knowledge of the

use of a CNC machine.

• Do not use gloves.

• Check where the

emergency stop button is

located.

• Never plug or unplug

cables from the electronic

box while the machine is

powered.

• Ensure that the workpiece

is rmly and securely

clamped.

• Check that the tools are

sharp and set correctly.

• Use a brush or a vacuum

cleaner to clean chips o

surfaces.

• Never reach into the CNC

while it is running and keep

your hands away from any

moving part during ma-

chining.

• Stand clear of the machine

whenever it is operational.

You should also warn other

people near the risk of

being too close to it

• Keep hands clear during

manual adjustments. When-

ever you are handling or

passing tools, avoid touch-

ing the cutting edges

• When you are nished with

your work, shut-down the

Raspberry Pi before turning

o the power switch of the

control box (not doing so

might corrupt the SD card).

• If the linear guides are

dusty, blow them with pres-

surised air to keep them

clean and free from chips.

• Clean the oor and work

area around the machine.

• Clean and put away person-

al protection equipment.

• Tag any defective equip-

ment and contact us if you

encounter any trouble.

CHECKLIST FOR A SAFE USE OF THE MACHINE

SAFETY SYMBOLS

MACHINE DESCRIPTION

The Evo CNC Milling Machine is a digitally controlled milling machine, which can be used for a regular process-

ing of wood, plastics and non-ferrous metals.

The machine has three axes which are oset by 90°. This way, it is possible to travel to any point within the

working space. Each axis is equipped with one or two stepper motors and with one mechanical micro-switch,

working as a limit sensor. The stepper motors drive the movable axes elements via a belt and pulley system The

position of the axis is determined during the homing procedure, at the beginning of the job, with the aid of the

limit sensors.

The Evo CNC machine is delivered as a kit and includes the following components:

• A 3-axis CNC router, with 4 motors and 4 limit switches

• A plug-and-play electronic control unit, already assembled and tested

• A plug-and-play interface unit, composed of a touch screen and keyboard

• PlanetCNC software, pre-installed on a Raspberry Pi 4 and already congured (software used to control your

machine)

• A lifetime license of PlanetCNC

• A power cable for the control unit (EU plug)

• An AMB (Kress) 1050 FME-1 milling motor

• A touch probe device to locate your workpieces easily

• All the basic tools necessary to assemble the machine

• A USB key with all the necessary documentation

In addition to the above mentioned items, you will need the following ones in order to be able to properly use

the machine:

• A spoilerboard. At rst, a simple wood panel is enough to get a grasp on CNC machining and we don’t think

it’s relevant to ship such an bulky object, which is easy to nd at your local hardware shop. When being

more experienced, we suggest building a threaded insert grid on a surfaced spoilerboard. The procedure to

build one is described on our website under the Learn section.

• A vacuum cleaner and a dust shoe, to help you work in a clean environment and to be protected from the

rotating tool while the machine is working.

• A CAM software. You will need a Computer Aided Manufacturing software to translate your 3D models into

a G-code readable by the machine. We suggest to use Fusion360.

• A table which can bear the weight of the machine.It needs to be robust and sti, as vibrations will aect

the precision of your cuts.

This manual suits for next models

2

Table of contents

Other MEKANIKA Power Tools manuals

Popular Power Tools manuals by other brands

Matrix

Matrix MT 220-1 Translation of the original instructions

Hytorc

Hytorc MXT-.7 user manual

Cembre

Cembre B62 Operating and maintenance manual

Hix

Hix DOUGHXPRESS TXM-15 Operator's manual

Adam Hall

Adam Hall SUPER CLAMP B SET 1 manual

Renfert

Renfert Basic Master Translation of the original instructions for use

Milwaukee

Milwaukee HEAVY DUTY M18 ONEFPRT Original instructions

Airec

Airec Compact 25 Installation and maintenance manual

AEG Powertools

AEG Powertools BST 18 X Original instructions

Festool

Festool Domino XL DF 700 EQ instruction manual

Black & Decker

Black & Decker ASI500 Original instruction

Avdel

Avdel 7530 instruction manual