MEL M2-iLAN Series User manual

HB-M2-iLAN-UDP-E.doc page 1 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

MIKROELEKTRONIK GMBH Intelligente Sensoren & Mess-Systeme

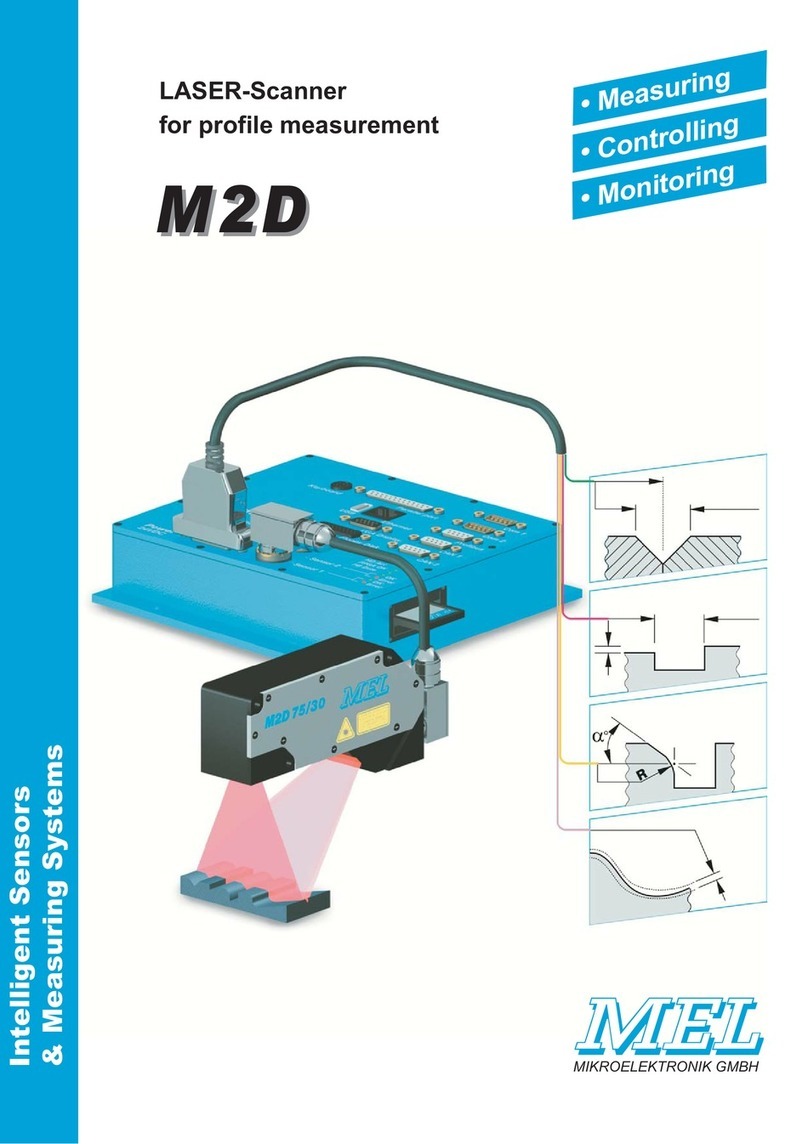

M2-iLAN

Laser-Scanner

M2D Laser Scanner

with integrated Ethernet-Interface

TCP/UDP

User Manual

MEL Mikroelektronik GmbH

Breslauer Str. 2

D-85386 Eching

Tel. +49 89 / 327 150-0

Fax +49 89 / 319 20 23

www.MELsensor.de March 2010

© Copyright MEL Mikroelektronik GmbH, 2006 ... 2010

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 2 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

Contents

Firmware-Version .........................................................................................................................................................3

System description .......................................................................................................................................................4

Product label.................................................................................................................................................................4

Scanner head and Electronic System...........................................................................................................................4

Connections.......................................................................................................................................................................4

Ethernet Hardware........................................................................................................................................................4

Ethernet cabling............................................................................................................................................................4

Multi-Scanner Arrays ....................................................................................................................................................5

How many Scanners can work in one network segment? ............................................................................................5

Factory default IP address............................................................................................................................................5

Scanner heads..............................................................................................................................................................5

Connectors........................................................................................................................................................................6

Ethernet cable...............................................................................................................................................................6

Control cable.................................................................................................................................................................6

Status LED’s.................................................................................................................................................................6

RJ-45 connector ...........................................................................................................................................................6

Special accessories......................................................................................................................................................7

Technical Data...................................................................................................................................................................8

Integrated electronic system.........................................................................................................................................8

Communication between Electronic system and PC.........................................................................................................9

Task of the Micro controller...........................................................................................................................................9

Task of the PC-Software...............................................................................................................................................9

Communication Components........................................................................................................................................9

Adjustment of Scanners IP-Address.............................................................................................................................9

Resolve IP Address conflicts ......................................................................................................................................10

MEL Configuration Software „EthernetScanner-2008“................................................................................................11

Temporary change of the IP Address .........................................................................................................................11

Temperature monitoring..............................................................................................................................................12

Pixelauslesen : Limit of scanners viewing area...........................................................................................................12

Scanner controls.........................................................................................................................................................13

Control commands......................................................................................................................................................13

Trigger and Synchronisation operating modes ...........................................................................................................13

External Trigger (Hardware-Trigger)...........................................................................................................................13

Synchronization..........................................................................................................................................................13

Ethernet-Trigger..........................................................................................................................................................13

Digital inputs...............................................................................................................................................................13

UDP transmission mode.............................................................................................................................................14

How to set UDP transmission mode...........................................................................................................................14

Data format and interface description.........................................................................................................................15

Frame Format of TCP data transfer from scanner head to electronic unit..................................................................15

Header and payload data............................................................................................................................................15

Encoder Data, FiFO fill status.....................................................................................................................................15

0x21: info telegram: scanner status information .........................................................................................................16

Info Telegram (the scanners answer to the command 0x21)......................................................................................16

Data format: Register addresses, Commands or Data ...............................................................................................16

Scanner controls.........................................................................................................................................................17

Data format.................................................................................................................................................................18

Sync signal and Status info, encoder information (protocol version 3) .......................................................................18

Meaning of the status byte 2 depending from register 0x11 .......................................................................................19

Value = [0]: Sensor temperature.................................................................................................................................19

Value= [1]: Register contents.....................................................................................................................................19

Value = [2, 3]: Version number electronic system and camera..................................................................................19

value = [4, 5, 6, 7, 8] : operating hours counter ..........................................................................................................19

Value = [9, 10, 11]: on counter....................................................................................................................................19

Value = [12]: Digital inputs 1 , 2 + Bit for Sensors with a mirror..................................................................................19

Value = [13]: Laser control Bit 2...9.............................................................................................................................20

Value = [14]: Version number.....................................................................................................................................20

Value = [15 ...31]: not assigned..................................................................................................................................20

Value = [32 ... 63] 32 Byte Eprom Data Register........................................................................................................21

Register 0x1B: Profile peak recognition threshold......................................................................................................21

HDR-shutter control, Register 0x24 (36).....................................................................................................................22

M2DF/LAN-Structure of Image Data...........................................................................................................................22

Read out complete image...........................................................................................................................................23

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 3 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

Synchronization of Sensors........................................................................................................................................23

Trigger Mode ..............................................................................................................................................................23

Calculation of shutter time ..........................................................................................................................................23

Number of pixels, encoder data..................................................................................................................................23

RS-232 Monitoring......................................................................................................................................................23

115.200 Baud .............................................................................................................................................................23

Web-Server.................................................................................................................................................................25

Available Read out Functions.....................................................................................................................................25

How to set the IP address over the Web ....................................................................................................................25

Requirements for connection to scanner ....................................................................................................................26

Updating (Flashing) Firmware.....................................................................................................................................27

Hardware Requirements.............................................................................................................................................27

Software Requirements ..............................................................................................................................................27

Updating (Flashing) procedure ...................................................................................................................................27

Updating (Flashing) over the Ethernet........................................................................................................................28

Trouble Shooting ........................................................................................................................................................29

Example code for Software engineers........................................................................................................................30

Data format for register addresses and commands....................................................................................................30

3. Command: 0x21 (dump).........................................................................................................................................31

example: // read out FiFo status and sensor temperature ..........................................................................................36

Syntax of HDR shutter control ....................................................................................................................................38

Ports...........................................................................................................................................................................38

Ethernet WinSock Implementation..............................................................................................................................39

Example: (“C”) using WinSock and Scanner functions: ............................................................................................. 39

UDP Implementation...................................................................................................................................................41

IP-Programming for UDP-transmission protocol:........................................................................................................41

Maintenance....................................................................................................................................................................43

Laser Safety................................................................................................................................................................43

Laser Power................................................................................................................................................................44

Environment................................................................................................................................................................44

Sunlight.......................................................................................................................................................................44

Water..........................................................................................................................................................................44

Changes and additions...............................................................................................................................................44

F

Fi

ir

rm

mw

wa

ar

re

e-

-V

Ve

er

rs

si

io

on

n

Hardware-Revision 4.0 with M12 connectors

FPGA Firmware-Revision 4.6

Controller Firmware Revision 2.0.59

This manual describes the installation of the scanner hardware and the use of MEL demo and calibration

software. The manual has been changed to the new version of hardware.

With the transit to the revision 4 hardware, the electronic system has been equipped with M12 connectors.

The scanner head is connected to the network with the standard Ethernet M12 connector. The power and

control connector is an M12 connector with 8 pins.

Tipp: default values should be read from the scanner.

after a reset, the scanner restores all values to default.

to read out the default values:

1. send reset command 0x1E

2. request info telegram 0x21

default values could be different from given values in this manual.

relevant is the actual interface description available from MEL.

when you read out default values from the scanner, these may be

the almost recent values.

Laser Safety

Please refer to the Chapter “Laser Safety and Maintenance” to find recommendations and guidelines for

use of controls, adjustments of performance and recommended practice to avoid any hazardous radiation

exposure (page 43). Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous radiation exposure.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 4 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

S

Sy

ys

st

te

em

m

d

de

es

sc

cr

ri

ip

pt

ti

io

on

n

With the new M2-iLAN „Ethernet“-Scanner the electronic system is integrated in the scanner head. The

system has no extra controller box, so it is highly compact, tight and rugged. The scanner head has two

M12 connectors for Ethernet and power supply & controls. Scanner heads designed for welding applications

additionally have water & air cooling fittings.

M2W-iL-models are rated up to 500°C (950° F) environment

temperature with water cooling, up to 150°C (240°F) with air cooling,

dry and clean atmosphere, non corrosive.

P

Pr

ro

od

du

uc

ct

t

l

la

ab

be

el

l

The product label specifies the type of scanner head, the range and

standoff distance and the serial number with production date

(YYYY.MM.XXX) (XXX= Serial number).

S

Sc

ca

an

nn

ne

er

r

h

he

ea

ad

d

a

an

nd

d

E

El

le

ec

ct

tr

ro

on

ni

ic

c

S

Sy

ys

st

te

em

m

The scanner head has a CCD camera, a line laser projector and an electronic system for digitizing the

camera signals. The electronic system sends the camera signal to the electronic system. The camera is

controlled by the automatic control through the electronic system or in external mode by the application

software. Adjustment for shutter time, video gain and laser intensity are made through either automatic or

under “manual” control by the application software.

Connections

E

Et

th

he

er

rn

ne

et

t

H

Ha

ar

rd

dw

wa

ar

re

e

Standard Ethernet components never have shown problems in the data transmission of the Ethernet

scanners. Network connection Rx+, Rx-, Tx+, Tx- is available on a 4-pin M12-connector D-coded according

to standards. The scanner should be connected with shielded Ethernet cables CAT 5e or better. Total cable

length for Ethernet cabling is 200m according to Standard IEE 802.3

We also use Ethernet scanners in the company network without any effect on the daily office work running

through the same network. Use Ethernet switches, hubs are not recommended. When several scanners are

monitored by one PC, the graphic card and CPU must be strong enough to collect all the data provided by

the scanners. When you doubt, that the Scanner does not deliver all images, you should check the image

counter (page 15: register 0x11, status messages.) The image counter number allows sorting images, if

they arrive in wrong order. This may happen accidentally when transmitting profile data over the internet.

E

Et

th

he

er

rn

ne

et

t

c

ca

ab

bl

li

in

ng

g

The Ethernet network connection is

made with M12 connectors, 4 pin D

coded. The control interface is

connected through an 8 pin M12

connector, the pin details are given

on page 6.

Ethernet cables should be double

shielded. The cables should be

according specification CAT 5e or

better.

When the Scanner is connected to

the network over a Ethernet switch,

normal (1:1 wired) patch cable may

be used. When you want to make a

direct connection from the Scanner

to the PC use a cross-wired cable.

Picture at the right side:

Connecting a scanner with switch and PC.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 5 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

M

Mu

ul

lt

ti

i-

-S

Sc

ca

an

nn

ne

er

r

A

Ar

rr

ra

ay

ys

s

Up to 32 Scanners could be integrated in a network. Normally, you should use a separate network card for

the connections to the scanner(s). The use of a separate network card is optional and depends from your

network settings, network traffic on the dedicated PC and system load. You may use a Ethernet switch, a

Ethernet cable to each scanner and power supply 10 … 28 V DC.

H

Ho

ow

w

m

ma

an

ny

y

S

Sc

ca

an

nn

ne

er

rs

s

c

ca

an

n

w

wo

or

rk

k

i

in

n

o

on

ne

e

n

ne

et

tw

wo

or

rk

k

s

se

eg

gm

me

en

nt

t?

?

The Scanner sends 290 Profile points per Scan with 93.5 Hz :

oTCP-IP Header

oM2DF-LAN-Header

oProfile data

oStatus information

oReserved Bytes for additional data

oadditional Information as Encoder-Data, FiFO

oCRC

Each Profile creates a 2048 Byte Block = 93.4 x 2.048 kBytes / s = 191.28 kByte / s.

The network channel has 100 Mbit = 12.500 kBytes / sec

This will allow theoretically maximum = 12.500 / 191 = 65.4 Scanners.

The numbers of collisions in a network rises, when the network load exceeds 50%. Therefore as a realistic

figure, we assume 50 % of maximum transmission rate.

This leads to the number of 32 Scanners for maximum usage in one network segment.

Segmentation of data blocks

Limitations of the network cards like setting of the MTU (Maximum Transfer Unit), and accordingly load in

the network causes that the 2048 Bytes will not be transferred in one packet, but segmented into two

packets of 1460 k and 588 k. The user must not think about this effect, though the TCP implementation of

the operating systems cares about sorting and reconciling the TCP packets. More likely, the software

engineer designing an application must know this and wait long enough to make sure that all packets have

been received, before using the data.

F

Fa

ac

ct

to

or

ry

y

d

de

ef

fa

au

ul

lt

t

I

IP

P

a

ad

dd

dr

re

es

ss

s

At the end of the manufacturing test the scanners are set to:

IP address 192.168.123.245

Subnet mask 255.255.255.0.

Before you integrate these units in your network, you should set the network address to a working address

which will operate in your network properly. For more technical details and background information see the

network tutorial. The set up procedure is given on page 24.

S

Sc

ca

an

nn

ne

er

r

h

he

ea

ad

ds

s

The scanner head power supply is connected with a 8 pin M12

connector. The control cable has power supply, sync signals, digital

inputs for encoders and control of firmware upload and RS-232 diagnose

interface. The pin definition is given on the next page.

The Ethernet connection is made with a 4 pin M12 connector according

to standard. The Ethernet cable connectors are male.

The connector for the control cable is male. The controls & power cable

has a female connector and at the other end is either with open leads for

clamps or with a male connector.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 6 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

Connectors

E

Et

th

he

er

rn

ne

et

t

c

ca

ab

bl

le

e

C

Co

on

nt

tr

ro

ol

l

c

ca

ab

bl

le

e

* when connecting the sync output to the command input 1, at start of the sensor (power on), the sensor is brought to

the programming mode. In this programming mode the firmware can be uploaded with the RS-232 connection or over

the Ethernet network.

** when the sync output is connected to the command input 2, at start of the sensor, the sensor will activate the RiP

mode and communicate only at the default IP address.

Please note: when both command inputs were connected to sync out, the sensor will go to the programming mode.

The activation of the Programming mode or RiP mode is made only when the sensor is switched on and had no

power before for a few 10 seconds.

*** colors are given as an example.

Tipp: the Scanner could be connected with one single*, highly flexible, cable for robotic applications. The cable used

is a Ethernet cable specially made for the use with robots. The power supply is taken over two unused wires in the

network cable, following the idea of the IEEE 802.3af standard. Details are given in the TE-M2-iLAN-connection-E.pdf.

Cables following this definition are available from MEL on request.

* single cable attachment: connection with a single cable specified for use with robots.

** PoE: Power over Ethernet, standard IEEE 802.3af.

S

St

ta

at

tu

us

s

L

LE

ED

D’

’s

s

Status LED’s Meaning color*** OK when

Power Power OK Green LED is lit

Eth-Link Ethernet Link in Function Yellow Blinking

100 Mbit Ethernet Link Activity Orange Blinking

System Hardware Self test OK Orange Blinking

FPGA FPGA Self test OK Orange LED is lit

R

RJ

J-

-4

45

5

c

co

on

nn

ne

ec

ct

to

or

r

Pin Signal Connector A Pin “Crossed” B Signal

1 Transmit data + Green +White 1 Red + White Receive data +

2 Transmit data - Green 2 Red Receive data -

3 Receive data + Red + White 3 Green +White Transmit data +

4 Not used - Blue 4 Blue Not used -

5 Not used + Blue + White 5 Blue + White Not used +

6 Receive data - Red 6 Green Transmit data -

7 Not used + Brown+ White 7 Brown+ White Not used +

8 Not used - Brown

Colors are given as

an example.

Cables could have

different colors.

8 Brown Not used -

Tipp: the M12-Ethernet cable has male connectors at both ends. The M12-control cable has either a female

connector at the electronic box and a male connector or open wires at the other end.

Pin-Nr. Signal Colors *** Remarks

1 Tx+ Green+white Transmit data Ethernet +

2 Rx+ Red+white Receive data Ethernet +

3 Tx- Green Transmit data Ethernet -

4 Rx- Red Receive data Ethernet -

Ethernet

M12 round

4-pin

D-coded

female Shield Connect to case!

Pin-Nr. Signal Colors*** Remarks

1 + 24 V DC White Supply for Electronic box

2 Digital input 1 Brown Encoder and command input 1*

3 GND Green Ground

4 Digital input 2 Yellow Encoder and command input 2 **

5 Sync out Grey Sync signal output (Master)

6 Sync in Orange Sync signal input (Slave); Hardware-Trigger

7 TxD Blue Rs-232 Diagnosis out

8 RxD Red RS-232 Programming data input

M12 round

8-pin

A-coded

male

Shield Connect to pin 3 (ground)

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 7 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

S

Sp

pe

ec

ci

ia

al

l

a

ac

cc

ce

es

ss

so

or

ri

ie

es

s

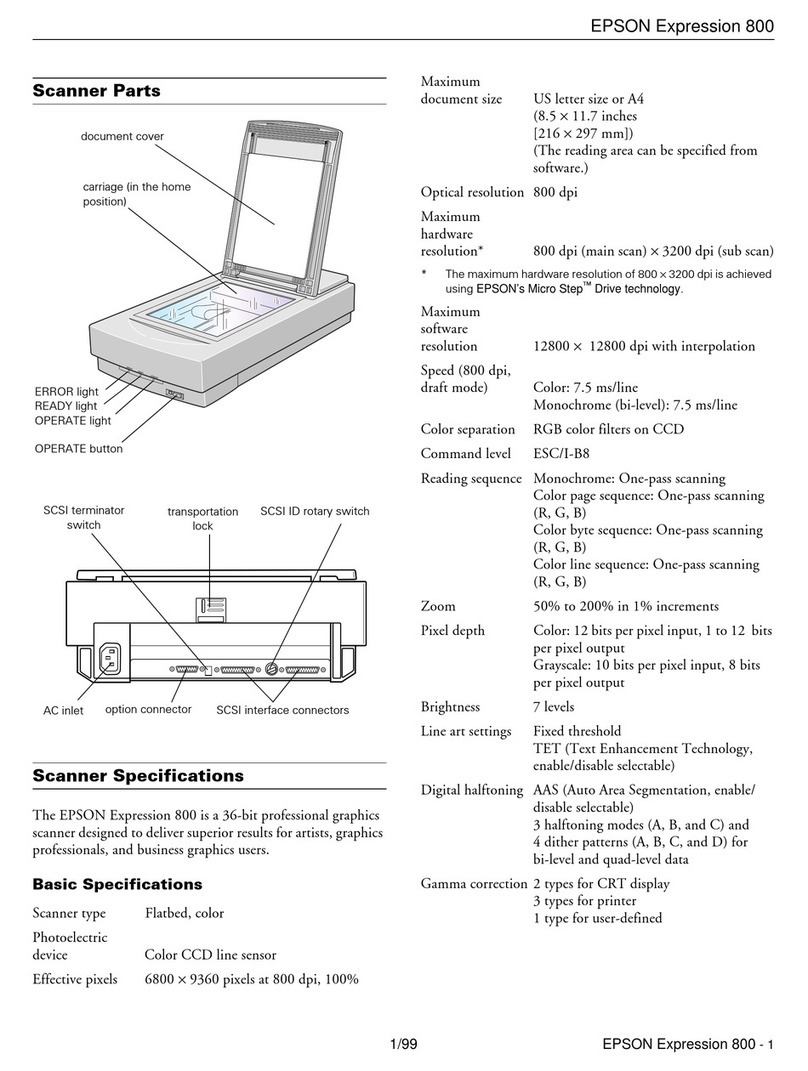

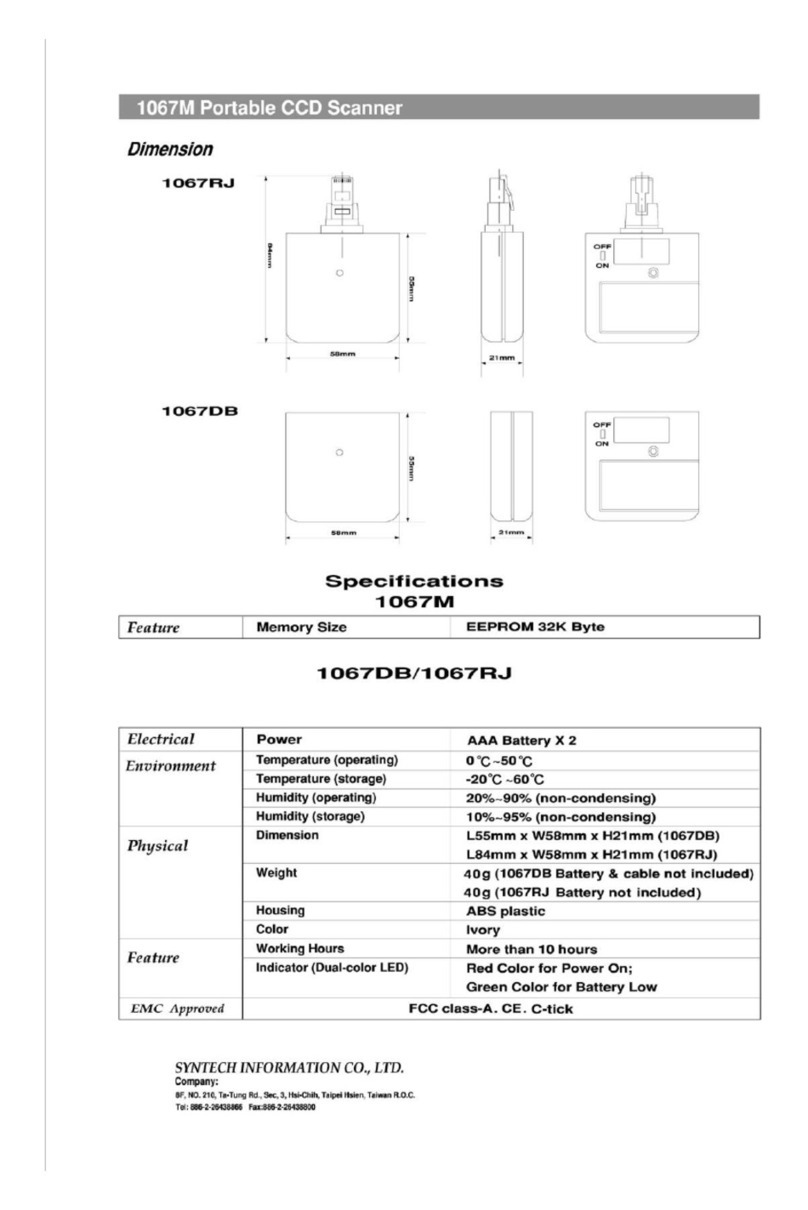

↑M2-RS232-ProgBox

M2-W-iLAN-80/40/55 →

Scanner head with air / water cooling option

Nr Description MEL

Part name

MEL

order

number

1 M2-RS232-Programming Adapter Box

Adapter to RS-232 interface, for Firmware-Upload, power switch and

default-IP- Address. Requires + 24V power supply!

M2-RS232-ProgBox i.550.006

2 Power supply + 24V, for M2-RS232-Box (Pos. 1) Power supply 24V/250 mA i.550.007

3 Connecting cable M12-8 pin; 2.0 m; free leads Ctrl-Cbl-W-M12-o i.550.008

4 Connecting cable M12-8 pin female socket – 8 pin, 0.4 m SKK 215 i.550.009

5 Connection cable M12-4 pin, D-coded connector – 4 pin

D-coded connectors, Length 0.4 m; PTFE SKK 216 i.550.010

6 Adapter M12 – RJ45 straight, with thread M 16x1.5 Eth-Adapter-G-M12 i.550.011

7 Adapter M12 – RJ45 at angle 90°, with thread M 16x1.5 Eth-Adapter-W-M12 i.550.012

8 Connector M12-4pin-D coded; straight, auto-clamps Eth-Con-D-G-M12 i.550.016

9 Connector M12-4pin-D coded; 90° angle, screw on clamps Eth-Con-D-W-M12 i.550.018

10 Connecting cable M12 male – 4 pin; RJ-45; 1 m Eth-Cbl-M-M12-RJ45 i.550.026

11 Connecting cable M12 female – 8 pin at angle 90° - free leads Ctrl-Cbl-8pWW-o i.550.027

12 Adapter for connecting two RJ45 network cables Adaptor-2N-RJ45 i.550.028

13 Network cable RJ-45, 5m 1:1 (patch) Network cable RJ45 i.550.029

14 Cross wired network cable RJ-45, 5 m Crosslink cable RJ45 i.550.030

15 Connector M12 - 4 pin D-coded with screw on clamps Con-M12 4 pin-m-scr i.550.031

16 Cable receptacle 8 pin female with screw on clamps Con-M12 8 pin-w-scr i.550.032

17 Water / air fittings (spare parts) WaAir-Stub i.550.033

18 Ethernet cable; CAT5e, 4-pin, AWG24 flexible; PUR chloride free

blue, shielded, straight connector, M12, D-coded – RJ45, 2m Eth-Cbl-M12-RJ45-2m i.550.041

19 Ethernet cable; CAT5e, 4-pin, AWG24 flexible; PUR chloride free

blue, shielded, straight connector, M12, D-coded – RJ45, 5m Eth-Cbl-M12-RJ45-5m i.550.042

20 Ethernet cable; CAT5e, 4-pin, AWG24 flexible; PUR chloride free

blue, shielded, straight connector, M12, D-coded – RJ45 – open

leads, length = 15m

Eth-Cbl-M12-o-15m i.550.040

21 Connecting cable M12-4pin crossed Ethernet cable with RJ-45

Cable length customer specific EthRJ45-X-Cbl-M12-custom i.550.043

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 8 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

Technical Data

Profiles update rate max. 93.5 Hz

Profile rate, Trigger-Mode approx. 60 Hz

Profile rate, external synchronized max. 93.5 Hz

Stability of time base 100 x 10-6

Min. / Max. Environment temperature min. 0°C (+ 32°F) max. 40°C (+ 95°F)

Min. / Max. Storage temperature min. –30°C (+ 2°F) max. 75°C (+ 167°F)

I

In

nt

te

eg

gr

ra

at

te

ed

d

e

el

le

ec

ct

tr

ro

on

ni

ic

c

s

sy

ys

st

te

em

m

Supply current 120 mA at 24 V; Laser on

Range of supply voltage + 10 ... 30 V DC

Digital inputs Low = 0 ... 2 V High = 5 ... 30 V

Weight 300 g

Dimensions 102 mm x 74 mm x 27,5 mm

Mounting holes for 4 x M5 screw

connections 12 pin round female for Scanner head

M12 - 8 Pin male supply and controls

Synchronization and external Trigger

M12 4 Pin female = Ethernet D coded

RJ-45-Ethernet internal for service

Protection class IP 65

Vibration: the electronic unit has been specially protected against shock and vibration.

Encoder signal connection

Encoder-Data is received at the digital inputs at the control connector. The encoder information is read and

transmitted embedded in the profile information over TCP Ethernet connection. The encoder data is always

in sync to the profile relating to this encoder data.

RS-232 interface for diagnosis and firmware update

Baud rate: Monitoring 115. 200 Baud

Baud rate: Firmware-Update 57.600 Baud

The RS 232 interface does not carry profile data or scanner control information.

Software: the current release of the MEL „EthernerScanner.exe“ Demo- and configuration software is

available as download from MEL FTP-Server: ftp://melsensor.de. Call MEL hotline for further details.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 9 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

Communication between Electronic system and PC

The micro controller in the electronic system communicates over Ethernet TCP/IP with the PC. The Scanner

head delivers image data to the micro controller and the FPGA in the electronic system.

T

Ta

as

sk

k

o

of

f

t

th

he

e

M

Mi

ic

cr

ro

o

c

co

on

nt

tr

ro

ol

ll

le

er

r

oRead out of the Scanner head

oSend Scann profile data over TCP/IP-Protocol

oReceive commands for the Scanner head with TCP/IP Protocol

oSend commands to the Scanner head

oChange and store the TCP/IP-Address on request

oSend Status information

oRun integrated Web Browser

T

Ta

as

sk

k

o

of

f

t

th

he

e

P

PC

C-

-S

So

of

ft

tw

wa

ar

re

e

oReceive profile data from Scanner

oDecode Pixel image data format (see „Data format“)

oProcess and display scan profile data

oSend commands to the Scanner head

C

Co

om

mm

mu

un

ni

ic

ca

at

ti

io

on

n

C

Co

om

mp

po

on

ne

en

nt

ts

s

TCP Clients and Server are components of the development environment in the software. In the readily

compiled software (*.exe File) these components exist in the form of “ports”. These ports manage data

traffic in and out to the individual elements of the application software.

The Scanner communicates with the outer world using port address, IP address and a valid subnet mask.

A Gateway is ignored, the scanner opens a peer to peer connection. Therefore the set up of these

communication components needs to be complete to allow proper function of the electronic components

and data communication.

The Scanner stores data in FiFo memory, before data is sent out in a package. The transmission protocol is

TCP/IP*.

* UDP firmware version is available on request!

A

Ad

dj

ju

us

st

tm

me

en

nt

t

o

of

f

S

Sc

ca

an

nn

ne

er

rs

s

I

IP

P-

-A

Ad

dd

dr

re

es

ss

s

The Scanners electronic system has a default address as well as a working IP address. The default IP

address is activated, when you set the RiP-Pin. This is done, when you connect the Sync out pin to the D1

pin before starting power. The default IP address is set firmly, and can not be changed by the user.

Before delivery, the scanners were normally set to the working-IP = 192.168.123.245. When another IP

address has been set, either a note in the shipment papers or a label on the electronic box of the scanner

should show the IP address.

When you want to set a new working IP address, use a Web browser and follow the procedure on page 24.

Please note: after transferring the new working IP address to the scanner electronic system, the

electronic system automatically restarts to make the change effective.

The Web Browser will then display a message to make you aware of the change.

When you receive this message connect to the scanner with the new IP address.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 10 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

R

Re

es

so

ol

lv

ve

e

I

IP

P

A

Ad

dd

dr

re

es

ss

s

c

co

on

nf

fl

li

ic

ct

ts

s

Using the default IP address is meant for communication with one single scanner, for adjustment of a new

working IP address or other service purpose. Using the default IP address for normal operation is not

recommended.

DHCP is not supported. The Scanner must have a fixed IP address, as well as the network card to which

the scanner shall communicate. Scanner and network card must be in the same network segment. This

means, the network address should vary only in the last three digits. Computers in the network must use

unique and different network addresses. When units in the network use the same address, a conflict exists.

The communication in the network could severely have problems, when this happens.

Tipp: label the units when installing different units in a network

take notes and make a plan of the network addresses used in your network.

when a conflict exists, physically disconnect the network cable form different units to find

out the source of conflict. ... only one unit at a time...

example:

Address Scanner 1: 192.168.123.222;

Address Scanner 2: 192.168.123.223;

Address Scanner 3: 192.168.123.224;

Address Scanner 4: 192.168.123.225;

Address Scanner 5: 192.168.123.226;

Address Scanner 6: 192.168.123.227;

Address Scanner 7: 192.168.123.224; // incorrect IP-Address = conflict!

Address Scanner 8: 192.168.123.229;

Address Scanner 9: 192.168.124.228; // different network segment

Address Network card: 192.168.123.199

The subnet mask for all Scanners and the network card = 255.255.255.0

Do not get mixed: a subnet mask 255.255.0.0 may also work. The subnet mask defines the maximum

number of units in your network. When no more than 254 scanners were present in your network, the

subnet mask 255.255.255.0 will be sufficient.

In our example Scanner 7 has been set erroneously to the IP address 192.169.123.224. this address is

already taken from another Scanner – so a conflict exists. The correct IP-address would have been

192.168.123.228.

Scanner 9 is in another subnet (another network segment). For Scanner 9, the network card should be set

to IP address = 192.168.124.10.

Tipp: how to find out the IP address of the scanner?

1. Use any terminal software, connect the RS-232 diagnostic port to Com-port 1 of your PC

2. Read out the information prompt send out at start up of the scanner.

3. For details see page 22.

I

IP

P-

-A

Ad

dd

dr

re

es

ss

s

f

fa

ac

ct

to

or

ry

y

d

de

ef

fa

au

ul

lt

t

oMAC-Address 8 Byte 00-08-DC-00-00-00

oSerial number 3 Byte MM-YY-ZZZ

oScanner-IP 4 Byte 169.254.150.160:3000 = default Address

oSubnet-Mask 4 Byte 255.255.0.0

oGateway IP 4 Byte 169.254.150.1

oTCP Port 2 Byte, integer last Segment of the TCP/IP-Address (for example 3000)

Back ground: the Scanner and the network card in the PC make a “peer to peer” connection. Once the

communication between these two peers has been initiated, no other network device will be allowed to communicate

with the active scanner. This means, the scanner can communicate only with one PC at a time. Besides the

communication over TCP at any time, from any other PC a http request (Web browser) could be made.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 11 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

M

ME

EL

L

C

Co

on

nf

fi

ig

gu

ur

ra

at

ti

io

on

n

S

So

of

ft

tw

wa

ar

re

e

„

„E

Et

th

he

er

rn

ne

et

tS

Sc

ca

an

nn

ne

er

r-

-2

20

00

08

8“

“

After the Start of the Scanner (switch on power), the configuration of the scanner is loaded from the internal

EPROM to the micro controllers memory. The MEL demo software then shows the following information:

oTCP/IP Address, Port and MAC Address

oIntensity, shutter time, Video gain

oScanner Status, Firmware-Version, Scanner head temperature

The main window of Ethernet-Demo-Software has the elements profile display and tabs for different function

groups. The profile display at the left side can be switched to display one bigger screen or four small

screens simultaneously. The colors of the profiles can be adjusted by defining RGB values in the settings.ini

file. Function groups are selected with the Tabs 1 … 16. The important Tabs are discussed in the following

text. The Tab 1 defines the IP address and assignment of the display window. The window count of the four

windows starts at 0 and counts up to 3. The big window is number 9.

T

Te

em

mp

po

or

ra

ar

ry

y

c

ch

ha

an

ng

ge

e

o

of

f

t

th

he

e

I

IP

P

A

Ad

dd

dr

re

es

ss

s

When you want to set the IP address only for a demonstration double click one of the entries in the Tab 1

and overwrite the IP address for a temporary change. The change will not be stored permanently. When

you restart the application, the previous setting will be read in from the ini file.

To make the IP address change permanent edit the EthernetScanner.ini file.

Tipp: use any Text editor to edit the EthernetScanner.ini File, but be aware: when you destroy

the ini File, the application could have a problem.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 12 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

To change the assignment of the window number, click the column Fenster in Tab 1 and select the window

number from the pull down list. The column Hz displays the current scan profile frequency.

Tab 4 displays system parameters:

oOperating hours counter, On counter

oTemperature of the Scanner head

o

o

Firmware-Version, MAC-Address, working und default IP-Address.

Tabs 6 ... 16 are reserved for diagnosis.

T

Te

em

mp

pe

er

ra

at

tu

ur

re

e

m

mo

on

ni

it

to

or

ri

in

ng

g

The temperature of the scanner head is shown in °Celsius on Tab 4. The current temperature is also stored

in the register 2 and can be read out from the PC. (see data format description, register 0x11 + status

register 2, Byte 12, page 15 and following pages).

P

Pi

ix

xe

el

la

au

us

sl

le

es

se

en

n

:

:

L

Li

im

mi

it

t

o

of

f

s

sc

ca

an

nn

ne

er

rs

s

v

vi

ie

ew

wi

in

ng

g

a

ar

re

ea

a

The function slider “Pixelauslesen begin” and “Pixelauslesen end” allows to crop the scanners viewing area.

This feature is helpful for scanning extremely difficult targets. It improves scan profiles by cutting off

unwanted reflections. Depending on the setting of the demarcation limits, the internal profile acquisition

algorithm will ignore reflections below or above the levels of demarcation, which could greatly enhance the

online scan profile in extreme situations. The effect can be monitored directly on screen.

Tipp: mathematical post processing of the profile will not be able to produce a similar effect.

The effect of erasing reflections and unwanted profile noise is due to removing these data

before creating the profile.

This is a function of the FPGA processing inside the scanner head.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 13 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

S

Sc

ca

an

nn

ne

er

r

c

co

on

nt

tr

ro

ol

ls

s

C

Co

on

nt

tr

ro

ol

l

c

co

om

mm

ma

an

nd

ds

s

No commands must be sent to the scanner, unless special operation is required. When no special

command is sent, the scanner is in automatic mode, which is best for most applications.

When the scanner is powered on, it sends data to the connected PC in a continuous stream. You must not

care to set the scanner to this operation mode, this will be made automatic, presumed once the application

software has been configured correctly. Windows TCP socket cares, that all packets will arrive at the PC, no

user interaction is required.

When creating a new communication with the scanner after a long waiting period, we recommend to send a

FiFO reset command just once in the beginning. This is only relevant for your own application software, to

avoid reading out old data from the FiFO memory at start. When using this command, you should trash the

first image after the reset and use only the second one. When reading data continuously, FiFo reset is not

recommended.

Tipp: examples for the use of register addresses and commands were given in the appendix.

T

Tr

ri

ig

gg

ge

er

r

a

an

nd

d

S

Sy

yn

nc

ch

hr

ro

on

ni

is

sa

at

ti

io

on

n

o

op

pe

er

ra

at

ti

in

ng

g

m

mo

od

de

es

s

Simultaneous Sync alternating Sync simultaneous Trigger alternating Trigger

E

Ex

xt

te

er

rn

na

al

l

T

Tr

ri

ig

gg

ge

er

r

(

(H

Ha

ar

rd

dw

wa

ar

re

e-

-T

Tr

ri

ig

gg

ge

er

r)

)

At Pin 6 = Sync-in, the leading edge of the trigger pulse makes the trigger event. The signal should not

oscillate. The Sync-input is an optic coupler with current limit. The voltage range is TTL … 24 V (max. 30 V

DC). When the trigger has been made, no additional trigger signal will be accepted during the active

measurement. The maximum profile rate is approximately 60 Hz.

Tipp: how to use trigger:

1. set register 0x14, Bit 3 to “1”

2. do trigger with a call of register 0x1D,see page 15

Please note: in trigger mode, synchronization with other scanners is not available.

S

Sy

yn

nc

ch

hr

ro

on

ni

iz

za

at

ti

io

on

n

The sync-input is used for synchronization of 1 master with other slave scanners. One scanner is defined to

be the master; the other scanners will be slaves. The sync output of the master scanner is wired to the

slave scanners sync input, ground is connected accordingly.

Please note: in sync mode trigger is not available.

E

Et

th

he

er

rn

ne

et

t-

-T

Tr

ri

ig

gg

ge

er

r

The Ethernet-Trigger mode is set in register 0x23 according to the definition on page 17. In this operation

mode, the scanner creates permanently profiles, but holds up data send out. Only after Ethernet trigger

event received, the scanner sends out the last profile acquired before. Depending on the speed of the PC,

profiles could be missing.

D

Di

ig

gi

it

ta

al

l

i

in

np

pu

ut

ts

s

Digital inputs 1 and 2 may be used to connect an A/B encoder to the scanner head.

Tipp: the encoder count can be read out from the registers 13 ... 16.

the information is transferred embedded into the scan profile data.

there is no need for special synchronization of the encoder data with the profile data.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 14 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

U

UD

DP

P

t

tr

ra

an

ns

sm

mi

is

ss

si

io

on

n

m

mo

od

de

e

H

Ho

ow

w

t

to

o

s

se

et

t

U

UD

DP

P

t

tr

ra

an

ns

sm

mi

is

ss

si

io

on

n

m

mo

od

de

e

Open MEL EthernetScanner-2008 UDP demo

software.

Set Tab 11:

Enter the values:

Scanner IP = the working TCP IP (left)

UDP destination IP = enter here the target IP and

port where the UDP packets

shall be sent.

TCP port can be 3000 or any other port number.

UDP port can be 3000 or any other port number.

Please make sure the ports are accessible in your

target system.

When your are done with the entries, click the checkbox next right to UDP destination port (see the arrow)

to activate the UDP mode and then click the command bar button below “activate new IP”.

The system will reload and connect to the designated values and mode.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 15 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

D

Da

at

ta

a

f

fo

or

rm

ma

at

t

a

an

nd

d

i

in

nt

te

er

rf

fa

ac

ce

e

d

de

es

sc

cr

ri

ip

pt

ti

io

on

n

F

Fr

ra

am

me

e

F

Fo

or

rm

ma

at

t

o

of

f

T

TC

CP

P

d

da

at

ta

a

t

tr

ra

an

ns

sf

fe

er

r

f

fr

ro

om

m

s

sc

ca

an

nn

ne

er

r

h

he

ea

ad

d

t

to

o

e

el

le

ec

ct

tr

ro

on

ni

ic

c

u

un

ni

it

t

Total block size = =2048 Byte. Packet size: 1460 and 588, or 2048 Bytes. The packet size is set by the

hardware and the communication channel of the attached network without any influence of the application

software. The TCP buffer may be set to standard value. The user must not care about re-assembling and

reconciling the TCP packets. This is done by the network card with the help of the operating system.

H

He

ea

ad

de

er

r

a

an

nd

d

p

pa

ay

yl

lo

oa

ad

d

d

da

at

ta

a

Address Parameter Type Byte Meaning Factory default

00...05 MAC unsigned char [6] Default MAC-Address 00:08:DC:00:00:00

06...09 Reserve unsigned char [4] Reserved

10...13 Lga unsigned char [4] Default GateWay 169.254.150.1

14...17 Lsm unsigned char [4] Default Subnet Mask 255.255.0.0

18...21 Lip unsigned char [4] Default IP-Address 169.254.150.160

22...23 Tcp unsigned char [2] Default TCP-Port 3000

24...25 Reserve unsigned char [2] Reserved

26...31 Mac unsigned char [6] Working MAC-Address 00:08:DC:xx:xx:xx *

32...35 Reserve unsigned char [4] Reserved Customer specific

36...39 Lga unsigned char [4] Working GateWay Customer specific

40...43 Lsm unsigned char [4] Working Subnet Mask Customer specific

44...47 Lip unsigned char [4] Working IP-Address Customer specific

48...49 Tcp unsigned char [2] Working TCP-Port Customer specific

50...51 Reserve unsigned char [2] Reserved

52...59 null_8 unsigned char [8] Synchronisations-Raster 8 Null bytes

60...60 Version unsigned char [1] Protocol-Version number Default = 3

0x10 = status 0x11 = fault

61...61 Status unsigned char [1] Scanner Status

62...62 pic_nr unsigned char [1] Image number

63...63 status2 unsigned char [1] Scanner Status

64...64 Reserve unsigned char [1] Reserved

65...65 Reserve unsigned char [1] Reserved

Header

66... Scan unsigned char [**]

Scan Data

Length and contents depends from

protocol version used

Scan

8 x 0x00 8 Bytes

Protocol number 1 Byte

Encoder Data 4 Bytes

Length of following Bytes 1 Byte

Function register n Bytes

Length of following Bytes 1 Byte

Status register m Bytes

…2040 Fill [ ... ] Fill bytes

2041.2042 [2] Pixel number horizontal Typ. = 290

2043.2044 [2] Pixel number vertical Typ. = 752

2045..47 FiFO FiFO-fill status ** 3 Bytes

additional data

* Serial number ** depending from transmission protocol (from Scanner head to electronic box).

E

En

nc

co

od

de

er

r

D

Da

at

ta

a,

,

F

Fi

iF

FO

O

f

fi

il

ll

l

s

st

ta

at

tu

us

s

Encoder-Data is transferred with each Scan-Profile - do not mix up with the special transfer protocol issued

by the special command 0x21, which calls the info telegram. The following chapter describes this info

telegram. On page 18, the description of the scan data block is given.

At the end of the image profile information, a block of 8 Bytes 0x00, followed by the version of protocol (for

example “3”) and then 4 bytes encoder data were transferred.

The last 3 Bytes before the end of the transmission block is the FiFO fill status data.

Tipp: the protocol-Version is given in the Header, Byte 60.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 16 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

0

0x

x2

21

1:

:

i

in

nf

fo

o

t

te

el

le

eg

gr

ra

am

m:

:

s

sc

ca

an

nn

ne

er

r

s

st

ta

at

tu

us

s

i

in

nf

fo

or

rm

ma

at

ti

io

on

n

The command 0x21 reads out the status information in one complete packet from the scanner. When you

have sent the command 0x21 to the scanner and watch out for a packet with the protocol version 0x10. This

protocol revision number is in the byte 60 of the header. When you found 0x10 in Byte 60, you have

identified the info telegram packet. Protocol version 0x11 is the message that something with profile scan

data status is wrong.

At the end of the packet, additionally 31 bytes of function register status is sent, then the FiFO fill status

information. The table on the next page shows the details.

When the command 0x21 is received by the scanner, a packet with 2048 Bytes is sent from the scanner to

the PC. The packet contains all information of the registers 0 … 63, but no scan profile data. From Byte 130

on, the firmware version is sent as a string. The end of the string is 0x00.

I

In

nf

fo

o

T

Te

el

le

eg

gr

ra

am

m

(

(t

th

he

e

s

sc

ca

an

nn

ne

er

rs

s

a

an

ns

sw

we

er

r

t

to

o

t

th

he

e

c

co

om

mm

ma

an

nd

d

0

0x

x2

21

1)

)

Byte

Nr.

Register

Nr.

Function Length|type Ending Firmware

00 ... 51 Header 52 Byte

52 … 59 Synchronization 8 x 0x00

60 … 60 Protocol version 1 Byte

61 … 61 Scanner Status 1 1 Byte

62 … 62 Image number 1 Byte

63 … 63 Scanner Status 2 1 Byte

Header

64 … 65

Reserve 2 Byte

66 … 97 0 ... 31 Status-Register 32 Byte -

98 … 129 32 ...63 Eprom Data 32 Byte -

130 … x - Firmware-Version * String 0x00, 0xFF

X+1 ... x+32 0 ... 30 Functions-Register 31 Byte 0xFF

...1.10.0

X+33 ... x+35 123...125 FiFO fill status 3 Byte 0xFF

... 2047 Fill bytes 0xFF

1.11.0+ ...

* the length of the firmware string is defined by the ending 0x00. the length of the firmware string varies with

each version! Between the register data and the FiFO-Bytes 0xFF may appear! The position of the FiFO-

Bytes is after the function registers. Always a block of 2048 Bytes is sent, at the end of the block “old” data

(trash) may exist.

command: 0x21, read out register-dump –Scanners action upon 0x21:

o64 EEPROM Registers are read out

othe protocol version is set to 0x10

othe sync raster is written 8-Null Bytes

ofrom Byte 130 of the data section the firmware-Version number is sent

ono Scan-Data were transferred

Data format of the Packet valid from Firmware Version 1.11.0 and higher.

D

Da

at

ta

a

f

fo

or

rm

ma

at

t:

:

R

Re

eg

gi

is

st

te

er

r

a

ad

dd

dr

re

es

ss

se

es

s,

,

C

Co

om

mm

ma

an

nd

ds

s

o

or

r

D

Da

at

ta

a

MSB = „0“ = command or Register number MSB = „1“ = Register content

To change a value, first send the register number and then the value.

The register number remains active, unless a different register number is sent.

Tipp: double registers were made active only when the higher register is transferred.

Order of bits

Register Data Register Data

Lo-Byte Lo-Byte Hi-byte Hi-byte

76543210 76543210 76543210 76543210

0xxxxxxx 1xxxxxxx 0xxxxxxx 1xxxxxxx

Tipp: if not otherwise stated: for registers Bit 7 is not used and always 0.

for data, Bit 7 is always high.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 17 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

S

Sc

ca

an

nn

ne

er

r

c

co

on

nt

tr

ro

ol

ls

s

Register

HEX/DEZ

Bit Function register

(marked light blue)

Remarks

0x0 0 6..0 Shutter time Low

0x1 1 2..0 Shutter time High Shutter time

0 = max 1022 = min 1023 = Laser off Manual control

0x2 2 6..0 Max shutter time Low

0x3 3 2..0 Max shutter time High Limit for max. shutter time an.

0 = max 1022 = min; for alt. Sync P 130 Automatic control

0x4 4 6..0 Begin pixel readout

0x5 5 6..0 End Pixel readout The range is 0 … 127. 1 Bit corresponds to 8 Pixel

condition: (Begin < End) Max is automatically limited

0x6 6 6..0 Video gain Low

0x7 7 2..0 Video gain high 0 = +6 dB 1023 = +40 dB (default = 400 ... dB)

Value is transferred only after sending high

0x8 8 6..0 Intensity threshold 1 – 127; Intensity threshold for the internal laser control

Default = 15

0x9 9 6..0 Laser value 1 – 127 value for Laser control (default = 95)

0xA 10 6..0 Peak width Limit 0 = 0ff; other = Peak width Limit, max. = 127 Pixel

0xB 11 0 FPGA OK LED 0 = on 1 = off

0xE 14 * Reset Position counter The counter is set to 0

0xF 15 0 Synchronization 0=simultaneous measurement 1=alternating measurement

0x10 16 0 set Scan profile, image complete 0=Scan profile data, 1=complete image (see page 22)

0x11

17

5..0

Sensor adjustment

Status messages

(marked yellow)

0

1

2

3

4,5,6,7,8

9,10,11

12

13

14

31..15

63..32

= Sensor temperature

= Register contents

= Version number electronic system

= Version number camera

= operating hours counter in 0,25 Seconds-Ticks

= on counter

= inputs 1 + 2 + Bit for Sensor with mirror

= Bit 2 … 9 of Laser control

= Version number example: 3.5xxxx

xxxx is the version number

= NC

= 32 Byte Eprom-Data (see below)

0x12 18 2..0 Set protocol version 0 = Version1 / 1 = Version2 / 2 = Version3 / 3 = Version 4

0x13 19 * Reset camera chip Image counter and camera were reset

0x14 20 2..0

3

5 ..4

Do not use!

Trigger mode | continuous

Definition field mode

0 = continuous 1 = single shot with trigger

00 = both fields| 01=only 1st field | 10 = only 2nd field

0x15 21 0 Shutter control mode 0=automatic, 1=extern / manual (Register 0 & 1)

0x16 22 0 Linearization 0=off, 1=on; Start value 1

0x17 23 0…1 Control of M20D-XF 1.000 Hz 0 = 300 Hz; 1 = 500 Hz; 2 = 700 Hz; 3 = 1.000 Hz

0x18 24 Special register for ISA Hardware Read out Status register do not use with Ethernet-Hardware!

0x19 25 Not used

0x1B 27 6.. 0 Threshold of Profile recognition Default = 10 Max = 127 = 50% of maximum description: p.

22

0x1C 28 * Reset FIFO Clear FIFO is erased

0x1D 29 * Single shot in Trigger mode Register 0x14 must be set to make this function available

0x1E 30 * Reset Sensor All register values were reset

0x1F 31 * Reset Ethernet module Ethernet module restarts

0x20 32 * Watch-Dog Test Watch-Dog resets Ethernet Module

0x21 33 * Information telegram from

Ethernet module 32 Register + 32 Eprom values are sent.

The transmission protocol version is 0x10

0x22 34 * Save new network settings See Manual page 14 and following.

0x23 35 0 Ethernet Trigger mode 0= deactivate 1= activate when active, read out picture with

accessing to register 0x1D

0 = deactivate 1 = activate + 5 Byte Data

Command Active Image 1.shutter 2.shutter

0x24 0x81 0x80+xx 1.st field 2.nd 1.st 2.nd

0x24 36 Set HDR mode

Dual shutter operation

Detailed description on page 22.

0x25 37 Not used Do not use!

0x26 38 MEL internal register Do not use!

0x27 39 Not used Do not use!

0x28 40 Not used Do not use!

0x29 41 Eprom command Register MEL internal register – do not use!

0 = deactivated

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 18 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

1 = read Eprom

2 = write Eprom data into Ram (1Byte = 7 Bit)

3 = read Eprom data (1 Byte = 8 Bit)

4 = erase Eprom data

5 = program Eprom

0x2A 42 6..0 Eprom Data 512 k must be written. Data is sliced to 7 Bit, which are

reconciled in the sensor to 8 Bit

0x7F 127 Dummy Register No operation

* each access to the register triggers the function. It is not required, and it makes no sense to write any value to the

register. Simply calling the register address makes the necessary function work.

The register 0x11 selects the content of the status register. The status register has the parameters temperature of

sensor head, register contents, version of electronic system and camera, operating hours counter, on counter, digital

inputs, version of EPROM Firmware and 32 Bytes EPROM data, serial umber, scan range geometry. This method is

valid for Ethernet Scanners, ISA board and i-Control.

Special register 0x18 (24)

The special register 0x18 allows to query sensor data direct. When a value smaller than 127 is written to the register,

the read out of the FiFO is stopped and the register is put to the data bus. The number of the register is the content of

the special register. Data will remain on the bus as long as the special register is written again with 127. Then normal

image transfer is possible again.

Register Bit Function Meaning

0 - 30 6..0

7

Control register

NC

Shows the content of all control registers. Except

Registers which act as „impulse switch“ like „Reset

Sensor“ - unused Registers and Bits give back a “0”

31 7..0 Status Register Status messages are selected with Register 17

123 7..0 FIFO number of Bytes 1 Bit 7..0

124 7..0 FIFO number of Bytes 2 Bit 15..8

125 2..0

7..3 FIFO number of Bytes 3

NC Bit 18..16

126 * Save values for Register 123 - 125

D

Da

at

ta

a

f

fo

or

rm

ma

at

t

S

Sy

yn

nc

c

s

si

ig

gn

na

al

l

a

an

nd

d

S

St

ta

at

tu

us

s

i

in

nf

fo

o,

,

e

en

nc

co

od

de

er

r

i

in

nf

fo

or

rm

ma

at

ti

io

on

n

(

(p

pr

ro

ot

to

oc

co

ol

l

v

ve

er

rs

si

io

on

n

3

3)

)

Byte Nr Value Bit Nr. Meaning

52 .. 59 0 8 times 0x00 for Synchronization

60 Version number 7...0 Version des Scan-Data format

0 0=not linear, 1=linear

6...1 Content of Register 17

61 Status Byte 1

7 Always 0

62 Image number Continuously counting from 0..253

63 Status Byte 2 The content of status register_2 is selected by Register 0x11

all values made of more than 1 Byte, always the Bit 7 is 0. Per Byte

only 7 Bit were transferred.

64, 65 Reserved

66 ...X Image data Data format Vers.1: 4 x 283 = 1132 Bytes *

Data format Vers. 2+3: 5 x (Reg.34 ;35 (Rev.4=291)) = 1455 Bytes

X+1..X+9 0 8 times 0x00 for Synchronization

Version number 7...0 Version of Data format (3)

Position encoder Reg.1 6..0 Position encoder Bit 6..0 Two’s complement

Position encoder Reg.2 6..0 Position encoder Bit 13..7

Position encoder Reg.3 6..0 Position encoder Bit 20..14

Position encoder Reg.4 5..0

6 Position encoder Bit 26..21

Direction of Position encoder

… 2040 Fill [ ... ] Fill bytes

2041.2042 Pixel number horizontal 2 Bytes Typ. = 290

2043.2044 Pixel number vertical 2 Bytes Typ. = 752

2045..47 FiFO 3 Bytes FiFO-fill status

The Data packet has always the length of 2048 Bytes. * iLAN Scanner supports only data format 3.

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 19 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

M

Me

ea

an

ni

in

ng

g

o

of

f

t

th

he

e

s

st

ta

at

tu

us

s

b

by

yt

te

e

2

2

d

de

ep

pe

en

nd

di

in

ng

g

f

fr

ro

om

m

r

re

eg

gi

is

st

te

er

r

0

0x

x1

11

1

V

Va

al

lu

ue

e

=

=

[

[0

0]

]:

:

S

Se

en

ns

so

or

r

t

te

em

mp

pe

er

ra

at

tu

ur

re

e

Reg. value Temperature Value (Hex) Value (Bin)

+126 C° 7E 1111 1110

+ 85 C° 55 1101 0101

+ 25 C° 19 1001 1001

+ 0 C° 00 0000 0000

- 1 C° FF 0000 0001

- 25 C° E7 0001 1001

0

- 55 C° C9 0011 0111

In 1 degree steps from -55 to +126 C°.

Bit 7 is the sign!

V

Va

al

lu

ue

e=

=

[

[1

1]

]:

:

R

Re

eg

gi

is

st

te

er

r

c

co

on

nt

te

en

nt

ts

s

Reg. value Bit Nr. Meaning

0 0= not linear, 1= linear

1 0= Register contents as after Reset, 1=after write to Register

2 0= Scan data, 1= complete image

3 Laser 0 = on 1 = off

4 Measurement control 0 = continuous 1 = single shot with Trigger

5 Laser control 0 = automatic 1 = extern (Register 0 & 1)

6 NC

1

7 0

V

Va

al

lu

ue

e

=

=

[

[2

2,

,

3

3]

]:

:

V

Ve

er

rs

si

io

on

n

n

nu

um

mb

be

er

r

e

el

le

ec

ct

tr

ro

on

ni

ic

c

s

sy

ys

st

te

em

m

a

an

nd

d

c

ca

am

me

er

ra

a

Reg. value Bit Nr. Meaning

2 7 ... 0 Version electronic system example: 36 corresponds to Revision 3.6

3 7 ... 0 camera

v

va

al

lu

ue

e

=

=

[

[4

4,

,

5

5,

,

6

6,

,

7

7,

,

8

8]

]

:

:

o

op

pe

er

ra

at

ti

in

ng

g

h

ho

ou

ur

rs

s

c

co

ou

un

nt

te

er

rs

s

(

(B

Bi

it

t

7

7

a

al

lw

wa

ay

ys

s

0

0)

)

2

25

50

0m

ms

se

ec

c

p

pe

er

r

c

co

ou

un

nt

t

Reg. value Bit Nr. Meaning

4 6..0 Operating hours counter Bit 6..0

5 6..0 Operating hours counter Bit 13..7

6 6..0 Operating hours counter Bit 20..14

7 6..0 Operating hours counter Bit 27..21

8 3..0 Operating hours counter Bit 31..28

V

Va

al

lu

ue

e

=

=

[

[9

9,

,

1

10

0,

,

1

11

1]

]:

:

o

on

n

c

co

ou

un

nt

te

er

r

Reg. value Bit Nr. Meaning

9 6..0 On counter Bit 6..0

10 6..0 On counter Bit 13..7

11 2..0 On counter Bit 16..14

Bit 7 is always 0. The maximum counter value is = 131.072

V

Va

al

lu

ue

e

=

=

[

[1

12

2]

]:

:

D

Di

ig

gi

it

ta

al

l

i

in

np

pu

ut

ts

s

1

1

,

,

2

2

+

+

B

Bi

it

t

f

fo

or

r

S

Se

en

ns

so

or

rs

s

w

wi

it

th

h

a

a

m

mi

ir

rr

ro

or

r

Reg. value Bit Nr. Meaning

0 Digital input 1

1 Digital input 2

2 Bit for Sensor with a mirror ; „1“ = with mirror

12

7...3 NC always 0

M2i-LAN Laser-Scanner manual

HB-M2-iLAN-UDP-E.doc page 20 of 44

MEL Mikroelektronik GmbH, Breslauer Str. 2, 85386 Eching / Germany www.MELSensor.de

V

Va

al

lu

ue

e

=

=

[

[1

13

3]

]:

:

L

La

as

se

er

r

c

co

on

nt

tr

ro

ol

l

B

Bi

it

t

2

2.

..

..

.9

9

Reg. value Bit Nr. Meaning

13

7 ... 0 Bit 7 ... 0 of the register 13 represent the Bits 9 ... 2 of the laser control value

in automatic mode. The lower bits were not sent back by the sensor, these can

not be read back. For adjustment, the bits 2 … 9 are sufficient for set up. For

set up the sensor firmly to a special value, we recommend the following

procedure:

1. set the Scanner in automatic mode on the target surface

2. read out Bit 2 ... 9 from status register

3. set Scanner in manual controlled (external) mode

4. write back the previously read out values

Bits 0 and 1 are set to „0“

V

Va

al

lu

ue

e

=

=

[

[1

14

4]

]:

:

V

Ve

er

rs

si

io

on

n

n

nu

um

mb

be

er

r

Reg. value Bit Nr. Meaning

14 7 ... 0 The revision of the firmware is determined from status registers 2 and 14.

Register 14 shows the 3rd digit of the version number.