MEL M2D/LAN User manual

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 2 of 39 www.MElsensor.com

C

Co

on

nt

te

en

nt

ts

s

Contents ..................................................................................................................................................................................2

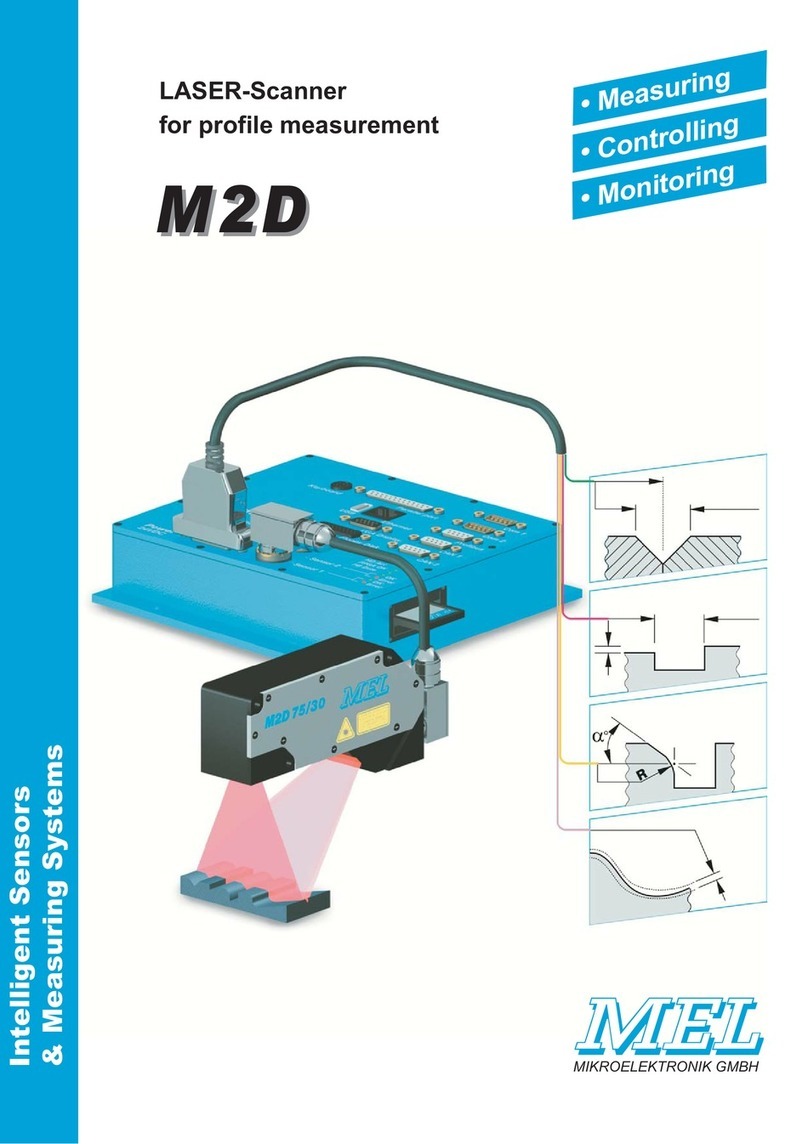

System description ..................................................................................................................................................................4

Scanner Head, Electronic-System and controls ......................................................................................................................4

Software Controlled Parameters.............................................................................................................................................4

Connecting the Ethernet-Scanner ...........................................................................................................................................4

Using standard Ethernet hardware ..........................................................................................................................................4

Cabling requirements ..............................................................................................................................................................5

Ethernet connectors RJ-45.....................................................................................................................................................6

Multi-Scanner Arrays ...............................................................................................................................................................6

How many scanners could be integrated in one network segment?........................................................................................6

Control Commands..................................................................................................................................................................6

External-Trigger / Hardware-Trigger........................................................................................................................................7

Synchronization .......................................................................................................................................................................7

Ethernet-Trigger Mode ............................................................................................................................................................7

Digital inputs ............................................................................................................................................................................7

Read out complete image........................................................................................................................................................7

Synchronize Sensors...............................................................................................................................................................7

Trigger Mode ...........................................................................................................................................................................7

Calculation of shutter time .......................................................................................................................................................8

Number of pixels, encoder data...............................................................................................................................................8

Register 0x1B: Profile peak recognition threshold ...................................................................................................................8

Status LED’s on the “Blue Box” ...............................................................................................................................................8

Power and signal connector D-Sub-25 pin ..............................................................................................................................9

Ground connection; connector D-Sub-25 ................................................................................................................................9

Technical data .......................................................................................................................................................................10

M2DF/LAN Laser-Scanner, electronic system in Blue Box with Ethernet interface ..............................................................10

Dimensions of the electronic box...........................................................................................................................................10

Other MEL Laser-Scanner hardware.....................................................................................................................................10

Communication between Electronic unit and PC...................................................................................................................11

Functions of the Micro-Controller in the Electronic-Box.........................................................................................................11

PC-Host-Software functions ..................................................................................................................................................11

Communication Components ................................................................................................................................................11

Set up of the Scanners working IP-Address ..........................................................................................................................11

Set the Scanner to the default IP address .............................................................................................................................11

Resolving IP-Address-Conflicts .............................................................................................................................................11

DHCP ....................................................................................................................................................................................12

Ping .......................................................................................................................................................................................12

IP parameters Default Values.......................................................................................................................................... 12

MEL Demo Software for Ethernet-Scanners .........................................................................................................................13

Main window..........................................................................................................................................................................13

Temperature readout.............................................................................................................................................................13

Using a temporary IP-Address...............................................................................................................................................14

Pixel Readout Limit (Demarcation Feature)..........................................................................................................................14

Data format and interface description....................................................................................................................................15

Frame format for TCP-Scanner profile transmission .............................................................................................................15

Structure of M2DF-LAN Header and payload Data ...............................................................................................................15

Sync and status information, position encoder (protocol revision 3.x) ...................................................................................15

Status information readout using command 0x21:................................................................................................................. 16

Encoder data .........................................................................................................................................................................16

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 3 of 39 www.MElsensor.com

Data format for register address, command and data ...........................................................................................................16

Scanner controls....................................................................................................................................................................17

Special commands for the Ethernet version ..........................................................................................................................17

M2DF / LAN-Data Format......................................................................................................................................................18

Meaning of the status byte 2 as a function of Register 0x11 .................................................................................................18

Register value [0] Scanner head temperature .......................................................................................................................18

Register value [1]: register contents ......................................................................................................................................18

Register value [2,3] : version number of camera and electronic system................................................................................18

Register value [4,5,6,7,8]: hours counter (bit 7 always 0) count every 250 msec.................................................................. 18

Register value [9,10,11]: on counter (bit 7 always 0) max. count = 131072 ..........................................................................18

Register value [12]: digital inputs...........................................................................................................................................18

Register value [13]: Laser Control .........................................................................................................................................19

Register value [14]: Revision number....................................................................................................................................19

Register value [15 … 31]: not used .......................................................................................................................................19

32 Byte Eprom data...............................................................................................................................................................20

Register 0x18 ........................................................................................................................................................................20

Protocol Version 1 .................................................................................................................................................................20

M2DF/LAN-Structure of Image Data......................................................................................................................................21

Protocol Version 3 .................................................................................................................................................................21

Integrated Web-Server ..........................................................................................................................................................22

Available Read out Functions ................................................................................................................................................22

How to set the IP address over the Web ...............................................................................................................................22

Requirements ........................................................................................................................................................................22

RS-232 Monitoring.................................................................................................................................................................23

Flashing Firmware .................................................................................................................................................................24

Trouble Shooting ...................................................................................................................................................................25

Example code for Software engineers...................................................................................................................................26

Data format for register addresses and commands...............................................................................................................26

3. Command: 0x21 (dump) ....................................................................................................................................................27

example: // read out FiFo status and sensor temperature .....................................................................................................32

Setting the IP-Address by software .......................................................................................................................................34

Representation of the Serial-Number ....................................................................................................................................34

Ports ......................................................................................................................................................................................35

Ethernet WinSock Implementation ........................................................................................................................................36

Example: (“C”) using WinSock and Scanner functions: ........................................................................................................36

UDP Implementation .............................................................................................................................................................37

IP-Programming for UDP-transmission protocol:...................................................................................................................38

Changes and additions..........................................................................................................................................................39

Disclaimer: This document may contain misprints and errors.

MEL does not cover any warranty claims based

on the fact of possible mismatch of this documentation.

Please note: in the following text, register addresses were given as hexadecimal numbers: 0x14 = “20” 14 hexadecimal = 20 decimal.

Bit 7 = MSB = “0” for all register addresses

Bit 7 = MSB = “1” for all commands and data

Firmware The Scanner head contains Firmware in an Eprom, defining the

functions of profile recognition and Scanner head control

algorithms. This Firmware is referred to as “Scanner head

Firmware”. This Firmware can be altered by exchange of the

Eprom. Current Revision state is 3.6.3.

Firmware of the electronic system is located in the blue box

electronic system. This firmware can be updated with a flash tool

supplied by MEL on request. The flash procedure requires a

working RS-232 connection to the electronic box and a.m. flash

tool. Current firmware revision of the electronic system is 1.13.5

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 4 of 39 www.MElsensor.com

S

Sy

ys

st

te

em

m

d

de

es

sc

cr

ri

ip

pt

ti

io

on

n

The M2D-LAN-Laser-Scanners come with an electronic box in the size of 102 x 70 x 28 mm. A standard RJ-45-

Ethernet connector is in the cover of the electronic system box. On the D-Sub-25-pin connector at the side, the

Ethernet-signals are also available. When the Ethernet is connected to the D-Sub connector, the cover may be

sealed optional, providing immunity against water and dust.

S

Sc

ca

an

nn

ne

er

r

H

He

ea

ad

d,

,

E

El

le

ec

ct

tr

ro

on

ni

ic

c-

-S

Sy

ys

st

te

em

m

a

an

nd

d

c

co

on

nt

tr

ro

ol

ls

s

The Scanner head is equipped with a CCD-Camera, a Line Laser projector and a electronic system for the

detection of the profile from the camera video signals. The Scanner head is connected to the Blue-Box with a 9-

pin Sub-D-connector. The camera in the scanner head is controlled through the Blue-Box. There are no Dip-

Switches for adjustment of shutter time, video gain and laser intensity. All adjustments are done in the

configuration software and permanently stored in a electrically erasable EPROM.

For software engineers, writing their own applications, MEL deploys examples with source-code in C++. For

documentation of hardware registers, scanner implementation and data format see Data format and interface

description.

S

So

of

ft

tw

wa

ar

re

e

C

Co

on

nt

tr

ro

ol

ll

le

ed

d

P

Pa

ar

ra

am

me

et

te

er

rs

s

TCP/IP: address; subnet mask; TCP-ports

Operation controls: shutter control

Laser “intensity” control; Video gain control

Operation modes: continuous - single shot; ext. trigger – free run

Synchronized – non-synchronized mode , Trigger with hardware / software

C

Co

on

nn

ne

ec

ct

ti

in

ng

g

t

th

he

e

E

Et

th

he

er

rn

ne

et

t-

-S

Sc

ca

an

nn

ne

er

r

When connecting the M2D-LAN-Scanner to a your LAN* use a 1:1 wired cable to the Ethernet-Switch, when

connecting directly to the Ethernet network card in the PC, use a cross-wired Ethernet cable, also known as

crossover-cable (X-over). Do not connect Ethernet card and Scanner with a 1:1-wired Ethernet cable!

* LAN = Local Area Network

U

Us

si

in

ng

g

s

st

ta

an

nd

da

ar

rd

d

E

Et

th

he

er

rn

ne

et

t

h

ha

ar

rd

dw

wa

ar

re

e

When testing transmission of the TCP data from the scanner, with standard hardware from the shelf no problems

have been found so far concerning Ethernet Switches and CAT-5e cables. Testing included sending the profiles

over the company network and wireless LAN (802.3g).

We do not recommend the use of „Hubs“: Hubs connect the ports in parallel, this may cause hangs on data

transmission or loss of information.

When “a bunch of scanners” were controlled by a PC, the PC and the graphic card must have good performance

in order to capture and process and display all scanners data fast enough. We recommend to check the image

numbers transmitted with every scan profile. See data format description Register Sync+Status Byte 11, page ….

for details.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 5 of 39 www.MElsensor.com

C

Ca

ab

bl

li

in

ng

g

r

re

eq

qu

ui

ir

re

em

me

en

nt

ts

s

The M2DFL-scanner requires only 4 wires for transmission of data: Tx-; Tx+; Rx- and Rx+. Standard CAT-5e or

CAT-6 cables have 8 wires organized in 4 pairs. For remote power feed, the remaining 4 wires can be used to

supply power to the unit. This wiring will not be according to standard 802.3af Power over Ethernet (PoE), but

when adapters* were carefully designed, it will work without problems.

CAT-5e specification for Twisted-Pair-Network-cables requires twisted leads with 100 Ohms Impedance and

shielded cable. Use always cables specified CAT-5e or better!

When a “switch” is used to connect the M2DFL-scanner to the PC, straight (1:1 wired) Ethernet-cables are to be

used. When connected the M2DFL-scanner directly to the network card in the PC, a cross-wired Ethernet-cable

needs to be used. Ethernet Switches should provide „auto-sense“. This means, the unit automatically detects

signal polarity.

The Ethernet electronic system provides two possibilities to make the Ethernet connection:

o RJ-45 connector at the top cover

o Dsub-25 pin connector

Both connections will provide the same function.

Both connections can never be used in parallel .

When the connection is made at the RJ-45 connector, no Ethernet cable must be connected at the D-Sub-25 pin

connector. Leaving the Ethernet cable hanging “open” from the D-Sub-connector, will cause problems.

The electric waves in the cable are reflected at the open cable end. Depending on the length of the open cable

end, the reflected waves phase shifts. The overlapping of the origin waves and the reflected wave creates a

“chaos”. Overlapping the origin and reflected waves makes the voltage on the cable vary over the location in the

cable – see drawing below!

When the distance of the open cable end is a quarter of the signal wavelength, the signal voltage is zero.

This is the reason, why the RJ-45 connector will not work when a open end of the Ethernet cable is hanging at the

D-sub connector. “Open” means: physically unconnected cable end.

The drawing illustrates the voltage over the cable situation.

The small flash (symbol for a short circuit) is the location where the RJ-45 connector is located.

The rule: a) when an Ethernet cable is present at the D-Sub connector, only this cable should be used.

Do not use the RJ-45 connector.

b) When no other Ethernet cable is at the D-Sub connector, the RJ-45 connector shall be

used to connect the Ethernet cable.

* these adapters are available on request!

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 6 of 39 www.MElsensor.com

E

Et

th

he

er

rn

ne

et

t

c

co

on

nn

ne

ec

ct

to

or

rs

s

R

RJ

J-

-4

45

5

Pin Signal connector A connector B

“normal”

Pin Connector B

“crossed”

Signal

1 TX + Green +White Green +White 1 Red + White Rx +

2 Tx - Green Green 2

Rot Rx -

3 Rx + Red + White Red + White 3 Green +White Tx +

4 nc - Blue Blue 4

Blue nc -

5 nc + Blue + White Blue + White 5 Blue + White nc +

6 Rx - Red Red 6

Green Tx -

7 nc + Brown+ White Brown+ White 7 Brown+ White nc +

8 nc - Brown Brown 8

Brown nc -

picture left: crosslink cable

direct connection from PC network card to scanner electronic box requires a

crosslink network cable. The position of the red and blue wires in the connectors

shows, that this cable is a crossed Ethernet cable, known as crosslink. When you

use a Ethernet switch, 1:1 patch cables should be used instead.

M

Mu

ul

lt

ti

i-

-S

Sc

ca

an

nn

ne

er

r

A

Ar

rr

ra

ay

ys

s

Setting up a multi-scanner array will not require specific “programming”. Configuration can be copied from one

Scanner to the next, yet the TCP/IP addresses of each scanner must then be set to different IP-address value.

(see pages …). Theoretically it is possible to connect more than 30 Scanners in one 100 Mbit Ethernet network

segment, providing no more than 50% load of the 100 Mbit network. Using 10 Mbit network equipment is not

recommended. Image data transmission and network performance

Standard Ethernet network switches, network cards and PC have no problems with M2D-Ethernet-Scanners.

When connecting multiple scanners to one PC, the PC must have enough performance to receive, process and

display the Scan profile information retrieved from the scanners. The performance of CPU and graphic card could

cause “dropped frames”. Use the image count number, delivered with the scan profile data (see data format

description, table 5 on page 12, status register Byte 11 ( 0 … 254) to detect lost profiles!

H

Ho

ow

w

m

ma

an

ny

y

s

sc

ca

an

nn

ne

er

rs

s

c

co

ou

ul

ld

d

b

be

e

i

in

nt

te

eg

gr

ra

at

te

ed

d

i

in

n

o

on

ne

e

n

ne

et

tw

wo

or

rk

k

s

se

eg

gm

me

en

nt

t?

?

The Scanner sends out 100 scan profiles per second with the following data:

o TCP-IP header

o M2DF-L-header, Scan profile data, reserved Bytes

o Additional information as encoder data, fill Bytes, FiFO-fill level data

o CRC error check data

Each scan profile with above data is packed into a 2048 Byte block = 100 x 2.048 kBytes / s = 204,8 kBytes /s

The 100 Mbit network = 12.500 kBytes / s could transport 12.500 / 226 = 61.03 Scanners. For real-time

applications, Administrators avoid network load above 50%. Therefore the recommendation = max. number of

scanners = 30.

C

Co

on

nt

tr

ro

ol

l

C

Co

om

mm

ma

an

nd

ds

s

With the exception of “Laser-ON”, there is no other command to be sent for activation of the scanner. When the

Laser is on, the scanner sends profile data as a “continuous stream”.

It is highly recommended, to send a first “FIFO reset” command, before measurements were made in regular

intervals. The command “FiFO-reset” destroys the first image (at least partially). Therefore ignore the first image

after “FiFO-reset” and wait for the second one. The command FiFO-reset makes sense, when no data has been

acquired for a long time, and the scanner has been waiting for new data. When data is read continuously, the

command FiFO-reset is not useful.

Commands for set up of trigger mode and sync mode are given in the data format description, page 14 and 19.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 7 of 39 www.MElsensor.com

simultaneous Sync alternating Sync simultaneous Trigger alternating Trigger

E

Ex

xt

te

er

rn

na

al

l-

-T

Tr

ri

ig

gg

ge

er

r

/

/

H

Ha

ar

rd

dw

wa

ar

re

e-

-T

Tr

ri

ig

gg

ge

er

r

Pin 15 = Sync-input is triggered with a 0/1 slope = low-high-transit. The trigger signal should be free from

hazardous oscillations. Pin 15 is an optical coupled input with current limit. The input accepts voltage from TTL …

24V, max. 30 V DC.

When a triggered measurement is made, no other trigger signal is considered from the sync input, while the

image is “read”. The maximum scan rate in trigger mode is approx. 75 Hz. Trigger mode must be preset with

register 0x14 (20) = “1”, single shot with trigger. In trigger mode, synchronization is not possible.

S

Sy

yn

nc

ch

hr

ro

on

ni

iz

za

at

ti

io

on

n

Synchronization uses the Sync-input pin 15. One scanner is dedicated to be “Master” while all others are “Slaves”.

Pin 2 of the “Master” is connected to Pin 15 of the Slaves, ground pins are connected accordingly. The Master

sends a sync out signal on pin 2. The slaves receive the sync signal on pin 15. Ground pins = 1, 14. After

receiving the sync pulse, the Slave-Scanner modifies his timing accordingly. For measurement on request, use

Ethernet-Trigger mode (see below!). The sync input can be left open without special wiring.

E

Et

th

he

er

rn

ne

et

t-

-T

Tr

ri

ig

gg

ge

er

r

M

Mo

od

de

e

Ethernet-Trigger Mode is set with Register 0x23 according to definition on page …. In this mode, the sensor

acquires profile data continuous, but sends out data over Ethernet only on request. The internal FiFO is not in

use. The actual profile at time of trigger event is sent out. Depending on the speed of the PC, images could be

missing.

D

Di

ig

gi

it

ta

al

l

i

in

np

pu

ut

ts

s

From PC board version 1.3 on, the digital inputs may be used to feed encoder signals. The digital A/B-inputs feed

a counter, which is read out over the registers 13…16. The encoder counter information is sent with every

complete profile data package. This makes sure, that the position of each profile is always in sync with the motion

position of the scanner.

R

Re

ea

ad

d

o

ou

ut

t

c

co

om

mp

pl

le

et

te

e

i

im

ma

ag

ge

e

The complete camera image is read out. No recognition of the scan data is made, that means, the sensor sends

out raw data with 8 bit resolution. When the register 0x10 is set to “1”, the sensor writes 2 fields complete into the

FiFo. After each field, 8 Byte zero’s and 4 status Bytes are transferred. The read out of a new image starts with a

hardware or software trigger event.

We recommend to empty the FiFO before reading Scanner data. The FiFo is 512 kByte.

Intensity of the pixels values are 0 … 254.

S

Sy

yn

nc

ch

hr

ro

on

ni

iz

ze

e

S

Se

en

ns

so

or

rs

s

„Synchronizing“ means the simultaneous or alternating read out of the sensors. For synchronization, the Pins

Sync out of the Master-Scanner and sync in of the Slave-Scanner unit must be connected, as well as ground pins.

Pin 2 of the master sensor is connected to pin 15 of the slave sensor. Both image counters work now

synchronous. Phase error is less than 10 µsec. When register 0x0F is set to „1“, both sensors measure

alternating. Shutter time in register „2“ and „3“ must be limited to the value 130, in order to avoid overlap of the

two sensors.

T

Tr

ri

ig

gg

ge

er

r

M

Mo

od

de

e

Trigger mode must be activated in the register 0x14, Bit 3 with a “1”. Hardware trigger is made with a leading

edge of the sync input, pin 15. Software trigger is made by accessing the register 0x1D. Software trigger and

hardware trigger both have the same function. In both modes, the sensor reacts on the leading (rising) 0/1-edge

of the trigger impulse. The capture process starts 65 µsec after trigger. The image counter is reset, two fields are

sent out.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 8 of 39 www.MElsensor.com

C

Ca

al

lc

cu

ul

la

at

ti

io

on

n

o

of

f

s

sh

hu

ut

tt

te

er

r

t

ti

im

me

e

The camera creates approximately 103 profiles per second. This

corresponds to 9.71 msec period. The maximum shutter time is

shorter than 9.71 msec, because of the minimum erase time

interval.

Maximum shutter time = 9.71 msec * 256 / 286 = 8.69 msec

This maximum shutter time value is divided in 16384 steps.

The sensitivity is not linear. Therefore the “regulation value”

(RegisterValue – see Register 0 …3) is linearised using 8

definite set values.

For the calculation of the shutter time using the regulation value ( Regelwert) (0 = longest 1022 = shortest shutter

time) the following approximation formula applies:

16384

2897Re16384 4xegistervalu

TimexMaxShuttereShutterTim −

=

N

Nu

um

mb

be

er

r

o

of

f

p

pi

ix

xe

el

ls

s,

,

e

en

nc

co

od

de

er

r

d

da

at

ta

a

The current camera model sends with 5 Byte data format selected and with protocol version 2 and 3 the number

of 291 pixels per profile. (protocol version 1 and 4 Byte is 283 pixels!). After the profile information with firmware

revision 1.9.11 4 Bytes of encoder data follow at the end of the data block. Up to firmware revision 1.9.10, the

encoder data has been transferred at the beginning of the block. See page 5 for details.

Register 12 sets the version of protocol ( 1 … 3).

R

Re

eg

gi

is

st

te

er

r

0

0x

x1

1B

B:

:

P

Pr

ro

of

fi

il

le

e

p

pe

ea

ak

k

r

re

ec

co

og

gn

ni

it

ti

io

on

n

t

th

hr

re

es

sh

ho

ol

ld

d

This register controls the algorithm responsible fort he profile detection in the FPGA. A change in setting should

be made only, when the result could be verified immediately. When no improvement is achieved, you should

immediately set back default value = 10. The effect of increasing Peak detection threshold may result in more or

less stray pixels on surfaces with noise optical response (creating speckles). Increasing Peak threshold could

remove those effects, depending on the situation on the camera. We recommend to use the option “read

complete image” to evaluate what the camera is picking up, before changing Peak threshold.

S

St

ta

at

tu

us

s

L

LE

ED

D’

’s

s

o

on

n

t

th

he

e

“

“B

Bl

lu

ue

e

B

Bo

ox

x”

”

Status LED’s Meaning Color* OK when

Power Power is ok green On

100 Mbit Ethernet Link is established yellow Blinking

Eth-Link Ethernet Link activity orange On / blinking

System hardware self diagnosis ok green On *

FPGA FPGA self diagnosis ok green Blinking *

* the System- and FPGA-LED’s start blink synchronous, when CPU_Prog Pin is set active!

Note: when a 100 Hz Scanner head and a 50 Hz electronic system (and vice versa) were connected, the

electronic unit will not be able to connect to the Ethernet. The System-LED will blink significantly slower than

normal (<< 1 Hz). The normal blinking rhythm is approx. 2 Hz.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 9 of 39 www.MElsensor.com

P

Po

ow

we

er

r

a

an

nd

d

s

si

ig

gn

na

al

l

c

co

on

nn

ne

ec

ct

to

or

r

D

D-

-S

Su

ub

b-

-2

25

5

p

pi

in

n

----------------------------Sensor-------------------------------------------------------------------------PC----------------------------------

D-Sub 25 RJ45-Ethernet RS-232

Pin Signal Meaning / signal level Func. Pin Func. Pin

1 Gnd Ground

Br. 1 1

2 Sync out Sync out from the Master is connected to Sync-in

of the Slaves.

3 TxD_PROG Send data RS-232 for Firmware-update * TX 2

4 Din 1 Digital input 1 Br. 1 4

5 RIP Reset IP Address →connect to ground = default IP * *

6 Tx- Transmit Data - Ethernet Rx - 6 Br. 1 6

7 Rx- Receive Data - Ethernet Tx - 2 Br. 2 7

8 Case PE ; ground ***

Br. 2 8

14 Gnd Ground, 0 V DC GND 5

15 Sync in Sync in from Master, TTL ... 24 V Logic 0/1 leading edge

triggers ext. Trigger mode must be set in register 0x14 !

16 RxD_PROG Receive data RS-232 for Firmware-update * RX 3

17 CPU_PROG Programming control for Firmware-update

For update connect to + Ub over a 3.000 Ohms resistor*

18 Din 2 Digital input 2

19 Tx+ Transmit Data + Ethernet Rx + 3

20 Rx+ Receive Data + Ethernet Tx + 1

21 + Ub supply +10 ... 30 V DC , approx. 5.3 W

Sync in = ext. Trigger Sync input has internal pull-down resistor.

* using firmware update is on customers risk (no warranty).

** connect RIP-Pin (Pin 5 to ground). Then cycle power. After restart, the Scanner will communicate on the default

IP address. Set new IP address using MEL-Demo-Software Rev.2.0.4.2, Tab 11. Release RIP-Pin from ground.

Cycle power. Now the new IP-address is active. For alternative method see also page 24.

*** ground should be applied in a central place at machine side. Avoid ground loops, connect ground leads in a

“star” structure. Connect protective ground in central place to the machine, connect the case with short leads.

Bridges for simulated RS-232 hardware handshake

Bridge 1: pins 1 – 4 -6 Bridge 2: 7 – 8 Connect Case of D-Sub-9Pin connector to Pin 5 (GND).

G

Gr

ro

ou

un

nd

d

c

co

on

nn

ne

ec

ct

ti

io

on

n;

;

c

co

on

nn

ne

ec

ct

to

or

r

D

D-

-S

Su

ub

b-

-2

25

5

The enclosure of the D-Sub connector is wired with a

short lead to bridge 1-14. The Ethernet cable shield is

connected with a short lead to the bridge 1-14.

Pin 8 is not connected.

connect Pin 1 to Pin 14 as a bridge,

then connect here

o Supply negative ( 0 V)

o Connector enclosure

o Ethernet cable Shield

4 Digital In 1

3 TxD Prog

2 Sync-Out

5 Reset IP

1 GND

8 case

7 Rx-

6 Tx-

Rx+ 20

+Ub 21

Tx+ 19

Digital In 2 18

RxD_Prog 16

CPU_Prog 17

Sync-In 15

GND 14

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 10 of 39 www.MElsensor.com

T

Te

ec

ch

hn

ni

ic

ca

al

l

d

da

at

ta

a

Frame rate 100 Hz, typical value = 103,4 Hz

Frame rate, trigger mode 100 Hz

Frame rate, extern sync mode 75 Hz

Timing drift 100 x 10-6

Min. / Max. ambient operating temperature min. 0°C ( + 32°F) max. 35°C ( + 95°F)

Min. Max. storage temperature min. –30°C ( + 2°F) max. 75°C ( + 167°F)

M

M2

2D

DF

F/

/L

LA

AN

N

L

La

as

se

er

r-

-S

Sc

ca

an

nn

ne

er

r,

,

e

el

le

ec

ct

tr

ro

on

ni

ic

c

s

sy

ys

st

te

em

m

i

in

n

B

Bl

lu

ue

e

B

Bo

ox

x

w

wi

it

th

h

E

Et

th

he

er

rn

ne

et

t

i

in

nt

te

er

rf

fa

ac

ce

e

Power consumption = 220 mA @ 24 V DC

Supply voltage range = + 10 ... 30 V DC

Digital inputs = Low = 0 … 2 V High = 5 V … 30V

dimensions = 102 x 74 x 28 mm

weight of electronic box = 300 g

mounting = D = 6 mm without thread (four metric M5)

connectors at the box = D-Sub 9pin female scanner connector

D-Sub-25pin male Supply, Ethernet, Sync / ext.Trigger

RJ-45 = Ethernet

D

Di

im

me

en

ns

si

io

on

ns

s

o

of

f

t

th

he

e

e

el

le

ec

ct

tr

ro

on

ni

ic

c

b

bo

ox

x

64

7

4

92

102 27,5

4

4,4

8

Please note: M2D Laser Scanner head dimensions were specific to the different models.

Please refer to the M2D catalogue for further information.

The electronic box is the same for all types of Scanner heads.

The exception may be with Scanner heads, which have enough space to integrate the electronic

board inside of the Scanner head enclosure.

Error and technical modification reserved!

O

Ot

th

he

er

r

M

ME

EL

L

L

La

as

se

er

r-

-S

Sc

ca

an

nn

ne

er

r

h

ha

ar

rd

dw

wa

ar

re

e

M2D-i-Control 50 Hz M2D-i-Control 100 Hz

M2D-ISA card 50 Hz M2D-ISA card 100 Hz

M20D-XF-ISA Laser-Scanner, 300 … 1.000 Profiles / sec.

Previous generation of M2D-“Blue-Box Rev.1” electronic systems is EOL.

A limited number of systems is available for repair and retrofit purpose on request.

Please contact MEL for details.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 11 of 39 www.MElsensor.com

C

Co

om

mm

mu

un

ni

ic

ca

at

ti

io

on

n

b

be

et

tw

we

ee

en

n

E

El

le

ec

ct

tr

ro

on

ni

ic

c

u

un

ni

it

t

a

an

nd

d

P

PC

C

A Micro-Controller in the blue-Box communicates with the PC over the Ethernet. The communication is peer-to-

peer. Ethernet switches can be used to communicate over a network. Do not use Hubs! The M2DF-LAN-Scanner

requires 100 Mbit network connection. When you use 10 MBit network equipment, communication could get

stuck.

F

Fu

un

nc

ct

ti

io

on

ns

s

o

of

f

t

th

he

e

M

Mi

ic

cr

ro

o-

-C

Co

on

nt

tr

ro

ol

ll

le

er

r

i

in

n

t

th

he

e

E

El

le

ec

ct

tr

ro

on

ni

ic

c-

-B

Bo

ox

x

o Read profile data from Scanner head

o Send out Scan data over TCP-protocol

o Receive commands for the scanner head over TCP-protocol

o Transfer commands to the scanner head

o Set IP-Address, when requested by PC

P

PC

C-

-H

Ho

os

st

t-

-S

So

of

ft

tw

wa

ar

re

e

f

fu

un

nc

ct

ti

io

on

ns

s

o Receive TCP frame and scan data from the electronic system

o Decode 4 / 5 Byte per Pixel in image data (see „Data-format“.)

o Evaluate scan / image data

o Send commands to the scanner head (Blue-Box).

C

Co

om

mm

mu

un

ni

ic

ca

at

ti

io

on

n

C

Co

om

mp

po

on

ne

en

nt

ts

s

TCP Clients and Server are Software-Components in the software development shell. In the application software,

they are noticeable only as “ports” which are used for data transfer from and to the application. Each Scanner has

its own TCP/IP-Address, according to the SubNet mask. Definitions of TCP/IP-Address and SubNet mask must

be made correctly during the set up procedure of the Ethernet-Scanner. These parameters are mandatory for

proper function of the hard- and software of the TCP/Ethernet protocol. The M2DF-LAN-Scanner stores data

before sending.

The Scanner stores data before sending. The scanner uses the TCP/IP protocol *. Adresses for TCP/IP, subnet

mask, gateway are stored in the Micro-Controller in the scanner electronic system. For set up either the MEL

configuration software or a Web-Browser could be used.

* UDP version is available on request.

S

Se

et

t

u

up

p

o

of

f

t

th

he

e

S

Sc

ca

an

nn

ne

er

rs

s

w

wo

or

rk

ki

in

ng

g

I

IP

P-

-A

Ad

dd

dr

re

es

ss

s

The electronic system in the blue box has a default IP address, which is activated when the Reset iP-pin (a.k.a.

RiP) is set to ground and power off/on-cycle, and a working IP-address which becomes active, when the RiP-pin

is released and power off/on has been cycled. When the scanner is operated at the default address, the MEL

EthernetScanner Software, Tab 11 allows to set a new working IP address, see page … for details.

The default address can not be changed by the user. As a factory preset, the working IP-address is set to

192.168.123.245 and the Subnet mask is set to 255.255.255.0. This preset can be changed upon request before

the delivery is made, with the commercial order. MEL will then make a note in the delivery papers or label the

electronic units accordingly.

S

Se

et

t

t

th

he

e

S

Sc

ca

an

nn

ne

er

r

t

to

o

t

th

he

e

d

de

ef

fa

au

ul

lt

t

I

IP

P

a

ad

dd

dr

re

es

ss

s

To set the default address set the Rip-Pin (Pin 5) to Ground, turn off power and on again. The setup can be made

using MEL-demo software, Rev. 2.4.0 and higher, Tab11. The “working-IP” address set up is stored in the

electronic box permanently after releasing the RIP-Pin from ground and cycling power. The Scanner then reboots

with the new “working IP-Address”.

We strictly recommend: do not use the default IP-address for normal operation!

R

Re

es

so

ol

lv

vi

in

ng

g

I

IP

P-

-A

Ad

dd

dr

re

es

ss

s-

-C

Co

on

nf

fl

li

ic

ct

ts

s

In the configuration-software port addresses of the scanners can be assigned freely with one scanners at a time.

Two scanners or other network devices in the same network never should be set up for the same IP-address.

Applications other than read and write data from the scanners should never use the ports assigned to the

scanners. A unique IP-address must be assigned to each scanner. In the network, two scanners or PCs never

must have the same network address. The device switched on first may work, the other one will create a conflict

and will not work, the network may be disturbed.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 12 of 39 www.MElsensor.com

D

DH

HC

CP

P

DHCP (dynamic host controlled IP numbering) is not supported. When DHCP is working in your network, restrict

DHCP addresses, so that no device can take over an IP address reserved for the scanners. The scanner

electronic does not react on DHCP request nor does it send DHCP request.

P

Pi

in

ng

g

The ping command can be sent from any PC in the network to verify, if the network operates, and if the target is

available for the network (“connected”). The ping command is sent using the “Run” Windows command line

interface from Windows start menu (with Linux use a “console”).

The M2DF-LAN-Scanners reacts on a ping command as every standard Ethernet network device.

Example of network collisions caused by duplicate addesses :

Address Scanner 1: 192.168.123.222;

Address Scanner 2: 192.168.123.223;

Address Scanner 3: 192.168.123.224;

Address Scanner 4: 192.168.123.225;

Address Scanner 5: 192.168.123.226;

Address Scanner 6: 192.168.123.227;

Address Scanner 7: 192.168.123.224; // wrong IP-Address = conflict with scanner # 3!

Address Scanner 8: 192.168.123.229;

Address Network card: 192.168.123.199

The Subnet mask for all Scanners and the network card = 255.255.255.0

Scanners, Gateway and PC need to be in the same network segment. 1

I

IP

P

p

pa

ar

ra

am

me

et

te

er

rs

s

D

De

ef

fa

au

ul

lt

t

V

Va

al

lu

ue

es

s

o MAC-Address 8 Byte 00-08-DC-00-00-00

o Serial number23 Byte = the last 3 Bytes of the MAC-Address

o Scanner-IP 4 Byte 169.254.150.160:3000 = default Address

o Subnet-Mask 4 Byte 255.255.255.0

o Gateway IP 4 Byte 169.254.150.1

o TCP Port 2 Byte, integer last segment in TCP/IP-address (for example 3000)

IP addresses of the gateways usually are at the start of the address range. Therefore numbers below .10 in the

last segment shall be kept free for routers and gateways.

1IP addresses in a network segment differ only in the last three digits!

2Serial-Numbers are set up at the factory; they can not be changed by the user!

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 13 of 39 www.MElsensor.com

M

ME

EL

L

D

De

em

mo

o

S

So

of

ft

tw

wa

ar

re

e

f

fo

or

r

E

Et

th

he

er

rn

ne

et

t-

-S

Sc

ca

an

nn

ne

er

rs

s

After starting the scanner, (switching on power supply), the scanners configuration is loaded from the permanent

internal memory. The configuration screen shows:

o TCP/IP address, port, serial number and MAC address

o Intensity, Shutter parameter, Video gain

o Scanner status, Scanner head temperature

M

Ma

ai

in

n

w

wi

in

nd

do

ow

w

The main window has profile displays on the left side, and 11 functions Tabs on the right side. The profile window

on the left side can be switched from display of one scanner to display of up to four scanners. The red profile is

the counter X, the white profile shows the coordinate Z as a function of x and the yellow curve is the intensity

display.

Tab 4

The most important functions are on Tab 1 and Tab 4 with

the display of networking parameters and scanner head

temperature, Tab 6 with RS 232 and Tab 11.

Tab1 shows the TCP/IP addresses of connected or

disconnected Scanners, port number, window number and

the frequency of the profile update rate. The window number

for display in the single scanner display mode should be set

to 9, profile numbers of the 4-scanners display start at 0.

T

Te

em

mp

pe

er

ra

at

tu

ur

re

e

r

re

ea

ad

do

ou

ut

t

Temperature of scanner head is shown in deg° Celsius in

the configuration tool in Tab4. The temperature value is sent

to register 2. (see “data-format” description, register 0x11 +

Status-Register 2, Byte 12).

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 14 of 39 www.MElsensor.com

Tab 4 displays System parameters:

o Hours counter, On counter

o Temperature of Scanner-head

o Firmware-Version

o

o

MAC-Address, working and default IP-Address.

Tab 6 shows the RS-232, Tab 7... 10 are reserved for diagnose.

Tab 11 provides the controls for setting your individual working IP-

address. When using Tab 11 to set the working IP address, the scanner

must be set to the default address before. An alternative method is

provided with the use of the Web-Browser. Tab 11

U

Us

si

in

ng

g

a

a

t

te

em

mp

po

or

ra

ar

ry

y

I

IP

P-

-A

Ad

dd

dr

re

es

ss

s

To modify a IP address simply double click in the IP field on Tab1 on an inactive IP address and overwrite the

temporary IP address. Press Enter when done and click the checkbox on the left side of Tab1 to connect to the

temp IP address. This temp IP address will be not saved when you close the connection or restart the application.

P

Pi

ix

xe

el

l

R

Re

ea

ad

do

ou

ut

t

L

Li

im

mi

it

t

(

(D

De

em

ma

ar

rc

ca

at

ti

io

on

n

F

Fe

ea

at

tu

ur

re

e)

)

This function sets a limitation to the readout range of the camera. It can be set with the two sliders named

“Pixelauslesen Beginn” and “Pixelauslesen Ende” on Tab 2/3 in the lower right side of the screen.

Setting the limits for the readout range is done by writing to the registers 4 and 5 (see page 14). This feature may

help to cut off reflections or other unwanted effects. Setting these limits, the application software may have less

problems when treating data from said profiles.

Pixel readout limit

(Demarcation)

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 15 of 39 www.MElsensor.com

D

Da

at

ta

a

f

fo

or

rm

ma

at

t

a

an

nd

d

i

in

nt

te

er

rf

fa

ac

ce

e

d

de

es

sc

cr

ri

ip

pt

ti

io

on

n

F

Fr

ra

am

me

e

f

fo

or

rm

ma

at

t

f

fo

or

r

T

TC

CP

P-

-S

Sc

ca

an

nn

ne

er

r

p

pr

ro

of

fi

il

le

e

t

tr

ra

an

ns

sm

mi

is

ss

si

io

on

n

Total block size limit =2048 Byte. Packet size can be 1460 and 588, or 2048 Bytes blocks, depending on network and system

load. TCP/IP receive buffer can be set to a defined size. Using standard settings, the a.m. block size is transferred.

S

St

tr

ru

uc

ct

tu

ur

re

e

o

of

f

M

M2

2D

DF

F-

-L

LA

AN

N

H

He

ea

ad

de

er

r

a

an

nd

d

p

pa

ay

yl

lo

oa

ad

d

D

Da

at

ta

a

Address Parameter Type Byte Meaning Default

00...05 mac unsigned char [6] Default MAC-Address 00:08:DC:00:00:00

06...09 reserve unsigned char [4] Reserved

10...13 lga unsigned char [4] Default Gateway 169.254.150.1

14...17 lsm unsigned char [4] Default Subnet Mask 255.255.0.0

18...21 lip unsigned char [4] Default IP-Address 169.254.150.160

22...23 tcp unsigned char [2] Default TCP-Port 3000

24...25 reserve unsigned char [2] Reserved

26...31 mac unsigned char [6] Working MAC-Address 00:08:DC:xx:xx:xx *

32...35 reserve unsigned char [4] Reserved Customer specific

36...39 lga unsigned char [4] Working Gateway Customer specific

40...43 lsm unsigned char [4] Working Subnet Mask Customer specific

44...47 lip unsigned char [4] Working IP-Address Customer specific

48...49 tcp unsigned char [2] Working TCP-Port Customer specific

50...51 reserve unsigned char [2] Reserved

52...59 null_8 unsigned char [8] Synchronization raster 8 Null bytes

60...60 version unsigned char [1] Protocol version number default = 1 range = 1…3 or 10

61...61 status unsigned char [1] Scanner status

62...62 pic_nr unsigned char [1] Image number

63...63 status2 unsigned char [1] Scanner status

64...64 reserve unsigned char [1] Reserved

65...65 reserve unsigned char [1] Reserved

Header

66... scan unsigned char [**] Scan Data and

Encoder Data

Length depends on protocol

version; 4 Bytes Encoder data

…2044 Fill

…2047 FiFO FiFO fill level **

Sync, Status, ScanData, Encoder, FiFO

* Serial number ** depends from protocol version (from scanner head to electronic system)

S

Sy

yn

nc

c

a

an

nd

d

s

st

ta

at

tu

us

s

i

in

nf

fo

or

rm

ma

at

ti

io

on

n,

,

p

po

os

si

it

ti

io

on

n

e

en

nc

co

od

de

er

r

(

(p

pr

ro

ot

to

oc

co

ol

l

r

re

ev

vi

is

si

io

on

n

3

3.

.x

x)

)

Sync + Status Byte-Nr. Value Bit-Nr. Remarks

52 … 59 0 8 Bytes 0x 00h for Synchronization

60 1 0 … 5 Version number

61 Status register 1 0

1… 6

7

0 = non linear 1= linear

content see register 0x11 (17)

always 0

62 Image number continuous, 0 ... 253

63 Status register 2 Content of status register 2 is selected with register 0x11

Values made of more than 1 Byte have Bit 7 always 0.

64; 65 reserved

66 … x Image data Scan Profile data

X+1…x+9 0 8 times 0x00 for synchronisation

Version number 7 …0 Version of data format = 3

Position encoder R1 0 … 6 Position encoder Bit 0 … 6

Position encoder R2 0 … 6 Position encoder Bit 7 … 13

Position encoder R3 0 … 6 Position encoder Bit 14 … 20

Position encoder R4 0 … 5

6

Position encoder Bit 21 … 26

Position encoder direction

Fill bytes

2045 7 … 0

2046 15… 8

Sync, Status, ScanData, Encoder, FiFO

2047

FiFO fill level data

23…16 Max value = 524287

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 16 of 39 www.MElsensor.com

S

St

ta

at

tu

us

s

i

in

nf

fo

or

rm

ma

at

ti

io

on

n

r

re

ea

ad

do

ou

ut

t

u

us

si

in

ng

g

c

co

om

mm

ma

an

nd

d

0

0x

x2

21

1:

:

1. Firmware version up to 1.10.0

when the scanner receives the command 0x21, a special status info-telegram block is sent out. To verify, if you

have got this special info-telegram block, check if a packet is received with version 0x10. The Header defines,

where the version information is located. The version is normally 1, 2 or 3. Version 0x10 marks a status packet.

The Status Packet contains 64 Byte Status, but no scan profile data.

Then the Ethernet-Version sends the Firmware Revision as string, end with 0x00, 0xFF.

2. Firmware Version 1.11.0 and higher

In addition to version 1.10 , at the end of the info-telegram block 31 Byte status register were sent, then 3 Bytes

FiFO-status.

Protocol 0x10 response to command 0x21 does not include scan profile data. Packet size is 2048 Byte.

Byte-Nr. Register Function Length | Type Ending Firmware

00 …51 Header -

52 … 59 Synchronisation 8 x 0x00 -

60 Protocol version -

61 Scanner Status 1 -

62 Image number -

63 Scanner Status 2 -

Header

64 … 65 Reserved -

66 … 97 0 … 31 Status Register 32 Byte -

98 … 129 32 …63 Eprom-Data 32 Byte -

130 … x Firmware-Version * String 0x00

1.10

X +1 …x+32 0 … 30 Functions Register 31 Byte 0xFF

X+33 …x+35 123...125 FiFO status 3 Byte 0xFF

appended Fill bytes 0xFF -

1.11+

* the length of the Firmware string is defined by the ending 0x00, 0xFF. The total length varies with the Firmware

version! The FiFO status (filling level) is given also with every scan profile packet of the length 2048 bytes.

Status registers are the registers marked in yellow on page 15. Status registers can be queried using register

0x11. Function registers are marked in light blue on page 15. These function registers can be read using register

0x21 command.

E

En

nc

co

od

de

er

r

d

da

at

ta

a

Encoder data is available in the profile data transmission protocol version 3. This is different from the special

status info-telegram which is received after sending command 0x21. Details for the info-telegram were given in

the following chapter, the description for the scan data block follows on the next page 18.

The profile information block ends with 8 Bytes 0x00. Then protocol revision number is given as 1 Byte, followed

by the 4 Bytes of encoder data. The end of the transmission block is all 0xFF’s, but the last 3 Bytes contain the

FiFO fill level data. (FiFO = first in first out buffer memory).

Note: the protocol version number is also given in the header, byte 60.

D

Da

at

ta

a

f

fo

or

rm

ma

at

t

f

fo

or

r

r

re

eg

gi

is

st

te

er

r

a

ad

dd

dr

re

es

ss

s,

,

c

co

om

mm

ma

an

nd

d

a

an

nd

d

d

da

at

ta

a

MSB = „0“ = command or register number MSB = „1“ = register content

To change a value first send the register number and then the value. The register number remains set until a new

register number or command is transferred. Register can not be read out except status registers. These can be

read out using the special function register 0x18.

For dual registers, the value is active when writing the higher register.

OrderofBits

Register Data Register Data

Lo-Byte Lo-Byte Hi-byte Hi-byte

76543210 76543210 76543210 76543210

0xxxxxxx 1xxxxxxx 0xxxxxxx 1xxxxxxx

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 17 of 39 www.MElsensor.com

S

Sc

ca

an

nn

ne

er

r

c

co

on

nt

tr

ro

ol

ls

s

Registers

Hex Dec

Bit Function Registers

Marked light blue

Remark

0x0 0 6 … 0 Shutter time low

0x1 1 2 … 0 Shutter time high

Shutter time

0= max. 1022 = min. 1023= Laser off

Manual control

0x2 2 6 … 0 Max shutter time low

0x3 3 2 … 0 Max shutter time high

defines limit for the max. shutter.

0 = max. 1022 = min. (single scanner)

Alternate sync meas. not below 130

Automatic control

0x4 4 6 … 0 Start readout pixels

0x5 5 6 … 0 End readout pixels

Value range = 0 … 127. 1 Bit corresponds to 8 pixels

Condition: begin < end, max. is limited automatic

0x6 6 6 … 0 Video gain low

0x7 7 2 … 0 Video gain high

< 256 = +27dB 1023 = 0dB default = 950 = +2,57 dB

value is set after first sending the high byte value

0x8 8 6 … 0 Intensity threshold 1 … 127 intensity threshold value for internal automatic laser

control; factory default = 15

0x9 9 6 … 0 Laser value 1 … 127 value for the laser control (default = 95)

0xA 10 6 … 0 Peak width limit 0 = 0ff; other = peak width limit, max. = 127 pixels

0xB 11 0 FPGA OK LED 0 = on 1 = off

0xE 14 * Reset position encoder Reset encoder counter

0xF 15 0 Synchronization 0 = simultaneous measmnt. 1 = alternating measmnt.

0x10 16 0 Adjustment scan, image 0 = scan data 1= complete image (see page 19.)

0x11

17

5 … 0

defines content of status

register

marked yellow

0 = sensor temperature

1 = register content

2 = version electronic board

3 = version camera

4 … 8 = hours counter seconds

9 … 11 = On/Off counter

12 = digital inputs 1 +2 + bit for sensors with mirror

13 = Bit 2 … 9 of Laser control

14 = Revision number example: 3.5xxxx

xxxx is the revision number

15 … 31 = NC

32 … 63 = 32 Byte Eprom Data (see below)

0x12 18 2 ... 0 Select scanner protocol version 0 = Version 1 1 = Version 2 2 = Version 3 3 = Version 4

0x13 19 Reset camera chip reset hours counter and camera

0x14

20

0 … 2

3

5 .. 4

Do not use!

Measurement control

Field out definition

Bit 0 … 2 is only for Rev.1 hardware

0 = continuous 1 = single shot triggered

00=both fields | 01=only 1st. field | 10=only 2nd field

0x15 21 0 Laser control 0 = automatic 1 = external (register 0& 1)

0x16 22 0 Linearization 0 = off 1= on default start value = 1

0x17 23 0 … 1 Sampling rate and resolution for

M20D-XF 300 .. 1000 Hz model

0 = 300 Hz; 1 = 500 Hz; 2 = 700 Hz; 3 = 1.000 Hz

0x18 24 Special Function Read out status of control registers and FiFO for ISA hardware

0x1B 27 7…0 Peak detection threshold Default = 10

0x1C 28 * Reset FiFO Erases all values in FiFO

0x1D 29 * Single picture in trigger-mode Register 0x14 (20) must be set before using trigger

0x1E 30 * Reset Sensor set all register values to default

S

Sp

pe

ec

ci

ia

al

l

c

co

om

mm

ma

an

nd

ds

s

f

fo

or

r

t

th

he

e

E

Et

th

he

er

rn

ne

et

t

v

ve

er

rs

si

io

on

n

0x1F 31 * Reset Blue Box Network Communication is restarted

0x20 32 * Watchdog test Watchdog issues reset on Ethernet-Scanner

0x21 33 * Poll Scanner information 32 register + 32 Eprom values set at start-up of the Ethernet

module were sent. Protocol version is set to 0x10 hex.

0x22 34 * new network settings Activate new IP address

0x23 35 0 Ethernet Trigger mode 0 = deactivate 1 = activate

when active, read image with register 0x1D (29)

The content of status register 2 is defined by register 0x11 (17). For all values made by more than one Byte, bit 7 is always 0.

This means only 7 Bit are transferred per Byte.

* Each access to the register triggers the function: just send the register address with no parameter.

Accessing the status register 0x11 selects the contents of the sensors status register. This allows to read out the parameters

of sensor temperature, register content, version of electronic board and camera, hours and on/off counters, digital inputs, laser

control, revision number, 32 byte of Eprom data, see the following pages.

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 18 of 39 www.MElsensor.com

M

M2

2D

DF

F

/

/

L

LA

AN

N-

-D

Da

at

ta

a

F

Fo

or

rm

ma

at

t

M

Me

ea

an

ni

in

ng

g

o

of

f

t

th

he

e

s

st

ta

at

tu

us

s

b

by

yt

te

e

2

2

a

as

s

a

a

f

fu

un

nc

ct

ti

io

on

n

o

of

f

R

Re

eg

gi

is

st

te

er

r

0

0x

x1

11

1

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[0

0]

]

S

Sc

ca

an

nn

ne

er

r

h

he

ea

ad

d

t

te

em

mp

pe

er

ra

at

tu

ur

re

e

Reg. value Temperature Hex Value Binary Value Bit 7 is the sign

+126 °C FE 1111 1110

+ 85 °C D5 1101 0101

+ 25 °C 99 1001 1001

+ 0 °C 80 1000 0000

- 1 °C 01 0000 0001

- 25° C 19 0001 1001

0

- 55 °C 37 0011 0111

In steps of 1 degree from – 55°C … + 126°C

Bit 7 is the sign.

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[1

1]

]:

:

r

re

eg

gi

is

st

te

er

r

c

co

on

nt

te

en

nt

ts

s

Reg. value Bit Nr. Meaning

0 0 = not linear, 1 = linear

1 0 = register contents as after reset, 1 = after write to register

2 0 = Scan data, 1 = complete image

3 Laser: 0 = 0n 1 = off

4 Measurement control: 0 = continuous 1 = single shot triggered

5 Laser control: 0 = automatic 1 = external (Register 0 & 1)

6 reserved

1

7 always 0

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[2

2,

,3

3]

]

:

:

v

ve

er

rs

si

io

on

n

n

nu

um

mb

be

er

r

o

of

f

c

ca

am

me

er

ra

a

a

an

nd

d

e

el

le

ec

ct

tr

ro

on

ni

ic

c

s

sy

ys

st

te

em

m

Reg. value Bit Nr. Firmware Version

2 7 … 0 Version of electronic unit

3 7 … 0 Version of camera

Note: Used data area: 0…4095 (see Eprom data register, pos. 48-51)

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[4

4,

,5

5,

,6

6,

,7

7,

,8

8]

]:

:

h

ho

ou

ur

rs

s

c

co

ou

un

nt

te

er

r

(

(b

bi

it

t

7

7

a

al

lw

wa

ay

ys

s

0

0)

)

c

co

ou

un

nt

t

e

ev

ve

er

ry

y

2

25

50

0

m

ms

se

ec

c

Reg. value Bit Nr. Hours counter Bit 7 always 0; 250 msec per count

4 6 … 0 Hours counter bit 6 … 0

5 6 … 0 Hours counter bit 13 … 7

6 6 … 0 Hours counter bit 20 … 14

7 6 … 0 Hours counter bit 21 … 27

8 6 … 0 Hours counter bit 28 … 34

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[9

9,

,1

10

0,

,1

11

1]

]:

:

o

on

n

c

co

ou

un

nt

te

er

r

(

(b

bi

it

t

7

7

a

al

lw

wa

ay

ys

s

0

0)

)

m

ma

ax

x.

.

c

co

ou

un

nt

t

=

=

1

13

31

10

07

72

2

Reg. value Bit Nr. On/OFF counter Bit 7 always 0; max. counter value = 131072

9 6 … 0 On/Off counter bit 6 … 0

10 6 … 0 On/Off counter bit 13 … 7

11 6 … 0 On/Off counter bit 16 … 14

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[1

12

2]

]:

:

d

di

ig

gi

it

ta

al

l

i

in

np

pu

ut

ts

s

Reg. Nr. Bit Nr. Digital inputs

12 0 Input 1

1 Input 2

2 Bit for sensor with mirror

7 … 3 always 0

M2D-Laser-Scanner with Ethernet-Interface Manual

HB-M2D-Ethernet-E Page 19 of 39 www.MElsensor.com

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[1

13

3]

]:

:

L

La

as

se

er

r

C

Co

on

nt

tr

ro

ol

l

Reg. Nr. Bit Nr. Laser Control

13 9 … 2 Laser control in automatic mode: Bits 0 …1 of the Laser control were not

available for read out. Bits 2 … 9 were available for read out and can be set as a

“fixed” value in the “manual” or external control mode.

Procedure:

1. set scanner to automatic control mode

2. direct the scanner onto a surface of interest

3. read out laser control Bit 2…9

4. set laser to “external (manual)” control mode

5. write back Bit 0 .. 1 as “0” and Bit 2...9 of the previously read out value

R

Re

eg

gi

is

st

te

er

r

v

va

al

lu

ue

e

[

[1

14

4]

]:

:

R

Re

ev

vi

is

si

io

on

n

n

nu

um

mb

be

er

r

Reg. Nr. Bit Nr. Revision number

14

7 … 0

The revision number of the firmware is made by the Status-Registers 2 and 14.