Menzi Muck IHI 30V4 User manual

30V4 • 35V4 ENG

CONTENTS

FOREWARD ............................................. 0-1

INTRODUCTION .................................... 0-1

MACHINE NUMBER............................... 0-2

MACHINE DIRECTION .......................... 0-3

SAFETY .................................................... 1-1

SAFETY INFORMATION........................ 1-1

SAFETY PRECAUTIONS ....................... 1-2

PRECAUTIONS BEFORE

OPERATION ........................................ 1-2

Precautions during Operation .............. 1-4

PRECAUTIONS FOR TRAVELING ..... 1-8

Precautions for Transporting................ 1-9

Precautions for Maintenance ............. 1-10

SAFETY SIGNS AND LABELS ............ 1-14

OPERATION ............................................. 2-1

NAMES OF COMPONENTS .................. 2-1

CONTROLS AND INSTRUMENTS ........ 2-2

Right Control Box ................................. 2-3

Left Control Box ................................. 2-11

Travel Levers ..................................... 2-12

Boom Swing Pedal............................. 2-12

Operator's Seat .................................. 2-13

Seat belt............................................. 2-13

AUX Pedal (Option) ........................... 2-13

Operator’s Cabin ................................ 2-14

Air conditioner (Option) ...................... 2-17

Heater (Option) .................................. 2-18

STARTING ENGINE ............................. 2-19

Check before Starting Engine ............ 2-19

Normal Starting .................................. 2-20

Starting in Cold Seasons ................... 2-20

Starting Engine with Booster Cables . 2-21

Check after Starting Engine ............... 2-22

Warming Up Engine ........................... 2-22

STOPPING ENGINE ............................ 2-23

EMERGENCY ACTIONS IF ENGINE

STOPS.................................................. 2-24

RUNNING IN NEW MACHINE.............. 2-25

LEVER OPERATIONS ......................... 2-26

Operation Mode ................................. 2-26

Operation Mode Plate ........................ 2-27

AF Multi-selection Method (for Machine

with AF Multi-selector Valve).............. 2-28

ABG Multi-selection Method (for Machine

with ABG Selector Valve)................... 2-29

ABCD Multi-selection Method

(for Machine with ABCD Selector

Valve)................................................. 2-30

CRAWLER EXTEND/RETRACT

OPERATION (35V4) ............................. 2-31

BLADE OPERATION ............................ 2-32

BOOM SWING OPERATION ............... 2-32

SWING OPERATION ........................... 2-33

TRAVELING ......................................... 2-34

Starting, Traveling and Stopping........ 2-34

Changing Direction ............................ 2-35

High Speed Traveling ........................ 2-36

Precautions While Traveling

on Slope............................................. 2-36

WORK INSTRUCTIONS....................... 2-37

Digging............................................... 2-37

Ditching .............................................. 2-37

Loading .............................................. 2-37

Gutter Digging .................................... 2-37

PRECAUTIONS FOR WORKS............. 2-38

PRECAUTION ON USE OF RUBBER

TRACK.................................................. 2-41

AUX WHEN USING SPECIAL

ATTACHMENT ..................................... 2-44

No. 1 AUX .......................................... 2-45

When Using Breaker .......................... 2-46

Courtesy of Machine.Market

30V4 • 35V4 ENG

When Using Iron Fork ........................ 2-47

No. 2 AUX .......................................... 2-48

No. 3 AUX .......................................... 2-49

TOWING ............................................... 2-50

TRANSPORT........................................ 2-51

Loading and Unloading the Machine . 2-51

Fixation at Transport .......................... 2-52

LIFTING THE MACHINE ...................... 2-53

MAINTENANCE ........................................ 3-1

PERIODIC REPLACEMENT OF THE

IMPORTANT PARTS.............................. 3-1

MAINTENANCE INTERVALS................. 3-2

RECOMMENDED LUBRICATION

TABLE .................................................... 3-6

LUBRICATE THE GREASE ................... 3-7

Attachment ........................................... 3-7

Boom Swing ......................................... 3-8

Blade.................................................... 3-8

Swing Bearing ...................................... 3-9

Ring Gear............................................. 3-9

MAINTENANCE OF BUCKET .............. 3-10

Replace the Tooth.............................. 3-10

Change the Bucket ............................ 3-11

Adjust the Bucket Clearance.............. 3-12

CRAWLER TRACK............................... 3-13

Rubber Track Maintenance................ 3-13

Inspection of Crawler Track ............... 3-14

Adjustment of Crawler Track.............. 3-15

INSPECTION OF THE CRAWLER

EXTENDING AND CONTRACTING

PORTION (35V4).................................. 3-16

TRAVEL REDUCTION GEAR .............. 3-17

Check Oil Level and Refilling ............. 3-17

Change Oil ......................................... 3-17

HYDRAULIC SYSTEM ......................... 3-18

Hydraulic Oil Level and Refilling ........ 3-18

Replace Return Filter Cartridge ......... 3-19

Change the Hydraulic Oil and Clean

the Strainer ........................................ 3-20

Air Breather Element Replacement.... 3-21

ENGINE OIL ......................................... 3-22

Check the Engine Oil Level

and Refill ............................................ 3-22

Replace the Engine Oil and Engine

Oil Filter.............................................. 3-23

FUEL SYSTEM ..................................... 3-24

Check Fuel Quantity and Refilling...... 3-24

Check and Clean Water Separator

and Replace Element......................... 3-25

Replace Fuel Filter ............................. 3-26

How To Discharge Air ........................ 3-26

COOLING SYSTEM ............................. 3-27

Check the Coolant Level and Refill .... 3-27

Change the Coolant ........................... 3-27

Check the Fan Belt ............................3-29

Inspect and Clean Radiator Fins

and Oil Cooler Fins ............................ 3-30

INTAKE AIR SYSTEM .......................... 3-31

Inspect Dust Indicator ........................ 3-31

Inspect and Clean Air Cleaner

Element .............................................. 3-32

Replace Air Cleaner Element............. 3-32

ENGINE ................................................ 3-33

Adjust Intake Valve and Exhaust

Valve Clearance................................. 3-33

Check of Fuel Injection System.......... 3-33

Inspect Crankcase Breather

System ............................................... 3-33

Clean Coolant System ....................... 3-33

Lap Intake and Exhaust Valves.......... 3-33

ELECTRIC SYSTEM ............................ 3-34

Replace the Fuses ............................. 3-34

Replace the Fusible Link.................... 3-34

Check the Battery .............................. 3-35

TIGHTEN BOLTS ................................. 3-36

Special Tightening Positions .............. 3-36

Standard Tightening Torques............. 3-38

Courtesy of Machine.Market

30V4 • 35V4 ENG

HANDLING IN COLD WEATHER......... 3-39

LONG TERM STORAGE ...................... 3-40

HYDRAULIC SYSTEM DIAGRAM ....... 3-41

ELECTRIC SYSTEM DIAGRAM .......... 3-42

SPECIFICATIONS .................................... 4-1

SPEED AND GRADEABILITY ................ 4-1

ENGINE .................................................. 4-1

MASS...................................................... 4-1

CAPACITY.............................................. 4-1

BUCKET ................................................. 4-2

DIMENSIONS ......................................... 4-3

WORKING RANGE ................................ 4-5

WORKING RANGE FOR OFFSET

DIGGING ................................................ 4-7

RATED OBJECT HANDLING

CAPACITIES TABLE .............................. 4-8

Courtesy of Machine.Market

FOREWORD

30V4 • 35V4 ENG 1

0FOREWARD

INTRODUCTION

This manual contains the safety, operation, maintenance and adjustment procedures of this

machine.

Read it and have good understanding before using the machine.

Contact our dealer immediately if you lose or damage this manual.

See the “Operation Manual of the Engine” for the engine.

If you hand over this machine to any third party, this manual should also be handed over to it.

The specifications of the machine may be improved and differ from descriptions of this manual.

Please contact our dealer if you have some problems or questions.

Courtesy of Machine.Market

30V4 • 35V4 ENG

SAFETY

Most accidents occur during works when preventive measures

against danger are neglected or basic safety instructions are

not observed.

Such accidents may be avoided by paying careful attention in

advance.

This manual describes the basic safety instructions to be

observed in daily operation, inspection and maintenance of

the machine.

Observe these instructions carefully for safety.

Check the safety with great care for any other matters not

described in this manual.

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-1

11 SAFETY

SAFETY INFORMATION

Read and understand the operation manual, safety signs and labels before using or maintaining

this machine.

The safety alert symbol is used to alert you to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible injury or death.

The signal words used with the safety alert symbol indicate a specific level of severity of the

potential hazard. All are used as attention-getting devices throughout this manual as well as on

labels fixed to the machine to assist in potential hazard recognition and prevention.

This safety alert symbol and signal word indicates an imminently

hazardous situation which, if not avoided, will result in death or serious

injury.

This safety alert symbol and signal word indicates a potentially

hazardous situation which, if not avoided, could result in death or serious

injury.

This safety alert symbol and signal word indicates a potentially

hazardous situation which, if not avoided, could result in minor or

moderate injury or serious damages of the machine.

This signal word indicates a potentially hazardous situation which, if not

avoided, could result in damages of the machine or reduction of the

service life.

We have made every effort for you to prevent accidents during operation; however, we cannot be

held responsible for predicting every kind of danger in all operating conditions.

It is the owner or user of the machine who is responsible for always paying attention to operate

the machine, as well as reading and understanding this manual enough to obtain the essential

knowledge and skills fundamental to correct machine operation.

NOTICE

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-2

SAFETY PRECAUTIONS

PRECAUTIONS BEFORE OPERATION

Read and understand the safety signs and labels

xThere are several specific safety signs on your

machine.

Please read and understand the safety signs and

labels.

xYou must replace a label if it is damaged, missing or

cannot be read.

Make a work plan

Start the work only after discussing with the person in

charge at the site.

Wear proper working clothes

For the sake of safety during working, wear clothes that

match your body.

Always wear required protective items such as protective

cap, protective goggles, reflective clothing, safety shoes,

and ear protection as required.

Watch for underground utilities

Mark the location of underground utilities such as gas

lines, sewers, and power lines before any digging

operations. If necessary, the utilities should be

temporarily discontinued.

WC-C100620

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-3

Perform "walk-around" inspection

Be sure to walk around the machine and inspect it before

starting work. If some defects are found, repair them

without fail.

Prevent a fire

xDo not leave oiled waste cloth, dead leaves, paper

trash or other flammable objects around the engine.

Such matters may cause a fire. Always inspect and

remove such matters.

xStop the engine and do not bring fire close to it while

refilling fuel.

xCheck if fuel, oil or hydraulic oil does not leak. If some

defects are found, repair them and wipe off leaked oil.

xCheck the installation position and usage of the fire

extinguisher.

Install the ROPS canopy

We recommend that the ROPS canopy should be

installed to avoid accidents, which may result in injury, if a

machine with a canopy should fall down.

Carefully mount and dismount the machine

Always use steps and handholds to mount and dismount

the machine.

Hold the handholds with both hands and face the machine

keeping a contact with at least three points of the steps

and handrails.

Never hold control levers at mounting and dismounting.

Start the engine at the operator's seat

If the engine is started from a position other than sitting in

the operator's seat, there is the danger that the machine

starts moving suddenly.

Start the engine only after carrying out checks while

sitting in the operator's seat.

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-4

PRECAUTIONS DURING OPERATION

Stay seated while operating

Never attempt to operate the excavator from any position

except the operator's seat. If you operate the machine

from any other position, such as standing by the window

or door, you may operate the machine inaccurately, which

can cause serious injury. Remember that you should not

get on or off the moving machine to be seated or to leave

the machine.

Fasten the seat belt

If the machine falls down, you may be thrown out of the

operator's seat or pressed under the machine. Such an

accident may result in serious injury or death.

Sit on the operator's seat and fasten the seat belt all the

time while operating the machine.

Clear all personnel from the machine and area

Be sure to barricade the job site to prevent entry of the

unauthorized. Confirm that there is no one around the

machine before starting the engine or operating the

machine.

Prevent accidents while moving

Always sound the horn to signal others nearby that you

are moving the machine. Check that no one is within the

working area of the machine before attempting to move it.

WC-C100630

Keep Out Keep Out

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-5

Never swing over personnel

Be sure that no personnel are working around the

machine before swinging.

Pay attention to invisible workers in a trench or pit in

particular. Follow the signal person's direction not to

swing over such workers.

Never leave the bucket in the raised position

Never leave the load suspended in mid air, when the

machine is out of service, or you have to leave the

machine. Always put down the bucket of load onto the

ground. Should a malfunction occur, it could fall, striking

equipment or personnel.

Do not swing above the truck cab

If you swing the bucket above the truck cab, the driver

may be injured by dropped soil and sand or the bucket

contacting the truck cab.

Do not swing the bucket above the truck cab when

loading soil and sand.

Provide adequate tailswing clearance

Confirm that there is a sufficient clearance around the

machine for swinging operation.

The operator tends to be unconscious of the area behind

the machine. Before tailswing, make sure that there are

no personnel or objects in such area.

Always observe the bucket and load

Always watch the moving bucket or load carefully.

Moving bucket or load without care may cause injury to

personnel or materials.

If you have to look away from it, stop the machine.

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-6

Never allow unauthorized personnel to ride on the

machine

Only operator is authorized to be on the machine during

operation. Never let unauthorized personnel ride on the

machine. Any person riding as a passenger can fall off

and suffer injury.

Danger for electric power line

If the machine should contact with an electric power line,

move the machine apart from the cable.

If it is impossible to move the machine, shout “Never

touch the shovel” to give a warning to the workers around

the machine.

Do not put on the step when you get off the shovel. Jump

down onto the ground.

Do not operate the engine in an enclosed area without

adequate ventilation

Diesel engine exhaust contains products of combustion

which may be harmful to your health. Always start and

operate the engine in a well ventilated area. If in an

enclosed area, vent the exhaust to the outside.

Do not dig near the machine

Do not dig the ground deep near the machine to prevent

falling due to collapse of the ground.

Do not dig at the base of a cliff

If you dig at the base of a cliff, it may collapse or stones

may drop, causing a danger. Do not dig a cliff.

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-7

Never exceed the machine performance

If you use a large bucket that exceeds the machine

performance, the machine may be broken or injury or

death may result.

Be sure to use a bucket or attachment that meets the

specifications.

Never lean out of the window

Do not lean out of the window, enter between the

attachment and cylinder or put your hand or arm between

them.

If the attachment moves, you may be caught by the

attachment, resulting in serious injury or death.

Courtesy of Machine.Market

SAFETY

30V4 • 35V4 ENG 1-8

PRECAUTIONS FOR TRAVELING

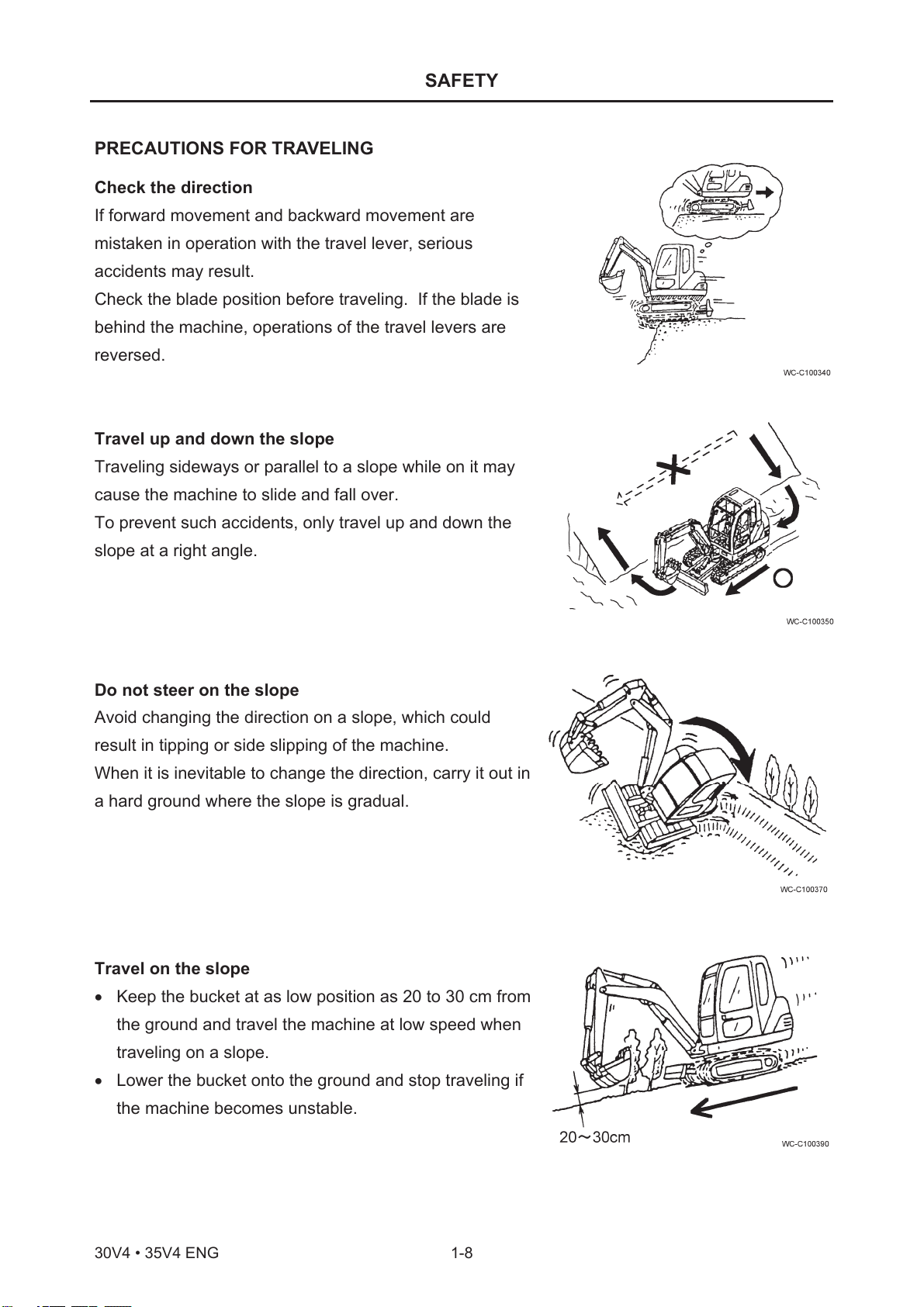

Check the direction

If forward movement and backward movement are

mistaken in operation with the travel lever, serious

accidents may result.

Check the blade position before traveling. If the blade is

behind the machine, operations of the travel levers are

reversed.

Travel up and down the slope

Traveling sideways or parallel to a slope while on it may

cause the machine to slide and fall over.

To prevent such accidents, only travel up and down the

slope at a right angle.

Do not steer on the slope

Avoid changing the direction on a slope, which could

result in tipping or side slipping of the machine.

When it is inevitable to change the direction, carry it out in

a hard ground where the slope is gradual.

Travel on the slope

xKeep the bucket at as low position as 20 to 30 cm from

the ground and travel the machine at low speed when

traveling on a slope.

xLower the bucket onto the ground and stop traveling if

the machine becomes unstable.

Courtesy of Machine.Market

This manual suits for next models

1

Table of contents

Other Menzi Muck Excavator manuals