Mercury Security © 2014 EP1501 DOC 10107-0036 REV 1.07 Page 8

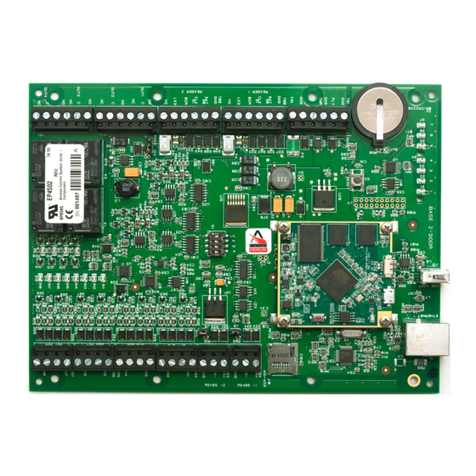

11. Status LEDs:

Power-up: All LED's OFF.

Initialization:

LED's 1, 2, 3, 4, 5, 6, and 7 are sequenced during initialization. LED's 1, 3, and 4 are turned ON for

approximately 1.5 seconds after the hardware initialization has completed, then the application code is

initialized. The amount of time the application takes to initialize depends on the size of the database,

about 3 seconds without a card database. Each 10,000 cards will add about 3 seconds to the

application initialization. When LED's 1, 2, 3 and 4 flash at the same time, data is being read from or

written to flash memory, do not cycle power when in this state.

If the sequence stops or repeats, perform the Bulk Erase Configuration Memory procedure in section 4.

If clearing the memory does not correct the initialization problem, contact technical support.

Running:

After initialization is complete, the LEDs have the following meanings: At power up, LEDs 2 through 7

are turned ON then OFF in sequence.

Off-Line / On-Line: Off-Line = 20 % ON, On-Line = 80 % ON

Host Communication Activity

Readers (combined):

Clock/Data or D1/D0 Mode = Flashes when Data is Received, Either Input.

RS-485 Mode = Flashes when Transmitting Data

F/2F Mode = Flashes when Data/Acknowledgment is Received

Input IN1 Status: OFF = Inactive, ON = Active, Flash = Trouble See Note 1

Input IN2 Status: OFF = Inactive, ON = Active, Flash = Trouble See Note 1

Ethernet Speed: OFF = 10 Mb/S, ON = 100 Mb/S

OFF = No Link, ON = Good Link, Flashing = Ethernet Activity

Note 1: If this input is defined, every three seconds the LED is pulsed to its opposite state for 0.1

seconds, otherwise, the LED is off.

12. IT Security

When installing the EP1501, it is important to ensure that it done in a secure manner.

Upon installation, the user accounts to the web configuration page should be created with secure

passwords, and that all DIP switches are in the off position for the normal operating mode. The EP1501

is shipped from the factory with a default login account, which is enabled when DIP 1 is moved from OFF

to ON. The default login user name and password will be available for five minutes once enabled.

Therefore, it is important that at least one user account is defined, and the DIP switches are set to OFF

before the EP1501 is commissioned. It is also highly recommended not to configure the EP1501 with an

IP address that is accessible from the public Internet.

To further enhance network security, options are available to disable SNMP, Zeroconf discovery, as well

as the web configuration module itself. Additionally, data encryption can also be enabled over the host

communication port.