Meritor Wabco MM-1012 User manual

Maintenance Manual MM-1012

Selective Catalytic Reduction Air Control

Unit

Issued 02-10

NOTRELEASED01-04-10

–PROPRIETARY –

Service Notes

Information contained in this publication was in effect at the time the publication

was approved for printing and is subject to change without notice or liability.

Meritor WABCO reserves the right to revise the information presented or to

discontinue the production of parts described at any time.

Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

About This Manual

This manual provides service procedures for the Meritor WABCO

selective catalytic reduction air control unit.

Before You Begin

1. Read and understand all instructions and procedures before

you begin to service components.

2. Read and observe all Warning and Caution hazard alert

messages in this publication. They provide information that can

help prevent serious personal injury, damage to components,

or both.

3. Follow your company’s maintenance and service, installation,

and diagnostics guidelines.

4. Use special tools when required to help avoid serious personal

injury and damage to components.

Hazard Alert Messages and Torque

Symbols

WARNING

A Warning alerts you to an instruction or procedure that you

must follow exactly to avoid serious personal injury and

damage to components.

CAUTION

A Caution alerts you to an instruction or procedure that you

must follow exactly to avoid damage to components.

@This symbol alerts you to tighten fasteners to a specified torque

value.

How to Obtain Additional Maintenance

and Service Information

On the Web

Visit Literature on Demand at arvinmeritor.com to access and order

product, service, aftermarket, and warranty literature for

ArvinMeritor’s truck, trailer and specialty vehicle components.

Literature on Demand DVD (LODonDVD)

The LODonDVD contains product, service and warranty information

for ArvinMeritor components. To order the DVD, visit Literature on

Demand at arvinmeritor.com and specify TP-0742.

How to Obtain Tools and Supplies

Specified in This Manual

Call ArvinMeritor’s Commercial Vehicle Aftermarket at

888-725-9355 to obtain Meritor tools and supplies.

Contents

pg. 1Section 1: Introduction

System Overview

Identification

How the ACU Works

2 Schematics

3Section 2: Removal and Installation

Replacement Requirements

4 General Requirements

Replacement Procedures

ACU Replacement

ACU Removal

ACU Installation

5Section 3: Troubleshooting

Oil and Other Contaminants

ACU Replacement

Diagnostics

6Section 4: Specifications

General Requirements

1 Introduction

1

Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

1 Introduction

System Overview

All vehicles equipped with a Detroit Diesel 2010 emissions engine

will have an air control unit (ACU) used to provide air pressure to the

urea dosing unit. The ACU is a combination valve integrating three

components: an electrical solenoid, a pressure reduction device,

and an outlet one way check valve.

The electric solenoid is a 12V continuous-duty solenoid. It is

controlled by an electronic control unit (ECU) dedicated to the

selective catalytic reduction (SCR) system. The pressure reduction

component of the ACU reduces the air brake system pressure to

80 psi (5.5 bar), providing pressure to the urea dosing unit and

injector. The outlet check valve provides protection to the air brake

system by preventing urea from entering the brake air system.

Identification

There are two ACU designs available; the most common will be a

normally closed design (part number 975 009 002 0) with one inlet

and one outlet. The second design is considered to be a normally

open design (part number 975 009 101 0) used on vehicles utilizing

a negative battery shut-off. This design will have two inlets and one

outlet. Figure 1.1.

Figure 1.1

How the ACU Works

The ACU is controlled by an ECU activated when the ECU sees an

ignition-controlled power supply. With the ignition key in the on or

run position, vehicle voltage is supplied to the ACU activating the

solenoid to the open position which allows air pressure to flow

through the ACU. The valve will remain open until the ignition key is

turned to the off position. When the key is turned off, the SCR ECU

will pulse a signal to the ACU to pulse air pressure through the SCR

lines pushing out any remaining urea fluid to keep the injector and

lines clean. This function is important because urea can crystallize

and clog the lines and the injector if the urea is subjected to too high

of a temperature.

If the ACU were to not operate correctly or stop operating altogether,

the urea in the SCR system may be incorrectly injected into the

engine exhaust causing higher emissions. When emissions exceed

the specification for any reason, the SCR ECU will turn on a warning

light on the dash panel and reduce the engine output and vehicle

speed. If the emission system is not repaired, the ECU will further

reduce the engine output allowing the vehicle to move at low

speeds, effectively a “limp home mode”, in order to have the

emission system repaired.

Figure 1.1

4007993a

NORMALLY OPEN

975 009 101 0

NORMALLY CLOSED

975 009 002 0

1 Introduction

2Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

Schematics

Figure 1.2

Figure 1.3

Figure 1.2

4007994a

UREA/AIR

MIXTURE

SENT TO

EXHAUST

PRIMARY

UREA

TANK

UREA

PUMP

UREA

DOSER

NORMALLY CLOSED CONFIGURATION

SECONDARYWET

AIR CONTROL

UNIT

Figure 1.3

4007995a

UREA/AIR

MIXTURE

SENT TO

EXHAUST

AIR CONTROL

UNIT

PRIMARY

UREA

TANK

UREA

PUMP

UREA

DOSER

NORMALLY OPEN CONFIGURATION

SECONDARYWET

2 Removal and Installation

3

Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

2 Removal and Installation

Hazard Alert Messages

Read and observe all Warning and Caution hazard alert messages in

this publication. They provide information that can help prevent

serious personal injury, damage to components, or both.

WARNING

To prevent serious eye injury, always wear safe eye protection

when you perform vehicle maintenance or service.

Park the vehicle on a level surface. Block the wheels to

prevent the vehicle from moving. Support the vehicle with

safety stands. Do not work under a vehicle supported only by

jacks. Jacks can slip and fall over. Serious personal injury can

result.

Remove all pressure from the air system before you

disconnect any component. Pressurized air can cause serious

personal injury.

Replacement Requirements

Any time a new ACU is installed, replace the oil desiccant cartridge

to ensure a clean air supply to the new part. When you drain the air

tanks before servicing the ACU, check for water or oil that may have

accumulated in the tanks. Water or oil in the air tanks could indicate

a problem with the air dryer or compressor contributing to the ACU

problem.

The air control unit can be found in the following locations

depending on the vehicle. Figure 2.1, Figure 2.2, Figure 2.3 and

Figure 2.4.

Figure 2.1

Figure 2.2

Figure 2.3

Figure 2.4

Figure 2.1

4007996a

WESTERN STAR, ALL MODELS

The ACU is

located under

the lower flange

of the left side

frame rail

behind the cab.

Figure 2.2

Figure 2.3

Figure 2.4

4007997a

24U MODELS, DUAL EXHAUST

The ACU is

located between

the flanges of the

left side frame

rail behind the

cab.

4007998a

The ACU is

located at the

top of the

frame

crossmember

to the right

of the cab

rear air

suspension.

3-PC. DAY CAB, 5-PC. SLEEPER CAB

4007999a

The ACU is located

near the right side frame

rail between the vertical

muffler and muffler

support.

3-PC. 2V2 UPRIGHT EXHAUST

2 Removal and Installation

4Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

General Requirements

앫Mount the air control unit so that there is no direct splash or

spray from a wheel.

앫Keep the air control unit at least 12 inches (305 mm) from any

heat producing sources like exhaust manifolds or pipes,

transmissions, etc.

앫Line sizing from and to the air control unit should be at least

1/4 inch (6.35 mm).

앫Make sure there are no valves or other devices in the air supply

line to the air control unit.

Replacement Procedures

ACU Replacement

If there is a problem with the ACU functioning correctly, replace the

entire valve. Do not attempt to service or repair the valve. Refer to

Limited Warranty Document TP-1011 for warranty information.

ACU Removal

1. Remove the air lines to and from the ACU.

2. Remove the electrical harness from the ACU.

3. Remove the two fasteners and remove the ACU.

4. Remove the threaded hose fittings from the removed ACU.

ACU Installation

1. Install the threaded hose fittings removed from the old ACU

onto the new ACU.

2. Using two new fasteners, bolt the ACU to the bracket and

tighten the fasteners to 11 ft-lb (15 N폷m). @

3. Verify the removed air lines are clean and then connect them to

the new ACU.

4. Connect the vehicle electrical harness to the ACU.

3 Troubleshooting

5

Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

3 Troubleshooting

Oil and Other Contaminants

The air control unit does not require maintenance. However, the ACU

can be affected by oil and other contaminants suspended in the air

as an aerosol. When these contaminants flow through the ACU, it

can cause the O-rings and rubber components to swell, affecting

the ability of the ACU to correctly control the air pressure.

Contaminants can also pass through the ACU and contaminate the

urea dosing system.

To prevent contaminants from reaching the ACU, an oil coalescing

device must be installed between the air compressor and the air

control unit. Either an air dryer with an integrated coalescing

desiccant cartridge or a standalone oil coalescing device is required.

Follow correct maintenance procedures and intervals for the oil

coalescing device used. If you do not use an oil coalescing device,

you will void any and all warranties provided on the ACU.

ACU Replacement

If there is a problem with the ACU functioning correctly, replace the

entire valve. Do not attempt to service or repair the valve. Refer to

Limited Warranty Document TP-1011 for warranty information.

Diagnostics

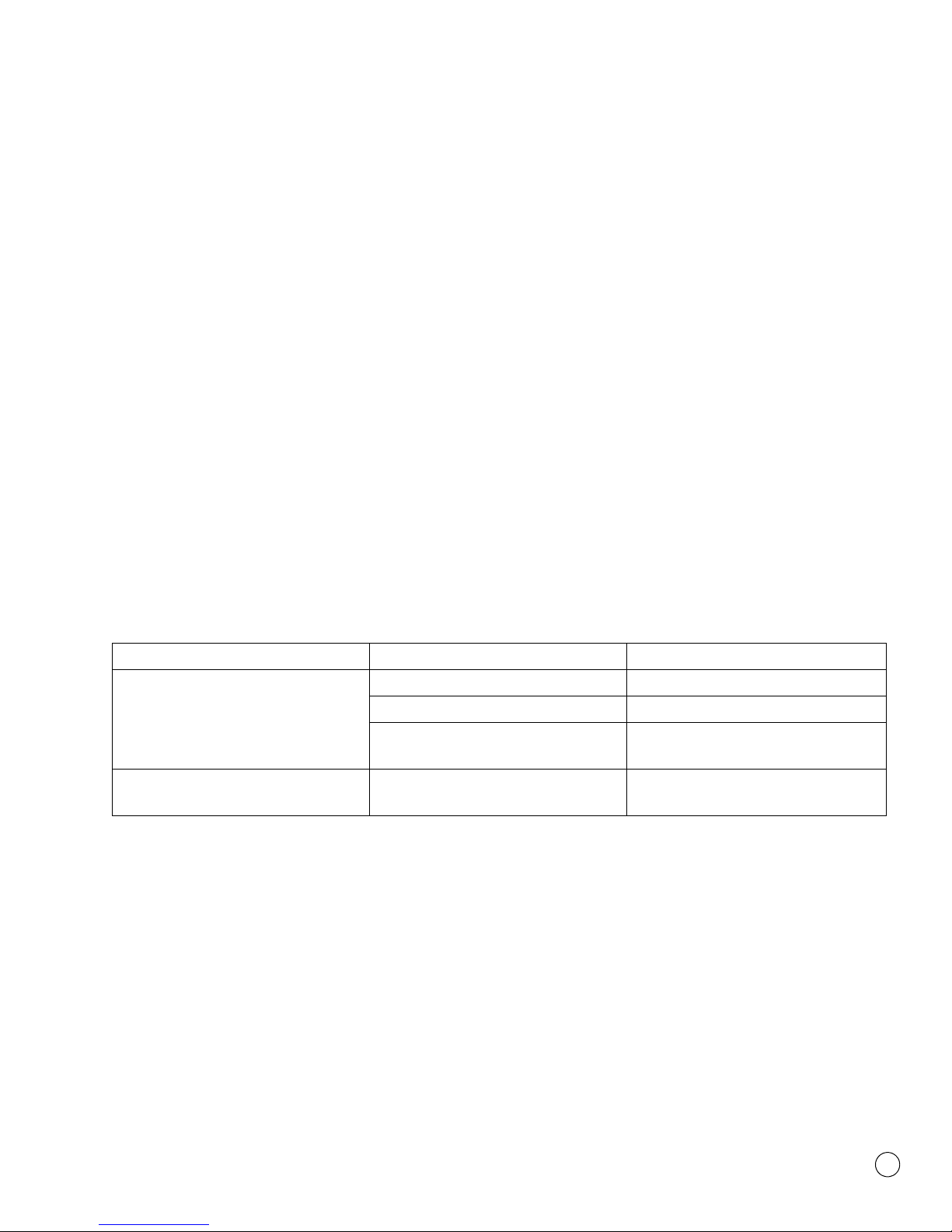

Condition Possible Cause Solution

ACU does not deliver air. There is no voltage to the ACU. Check the vehicle fuse/power supply.

The ACU solenoid is not operating. Replace the ACU.

The check valve is stuck in the closed

position.

Replace the ACU.

Air pressure delivered to the SCR dosing unit

is too high or too low.

The pressure limiting portion of the ACU is not

functioning.

Replace the ACU.

4 Specifications

6Meritor WABCO Maintenance Manual MM-1012 (Issued 02-10)

4 Specifications

General Requirements

앫Mount the air control unit so that there is no direct splash or

spray from a wheel.

앫Keep the air control unit at least 12 inches (305 mm) from any

heat producing sources like exhaust manifolds or pipes,

transmissions, etc.

앫Line sizing from and to the air control unit should be at least

1/4 inch (6.35 mm).

앫Make sure there are no valves or other devices in the air supply

line to the air control unit.

Operating Environment Requirements

Operating Parameter Requirement

Temperature (ambient operating range) –40°F to 175°F

(–40°C to 80°C)

Electrical Power 12 +/−3V DC

Minimum Inlet Pressure 87 psi (6 bar)

Maximum Working Pressure 145 psi (10 bar)

Installed Position No Restriction

Meritor WABCO Vehicle Control Systems

2135 West Maple Road Printed in USA

Troy, MI 48084-7121

800-535-5560 Copyright 2010 Issued 02-10

meritorwabco.com ArvinMeritor, Inc. Maintenance Manual MM-1012 (16579/22882)

Table of contents