DEICO DE9005 User manual

Table of contents

Popular Control Unit manuals by other brands

Keysight Technologies

Keysight Technologies VXI bus 75000 C Series Service guide

AMX

AMX DCE-1 instruction manual

EcoDim

EcoDim ECO-DIM.03 quick guide

Cypress

Cypress CY8CKIT-019 Guide

Weinmann & Schanz

Weinmann & Schanz Heatapp! System Installation instruction

Toto

Toto EcoPower TET1LN(32)#CP installation manual

Omron

Omron CJ Series Operation manual

SAMES KREMLIN

SAMES KREMLIN GNM 6080 instruction manual

Trane

Trane VAV-UCM 4.2 Installation & maintenance guide

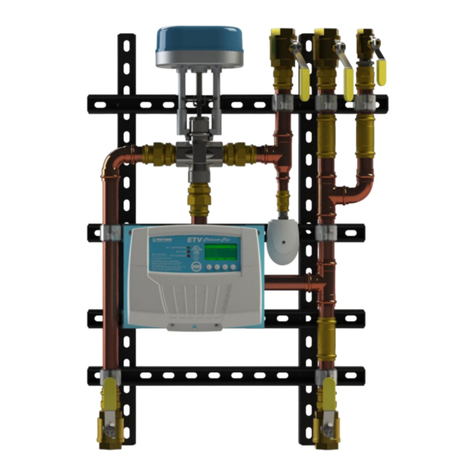

heat-timer

heat-timer ETS-LT Installation and operation manual

tempLED

tempLED RayTrack Multisensor installation guide

aFe Power

aFe Power 77-43010 instruction manual

Beninca

Beninca RI.624 operating instructions

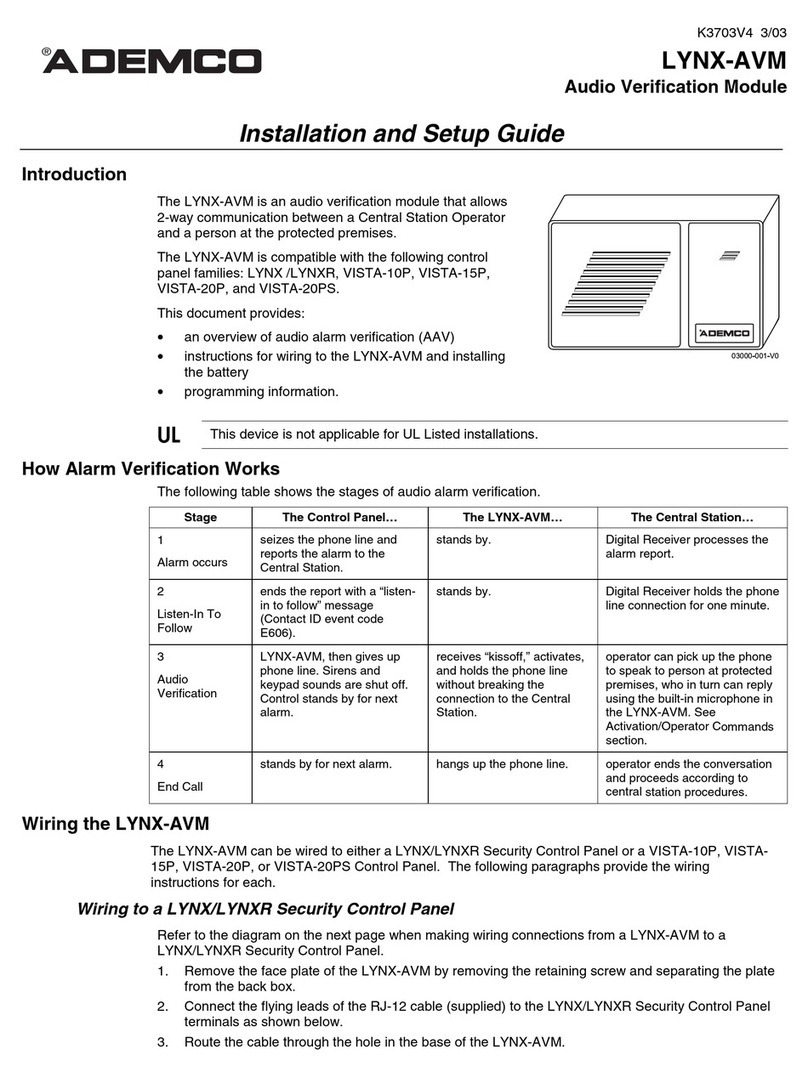

ADEMCO

ADEMCO LYNX-AVM Installation and setup guide

Burkert

Burkert 5406 operating instructions

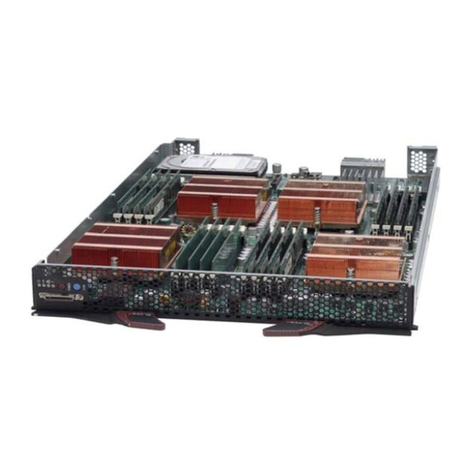

Supermicro

Supermicro SBA-7141M-T user manual

Morningstar

Morningstar RelayDriver Installation and operation manual

Beale Street Audio

Beale Street Audio VCRI installation guide