Hattersley 1934 PICV Quick start guide

Pressure Independent

Control Valve (PICV)

General Notes

The Hatterley Fig. 1934 PICV;

• can be used in variable volume heating and

chilled water systems

• provides modulating control for terminal units

when installed with a modulating actuator

• has an equal percentage control characteristic

at all pre-set flow rates with actuator

• has built in Differential Pressure Control

• has an operating temperature: 0 to 90˚C

• has a maximum working ∆P of 400kPa

• has a maximum operating pressure of 25 bar

• Integral test points for verification of ∆P and

valve performance

PICV Fig. 1934

MIDDLE EAST & NORTH AFRICA

SALES OFFICE,

BUILDING 4, OFFICE 901,

THE GALLERIES, PO BOX 17415,

DOWNTOWN JEBEL ALI

DUBAI, UAE

TELEPHONE: 5800 816 4(0) 971+

EXPORT SALES ENQUIRES:

Installation and Operating Instructions

Limits OfUse

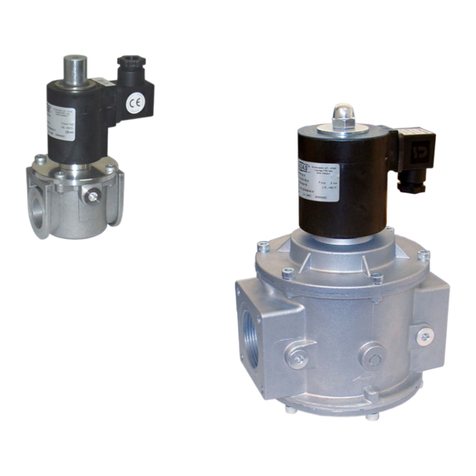

These valves have been categorised in accordance with the Pressure

Equipment Directive–PED.

The fluid to be transported is limited to group 2 liquids i.e. non-hazardous.

On no account must these valves be used on any group 1 liquids, group 1

gases or group 2 gases.

Installation

These instructions are issued as guidelines only and do not cover all installed

conditions. If unsure, please contact our Technical Helpline before installation.

• Hattersley products are designed for installation and use within suitably

designed systems reflecting CIBSE, BSRIA and HVAC guidelines. Particular

care should be taking with regards to;

-accessibility to valve for setting/adjustment

-tube cutting

-jointing

-bracketing/supports

• orientation: whilst the PICV can operate correctly in different orientations,

there are recommendations regarding the orientation of actuators - Please refer

to separate actuator IOM

• would normally be installed on return pipework, i.e. after the equipment it is

controlling, but can be installed in flow if required.

• ensure direction of flow is correct - indicated by cast arrow on body.

• Fig. 1934 operates between a minimum and maximum pressure drop across

the valve - see commissioning.

• PICV’s are not designed as isolation valves. Dedicated isolation valves

should be installed to isolate against system pressure, i.e. for maintenance

etc., when disconnecting/draining pipework.

• systems should be installed with strainers to protect the PICV and other

installed items.

Hattersley – Pressure Independent Control Valve – Fig. 1934

Installation and Operating Instructions

Flushing

Control valves, like the PICV, are sized to give good control over the system

flow, therefore have been designed with small convoluted flow paths. Even

when fully open these flow paths may not allow adequate water velocities for

flushing of the coil. In line with BSRIA recommendations, it is recommended

that a flushing point be located between the coil and the PICV. This allows

the coil to be flushed without the water passing through the PICV. As per the

Hook-Up Elite Prime range.

Installation Cont.

Please note this valve must not be used for end of line service or as an

isolation valve. In order for the valve to function as intended water quality

should be maintained at all times (e.g. as per BSRIA BG50 or equivalent).

Set Position

The PICV set position can be established by

use of lookup table on page 5

•Identify installed valve from marking

on side of body

•Check flow rate required

•Read across chart:

-Valve = DN15 SF

-Required flow rate = 0.15 l/sec

Set position = 6

To set the flow rate, using your hand, turn the dial to close the valve

(position 0), then re-open the valve by turning the dial anti-clockwise until

position 6 is reached. Please note at no point should any tools, such as

spanners, be used to set the dial.

Commissioning

The Fig. 1934 controls the flow rate depending on its set position, therefore,

removing the need to measure the flow rate.

The Fig. 1934 maintains a constant differential pressure across its internal

seat, any excess pressure being removed by the internal differential pressure

controller.

To ensure that sufficient pressure is available for the differential pressure

controller to control the flow rate correctly, a differential pressure reading

should be taken using the test points provided.

When taking differential pressure readings, it is important that the system

is running at full load, i.e. at their set position. This ensures that differential

pressure readings are carried out in the most unfavourable conditions,

guaranteeing optimum performance in normal running conditions.

To ensure that all PICVs are working at the required differential pressure, it

is necessary to check the least favoured / index PICV. By verifying the least

favoured PICV is set to the required differential pressure, all other PICVs must

have a higher differential pressure. However, we would also recommend that

a selection of other PICVs are tested along the circuit to verify this.

Hattersley – Pressure Independent Control Valve – Fig. 1934

Installation and Operating Instructions

Differential Pressure Requirements

Each valve size DN15 at each % setting option requires a specific constant ΔP

(Differential Pressure) to ensure the PICV is within its working range.

For flow rates in between settings, extrapolation of position can be used.

The pump speed should be set to ensure that the required differential pressure

is always available. By setting the differential pressure across the least favoured

PICV to the value stated in the above table, it ensures that minimum pump energy

is used, therefore, reducing system running costs and CO2emissions.

To set pump speed to achieve this; whilst measuring ΔP, increase pump speed

until ΔP is at, or just above, the minimum shown in the table above. Flow rate

verification should be carried out using separate Flow Measurement Devices

(FMD) where fitted. In line with CIBSE & BSRIA recommendations, we recommend

that as a minimum requirement, FMDs are installed in all branches.

Where flow rate verification is required at terminals, FMDs may also be installed

at each terminal. Terminal flow rates can also be confirmed by measuring branch

flow rates and closing individual terminal PICVs one at a time and measuring the

reduction in flow at the branch. Care should be taken to ensure that reduced flow

rates are still within the measuring range of the branch FMD, i.e. that the measured

‘signal’ doesn’t drop below 1kPa.

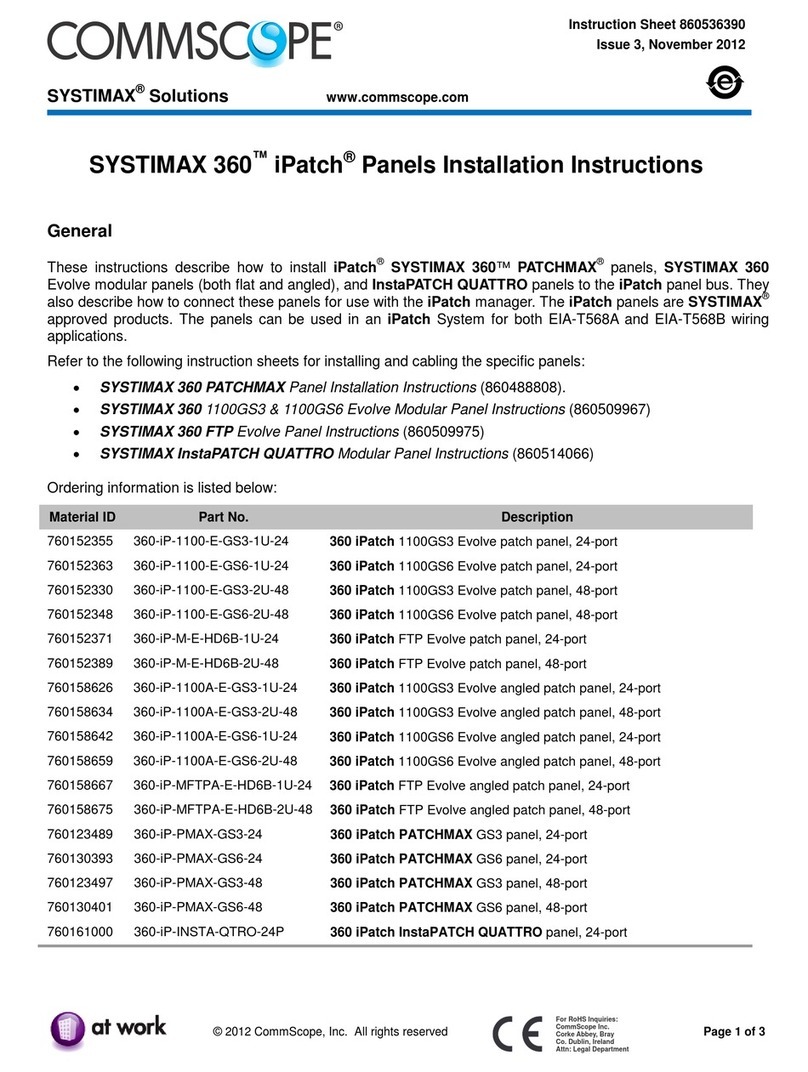

DN15 LF DN15 SF DN15 HF

POS Typical

ΔP FLOW POS Typical

ΔP FLOW POS Typical

ΔP FLOW

2 15 0.008 2 20 0.060 2 25 0.085

3 15 0.015 3 20 0.085 3 30 0.130

4 15 0.028 4 20 0.115 4 35 0.175

5 15 0.038 5 20 0.130 5 35 0.210

6 20 0.050 6 20 0.150 6 35 0.250

7 20 0.060 7 20 0.170 7 40 0.280

8 20 0.070 8 25 0.180 8 45 0.300

9 20 0.075 9 25 0.190 9 45 0.320

10 20 0.080 10 25 0.200 10 50 0.340

Installation and Operating Instructions

Hattersley – Pressure Independent Control Valve – Fig. 1934

H_PICV_FIG. 1934_0818

IOM_HNH002941

• Designed and manufactured under quality management

systems in accordance with BS EN ISO 9001:2008 FM311 ISO 9001

EPSILON TERRACE, WEST ROAD

IPSWICH, IP3 9FJ

HOME SALES: +44 (0)1473 277410

EXPORT SALES: +44 (0)1473 277450

TECHNICAL HELPLINE: +44 (0)1473 277400

FAX: +44 (0)1473 277411

EMAIL: [email protected]

www.hattersley.com

MIDDLE EAST & NORTH AFRICA

SALES OFFICE,

BUILDING 4, OFFICE 901,

THE GALLERIES, PO BOX 17415,

DOWNTOWN JEBEL ALI

DUBAI, UAE

TELEPHONE: 5800 816 4(0) 971+

EXPORT SALES ENQUIRES:

To visit our Video Library go to:

www.youtube.com/user/CraneBSU

www.cranebsu.com

Every effort has been made to ensure that the information contained in this publication is accurate

at the time of publishing. Crane Ltd assumes no responsibility or liability for typographical errors or

omissions or for any misinterpretation of the information within the publication and reserves the right

to change without notice.

Table of contents

Other Hattersley Control Unit manuals