MERMAID MARINE I-3 Original operating instructions

MERMAID MARINE

ICE MAKER

MODELS I-3 AND I-3i

INSTALLATION

&

OPERATIONS GUIDE

CONTROL MASTERS, INC.

Mermaid Air Distributor

11623 Columbia Park Drive East

Jacksonville, FL 32258

Phone: 904-260-9756

www.controlmastersinc.com

TABLE OF CONTENTS

SECTION 1 (OVERVIEW)

A. Introduction to Mermaid

SECTION 2 (SAFETY)

A. Safety and Warranty Precautions

SECTION 3 (INSTALLATION)

A. Ice Maker Installation

B. Water Connections

C. Mounting the Unit

D. Built-in Installations

SECTION 4 (START-UP)

A. Initial Start-up

SECTION 5 (OPERATION)

A. Normal Operation

B. Adjusting Temperature Control

C. Adjusting Ice Cube Size

SECTION 6 (MAINTENANCE)

A. Care and Cleaning

B. Defrosting

C. Storage

SECTION 7 (TROUBLESHOOTING)

A. What to check for?

SECTION 1

(OVERVIEW)

A. Introduction:

Congratulations!! You have just purchased one the most dependable Marine Ice Makers

on the market today, a MERMAID.

Mermaid supplies pleasure boat owners, custom boat builders, yacht brokers, boat dealers

and marinas around the world with their ice making needs.

Mermaid icemakers are manufactured to the highest of quality standards using only top

of the line components and materials assembled by long-term qualified technicians. All

of our icemakers are modularized, self contained, prewired, precharged and manufactured

out of 304 and 430 -18 gauge stainless steel. All of our icemaker components, such as

the evaporator, compressor and condensing coil, are manufactured in the USA.

In short, you’re never out on a limb with a Mermaid. Mermaid factory warranty

covers all issues with your machine for a one-year period. After 1 year, any

certified technician, marine, household or commercial, can service any Mermaid Ice

Maker.

IMPRORTANT

PLEASE READ ALL INSTRUCTIONS COMPLETELY BEFORE ATTEMPTING

TO INSTALL OR OPERATE THE UNIT. ALL ICE MAKERS REQUIRE A

CONNECTION TO THE WATER SUPPLY AND IMPROPER HOOK-UP CAN

RESULT IN SUBSTANTIAL PROPERTY DAMAGE! IF YOU ARE UNSURE OF

YOUR ABILITY TO SAFELY CONNECT THE WATER SUPPLY TO THE

UNIT, CONSULT A LICENSED PLUMBER OR TECHNICIAN FOR

ASSISTANCE.

SECTION 2

(SAFETY PRECAUTIONS)

WARNING!

•NEVER ATTEMPT TO INSTALL, REPAIR OR PERFORM

MAINTENANCE ON THE UNIT UNTIL THE ELECTRICITY

HAS BEEN DISCONNECTED.

•ALTERING, CUTTING OF POWER CORD, REMOVAL OF

CORD, REMOVAL OF POWER PLUG, OR DIRECT WIRING

CAN CASE SERIOUS INJURY/DEATH OR SEVERE

PROPERTY DAMAGE/LOSS AND WILL VOID THE

WARRANTY.

CAUTION!

•DO NOT LIFT UNIT BY DOOR HANDLE ALONE. THE

DOOR LATCH IS NOT DESIGNED TO WITHSTAND THE

WEIGHT OF THE UNIT.

•NEVER USE AN ICE PICK OR ANY OTHER SHARP OBJECT

TO AID THE DEFROSTING TIME. USAGE OF SUCH TOOLS

CAN AND WILL CAUSE DAMAGE TO THE COOLING

PORTION OF THE MACHINE AND WILL VOID THE

WARRANTY.

•FAILURE TO MAINTAIN THE AIR GRILL (CONDENSER)

LOCATED BEHIND THE FRONT PANEL CAN AND WILL

CAUSE CONDENSER FAILURE. THIS IS NOT A

WARRANTY REPAIR.

•NEVER INSTALL THE UNIT BEHIND NON-VENTED

CLOSED DOORS. OBSTRUCTING FREE AIR FLOW CAN

AND WILL CAUSE THE UNIT TO MALFUNCTION AND

VOID THE WARRANTY.

SECTION 3

(INSTALLATION)

SITE PREPARATION:

The icemaker needs to be mounted in an area where it will physically fit, as well as

accommodate an unblocked intake vent. In addition, you need to insure there is

enough space for the water hose to be connected.

A. INSTALLING THE ICE MAKER:

1. Position the unit on a flat, level surface, capable of supporting the entire weight of

the unit. Remember, when the unit has produced its ice, the weight will be

substantially higher. A fiberglass shelf may be necessary for a proper installation.

2. Ensure that there is room behind the unit for your water hose connection and

power supply. It is advisable to leave extra water line to prevent kinking

(described later).

3. Your Mermaid product has been designed for either free standing (I-3 model) or

built-in installation (I-3i model). When built-in, your Mermaid product does not

require additional air space for top, sides, or rear. However, the front grill MUST

NOT be obstructed. It is advisable to have at least a 1/8” to a ¼” size over the

standard unit size. This will aid in the installation and removal of the unit.

DIMENSIONS:

WIDTH HEIGHT DEPTH

14.0” 24.0” 16.0”

4. If your unit was ordered with a mounting flange, the unit should have arrived with

it pre-attached. If you would later like to build the icemaker in, we are able to

provide you with the mounting flange for a later installation. Simply contact the

factory and we would be happy to assist.

B. CONNECTING THE WATER SUPPLY:

1. Locate the ¼” copper water line with the white quick disconnect exiting the rear

of the machine. For your convenience, the water valve connection has been

previously established in the underside of the machine. No additional connections

are necessary behind the front or rear grills of the ice makers.

2. The copper tubing, exiting the rear of the machine, will have a quick disconnect

¼” fitting ready to accept either a ¼” plastic (PVC) line or copper line. This will

depend on the water line established for your vessel. Either line is acceptable.

3. Simply insert the plastic or copper line in the quick disconnect fitting until tight.

No tooling is required for this connection.

4. During built-in installations, ensure that the plastic or copper line does not kink

during your mounting of the unit. It is recommended to leave a few feet of slack

coiled behind the machine (in either the plastic or copper line) for ease of removal

in the event the unit needs to be serviced.

5. To remove the water line from the Mermaid Ice Maker, depress the white or grey

ring on the very end of the coupling fitting at the end with your water line and

pull gently on the plastic or copper line. Ensure that if you disconnect both, that

you re-establish a secure connection on both ends to avoid any water leaks.

Improper connection or removal resulting in water damage is NOT covered by

warranty. Ensure you follow all necessary precautions.

NOTE

AFTER COMPLETING THE WATER CONNECTIONS, TURN ON THE

WATER SUPPLY AND RECHECK THE WATER CONNECTIONS

BEFORE PERMANANTELY INSTALLING THE UNIT. DO NOT USE

TAPES OR SEALANTS ON CONNECTIONS. THERE NEEDS TO BE A

MINIMUM OF 20PSI AND A MAXIMUM OF 120PSI TO OPERATE THIS

UNIT.

C. MOUNTING THE UNIT:

1. The power cord is strapped to the rear of the machine. Plug 6 ft. power cord into

receptacle. DO NOT use an extension cord to connect the power to the unit.

Electrical grounding is required. This unit is specifically designed with a 6ft.

three-prong grounding plug. Be sure that the receptacle it is to be plugged into is

the same. If it is not, consult with an electrician about changing the receptacle to

a proper mate or properly installing one near the machine.

2. Gently push the unit into position ensuring NO kinks have occurred in the water

line.

3. Ensure there is at least 1-1.5 inch clearance behind the unit for electrical

connections. DO NOT push the unit directly into the plug assembly. It is

imperative that the plug assembly is free from contact of the back of the unit.

SECTION 4

(START-UP)

A. INITIAL START-UP:

Once installation is complete, the unit is ready for initial start-up and operation.

1. Ensure the unit is plugged into a proper three-prong 115v polarized grounding

outlet.

2. Move the ON-OFF switch to the ON position.

3. As soon as the icemaker mold reaches the proper temperature, the ice mechanism

will fill the mold with water. It is not uncommon for the first few rounds of cubes

to be smaller than desired. This is due to air in the water inlet line. Subsequent

cubes will be of standard size. Approximate time for first cycle is 45-60 minutes.

Allow a full 24 hours for a full bin of ice.

4. The unit will operate under 3.29-4.0 115 Volt Amps.

NOTE

IT IS POSSIBLE THAT DIRT OR SCALE WILL DISLODGE IN THE

WATER LINE. IT IS ADVISABLE TO DISCARD THE FIRST FULL

ROUND OF ICE CUBES. SHOULD THIS PROBLEM PERSIST, AN

OPTIONAL WATER FILTER MAY WANT TO BE ADDED ON THE

INCOMING WATER LINE TO THE ICE MAKER.

SECTION 5

(OPERATION)

A. NORMAL OPERATION:

The icemaker is designed to create between 20-25lbs of ice within a 24-hour time

frame. It is not uncommon for the machine to make less ice if the door is open

frequently during this time. The core temperature needs to stay within 14-16 degrees

Fahrenheit to create the maximum quantity of cubes. Frequent door opening

occurrences will inhibit this temperature from being reached.

The production may also be interrupted by raising the bin arm into an upright and

locked position (the unit will still maintain temperature for ice storage). By raising

the bar you are simply deactivating the ice production module.

NOTE

IT IS ADVISABLE WHEN ICE PRODUCTION IS NOT DESIRED TO RAISE

THIS ARM. WHEN THE MACHINE IS ON AND POWER IS SUPPLIED,

THE UNIT WILL MAKE CONSTANT ICE. DO NOT SIMPLY TURN THE

MACHINE TO THE OFF POSITION WITH ICE IN THE TRAY. THE UNIT

WILL COME TO ROOM TEMPERATURE – MELTING THE ICE – AND

MAY CAUSE SEVERE WATER DAMAGE TO YOUR BOAT.

It is normal for certain sounds to be heard. At times, you may hear the compressor

turn on/off, the fan turn on/off, the water solenoid valve activating, and most

common, the ice falling into the ice bucket.

CAUTION

DURING PERIODS OF LIMITED USE OR HIGH AMBIENT

TEMPERATURES, IT IS COMMON FOR CUBES TO FUSE TOGETHER.

NEVER USE AN ICE PICK, KNIFE, OR OTHER SHARP INSTRUMENT TO

SEPARATE THE CUBES. DAMAGE TO THE CORE OF THE UNIT CAN

OCCUR. SIMPLY SHAKE THE ICE BUCKET TO LOOSEN THE CUBES.

If the icemaker is not used regularly, the ice bucket should be emptied periodically to

ensure fresh cubes.

It is normal for cubes to appear cloudy. This is caused by air being trapped in the

water due to fast freezing. It has nothing to do with health, taste or chemical make-up

of the water. It is the same air that is in every glass of water you drink

To provide for higher ice rate (production of more cubes), adjust the temperature

control to a warmer setting. If hollow cubes result, adjust temperature somewhat

colder. For less cube production, adjust to a colder setting.

While the machine is operating, it is necessary to keep the ice bucket fully inserted as

much as possible to avoid cubes falling in the core of the unit. Should this occur,

simply remove the ice cubes carefully. DO NOT use a pick or a sharp object should

they be stuck. If necessary, thaw the ice machine.

B. ADJUSTING THE TEMPERATURE CONTROL:

Model I-3 has an adjustable temperature dial located behind the louvered air intake

vent on the front of the machine.

1. Remove the air intake vent.

2. Locate the black or grey dial mounted next to the condensing unit.

3. To create more cubes, turn the dial to the left (counterclockwise) one or two

digits. All the way to the warmest setting will not drastically aid the ice

production time.

4. To create less cubes, turn the dial to the right (clockwise) one or two digits. All

the way to the coldest setting will not drastically aid in the ice production time.

C. ADJUSTING ICE CUBE SIZE:

On the Mermaid I-3 and I-3i models, the size of the cubes may need to be adjusted

based on personal preference and water pressure coming to the unit.

1. Open the front of the icemaker.

2. Locate the icemaker mechanism in the upper left corner of the unit.

3. Carefully remove the white mechanism cover. No tools are necessary to

accomplish this.

4. Locate the adjusting screw on the icemaker assembly control box. The adjusting

screw is just below the minus (-) and plus (+) signs on the control box.

5. Turn the adjusting screw toward the minus (-) sign (clockwise) for smaller cubes

or toward the plus (+) sign (counterclockwise) for larger cubes.

6. Install the white mechanism cover.

SECTION 6

(MAINTENANCE)

A. CARE AND CLEANING:

Periodic cleaning and proper maintenance will ensure efficiency, top performance,

and a longer operating life of the Mermaid I-3 Icemaker. We would recommend the

following:

1. Periodically clean the interior with mild soap and warm water.

2. Avoid use of solvent cleaners or abrasives on the interior. These chemicals could

transmit to the ice cubes.

3. The exterior may be cleaned with “Sheila Shine” or WD-40. Use a small amount

of each as overuse of these products will create a film on the exterior of the

machine. This will not hurt the machine but will create a greasy feeling to you.

4. The intake grill needs to be clear of all debris. Free air needs to be able to flow

through the louvered vents. The condensing coil located behind the vent should

be cleaned three to four times a year by using a small brush or vacuum. Be sure

not to damage the coils in the process.

CAUTION

THE CONDENSOR FINS ARE SHARP!! DO NOT RUN HANDS OVER THE

CONDENSOR FINS.

B. DEFROSTING:

CAUTION

DO NOT USE ANY ELECTRICAL HEATING DEVICE, ICE PICK, KNIFE, OR

ANY OTHER SHARP OBJECT TO ATTEMPT TO AID IN THE DEFROSTING

PROCESS. THIS WILL DAMAGE THE CORE OF THE MACHINE AND WILL

VOID THE WARRANTY.

Manual machines should be defrosted every eight weeks. However, this may not be

practical in areas of high heat/humidity and heavy usage. In these circumstances, it

will be necessary to defrost your unit whenever the frost thickness exceeds ¼”. To

defrost, turn the unit to the OFF position, remove the remaining cubes and prop door

open. It would be advisable to use a towel to absorb the melting frost to ensure it

does not escape the unit and create water damage.

C. STORAGE:

If the unit is to be stored or not used for a prolonged period of time, it is advisable to

drain the water system. Please follow these steps:

1. Shut the water supply off to the machine.

2. Disconnect the water supply from the water connection at the back of the

machine. Or, you may simply disconnect the water supply line behind the front

grill. The water valve has a ¼” copper tube with a compression fitting located on

top of the valve. Carefully disconnect this line. This is only advisable if you are

not willing to remove the installed icemaker. I3 models are not built-in and

disconnecting the quick disconnect fitting is advised.

3. Allow the unit to operate for approximately one hour or so until the unit has

discharged all the ice in the mechanism.

4. Dry out any remaining water left in the icemaker mechanism.

5. Prop the door open.

6. Disconnect the unit from the 115v power supply.

SECTION 7

(TROUBLESHOOTING)

A. WHAT TO CHECK FOR?

Before calling for service, please review the troubleshooting checklist below. Should

you still need attention, please don’t hesitate to contact us.

PROBLEM POSSIBLE CAUSE REMEDY

1) The unit is not

cold enough Door gasket not sealed properly Inspect the latch and gasket on door for

proper seal

Dirty condensing coil Clean condensing coil. Refer back to

“Care and Cleaning” section

Airflow to front grill is

obstructed

Remove item(s) blocking intake

Temperature not set cold enough Turn dial to colder setting. Refer back

to “Adjusting The Temperature

Control.”

2) The unit frosts

up Unit is a manual defrost product Refer back to “Defrosting”

3) Water is

leaking out the

back of the unit

Water supply connection is

leaking Inspect all water connections and

tighten fittings.

4) Ice cubes are

sticking together Door gasket not properly sealed

Or infrequent use of cubes Adjust door gasket/latch or break apart

cubes by shaking the bucket. DO NOT

use sharp objects.

5) Noise during

operation Tubing lines are touching or

rubbing Inspect plumbing connections under

machine to ensure they are not touching

any other components.

6) No ice Bin arm is locked in the upright

position Manually lower bin arm

7) Not enough

ice Control setting too cold or ice

cube size too large Adjust temperature control. Refer to

“Adjusting The Temperature

Control” or Refer to “Adjusting Ice

Cube Size.”

8) Water leaks

into ice bucket Water level set too high Set cube size smaller. Refer to

“Adjusting Ice Cube Size.”

Should the above information not be sufficient, please contact CMI at 904-260-9756 or you

may contact Mermaid for direct factory support during normal business hours of 8:00AM to

5:00PM EST Monday through Friday at 800-330-3553.

We hope you enjoy your Mermaid I-3 or I-3i Product and we thank you for your

business!

This manual suits for next models

1

Table of contents

Popular Ice Maker manuals by other brands

KitchenAid

KitchenAid KUIS185EBL parts manual

Nostalgia Electrics

Nostalgia Electrics RSM702COKE Instructions and recipes

frozy

frozy FR25 SI user manual

KitchenAid

KitchenAid KUIC15NLXS Use & care guide

Hoshizaki

Hoshizaki Serenity Series KMS-2000MLH Service manual

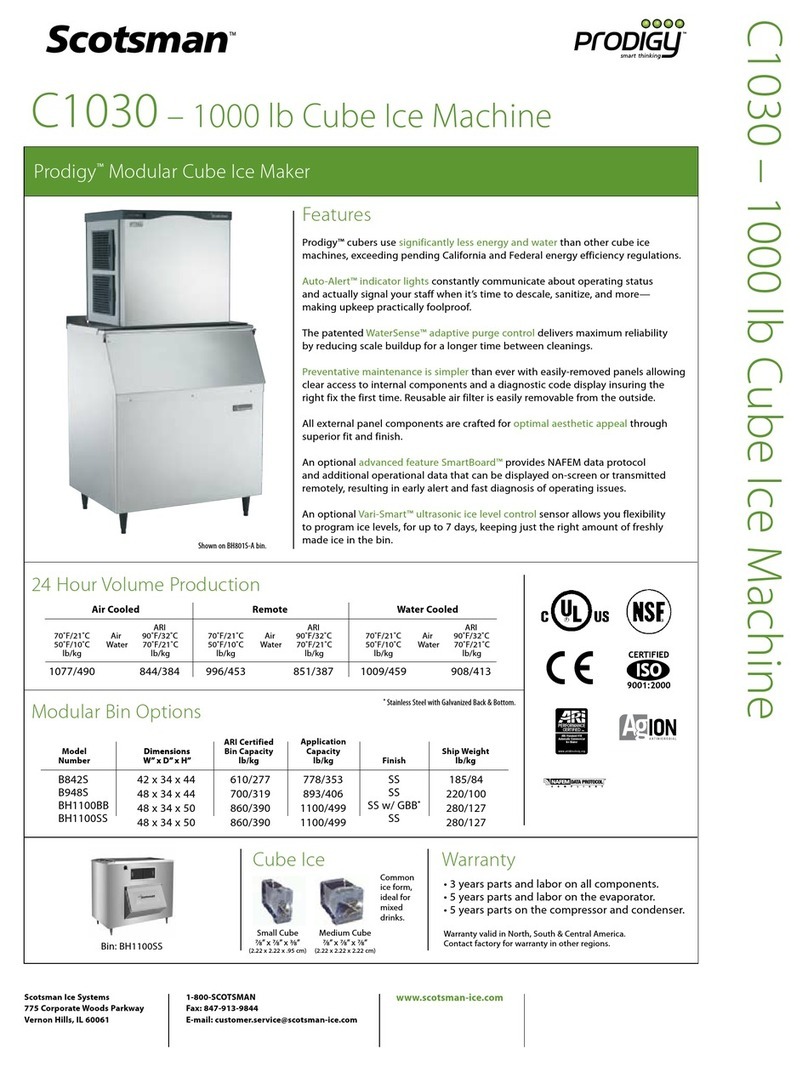

Scotsman

Scotsman Prodigy C1030 Specification sheet