Merriott EMMETI ClimaAir CA VS 7-2P User manual

ClimaAir

Installation, operating

& instruction manual

Fan Convector

PLEASE LEAVE THIS MANUAL WITH THE END USER

Product Information

. Safety and General Information

. Safety Information

. General Information

. Technical Data

. Dimensions

. Installation

. Positioning the Unit

. Installation Clearances

. Side Opening

. Vertical Floor or Wall Installation

. Horizontal Ceiling Installation (VS, VSI)

. Mounting Front Grille Safety Support (CA VS)

. Air Intake Grille Fixing

. Water Connections

. Condensate Discharge

. Filling and Venting the System

. Electrical Connections

. Maintenance

. Cleaning the Outer Casing

. Cleaning the Air Filter

. Faults and Troubleshooting

. Troubleshooting

. Fault-Finding Guide

. Instructions -Way Valve

. Warnings

. -Way Valve Parts List

. Return Valve Pre-Setting Screw Adjustment

. Valve Insulation

. Control Panel Connection and Configuration

. Connection and Configuration of Control Panel

. Cooling Mode Additional Functionality

. Night-Time Heating Additional Functionality

. -Pipe & -Pipe Models with

Integrated Control

. -Pipe & -Pipe Models with

Wall-Mounted Remote Control

. Connection of Multiple Units Using

Wall-Mounted Remote Control

. LED Indications (A) -Pipe & -Pipe Models

with Wall-Mounted Remote Control

. Remote Control Panel Mounting

. Wiring Connection to Remote Control

. Presence Detection Sensor Input Connection

– Remote Control Units

. Integrated and Remote Control Setup Menu

. Setup Menu

. -V Models

. -V Fan Control

. Connection Diagram with -V DC

Thermostats/Signals

. Fan Speed Regulation

. User Instructions

. Integrated and Remote Control Operation

. Display

. Key Function

. Activation

. Heating/Cooling Mode Settings

. Stand-By

. Temperature Selection

. Automatic Operation

. Silent Operation

. Night-Time Operation

. Operation at Maximum Fan Speed

. Key Lock

. Reduce Brightness to Minimum

. Room Temperature Probe Regulation Offset

. Switching Off for Longer Periods

Contents

3

Product Information

We want to thank you for choosing one of our products. We are confident that you will be happy with your selection because

it represents the state of the art in the technology of climate control.

ClimaAir Fan Convectors are available with casing or without casing, in different lengths.

CA VS - Surface Mounted Models can be mounted vertically on the wall or horizontally on the ceiling, with the option for integrated

controls (not ceiling), remote control or V option with BMS input or V remote control input. All units are available in or -pipe

options, and all units are supplied with pre-fitted valves.

CA VSI - Recessed Models can be mounted vertically (recessed wall mounting) or horizontally (recessed ceiling mounted), with the option

for remote control or V option with BMS input or V remote control input.

Conformity

This unit complies with European directives:

>Low voltage directive //EU

>Electro-magnetic compatibility //EU

>RoHS Directive //EU

This unit complies with UK directives:

>Electrical Equipment (Safety) Regulations

>Electromagnetic Compatibility Regulations

>RoHS Regulations

Symbols

The following symbols provide the necessary guidance for correct, safe use of this product.

Hot Surface

Signals that the parts of the product could be hot

and should not be touched without great care.

Protective Earth

Identifies any terminal intended for connection

to an external conductor for protection against

electric shock in case of a fault, or the terminal of

a protective earth electrode.

Refer To Manual

Refer to relevant instructions within the

product manual.

Warning / Caution

Signals that an appropriate safety instruction

should be followed or caution to a potential hazard.

Dangerous Voltages

Indicates hazards arising from dangerous voltages.

Heavy

Indicates that this product is heavy, and provision

should be made for safe lifting and handling.

Safety Pictograms

These symbols may appear in the manual or on the product:

ClimaAir

ClimaAir4

Safety and General Information

.

. Safety Information

This appliance MUST NOT be

installed in a bathroom or other

similar high humidity areas.

This appliance MUST be earthed.

This appliance must be installed

by a qualified engineer.

The electrical installation must

comply with local or national

wiring regulations and should

be carried out by a qualified

electrician.

This appliance can be used by

children aged from 8 years and

above and persons with reduced

physical, sensory or mental

capabilities or lack of experience

and knowledge if they have been

given supervision or instruction

concerning use of the appliance

in a safe way and understand the

hazards involved. Children shall

not play with the appliance.

Cleaning and user maintenance

shall not be made by children

without supervision.

For the correct installation of this

product, it is essential that fixing

is carried out in such a way that

it is suitable for intended use and

predictable misuse. A number of

elements need to be taken into

consideration including the fixing

method used to secure it to the

wall, the type and condition of

the wall itself, and any additional

potential forces or weights that

may happen to be applied to the

unit, prior to finalising installation.

This product must not be installed

immediately below a socket outlet.

This product must not be installed in

areas where excessive dust exists.

This product can be hot when in

use, and as such, presents a risk

of burns to users on prolonged

contact. The temperature of the

product is dependent on system

water temperature, as set by the

installer or end user. Installers

and users should ensure that

those who may come into close

proximity to the product are

aware of the risk of burns.

The recessed ClimaAir model

does not have a grille or covering

plate. The installer must provide

safety guards and air inlet/outlet

grills to prevent accidental

contact with the device.

DO NOT cover or obstruct the air

inlet or outlet grilles.

Isolate electrical supply before

carrying out any cleaning or

maintenance activities.

This instruction leaflet is an

integral part of the appliance.

The installer MUST ensure it is

left with the end user.

All repair and maintenance

activities must be performed by

suitably qualified personnel.

ClimaAir 5

. General Information

Before proceeding with the installation, unpack the product and

make sure that all the components are present, and that there is

no concealed shipping damage.

Components include:

>Unit

>Instruction manual

>Template

>Accessories/mounting kit

This appliance has been designed both for heating and/or

cooling applications and must be installed for this use only.

The installation must take into consideration stated

performance characteristics.

Check the location where the product is to be installed, the

wall surface must be flat and the specified product clearances

available. If fitted to a stud wall, there may be an adverse effect

on sound levels especially at higher fan speeds. If the product is to

be used for cooling applications, the disposal of condensate must

be considered.

If the appliance is not used for a long period of time,

it is recommended that the product is electrically isolated,

and the connecting valves are closed. Frost prevention

measures must be taken including use of anti-freeze

if appropiate.

Avoid prolonged physical contact with the direct air flow.

Do not leave the room closed for long periods. Periodically open

the windows to ensure fresh air exchange.

In the event of a water leak, isolate the electrical supply and

close connecting valves. Contact the installer or suitable

service engineer.

The manufacturer accepts no responsibility, either contractual

or for consequential loss, for any damage caused to persons,

animals of property as a result of incorrect installation, alteration,

maintenance or improper use.

To ensure that the installation is carried out correctly and that the

unit will perform as designed, carefully follow the instructions in

this manual. Failure to follow the instructions can not only cause

malfunctions of the appliance but will also invalidate the warranty

and hence Purmo Group shall not respond for any damage to

persons, animals or property.

. Technical Data

-Pipe Models

Technical Data (DC) Model VS CA VS -P CA VS -P CA VS -P CA VS -P CA VS -P

Model VSI CA VSI -P CA VSI -P CA VSI -P CA VSI -P CA VSI -P

Length VS mm

Length VSI mm

Heat exchanger water content VS/VSI L. . . . .

Maximum working pressure bar

Maximum inlet water temperature °C

Minimum inlet water temperature °C

Water connections Eurocone /" Eurocone /" Eurocone /" Eurocone /" Eurocone /"

Power supply V/ph/Hz // // // // //

Maximum power W

Weight VS kg

Weight VSI kg

-Pipe Models

Technical Data (DC) Model VS CA VS -P CA VS -P CA VS -P CA VS -P CA VS -P

Model VSI CA VSI -P CA VSI -P CA VSI -P CA VSI -P CA VSI -P

Length VS mm

Length VSI mm

Cooling coil water content L. . . . .

Heating coil water content L. . . . .

Maximum working pressure bar

Maximum inlet water temperature °C

Minimum inlet water temperature °C

Water connections Eurocone /" Eurocone /" Eurocone /" Eurocone /" Eurocone /"

Power supply V/ph/Hz // // // // //

Maximum power W

Weight VS kg

Weight VSI kg

ClimaAir6

Safety and General Information (cont...)

.

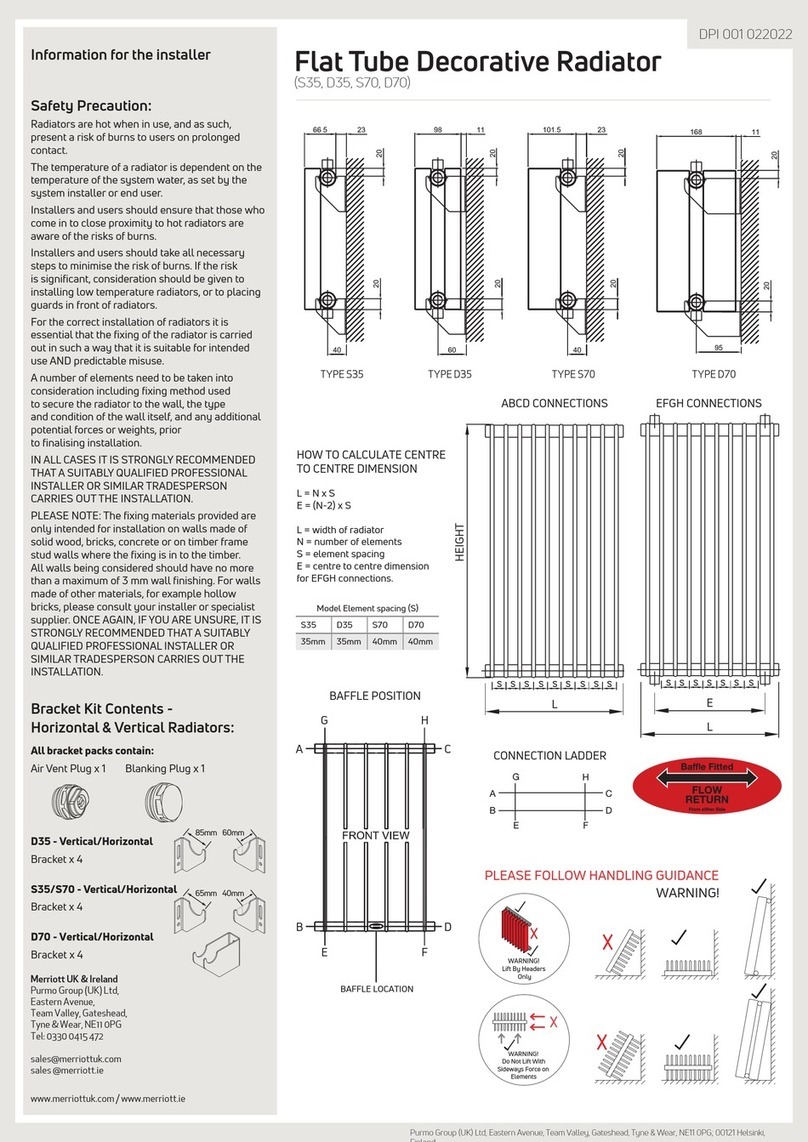

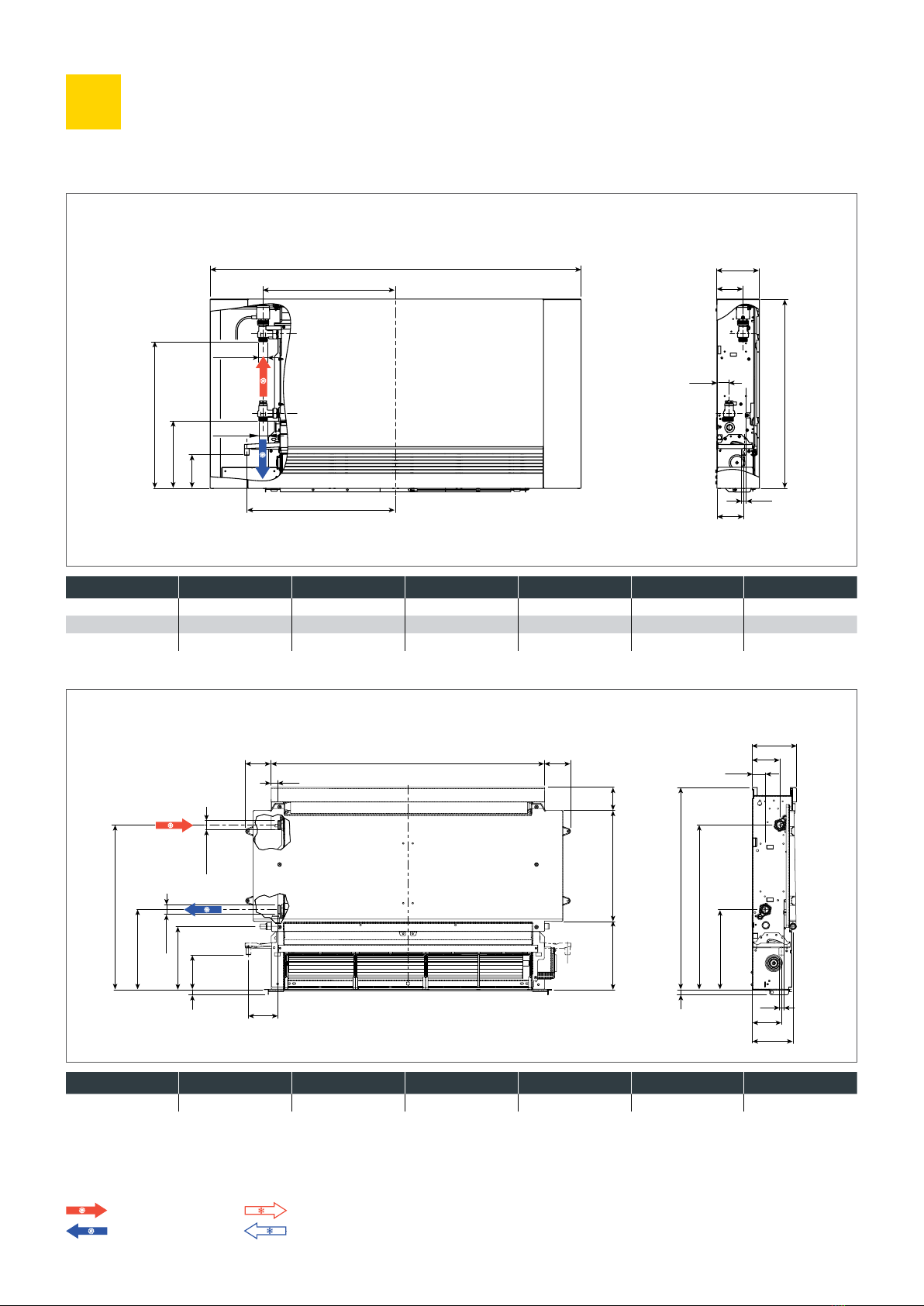

. Dimensions

FRONT VIEW SIDE VIEW

CA VSI -Pipe Models

Note: Optional feet are mm

Note: -pipe recessed unit shown without factory-fitted valves (included).

HEATING CIRCUIT IN COOLING CIRCUIT IN

HEATING CIRCUIT OUT COOLING CIRCUIT OUT

FRONT VIEW SIDE VIEW

CA VS -Pipe Models

Dimensions Model CA VS -P CA VS -P CA VS -P CA VS -P CA VS -P

Amm

a mm

a mm

37.5

80

131

579

449

206

102

83

G3/4"EK

G3/4"EK

A

a1

a2

∅ 14

126

A

73.573.5

18.5

468.5

228

G3/4“EK

180.5

14 99.5

G3/4“EK

194.5 316 65.5

576

14

468.5

228

79.5

37.5

∅ 14

83.2

116

83.5

126

A

73.573.5

18.5

468.5

228

G3/4“EK

180.5

14 99.5

G3/4“EK

194.5 316 65.5

576

14

468.5

228

79.5

37.5

∅ 14

83.2

116

83.5

37.5

80

131

579

449

206

102

83

G3/4"EK

G3/4"EK

A

a1

a2

∅ 14

Dimensions Model CA VSI -P CA VSI -P CA VSI -P CA VSI -P CA VSI -P

Amm

ClimaAir 7

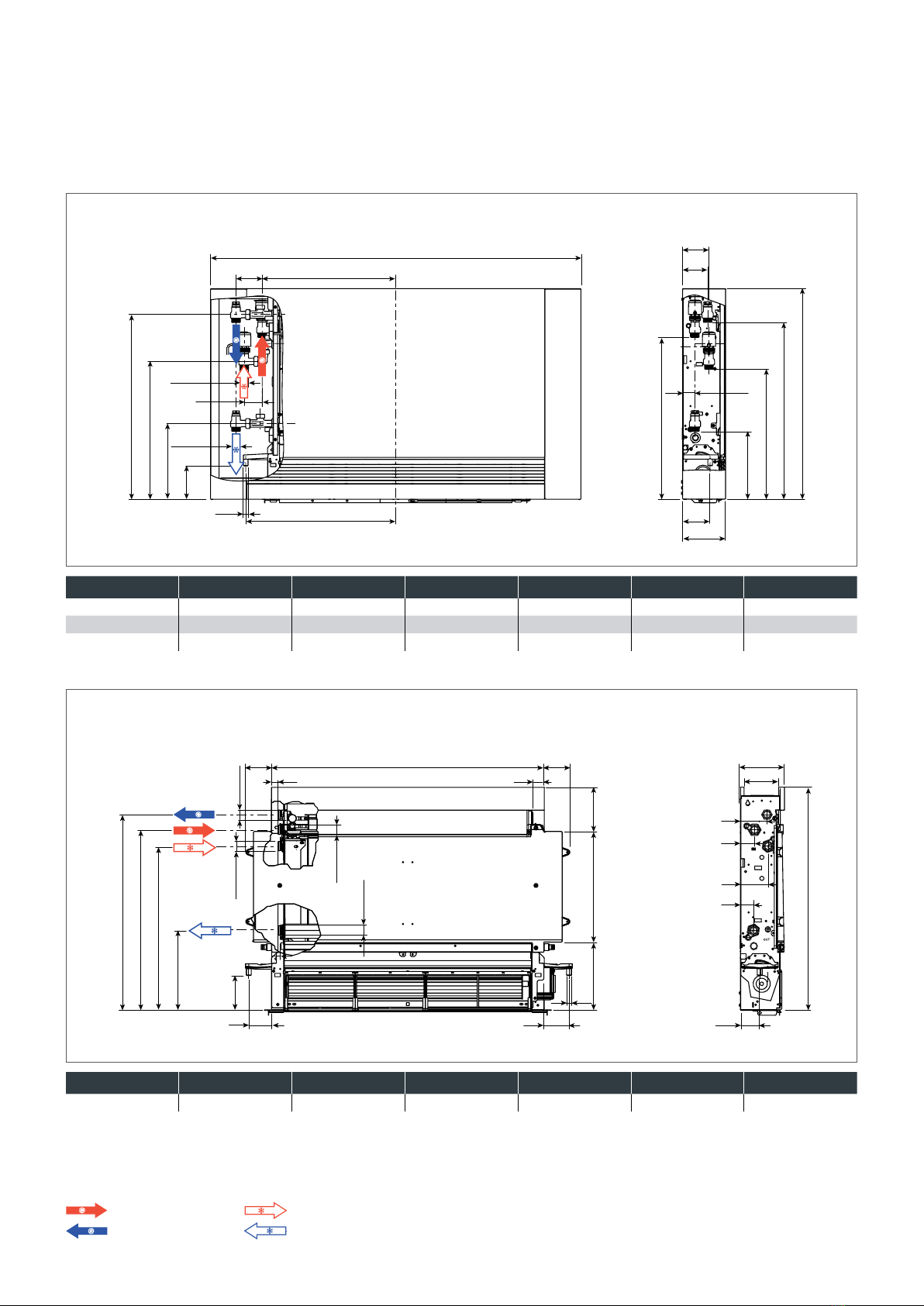

FRONT VIEW SIDE VIEW

CA VSI -Pipe Models

Note: Optional feet are mm

Note: -pipe recessed unit shown without factory-fitted valves (included).

HEATING CIRCUIT IN COOLING CIRCUIT IN

HEATING CIRCUIT OUT COOLING CIRCUIT OUT

FRONT VIEW SIDE VIEW

CA VS -Pipe Models

Dimensions Model CA VS -P CA VS -P CA VS -P CA VS -P CA VS -P

Amm

a mm

a mm

Dimensions Model CA VSI -P CA VSI -P CA VSI -P CA VSI -P CA VSI -P

Amm

80

131

639

83

G3/4"EK

102

230

206

394

536

491

37.5

76

418

560

79

54

∅14

G3/4"EK

a2

A

a1

80

131

639

83

G3/4"EK

102

230

206

394

536

491

37.5

76

418

560

79

54

∅14

G3/4"EK

a2

A

a1

126

636

228

468

98.5

515

558

73.5

65 72

55.5

A

30

73.5

30

125.6316194.4

∅ 14

37

80

41

76

99.5 G3/4“EK G3/4“EK

G3/4“EK

G3/4“EK

126

636

228

468

98.5

515

558

73.5

65 72

55.5

A

30

73.5

30

125.6316194.4

∅ 14

37

80

41

76

99.5 G3/4“EK G3/4“EK

G3/4“EK

G3/4“EK

ClimaAir8

Installation

.

. Positioning the Unit

This unit must not be installed in a bathroom, in damp

areas or places with possible contact with water.

Avoid installing the unit:

> In positions subject to exposure to direct sunlight.

> In proximity to sources of heat.

> In places with oil fumes.

> In places subject to high frequency radio waves.

The following instructions refer to units with standard water

connections on the left hand side.

Make sure that:

> The wall on which the unit is to be installed is strong

enough to support the weight.

> The installation does not interfere with existing pipes

or electric wires.

> The wall is perfectly flat.

> That the air inlet and outlet are free of obstructions.

> The installation wall is preferably an external wall to

allow the discharge of the condensate outside.

> In case of ceiling installation the airflow is not directed

towards room occupants.

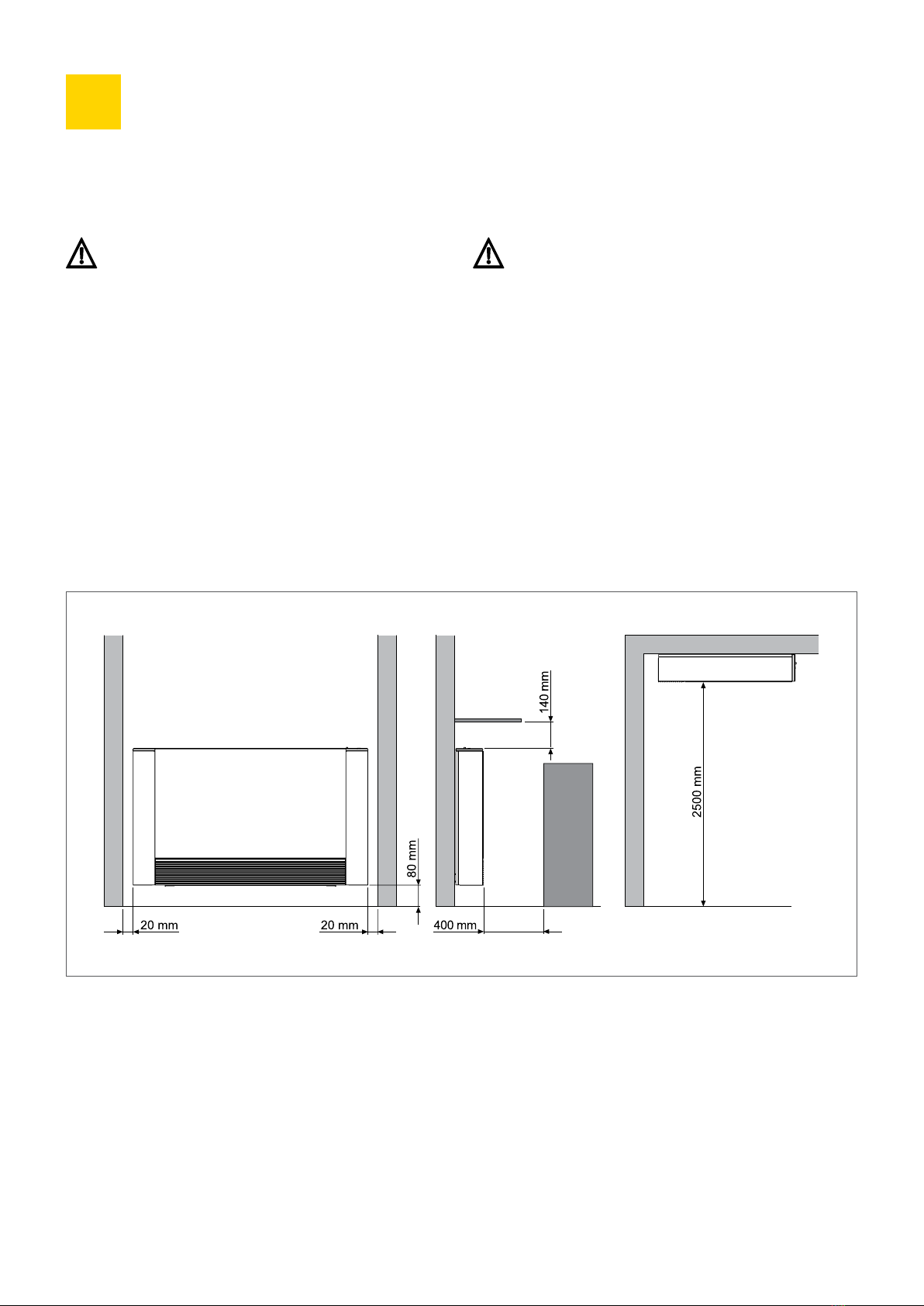

. Installation Clearances

The figure below indicates the minimum clearance between the CA VS Surface Mounted unit and any adjacent furniture.

ClimaAir 9

. Side Opening

>On the left-hand side, lift the cover that protects the screw,

loosen the screw that fixes the left panel, then move it slightly

to the left and lift it up.

>On the opposite side, lift the cover that protects the screw

and unscrew it.

>Move the side panel slightly to the right and lift it out.

. Vertical Floor or Wall Installation

When mounting on the floor with support feet, refer to the

product instructions supplied, and the instructions supplied

with the support feet.

Use the paper template provided to trace the position of the

bracket fixing holes on the wall. Drill the holes, insert the wall

plugs or other suitable fixing and secure the brackets.

Do not over-tighten the screws, check alignment with a spirit

level and make final adjustment. Mark the lower fixing points,

remove unit, then drill and plug wall. Fully tightening the bracket

screws, refit unit, check alignment and stability then secure using

bottom screw fixings.

AWall Plugs

BBrackets

B

AD

A

B

C

NOTE: Take care to ensure correct orientation of the wall brackets.

These should be fixed with small tabs pointing towards the fixing surface.

A AB

B

ACover

BFixing screws

CLeft panel

DRight panel

ClimaAir10

Installation (cont...)

.

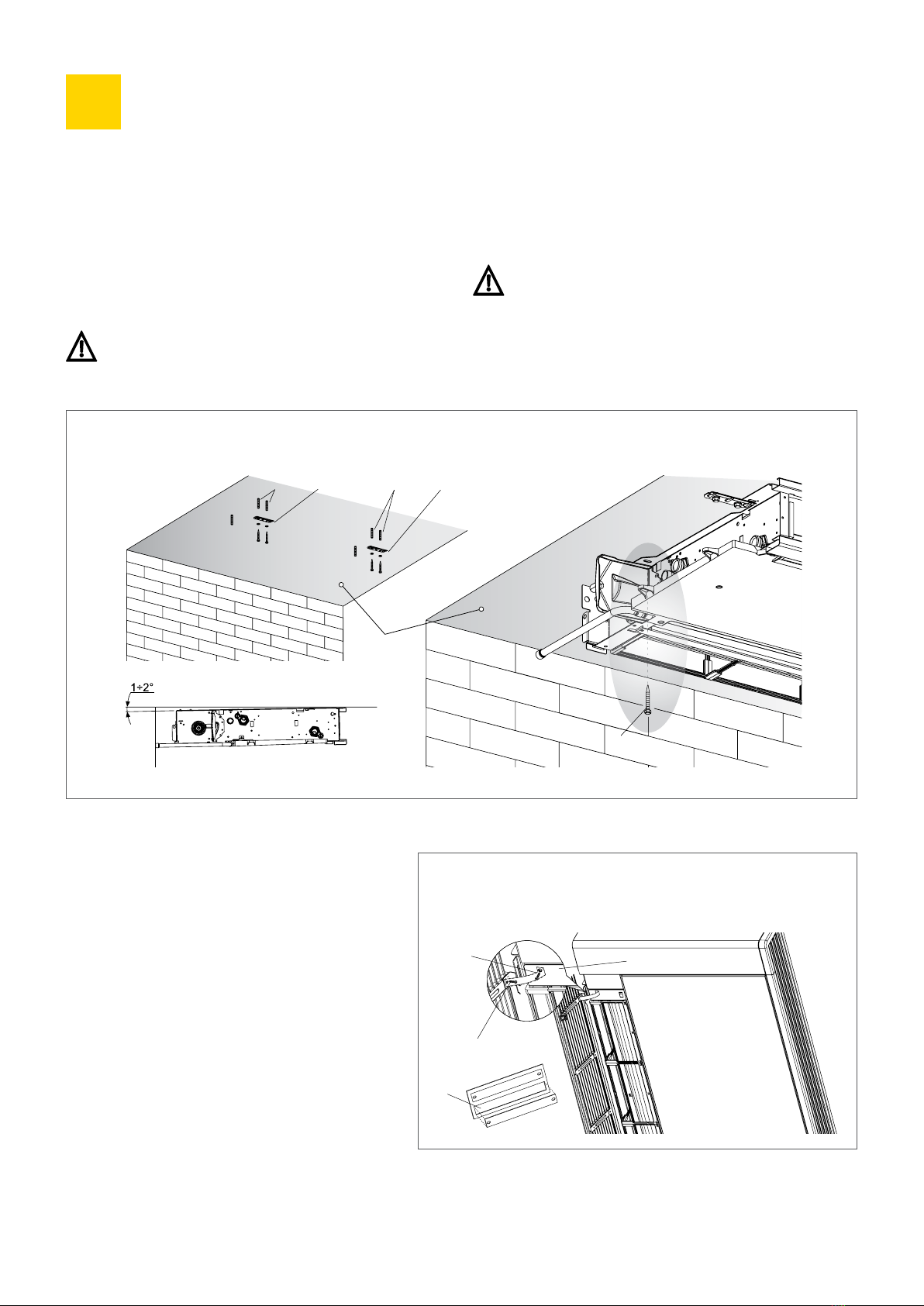

. Horizontal Ceiling Installation (VS, VSI)

Using the paper template provided, trace on the ceiling the

position of the two fixing brackets and the two rear screws.

Using a suitable drill, make the holes and insert the wall plugs

( for each bracket). Fix the two brackets. Do not over-tighten

the screws. Position the unit on the two brackets, keeping it in

position and then fix the two screws into the rear toggle bolts,

one on each side.

Make sure that there is sufficient inclination of the unit

towards the drainage pipe to facilitate the water drainage.

Additional washers or spacers may be needed.

Fully tighten all fixing screws.

For installation of the CA VS versions, horizontal condensation

collection tray accessory kits are available.

Carefully check the inclination of the condensate pipe.

Any backflow can cause water leakage.

AWall Plugs

BBrackets

CScrews

DDrainage Pipe

ceiling

A A

B

B

C

D

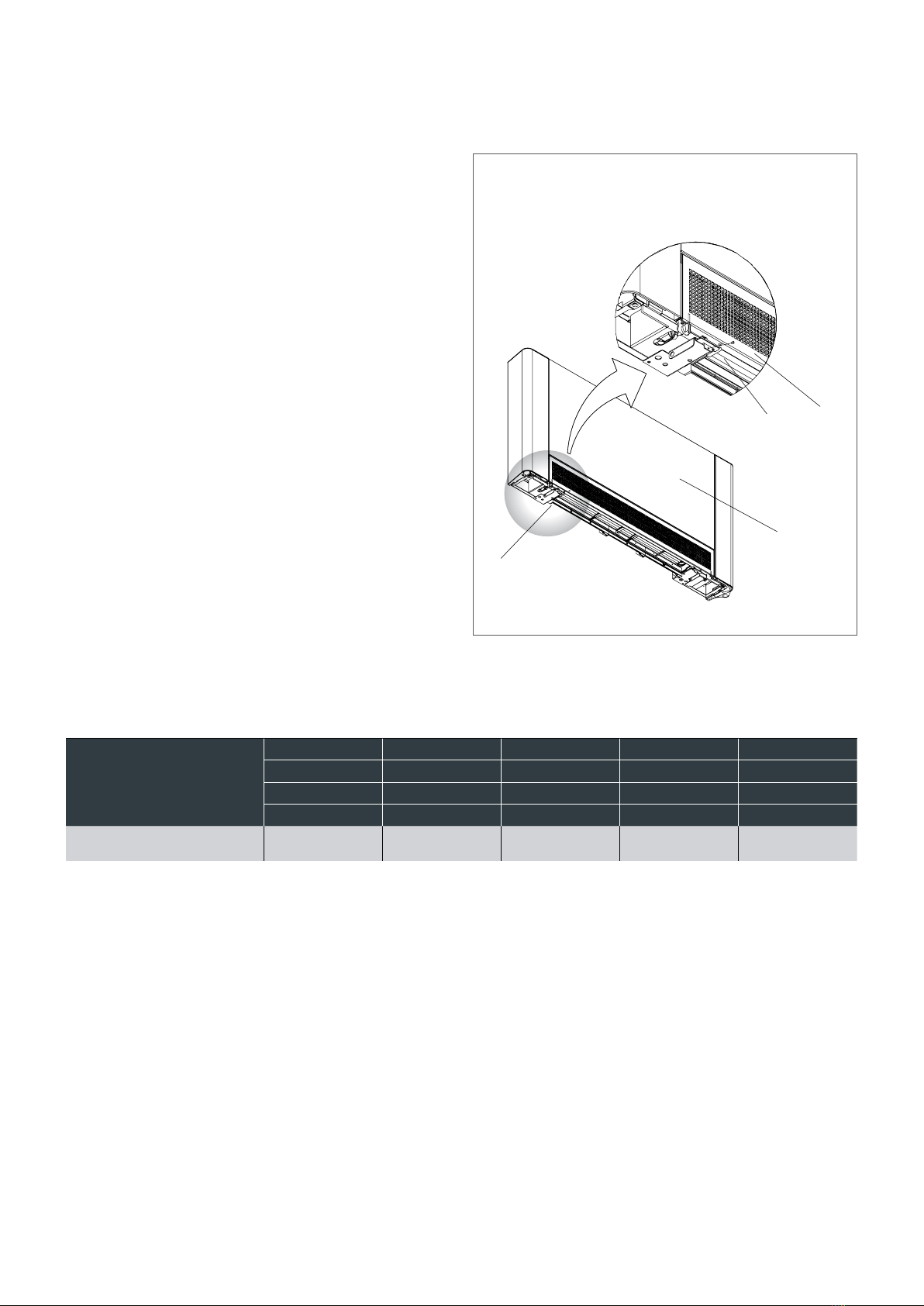

. Mounting Front Grille

Safety Support (CA VS)

When the unit is installed horizontally the inlet grille

must be attached to the chassis using the two tie straps

supplied in the accessory bag. This prevents the grille

from falling and ensures safe filter replacement.

Separate the two tie straps then;

>Remove the front grille and completely unscrew the

spring-loaded fixing screws.

>Fix one end of each tie to the chassis using the

spring-loaded fixing screws.

>Fix the other end of each tie to the grille using the

supplied screws.

>Refit the grille.

ATies

BSpring-loaded screws

CScrew fixing

A

A

B

C

ClimaAir 11

. Air Intake Grille Fixing

If the inlet grille is accidentally removed or left loose the fan will

stop and the grille safety alarm will activate. To prevent this from

happening the grille can be secured using the screws provided

(type TC . x .mm).

Fit the grille and secure by fitting the fixing screws into the

dedicated holes located on the grille's fixing bars as shown right.

The system should be designed and installed following best

practice by a qualified installer. The choice and sizing of the

pipework should take into account the number and size of the

units installed, and the performance characteristics of each unit.

Undersized pipes can cause malfunction of the units.

A suitable thread sealant should be used. The use of Teflon thread

sealant is advised when there is anti-freeze in the hydraulic circuit.

The water connection pipes and joints must be thermally insulated.

Partially insulating the pipes should be avoided and the insulation

should not be over-tightened.

After making the water connections check for leaks and cover

the connections with insulating material.

AInsert grille tab into lower bracket slot

BFixing screws

CCorrect position of grille tab

AB

C

Front View

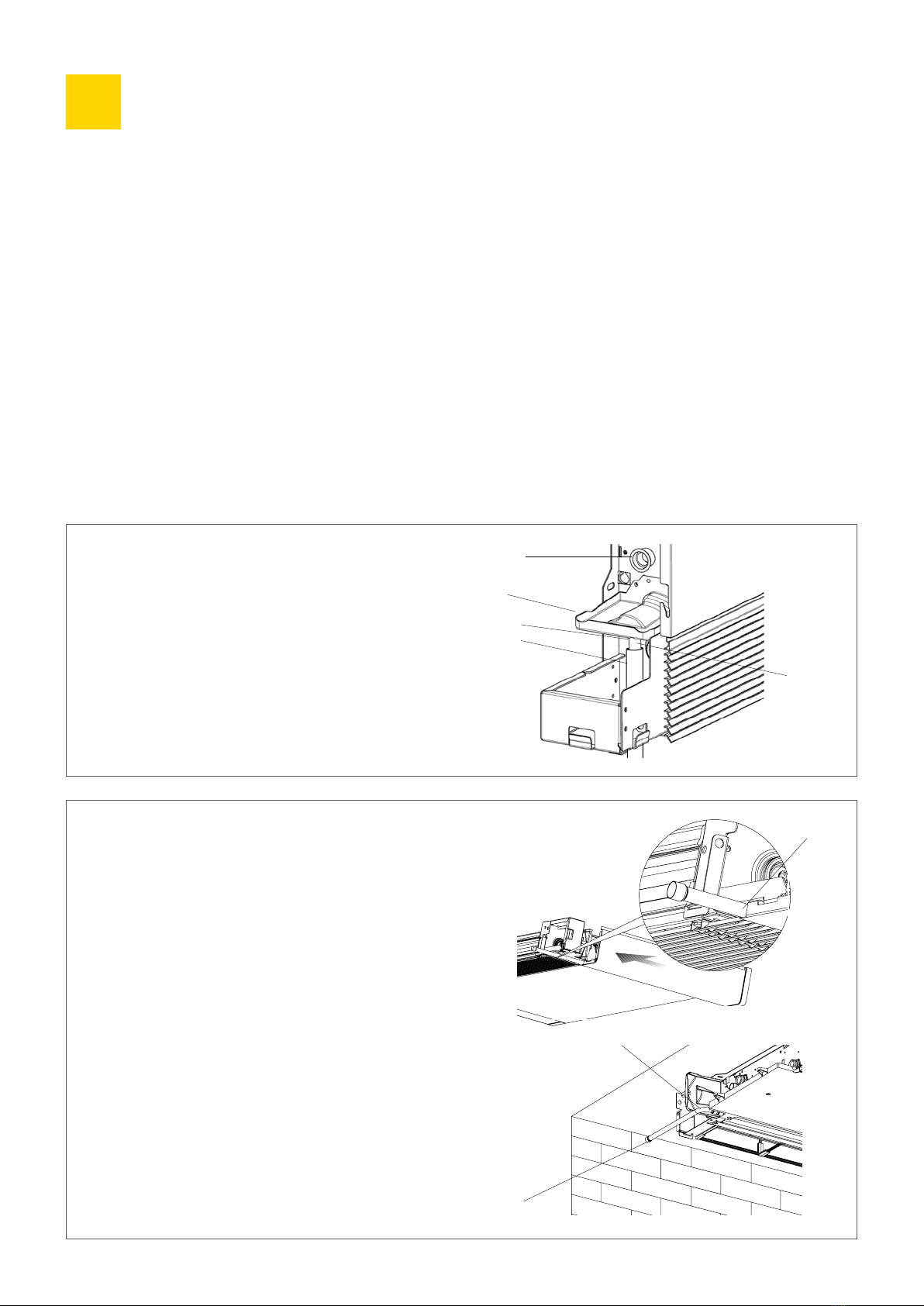

. Water Connections

Minimum Pipeline Diameters

Model

CA VS -P CA VS -P CA VS -P CA VS -P CA VS -P

CA VSI -P CA VSI -P CA VSI -P CA VSI -P CA VSI -P

CA VS -P CA VS -P CA VS -P CA VS -P CA VS -P

CA VSI -P CA VSI -P CA VSI -P CA VSI -P CA VSI -P

Minimum

Pipeline diameters mm

ClimaAir12

Installation (cont...)

.

. Condensate Discharge

The condensate discharge pipes must be suitably sized (minimum

inside pipe diameter mm) and the pipeline positioned so that

it keeps a constant inclination, never less than . In a vertical

installation, the discharge pipe is connected directly to the

discharge tray, positioned underneath the water connections.

In a horizontal installation the discharge tube is connected to

the one already present in the unit.

For installation of the CA VS versions in a horizontal position,

horizontal condensation collection tray accessory kits

are available.

>If possible, the condensate pipework should be directed into

a rainwater discharge.

>When discharging directly into the main drains, it is essential

to make a syphon to prevent bad odours coming up the pipe

into the room. The curve of the syphon must be lower than the

condensation collection bowl.

>If the condensate needs to be discharged into a container, the

container must be open to the atmosphere and the tube must

not be immersed in water so that the normal outflow is

not restricted.

>If there is a height difference that could interfere with the

outflow of condensate, a pump must be fitted.

>In a vertical installation mount the pump under the lateral

drainage tray.

>In a horizontal installation the pump position must be decided

according to the specific requirements.

Such pumps are readily available.

On completion of the installation, it is advisable to check the

correct outflow of the condensate by slowly pouring about .l

of water into the collection tray in about minutes.

B

A

Condensate Discharge Pipe Connection

– Horizontally Mounted Units

To mount the horizontal condensate tray on the CAVS units

refer to the instructions supplied with accessory kits.

>Check that the "L" pipe (A) and the flexible rubber hose are

correctly connected to the condensate tray.

>Slide in the side of the unit keeping the pipe in position up

against the front grille.

>Fully close the side checking that the pipe remains tight in

the special groove on the side.

N.B. For a horizontal installation carefully note the

following precautions:

>Make sure that the unit is installed perfectly level or with

a slight inclination towards the condensate discharge point.

>Carefully insulate the flow and return pipes to the unit to

prevent any drops of condensate falling outside the drip tray.

>Insulate the condensate discharge pipe (B) along its

complete length.

Condensate Discharge Pipe Connection

- Vertically Mounted Units

Check that the condensate collection tray is present and

is correctly installed. Connect the discharge pipe (B) to

condensate collection tray (A).

ADischarge fitting

BCondensate pipework

CInternal charge point

DCondensate collection tray

B

A

C

D

Ømm

Ømm

ClimaAir 13

. Filling and Venting the System

When starting up the system, make sure that the return valve is

open. Refer to section . for correct setting. If there is no electric

power and the actuator valve has not already been powered up,

use the special tool, press the valve actuator and use the tool to

keep it open.

>Open all the shut off valves (manual or automatic).

>Start to slowly fill the system.

>For units installed in a vertical position, open the highest vent

of the heat exchanger; for appliances installed in a horizontal

position, open the highest positioned vent; for the -pipe

versions open the highest vents on both heat exchangers.

Vents can be opened using a screwdriver.

>When water starts coming out of the air vents, close them

and continue filling the system until reaching the nominal

system pressure.

>Check for leaks.

It is advisable to repeat these operations after the appliance

has been running for a few hours and to periodically check the

system pressure.

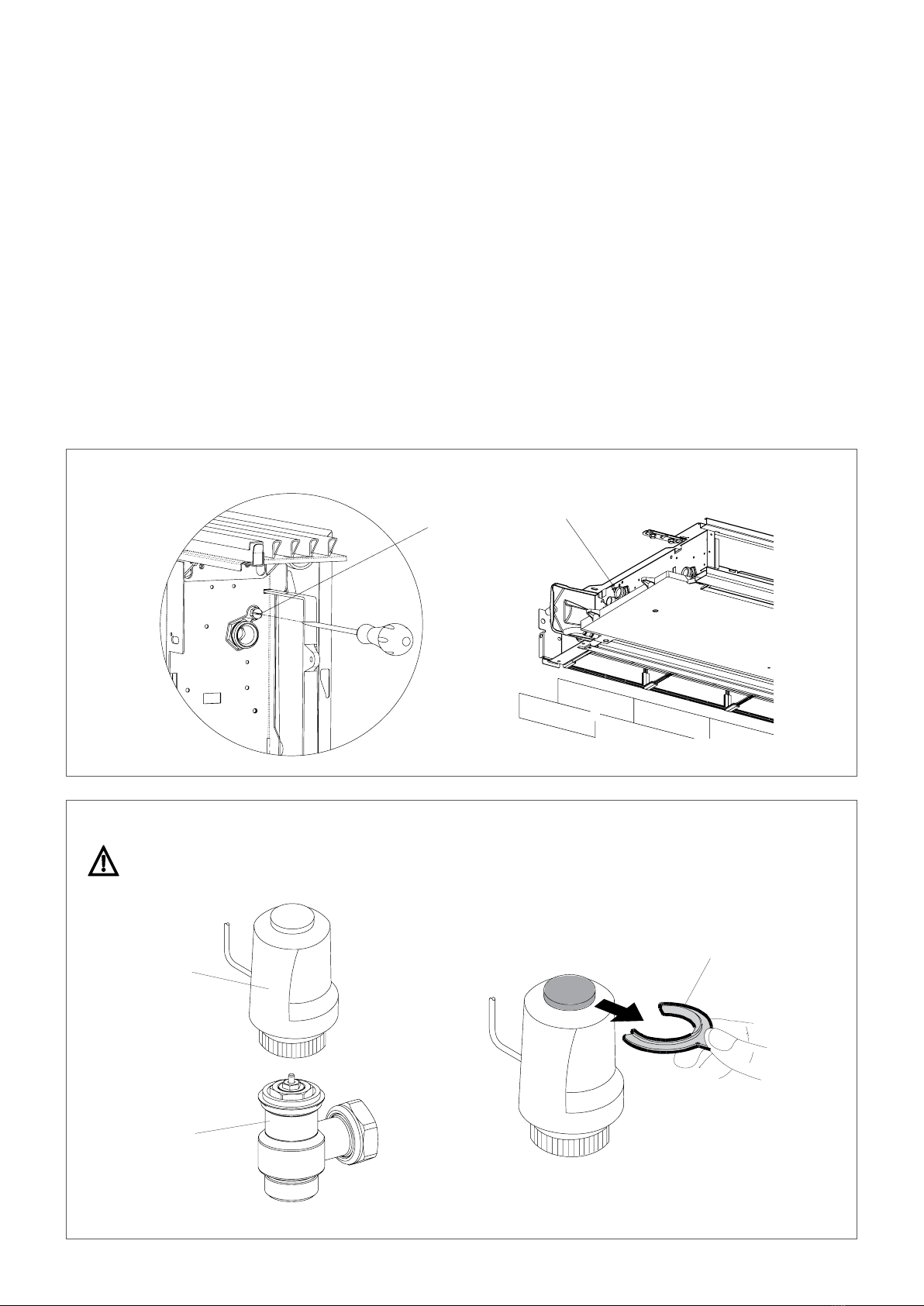

AThermostatic head

BValve

CRed plastic clip

WARNING: Commissioning Instructions – Opening the Thermostatic Valve

Remove the 'red plastic' clip from the thermostatic head before starting the system.

AVenting of the heat exchange

AA

C

A

B

ClimaAir14

Installation (cont...)

.

. Maintenance

Routine maintenance is essential to keep this product in a safe

and reliable working condition. End user maintenance activities

should be limited to cleaning of the outer casing and cleaning

of the air filter at appropriate intervals. Any other repair or

maintenance activity should be carried out by a qualified installer.

. Cleaning the Air Filter

To maintain air flow levels through the unit, air filters should be

cleaned at regular intervals. The frequency of cleaning should

take into consideration the concentration of impurities in the

local environment and duration of operation. Filter cleaning should

also be considered after a period of inactivity.

. Electrical Connections

Electrical connection must be made by a qualified

electrician in accordance with local and national

wiring regulations.

The unit must be connected to the mains supply using

a switched fused spur having mm separation on all poles.

This appliance must be earthed.

>Switch off electrical supply before making electrical connections.

>Remove control box cover.

>Make electrical connections to pcb.

>Secure power supply cables using strain relief clamps attached

to the control box.

>Refit control box cover.

. Cleaning the Outer Casing

Disconnect electrical supply before carrying out any

cleaning or maintenance activities.

Do not use abrasive cloths or abrasive or corrosive

detergents to avoid damaging the painted surfaces.

Wait until the parts have cooled down to avoid the risk

of burns. When necessary, clean the outer surfaces

of the ClimaAir with a soft damp cloth.

Removing the Filter

>Remove the front grille by lifting it slightly

and turn it until it comes completely out of

its seat.

>Remove the filter by pulling horizontally

outwards.

ALift front grille

BRotate grille forward

CFilter exposed

DRemove filter

AB

CD

ClimaAir 15

Cleaning the Filter

>Remove any dust with a vacuum cleaner.

>Wash the filter with clean running water. Do not use

detergents or solvents.

>Leave to dry.

>Re-fit the filter taking care to insert the lower back

edge into its seat.

Never use the unit without filters.

The appliance is fitted with a safety switch that

prevents operation of the fan with the front grille

missing or out of position.

After refitting the filter, check that the grille is

correctly mounted.

Energy Saving Tips

>Always keep the filters clean and as far as possible keep

the doors and windows closed in the room being conditioned

when the unit is in use.

>Limit where possible the effect of direct sun rays in the

rooms being conditioned (use curtains, shutters etc.).

>To refit the grille, insert the two lugs into the lower slots,

rotate it and attach to the upper chassis slots.

AFilter

BLower edge

CFilter locating channel

ATabs

BSlots

ABBC

A

B

ClimaAir16

Faults and Troubleshooting

.

. Troubleshooting

In the event of a water leak or malfunction immediately

cut off the power supply and close the system valves to

the unit.

Should one of the following faults occur, contact a qualified

service engineer. DO NOT intervene personally.

>The fan does not activate even if there is hot or cold water in

the hydraulic circuit.

>The appliance leaks water during the heating function.

>The appliance leaks water only during the cooling function.

>The appliance makes an excessive noise.

>Condensate forms on the front panel.

. Fault-Finding Guide

These operations must be carried out by a qualified installer or by a specialised service centre.

Effect Cause Solution

A delayed fan start up following set

temperature change or change of function.

The unit valves need time to open and as a

result the hot or cold water takes time to

circulate in the appliance.

Wait for or minutes for the unit valves

to open.

The fan does not function No hot or cold water in the system. Check that the boiler or chiller are functioning

correctly.

The fan does not activate even if there is hot or

cold water in the hydraulic circuit.

The hydraulic valve remains closed. Remove the valve actuator and check if water

circulation is restored. Check the valve actuator

by powering it from a separate V source. If

it activates then check the electronic control.

The fan motor is blocked or burnt out. Replace motor.

The micro-switch that stops the fan when the

filter grille is opened does not close correctly.

Check correct fitting of grille and that the

micro-switch contact is activated.

The electrical connections are not correct. Check the electrical connections.

The appliance leaks water during the

heating function.

Leaks in the hydraulic connections of

the system.

Check the leak and fully tighten the

connections.

Leaks in the valve unit. Check the condition of the gaskets.

Condensation forms on the front panel. Front panel insulation damaged or detached. Check the correct positioning of the

thermo-acoustic insulation, paying attention to

insulation in the front above the heat exchanger.

There are drops of water on the air outlet grille. In situations of high humidity (>)

condensation could form, especially at the

minimum fan speeds.

As soon as the humidity starts falling the

phenomenon disappears. In any case the

presence of a few drops of water in the

appliance does not indicate a malfunction.

The appliance leaks water only during the

cooling function.

The condensate tray is blocked. Slowly pour a bottle of water into the low part

of the heat exchanger to check the drainage;

if necessary, clean the tray and/or increase the

inclination of the drainage pipe.

The condensation discharge does not need an

inclination for correct drainage.

The connection pipes and the valve unit are not

insulated well.

Check the insulation of the pipes.

The appliance makes a strange noise. The fan fouling adjacent parts. Check if the filters are clogged and clean

if necessary.

The fan is unbalanced. An unbalanced fan can cause excessive

vibrations in the unit; replace the fan.

Check if the filters are clogged and clean them

if necessary.

Clean the filters.

ClimaAir 17

. Warnings

These instructions relate to the valve kits supplied with

the unit. The general instructions and basic safety rules

detailed in this manual should be followed.

For correct operating performance of this unit, the flow

and return pipework must be correctly fitted according to

the detail provided in these instructions.

Instructions -Way Valve

.

. -Way Valve Parts List

> x automatic valve with thermoelectric head for CA VS

& CA VSI models.

> x return with presetting for correct balancing of the system.

> x Connection /" Eurocone extention pipe (for use with pipe

connection from floor).

>Insulation pieces are supplied loose when the product is

supplied. These should be fitted to the flow and return valves

once the pipework connections have been made.

PLEASE NOTE: Valves are factory fitted but not tightened. For floor connections extension piece D (or similar) must be used

to clear outside edge of condensate tray.

Pipe Connection from Floor - with Optional /" EK Extension

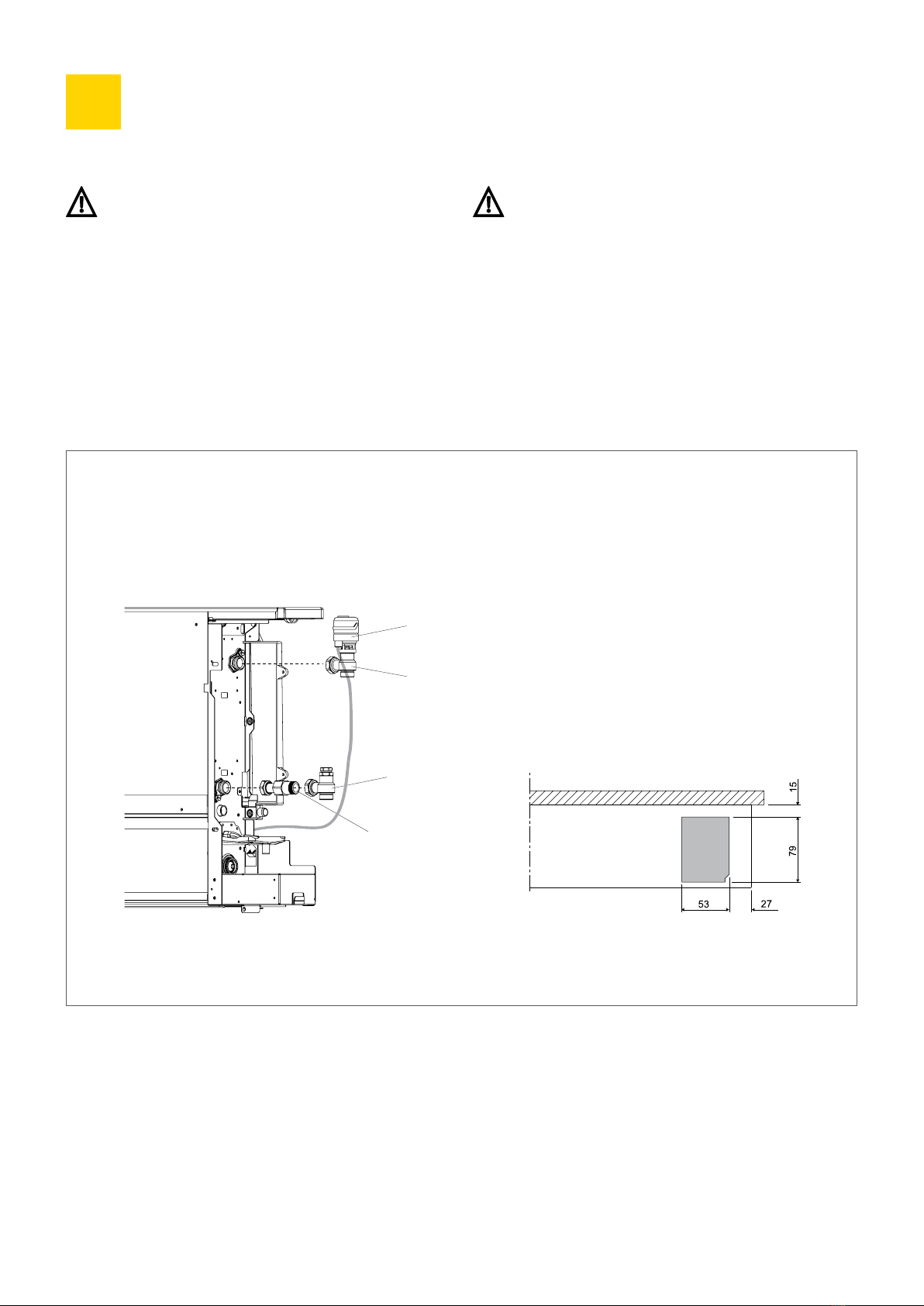

AThermostatic head

B-way valve

CReturn valve connection

D/" Eurocone extension (optional – can be supplied as accessory)

A

C

B

D

ClimaAir18

Instructions -Way Valve (cont...)

.

Pipe Connection from Wall - with Optional ° Elbow Fitting

AThermostatic head

B-way valve

C° elbow fitting (optional – can be supplied as accessory)

DReturn valve connection

PLEASE NOTE: Valves are factory fitted but not tightened. For through-the-wall connections °elbow C (or similar)

should be used.

A

C

B

D

ClimaAir 19

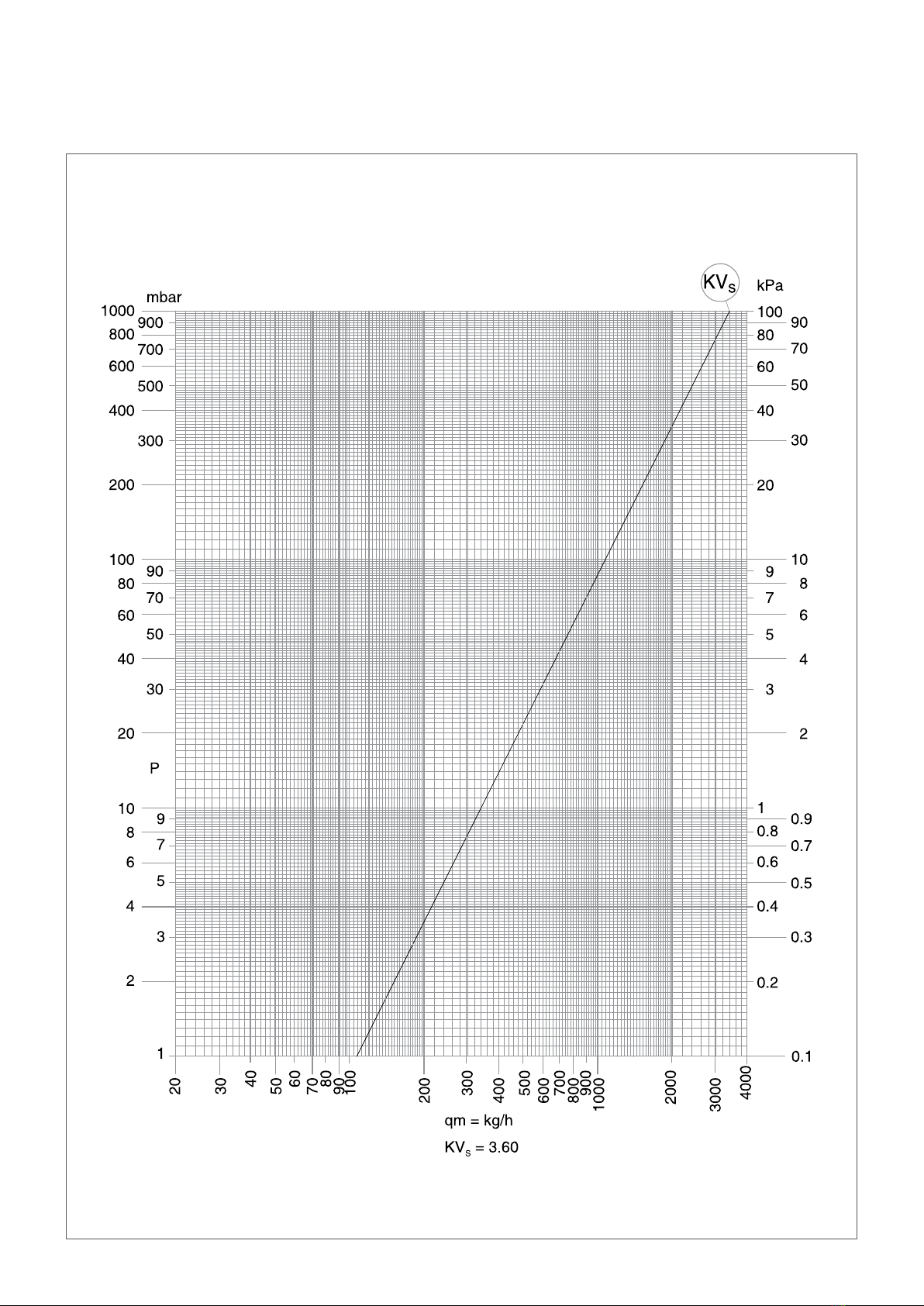

Pressure Drop Diagram

Pressure drop figures based on the -way valve fully open position.

ClimaAir20

. Return Valve Pre-Setting Screw Adjustment

The system can be balanced using the return valve(s) fitted to

the unit. The following procedure must be carried out for correct

regulation and balancing of the system:

Return valve pre-setting adjustment:

>Remove the top cap to reveal the adjustment mechanism.

>Use a screwdriver to loosen and remove the slotted pin inside

the central hexagonal recess.

>Use a mm Allen key to close the adjustment screw (A).

>Screw the slotted pin back in as far as it will go.

>Mark a reference point “x” aligned to the pin slot for adjustment

of the pin (B) .

>Use the screwdriver to open up the pin. The number of turns

should be determined from the ∆P-Q chart (C).

>Use the Allen key to open up the adjustment screw as far as it

will go (D).

>The pre-setting is now done and does not change when opening

and closing the adjustment screw with the Allen key. Replace

the cap.

Instructions -Way Valve (cont...)

.

Screwdriver

Screwdriver

Allen Key

Allen Key

Top Cap

This manual suits for next models

19

Table of contents

Other Merriott Heater manuals

Popular Heater manuals by other brands

Gasmate

Gasmate ALLURE instructions

Benchmark

Benchmark SYSTEMATE 2000 Series Design, installation and servicing instructions

Sunshower

Sunshower PURE XL installation guide

Chromalox

Chromalox ADH-005 Installation, operation and renewal parts identification

CTC Union

CTC Union CLATRONIC HL 3631 instruction manual

Consort

Consort LST500EWIFI Installation & Control Guide