Merry Tiller G80 Setup guide

"The Original Since 1947"

"Works the Garden -

Not

the Gardener"

u.s.

Patent Numbers 2614474 and 2634666

OWNER'S

"INSTRUCTIONS

M~

UAL

AND

ILLUSTRATED

PARTS

LIST

~

,

/ •

SUBURBAN

·MERRY rlLLER

MODEL

GSO

•

o Manufactured

by

•

MERRY

MANUFACTURING CO.

o

Box

370t •

EDMONDS. WASHINGTON 98020

o o !' -

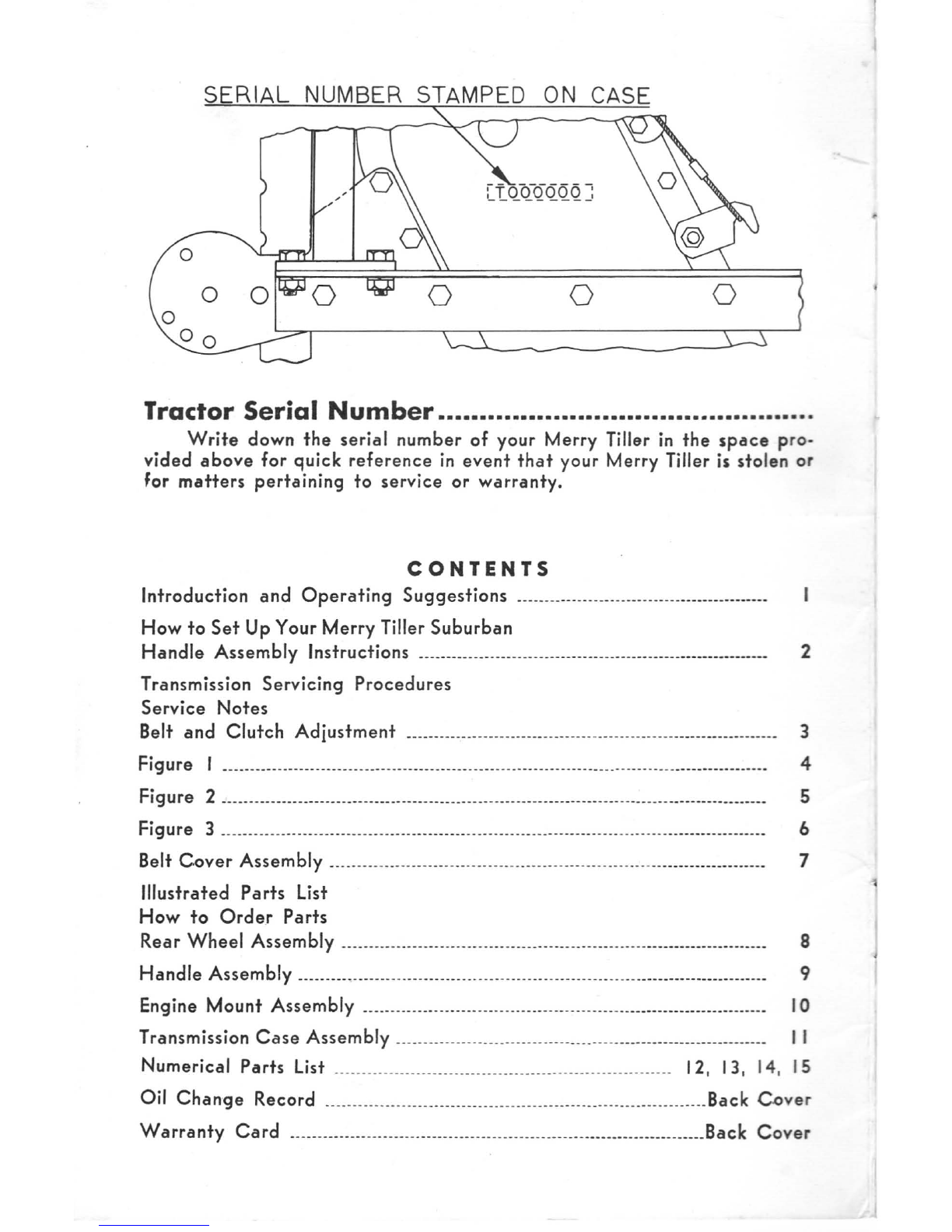

SERIAL

NUMBER STAMPED

ON

CASE

o

Tractor

Serial

Number

.............................................

.

Write

down

the

serial

number

of

your

Merry

Tiller

in

the

space

pro-

vided

above

for

quick

reference

in

event

that

your

Merry Tiller is

stolen

or

for

matters

pertaining

to

service

or

warranty.

CONTENTS

Introduction

and

Operating

Suggestions

_____________________________________________

_

How

to

Set

Up Your

Merry

Tiller

Suburban

Handle

Assembly

Instructions

________________________________________________________________

2

Transmission

Servicing

Procedures

Service

Notes

Belt

and

Clutch

Adjustment

___________

________________

___

_____________

_

_______

________

__ __

_____

3

Figure I

____________

____

__

__

____________________

___

_________________________________________

_________

_______

4

Figure 2

______________________________________________

___

_________________________

_

_________________________

5

Figure 3

__________________________

_

__

_

____________________

___

___________________

___

_________________________

6

Belt

Cover

Assembly

______________________________

__

__

__________________

___

___

_

_____________________

7

Illustrated

Parts

List

How

to

Order

Parts

Rear

Wheel

Assembly

_______

_

______________________

__

______________________________________________

8

Handle

Assembly

________________

_______

___

___

__

________________________________

__

______________

_______

9

Engine

Mount

Assembly

_____

__

__________________

_______

__

_____________________

__

______

___________

10

Transmission

Case

Assembly

__

__

____

__

__________________

_________

___

____________________________

I I

Numerical

Parts

List

_________

_

________________________

_

__________

_

_______________

_ 12, 13, 14,

15

Oil

Change

Record

__

__________

__

_____

_________

_____________

_________

___

__

___

____________

Back

Cover

Warranty

Card

__

__

______

_____________

_______

_________________________

_____________________

Back

Cover

INTRODUCTION

AND

OPERATING SUGGESTIONS

Your

Merry

Tiller

is

the

most

versatile

garden

tractor

ever

developed

for

the

home

gardener

and

does

a soil

preparation

job

second

to

none,

so

a

few

minutes

spent

in

studying

the

following

instructions

will

pay

many

dividends.

The

tiller

will

dig

deeper

and

move

forward

slower

by

pushing

down

on

the

handles,

and

it

will

go

ahead

faster

but

at

a

shallower

depth

by

raising

up

on

the

handles.

The

speed

of

the

rotors

is

controlled

by

the

use

of

the

throttle.

To

control

the

depth

of

tilling,

the

Merry

Tiller

must

be

operated

with

both

the

proper

throttle

speed

and

correct

up-and-down

hand

pressure

on

the

handles.

Raising

up

means

going

forward.

This

action

releases

the

grip

of

the

skid

in

the

soil,

allowing

the

Merry

Tiller

to

progress

ahead.

Pushing

down

means

slowing

down

or

even

standing

still. This

directs

the

skid

into

the

soil,

thus

holding

the

Merry

Tiller

back.

Adjust

throttle

for

desired

speed

of

rotors

.

When

a

person

is

first

learning

the

proper

use

of

the

Merry

Tiller,

it

is

not

unlikely

that

he

will

encounter

an

uneven

or

"bucking"

action

in

the

operation

of

the

machine.

A

little

practice

will

accustom

the

operator

on

how

to

overcome

this.

Never

push

on

the

machine

if

it

has

dug

itself

in

to

a

depth

of

six

to

ten

inches

in

order

to

get

it

to

move

forward,

This

is

ac-

complished

by

slightly

raising

up on

the

handles

and

tilting

the

machine

slowly

from

one

side

to

the

other.

To

acquire

the

knack

of

letting

the

Merry

Tiller

do

the

work

without

effort

on

the

part

of

the

operator,

we

offer

the

following

suggestions:

I.

Adjust

tail

skid

and

rear

wheels

so

the

handles

are

at

such

a

height

that

your

arms

hang

straight

down

to

contact

them.

Rear

wheels

should

be

removed

for

deep

talaqe

or

ease

of

turning

in

confined

areas.

Caution:

Keep

hands

clear

of

belt

while

engine

is

running.

2.

Operate

the

Merry

Tiller

at

about

half

throttle.

3.

Don't

hurry

the

job

-

proceed

at

a slow

walk

-

give

the

machine

time

to

do

its

job.

4.

Concentrate

on

keeping

your

arms

relaxed.

(There

is

a

natural

tendency

for

any

beginner

to

tense

up.)

Operation

actually

takes

very

little

effort.

Let

the

Tiller

do

the

work.

5,

When

tilling

on

sloping

ground,

turn

the

front

of

the

machine

up

hill

to

sufficiently

counteract

the

tendency

to

run

down

hill.

6.

For

best

results,

operate

at

reduced

throttle

settings

when

the

ground

is

extremely

hard

or

rough.

7.

When

cultivating,

raise

the

tail

skid until

the

handles

are

the

proper

height

as

described

in

Item

1

or

set

rear

wheels

in

position.

Pro-

ceed

at

a

slow

walk,

watching

the

rotor

as

it

tills

along

the

row.

S.

TIGHTEN

ALL NUTS

AND

BOLTS PERIODICALLY

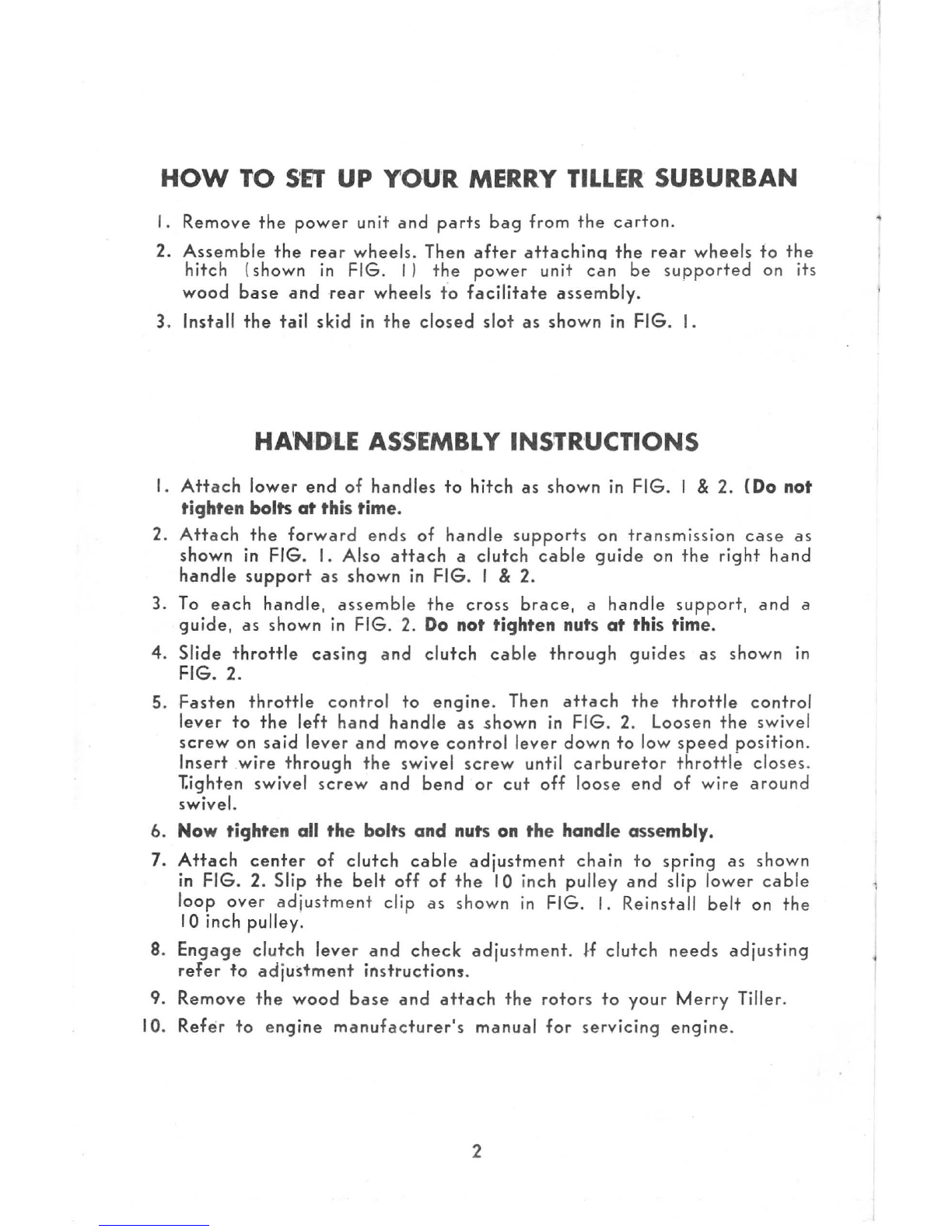

HOW

TO

SEll'

UP

YOUR

MERRY

TILLER

SUBURBAN

I.

Remove

the

power

unit

and

parts

bag

from

the

carton.

2.

Assemble

the

rear

wheels

. Then

after

attachinq

the

rear

wheels

fo

the

hitch

(

shown

in

FIG. I )

the

power

unit

can

be

supported

on its

wood

base

and

rear

wheels

to

facilitate

assembly.

3. Install

the

tail

skid

in

the

closed

slot

as

shown

in FIG. I.

HA'N'D1

LE

ASS

'E'MBLY INSTRUCTIONS

I.

Attach

lower

end

of

handles

to

hitch

as

shown

in

FIG. I & 2. (Do not

tighten bolts

at

this time.

2.

Attach

the

forwa

rd

ends

of

handle

supports

on

transmission

case

as

shown

in

FIG. I. Also

attach

a

clutch

cable

guide

on

the

right

hand

handle

support

as

shown

in

FIG

. 1 & 2.

3.

To

each

handle,

assemble

the

cross

brace,

a

handle

support,

and

a

guide,

as shown

in

FIG. 2.

Do

not tighten

nuts

at

this

time.

4.

Slide

throttle

casing

and

clutch

cable

through

guides

as

shown

in

FIG. 2.

5.

Fasten

throttle

control

to

engine.

Then

attach

the

throttle

control

lever

to

the

left

hand

handle

as

shown

in

FIG

. 2. Loosen

the

swivel

screw

on

said

lever

and

move

control

lever

down

to

low

speed

position.

Insert

.

wire

through

the

swivel

screw

until

carburetor

throttle

closes

.

T.ighten swivel

screw

and

bend

or

cut

off

loose

end

of

wire

around

swivel.

6. Now tighten all the bolts and nuts

on

the handle assembly.

7.

Attach

center

of

clutch

cable

adjustment

chain

to

spring

as

shown

in FIG. 2. Slip

the

belt

off

of

the

10 inch

pulley

and

slip

lower

cable

loop

over

adjustment

clip as

shown

in

FIG. I. Reinstall

belt

on

the

10 inch

pulley

.

8.

Engage

clutch

lever

and

check

adjustment

. H

clutch

needs

adjusting

refer

to

adjustment

instructions

.

9.

Remove

the

wood

base

and

attach

the

rotors

to

your

Merry

Tiller.

10.

Refer

to

engine

manufacturer's

manual

for

servicing

engine.

2

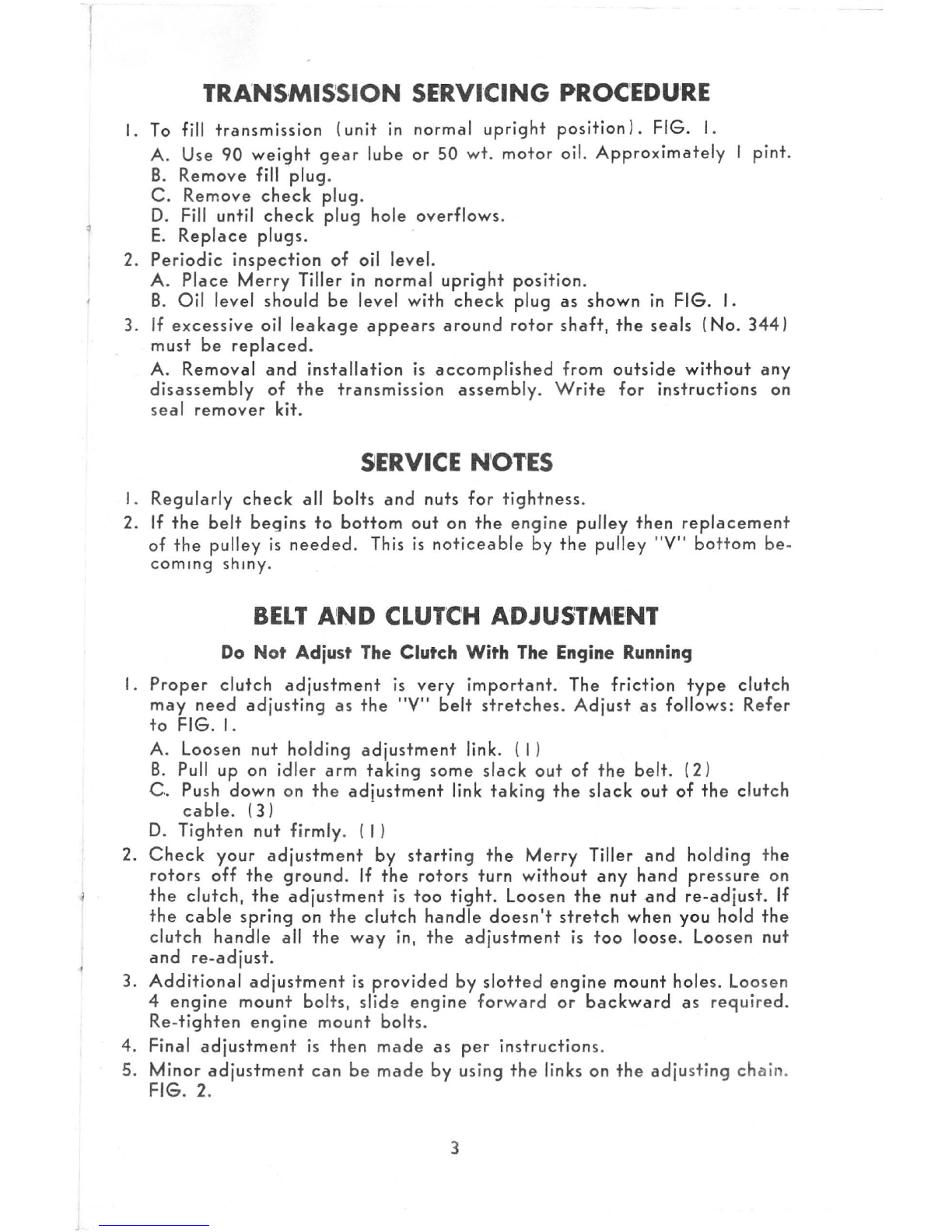

TRANS,

MISSION

SERVICING PROC'

EDU'RE

I.

To fill

transmission

(unit

in

normal

upright

position).

FIG. I.

A. Use

90

weight

gear

lube

or

50

wt.

motor

oil.

Approximately

1

pint.

B.

Remove

fill

plug

.

C.

Remove

check

plug.

D.

Fill until

check

plug

hole

overflows.

E.

Replace

plugs.

2.

Periodic

inspection

of

oil

level.

A.

Place

Merry

Tiller in

normal

upright

position.

B.

Oil

level

should

be

level

with

check

plug

as

shown

in

FIG.

I.

3. If

excessive

oil

leakage

appears

around

rotor

shaft,

the

seals

(No.

344)

must

be

replaced.

A.

Removal

and

installation

is

accomplished

from

outside

without

any

disassembly

of

the

transmission

assembly.

Write

for

instructions

on

seal

remover

kit.

SERVICE N'

OTES

I.

Regularly

check

all

bolts

and

nuts

for

tightness.

2. If

the

belt

begins

to

bottom

out

on

the

engine

pulley

then

replacement

of

the

pulley

is

needed.

This

is

noticeable

by

the

pulley

"V"

bottom

be-

coming

shinY.

BElT AI

ND

CLUrCH

ADJU5rM

'ENT

Do

Not Adjust

The

Clutch With

The

Engine

Running

I.

Proper

clutch

adjustment

is

very

important.

The

friction

type

clutch

may

need

adjusting

as

the

"V"

belt

stretches.

Adjust

as

follows:

Refer

to

FIG.

I.

A.

Loosen

nut

holding

adjustment

link.

(I)

B. Pull

up

on

idler

arm

taking

some

slack

out

of

the

belt.

(2)

C.

Push

down

on

the

adiustment

link

taking

the

slack

out

of

the

clutch

cable.

(3)

D.

Tighten

nut

firmly.

(I)

2.

Check

your

adjustment

by

starting

the

Merry

Tiller

and

holding

the

rotors

off

the

ground.

If

the

rotors

turn

without

any

hand

pressure

on

the

clutch,

the

adjustment

is

too

tight.

Loosen

the

nut

and

re-adjust.

If

the

cable

spring

on

the

clutch

handle

doesn't

stretch

when

you

hold

the

clutch

handle

all

the

way

in,

the

adjustment

is

too

loose.

Loosen

nut

and

re-adjust.

3.

Additional

adjustment

is

provided

by

slotted

engine

mount

holes.

Loosen

4

engine

mount

bolts,

slide

engine

forward

or

backward

as

required.

Re-

tighten

engine

mount

bolts

.

4. Final

adjustment

is

then

made

as

per

instructions

.

5.

Minor

adjustment

can

be

made

by

us

in

g

the

links on

the

adju

sting

chain

.

FIG.

2.

3

TAIL

SKID

FIGURE I

R/H

S

IDE

VI

EW

4

o 0

J

FIGURE

2

REAR

V

IE

W

5

FIGURE 3

2659

2647

\

.J

BELT

COVER ASSEMBLY

'

Herpful

Hint

When

installing

the

Brackets on

the

Unit

do

not

tighten

capscrews

until

step

3

is

completed

below.

Assembl.y

I.

Attach

No.

2659

Bracket

on

Case

Fig.

3.

2.

Attach

No.

2648

Bracket

on Engine

Mount

Fig. 3.

3.

Mount

No.

2658

Cover

over

the

Brackets,

and

No.

2647

Belt

Release.

Fig. 3. Using 3 No.

2560

Capscrews,

3 No. 2661 Locknuts

and

one

No.

400

Washer

on

the

Locknut

side

of

the

No

2647

Belt

Release.

(To

protect

the

slots from

damage

.)

COVER ASSEMBLY

2662

.

-2560

~

-400

2

-2661

2 6 5

7

26

59

26

6

1

-

~

-

t.

2

56

0

--

!!

-

~

6'

ILLUSTRATED PARTS

LIST-MODEL

G80

HOW

TO

ORDER

PARTS

I.

THE MODEL NUMBER

OF

YOUR MERRY TILLER MUST

BE

GIVEN

WHEN

ORDERING

PARTS

. THE MODEL NUMBER

IS

INDICATED

ON

THE

UPPER

L.

H.

CORNER

OF

HANDLE

CROSS BRACE NEXT TO THE MERRY TILLER

OVAL.

MODEL

NO.

2.

HOW

TO FIND THE CORRECT NUMBER

OF

PARTS

YOU NEED.

Refer

to

the

following

pages

illustrating

parts

and

locate

the

part

needed

in

the

correct

exploded

view

and

note

the

part

number.

All

parts

shown

that

have

part

numbers

can

be

purchased

separately.

After

the

part

number

has

been

identified,

refer

to

the

fol-

lowing

Parts

List,

pages

12, 13, 14, 15,

where

these

parts

are

listed

in

numerical

order.

,

• • * * • •

REAR

WHEEL ASSEMBLY

2479

10.3

3

I

~

~

--'

-r

8

HANDLE

ASSEMBLY

2620

9

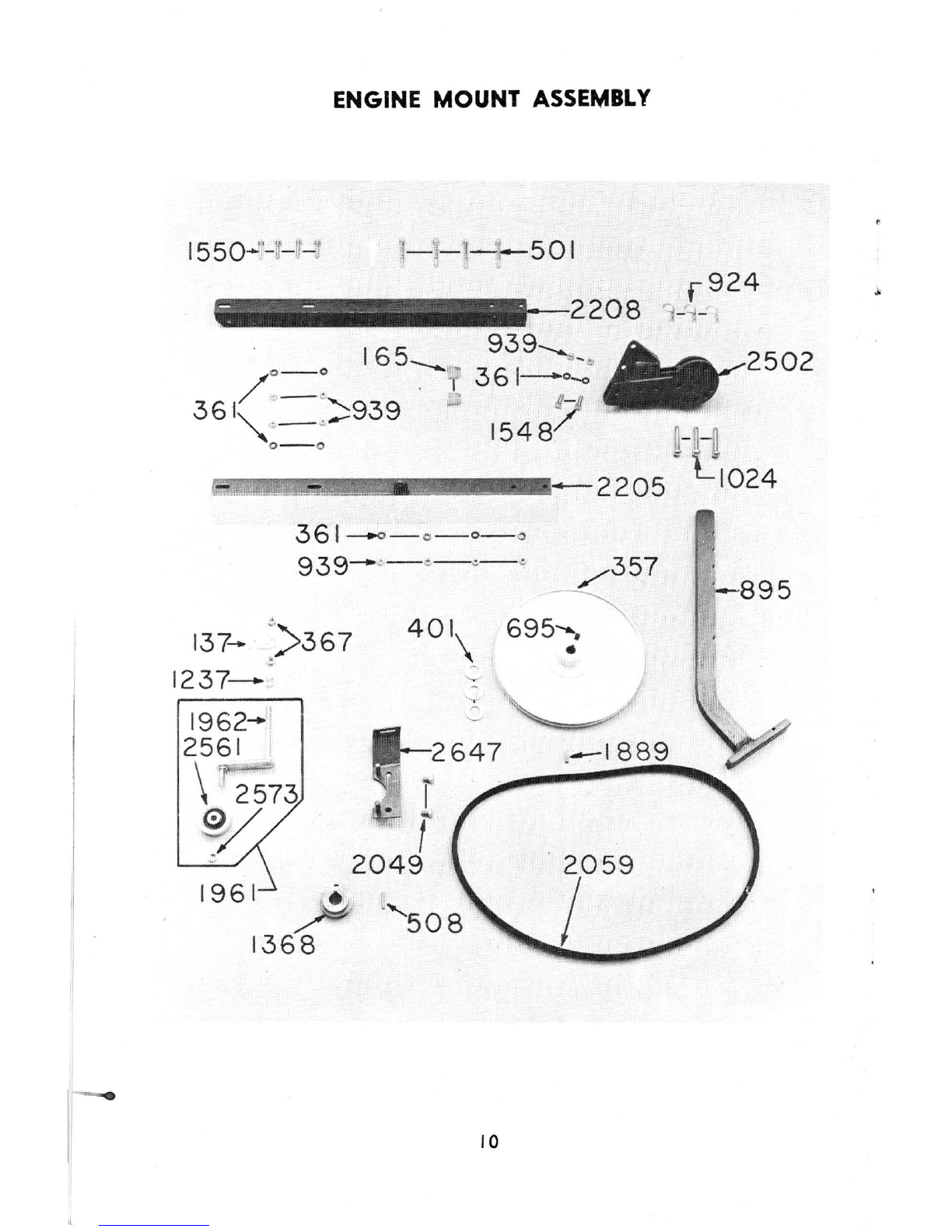

ENGINE MOUNT

ASSEMBLY

361-.0-

0- 0- 0

939-

,,

-

e

-¢-

~

/357

----~

137- :

>367

401\

695-:. "

1237-

!i

1962-

'

2561

\

~

2573

';;

'-

~'

~

tr

2647

.

-1889

~I

r

~~

2049

1961 P

1368

10

502

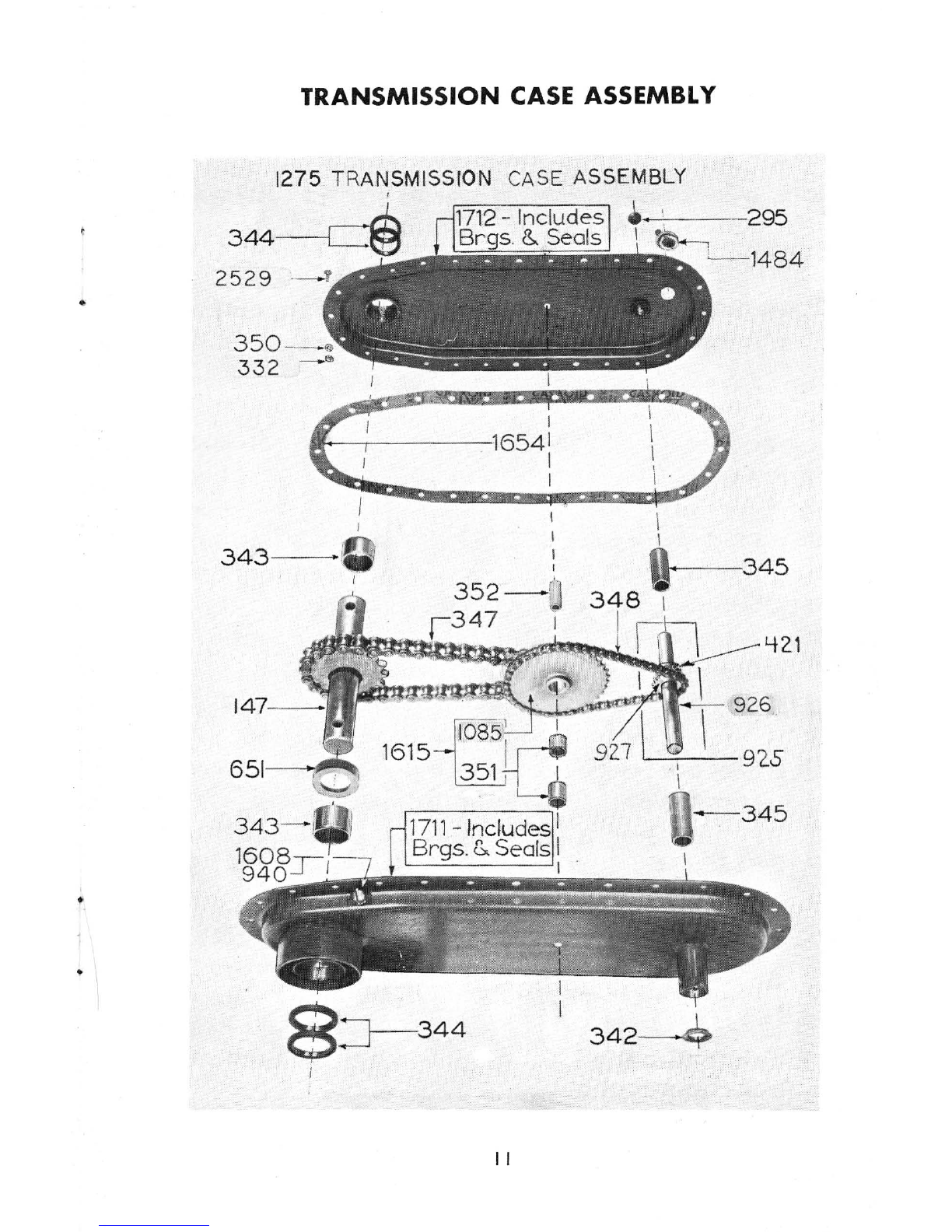

TRANSMISSION

CASE

ASSEMBLY

1275 TRAN

SM

ISSION CASE ASSEMBLY

,

344

-

--j

."-;,ilI

I

11f+-----.-----1

654

i

. I

I

343

-----

-t_

I

651

-~'

8:J--

344

"

1.........:-

--

295

,

I .

\

\

1484

348

~

-.

--34

5

342

~

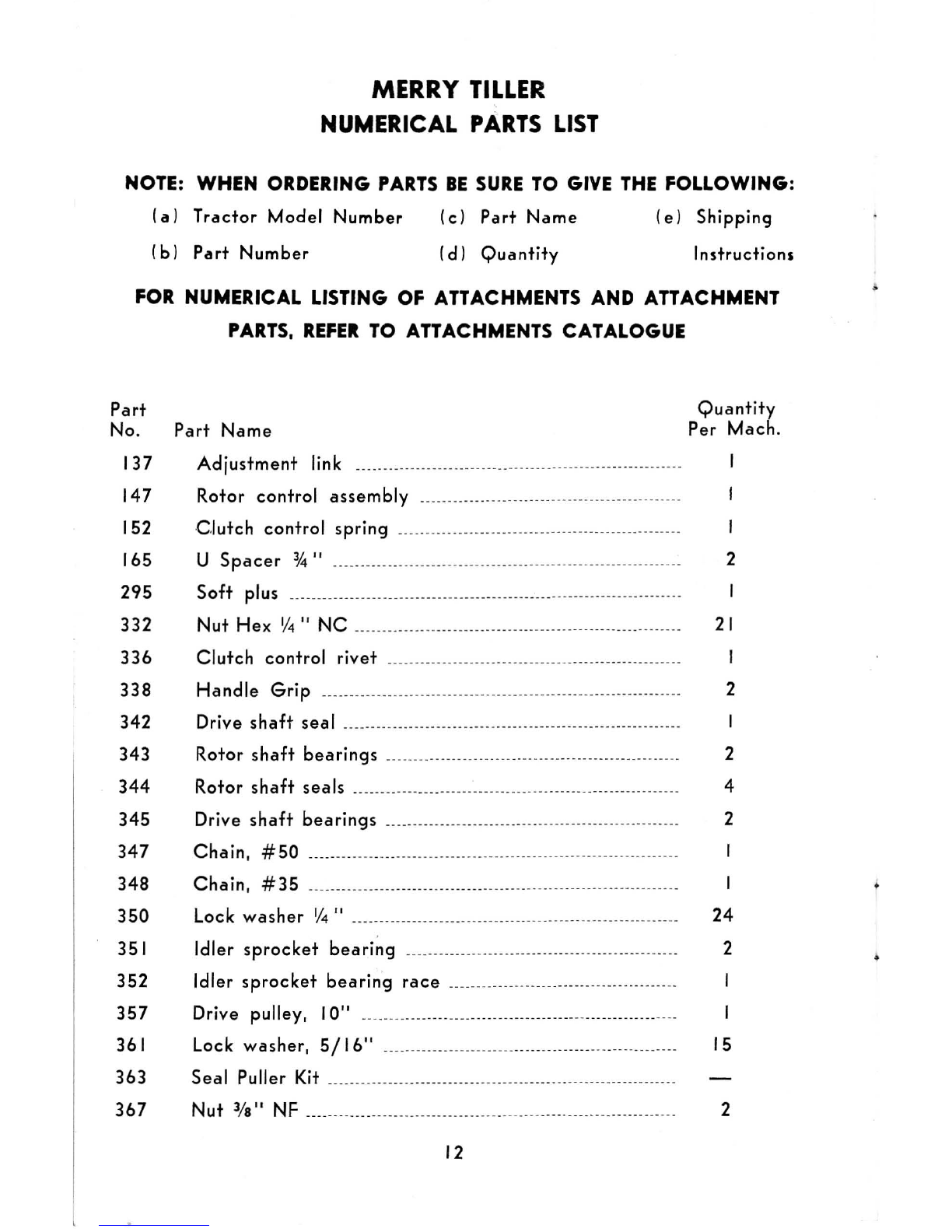

MERRY

TILLER

NUMERICAL

PARTS

LIST

NOTE: WHEN ORDERING

PARTS

BE

SURE

TO

GIVE

THE

FOLLOWING:

(a)

Tractor

Model

Number

(c)

Part

Name

(e)

Shipping

(b)

Part

Number

(d)

Quantity

Instruction,

FOR

NUMERICAL LISTING OF ATTACHMENTS AND ATTACHMENT

PARTS,

REFER

TO

AnACHMENTS

CATALOGUE

Part

No.

Part

Name

137

Adjustment

link

147

Rotor

control

assembly

_____

__

___

__ __

_

_____

_

_______

___

_________

_

______

_

Q u

antity

Per

Mach.

152

Clutch

control

spring

___________________

_

______________

___

_______________

I

165 U

Spacer

¥.!"

__________

_

__

______

__ __

___

__

_____________

___

__

____

_______

_

___

__

_ 2

295

Soft

plus

__

_

___

__

_____________________

_

______

_

___________

__ __ __

-

--------------

---

332

Nut

Hex

if4"

NC

_

____________

__

__________

_

__

_______________

_____

_

__

_

________

21

336

Clutch

control

rivet

________

_

_____

_

_____

___

___________

____

___

_

_____

_

___

__

_

338

342

343

344

345

347

Handle

G r

ip

_________

_

__ __

_

____

___

_______________

___

_

__

___

________

---

---

------

Drive

shaft

sea

I

____

____

__

__ __

_

__

_

__

_

__

____

_

__________

_

________

__

__

__

__

_

_____

_

Rotor

shaft

bearings

--------------------

-

------

-

-----------

-

---

--

----

--

--

-

Rotor

shaft

seals

__

_________________

____

__

_

__

_

_______

____

_

__

_

_________

______

_

Drive

shaft

bea

ri

ngs

--

-

--

--------

--

-

--

-

---

-

--

---

----

---------

-----

---

-----

Chain,

#50

_____ _____

__

__

____

__

_____

____

______

_

____________

_

__

_

_______________

_

348

Cha

in, #

35

___

_____

____

_____

_

___

____

__

____

_____

__

_

___

__

___

_

____

__

--

---------

__

_

2

2

4

2

350

Lock

washer

if

4"

___

_

___________

_____

___

________

___

__

__

____

__

___

_

_______

_

____

24

351

Idler

sprocket

bearing

____

___

____

_____

_

__

__ __

_____

_

____________

_

___

____

_ 2

352

Idler

sprocket

bearing

race

__

__

____

____

___

____

_

___

__________

___

__

_

__

_

357

Drive

pulley

, I

0"

____

_

___

___

____

__

____

___

__

__

______

__

____

______________

---

_

361 Lock

washer,

5/

16"

__

___

__

___

_

_______

__

____

_____

__

__

______

__

___

___

___

____ 15

363

Seal

Puller Kit

_____

_________

__

_____

_

___

__

_

___

_

__

___

____

____________

_-__

_____

__

367

Nut

l/S" NF _

___

____

_________

___

_

__

_

_________

_

____

_

____

_________

___________

____

_ 2

12

Part

No.

Part

Name

396

400

401

421

501

508

Lock

Washer

3/

S" ____________ __

_______

_____

__

__

______

_

____________

_

Washer

Flat 1/4"

___

______

___

___

__

_

______

___

Drive

shaft

washer

5/

S"

_____

-

__

_

__

____ _ _

______

__

_____

__

_____

______

_

Roll

Pin 1/4" X

1_

Y4"

_____

___

_____

______

__

--

-

____

_

__

_

___

_

__

__

___

_

Cap

screw

5/16"

NF

x 21

/2"

____________________

_

_________

_

Engine pulley key _

______

___

_________

_

___

_

651

Spacer-Rotor

shaft

_

____

___

____

_

__

_

__

______

__

__

__

_

______

__

_

_____

__ __

__

695

Set

Screw

5/16"

NC x

3/.1"

_

___

____

___

__

__

__

_

_________

__

___

__

_____

_

895

924

925

926

Rear Skid

____

_

_____

_

__________

____

_______

__

__

_

___ ___

_

___

_

___

_

__

------

-

--

--

-- --

---

Hairpin

cotter

__

____

_

______

______

__

_

__

__

____

__

___

__

___

-

--

-

----

-- - -------

Drive

shaft

w/

sprocket

_

_________

__

_____

___

__

___

__

__ __

_____

___

____

__

__

Drive

shaft

w/o

sprocket

_______

_

__

___. _

__

___

__

__

____

___

_

927

Sprocket

-Drive

shaft

__

__

____

939

940

1024

1033

1080

1085

1237

1275

1368

1484

1539

1548

1550

1608

1615

1654

Nut

5/16"

Check

plug

gasket

5/16"

ID

__

_

Pin,

3Ja"

x

21/4"

_

__

_

__

_

__

____

__ __

____

_._.

__

.

__ __

_.._

__

..

___

._

..._.._..__..

__

Wheel,

10

x

1.75

..

_______

_. .. _ _

Nut, sq.

3/

S"

NC

__

___..._

__

_

__

__

___

__

Idler

sprocket

w/o

bearing

___

___

_.._

..

.

__

.

____

__

._

__

_._

Spring-compression idler arm

__ __

.___

__

_._

__

.

Replacement

case

assembly ._

__

___...

___

___

._

.

__

..

___

_

Engine pulley,

%"

bore

_________

__

..

__

_..

__

_.. ___.

___

.

Oil filler plug

__

.

___

...__

._

___

__

_ __

____

___

Nut -Keps-I

032

Screw,

cap

5/16"

NF

x

1"

__ ____

Screw-cap

hx

hd.

5/16"

NF

x

1-1/2

" Pltd.

__

Screw, rd. Hd.

5/16"

NF

x

1/

2"

___

_ _

Idler

sprocket

assembly with brgs.

Gasket

__

__

__

__________

__

__

__

1711

Case

assy. -L.H.

w/brg.

&

seals_

1712

Case

assy. -R.H. w

/brg.

& seals _

13

Quantity

Per Mach.

2

I

3

4

I

5

15

I

5

2

2

.I

2

2

4

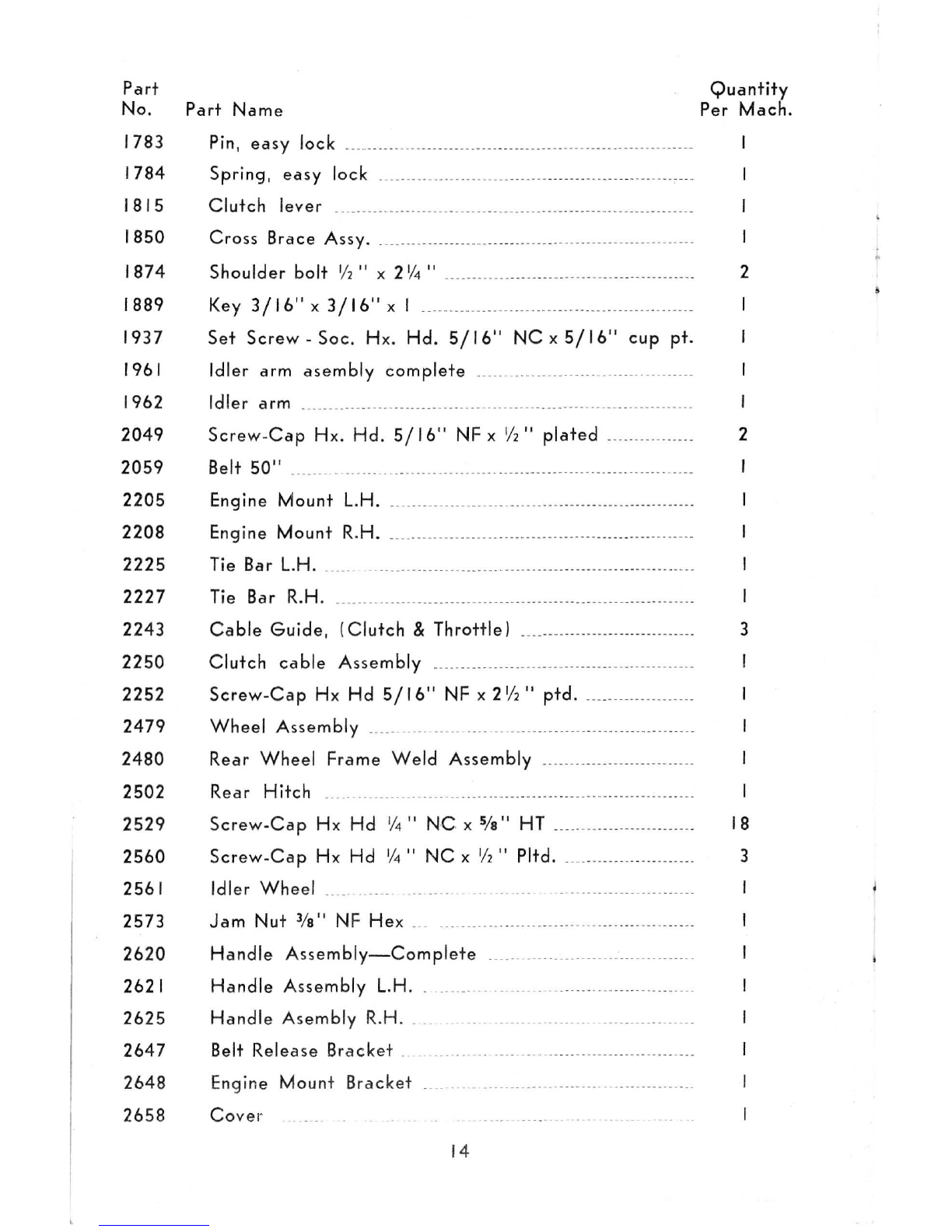

Part

No.

Part

Name

1783

1784

1815

1850

1874

1889

Pin,

easy

lock

__

_

Spring,

easy

lock

Clutch

lever _

__

___

_

___

____

__

__

_

___

_____

________

____

_________

__

__

_

_______

____

_

Cross

Brace

Assy

. _

________

_____

____

__

___

_._

_____

_

__

________

__

___

_

____

_

__

_

Shoulder bolt 1

12

" x 2

\/4

"

___

_______

____

__

_

_________

__ __

_______

____

___

_

Key

3/16"

x

3/16"

x I

________

____

___

___

_

__

______

__

__

_

____

__

__

_____

_

1937

Set

Screw

-Soc. Hx. Hd.

5/16"

NC

x

5/16

"

cup

pt.

1961

Idler arm

asembly

complete

_

_____________

_

__

__

__

___

____

_____

___

_

1962

2049

2059

Idler arm _

__________

___

_

__

_

_______

__

___

_

__

__

____________

_

____ ____

_____

__________

_

Screw-Cap

Hx. Hd.

5/16"

NF

x 1/2"

plated

_____

________

__

_

Belt

50"

_

_____

_______

__

__

__

_

____________

__

___

_

__

_0

__ __

_____

______

__

_

__

___

_

__

_ _ _ _ _

2205 Engine Mount L.H.

____

______

____ ____

___

_

__

_

___________

__

__

____________

_

__

_

2208

2225

2227

2243

Eng

ine Mount R.H. _

___

___

____

_

___

_

____

_

___________

____

_______

__

____

______

_

Tie Bar L.H.

___

_

____

__

_____

__

_____

_

____

__

_

___

_

___ ___

_

___

_

____

___

__

__

_______

___

Tie Bar R.H.

______

__

_____

__

___

____

_

__

__

__

_

__

___

___

__

____________

_

_______

____

._

Cable

Guide

,

(Clutch

& Throttle) __

__

-

_______________

___

___

__

_

__

_

2250

Clutch

cable

Assembly _

__

_____

__

__

__

_

___

_

__

_____.

__

_____________

__

___

_

2252

Screw-Cap

Hx Hd

5/16"

NF

x 2 1

/

2"

ptd.

___

_______

__

_

___ ___

_

2479

Wheel

Assembly

_____

_.

____

_.

___

__

__

__

___

_

__

_._

___

___

_

___

___

_

___________

_

2480

Rear

Wheel

Frame

Weld

Assembly _

__ __

___

__

_________

_

_______

_

2502 Rea r Hitch _

__

____

_____

____

___

_

________

___

._

__

__

_

___

_______

___

__

__

___ ___

__

_

2529

2560

2561

2573

2620

2621

2625

2647

2648

2658

Scr

ew-Cap

Hx Hd 1

/4"

NG

x

Sfs"

HT

_

____

___

__

_

__________

_

___

_

Screw-Cap

Hx Hd 1

/4

"

NC

x 1

12

" Pltd. _

__

_

_______

_

____

_

__

____

_

Idler

Wheel

_

__

----.

-----

---

-.-

--

-- -- --

Jam

Nut

3/

S" NF Hex _

Handle

As

s

embly-Complete

____

_____

_____

_..

______

__.

_____

_____

_

Handle

Assembly

L.H

.

__

__

__

___ ___

_____

__

Handle

Asembly R.

Ho

__

Belt Release

Br

ac

ket _

En

gine Mount

Br

acket

Cov

er

14

Quantity

Per Mach.

2

2

I

3

18

3

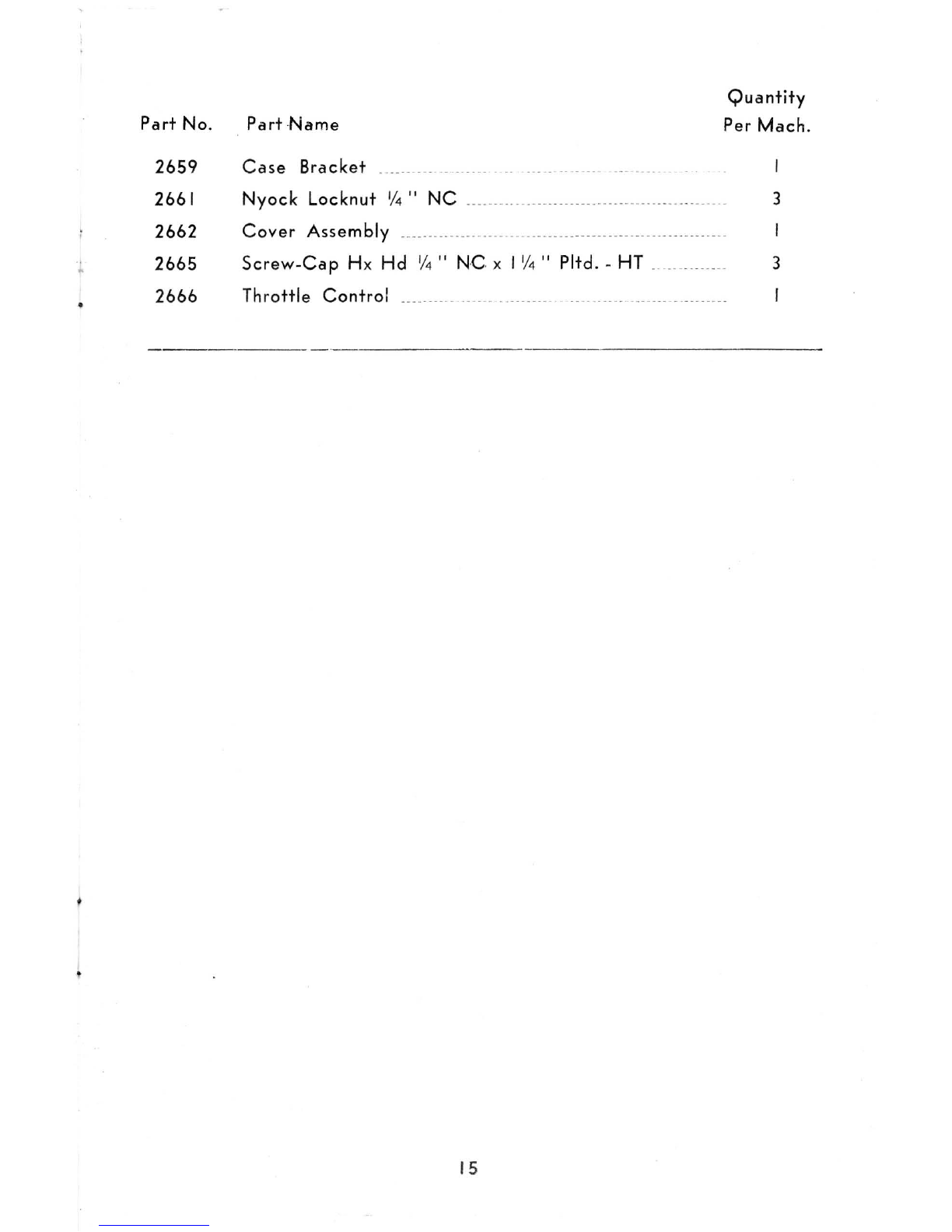

Part

No.

Part

Name

Quantity

Per

Mach.

2659

Case

Bracket

2661

2662

2665

Nyock

Locknut

'/4

"

NC

_

_________

__

___

_____

________

___

___

__

Cover

Assembly

___

______

__________

_

__

_

____

_

__

_____

_______________

__

_

_____

__

Screw-Cap

Hx

Hd

'

/4

"

NC

x 1'

/4

" Pltd. -HT __._

___

..___

2666

Throttle

Control

_____

..

__

_

___

__

_

_______

_ ._

___ ___

_.

__

_

__

__

_

__

____

.

15

3

3

OIL

CHANGE

RECORD

16

IRJMMMIMM~

WAR

RAN

TV

CE

RT

I

Fie

ATE

M~~~

:J0R

ONE

YEAR

from purchase

date,

Merry Manufacturing

Company

will

replace

for

the

original purchaser,

FREE

OF

CHARGE, any

part

or

parts

found, upon

examination

at

our

factory

at

Edmonds, Washington, to

be

defective

under normal

use and service, on

account

of

defects

in

material

or workmanship.

ALL

TRANSPORTATION CHARGES ON

PARTS

SUBMITIED

FOR

REPLACEMENT

UNDER

THIS WARRANTY

MUST

BE

BORNE

BY

PURCHASER.

THIS WARRANTY shall

not

be

effective

If

the

product

has been

subject

to

misuse,

negligence or accident, nor if

the

product

has been

repaired

or

altered

outside

of

our Edmonds Factory, or Authorized. Service Station,

in

any

respect

which,

in

our

judgment,

affects

its condition

or

operation.

FOR

COMMERCIAL

USE,

WARRANTY

LIMITED

TO

THIRTY

DAYS.

The

engine

is

covered under

separate

Warranty

from Engine Manufacturer.

MERRY

MANUFACTURING

COMPANY

Th;s

Warranty

shall

be

e

ff

e c t i v e

only

providing

ottached

Warranty

Card

is

properly

filled

oul

and

returned

to

Merry

Manu-

facturing

Co.

ot

time

of

purchase.

SAVE THIS

WARRANTY

CARD

Fill

in

this information

and

retain

for

your own

record.

Serial No...............................................

IMPORTANT

(Not

engine Serial No.)

Model No..............................................

To

make

Warranty

valid.

fill

in

and

return

attached

card.

Purchased

from ..._.........

________

.

_____

.

__

..

___

..

.'

Date

Purchased

..

______________________

..

__

...

____

..

For

Prompt

and

Accurate

Service

Serial

Number

must always

be

given

when

ordering

parts

or

writing

for

any

information.

r-

)

Merry

Manufacturing

Co

•

Box

370

Edmonds, Wash.

98020

Be

sure

to

fill

in

the

attached

Warranty

Card

below

and

mail

it

immediately!

WARRANTY CARD

Please print carefully

In

IDk

Serial No.__

_____

__

__

__

_______

_

___

Model No._

___________

_

___________

Date Purchased

________________

_

I

Not

engine

S.ri

,al No.!

De

aIer

Pu

rch

ased f

rom

____

___________

__

___________

_

____________________________________________________________

_

, Address

______

____

________________________

__

____________________________

State

________________

Zip

_______________

_

OwnerI s Name _

________

__

_______________

_

____

_

_______________________________________________________________________

_

i Add

re

ss

----

-

---------

----

_

---

--

-----

--

------

--

----

----

---

:..

--

---

-

----

---

_

--

-

-----

..

-----

-

---

-----

----

----

-

----------

_____

_

I

I

Town

----

--

-

------------

--

----------------

--

-----

County

----

---

--

-

--------

--

------

--

--

-

-----

State

----------------

Please Check One of the Following:

Suburban 0 Rural 0 Commercial 0

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Sunforce

Sunforce SOLAR user manual

GARDEN OF EDEN

GARDEN OF EDEN 55627 user manual

Goizper Group

Goizper Group MATABI POLMINOR instruction manual

Rain Bird

Rain Bird 11000 Series Operation & maintenance manual

Cub Cadet

Cub Cadet BB 230 brochure

EXTOL PREMIUM

EXTOL PREMIUM 8891590 Translation of the original user manual

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

Snapper

Snapper 1691351 installation instructions