MESSRING M-LIGHT LED User manual

8LE-D23_BA_E

20.03.2015

1/58

OPERATING INSTRUCTION

M=LIGHT LED, 1000W 8LE-D23

Contents

Chapter 1 About this Operating Instruction 2

Chapter 2 Health and Safety 5

Chapter 3 System Description 9

Chapter 4 Setup and Functioning 12

Chapter 5 Software 20

Chapter 6 Maintenance 44

Chapter 7 Technical Data 50

Chapter 8 Handling 52

Chapter 9 Special Accessories 57

Effective from Serial Number

15-00000

Effective from Software Release Number

2.0.0

Meaning of this Operating Instruction

About this Operating Instruction

2/58

20.03.2015

8LE-D23_BA_E

Chapter 1 About this Operating Instruction

Contents

1.1. Meaning of this Operating Instruction 2

1.2. Description of Signs and Symbols 3

1.2.1. Warnings 3

1.2.2. Description of More Signs and Symbols 4

1.2.3. Contact 4

Property Rights According to ISO 16016

The content of this operating instruction is our intellectual property. We ask for your understanding,

that we cannot allow the transmission in whole or in part of this document to a third party,

especially to our competitors.

1.1. Meaning of this Operating Instruction

The operating instruction is part of your product. Consequently, you must keep this operating

instruction so that it is easily accessible for the operating personnel at all times.

When selling or leaving the product to third parties, the operating instruction must be handed over

to the new owner or user. Immediately replace the operating instruction if it is lost or incomplete. In

this case, contact MESSRING Systembau MSG GmbH.

Together with this operating instruction, you shall receive documents of third party manufacturers,

if necessary. Also familiarize yourself with these instructions and read the safety instructions and

warnings contained therein.

For your own safety, observe all safety instructions and warnings in chapter 2 of this operating

instruction. Also observe the warnings and safety instructions on the individual components and

activities in the other chapters.

About this Operating Instruction

Description of Signs and Symbols

8LE-D23_BA_E

20.03.2015

3/58

1.2. Description of Signs and Symbols

1.2.1. Warnings

Depending on the scope of the consequences occurring in case of non-compliance with a warning

(death, irreversible or reversible injury, damage to property), there are 4 different risk levels. Each

risk level is marked with a certain signal word and a warning sign.

DANGER!

Refers to a dangerous situation which will lead to death or severe injury

if it is not avoided.

irreversible

WARNING!

Refers to a dangerous situation which may lead to death or severe injury

if it is not avoided.

irreversible

CAUTION!

Refers to a dangerous situation which may lead to minor or moderately

severe injury if it is not avoided.

reversible

NOTICE!

Damage to property

Description of Signs and Symbols

About this Operating Instruction

4/58

20.03.2015

8LE-D23_BA_E

Warning sign

Meaning

Hazard due to electric voltage

Hazard due to optical radiation

1.2.2. Description of More Signs and Symbols

Symbol

Meaning

…

Step.

Result of a sequence of actions.

Hint / additional information.

New test

Element of the CrashSoft user interface or labeling of an operating element.

1.2.3. Contact

MESSRING Systembau MSG GmbH

Robert-Stirling-Ring 1

82152 Krailling

Germany

Phone: +49 89 898139-0

Fax: +49 89 898139-924

Email: service@messring.de

Health and Safety

Introduction

8LE-D23_BA_E

20.03.2015

5/58

Chapter 2 Health and Safety

Contents

2.1. Introduction 5

2.1.1. Target Groups 5

2.1.2. Main Sources of Danger 6

2.2. Purpose 8

2.2.1. Intended Use 8

2.2.2. Warning of Misuse 8

2.1. Introduction

This chapter provides information on hazards which emanate from the LED

light. The safety instructions and warnings aim to avoid fatal accidents, severe

injuries and damage to property.

Carefully read and observe all instructions in this chapter.

Observe the safety instructions and warnings on the individual

components and activities in the following chapters.

Completely read this operating instruction before beginning with

operation or maintenance of the M=Light-LED.

Observe regional, national and company-internal standards, directives

and regulations.

2.1.1. Target Groups

The chapter Health and Safety contains information for the following groups of people:

I Operator of the equipment in which the M=Light-LED are integrated

I Operating personnel

I Maintenance personnel

Introduction

Health and Safety

6/58

20.03.2015

8LE-D23_BA_E

2.1.2. Main Sources of Danger

DANGER!

Electric shock due to electric charge inside the housing.

Immediately after disconnection, the contacts of the mains plug may still carry

voltage for a short period.

Do NOT touch the contacts of the mains plug directly after switch-off.

DANGER!

Functional impairment of electrical devices due to electromagnetic

radiation.

Electromagnetic radiation emitted by the M=Light LED may impair proper

function of electromedical devices.

Keep a distance off the operating M=Light LED of at least 1 m if you

have a cardiac pacemaker, defibrillators or other electronic implants.

DANGER!

Striking of persons due to falling M=Light LED

M=Light LED falling from the crash lighting frame may strike persons dead.

The M=Light LED must be securely screw-fixed with the crash lighting

frame using an attachment screw of proper dimension.

For screw-fixing the M=Light LED to the crash lighting frame, exclusively

use the attachment holes in the support bracket (Figure 10, Item 3 and 4,

page 19).

DANGER!

Electric shock and burning hazards at melting power cable.

Using the wrong power cable may lead to overheated power cable and thus to

the risk of burning hazards and electric shock due to melting power cable.

Only use the power cable delivered with the M=Light LED by

MESSRING.

Health and Safety

Introduction

8LE-D23_BA_E

20.03.2015

7/58

CAUTION!

Damage to the eyes due to intensive irradiation of the eyes.

Chronic irradiation with light from the M=Light-LED may lead to damage of the

retina and cornea of the eyes.

Keep appropriate safety distance to the switched-on lamp.

When working at the switched-on lamp, wear protective goggles, e.g.

Infield, Terminator Orange UV-400 / Art.no.: 9380420

Do NOT stay within radiation range of the lamp longer than required.

Do NOT directly look into the beam of light.

Do NOT use M=Light LED as lighting for work spaces.

CAUTION!

Burns at hot surfaces

Burning hazard at the housing of the M=Light LED at temperatures of up to

100°C during operation at 120 V nominal voltage.

After operation at 120 V nominal voltage, leave the M=Light LED to

cool before touching it.

Before touching the M=Light LED, read the temperature in the bottom

line of the M=Light Control software.

Burning hazard at the shaft of the lamp suspension after longer operating

time.

Do NOT touch the shaft of the light suspension during operation or

shortly after switch-off of the light.

NOTICE!

Damage and breakdown of the M=Light LED

Overheating of the M=Light LED due to insufficient ventilation

Do NOT cover the ventilation slots.

NEVER position the M=Light LED directly on the housing.

Do NOT mount the M=Light LED in the flow range of the exhaust air of

other lights and lamps.

NOTICE!

Damage and breakdown of individual LEDs due to deposits of grease

or sweat.

Destruction of individual LEDs due to overheated grease or sweat residues.

Do NOT touch the LED array.

If required, rub the LEDs with a dry, clean cotton cloth.

Do NOT use cleaning agents.

Purpose

Health and Safety

8/58

20.03.2015

8LE-D23_BA_E

2.2. Purpose

2.2.1. Intended Use

Stationary lighting of fast sequences that are recorded by means of high-speed cameras in the

indoor area. These may be e.g.:

I Vehicle and sled tests in crash test facilities.

I Airbag ignition and unfolding.

I Tests with partial car bodies or vehicle interior equipment

2.2.2. Warning of Misuse

Do NOT use M=Light-LED in outdoor areas.

Do NOT use M=Light-LED as working lighting for permanent work spaces.

Do NOT use M=Light-LED as on-board lighting.

System Description

Purpose

8LE-D23_BA_E

20.03.2015

9/58

Chapter 3 System Description

Contents

3.1. Setup and Functioning 10

3.2. Main Components of M=Light LED 11

3.3. Special Properties and Performance Data 11

Setup and Functioning

System Description

10/58

20.03.2015

8LE-D23_BA_E

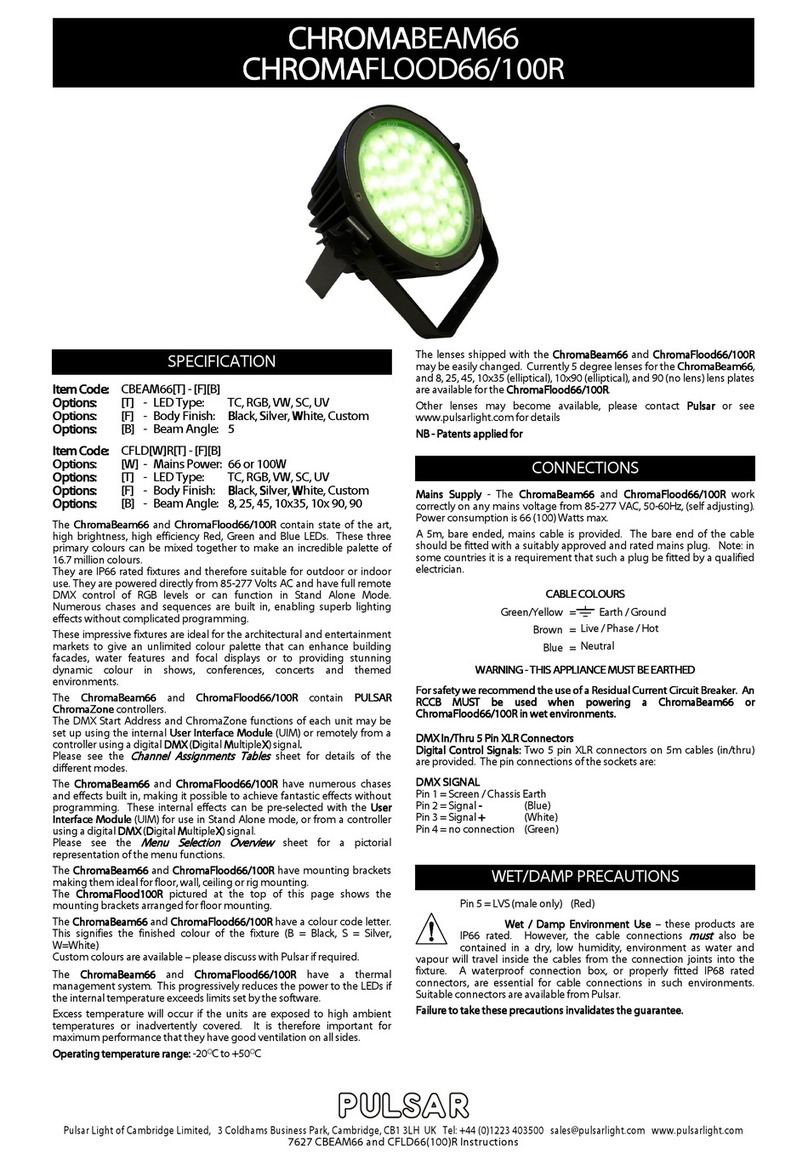

3.1. Setup and Functioning

LED flood light for steady and pulsed operation.

Pulsed operation is synchronized with the high-speed camera. In pulsed operation, 80% more

lighting power can be output compared to steady operation. This is possible because the lighting is

only switched on when the camera requires light. The M=Light-LED can optionally be operated

manually or via the CAN-bus with the help of the software. In pulsed operation it is possible to

eliminate backlight effects due to control of separate M=Light-LED groups. For elimination of

backlight effects, only one camera synchronized with one M=Light-LED group is switched on

(Figure 1).

Figure 1: Synchronization in pulsed operation

Item:

Description

1

Camera 1 switched on

2

M=Light LED group 1 switched on

3

M=Light LED group 2 switched off

4

Camera 2 switched off

5

Camera 1 switched off

6

M=Light LED group 1 switched off

7

M=Light LED group 2 switched on

8

Camera 2 switched on

System Description

Main Components of M=Light LED

8LE-D23_BA_E

20.03.2015

11/58

3.2. Main Components of M=Light LED

I LED array with status indication

I Aluminum housing

I Support bracket for one- and two-point attachment

I CAN-bus connections

I M=Light control software for control of the M=Light LED via CAN-bus

I CAN-bus interface for control of the CAN-bus via PC-USB connection (optional).

3.3. Special Properties and Performance Data

I No warm-up time required - ready for operation directly after switch-on.

I Test object is NOT overheated by radiation of heat.

I Can be synchronized with camera shutter.

I CAN-bus-controlled

I Non-flickering and dimmable

I Stable aluminum housing

I Customized lighting angles

I Service life of the LEDs more than 50,000 hours

I Delay between trigger input and light flash approx 10 µs

Special Properties and Performance Data

Setup and Functioning

12/58

20.03.2015

8LE-D23_BA_E

Chapter 4 Setup and Functioning

Contents

4.1. LED Array 13

4.2. Rear Side of the Housing 15

4.2.1. Connecting / Disconnecting Voltage Supply 15

4.2.2. Establishing Signal Connections 16

4.2.3. Contact Assignment of CAN-Bus Connections 18

4.3. Support Bracket 19

Setup and Functioning

LED Array

8LE-D23_BA_E

20.03.2015

13/58

4.1. LED Array

Figure 2: LED array with status indication

Item:

Description

1

Status indication in the LED array

2

LEDs

3

Front plate

The status display in the LED Array indicates the major operating conditions of the M=Light-LED

Indication:

Operating condition

Permanent

green

M=Light-LED is ready for operation and can be switched on (temperature ≤ 30°C).

Permanent

blue

M=Light-LED is ready for operation and can be switched on (temperature ≥ 30°C; ≤ 90°C).

Flashing

blue

The maintenance counter was scanned by the Maintenance command. After the last

maintenance the M=Light LED has been switched on for more than 150 hours

Permanent

yellow

M=Light LED has heated up so much that the ventilators are switched on. Operation of the

M=Light LED can be continued without further restrictions.

I The current temperature of the M=Light LED is > 40°C

Permanent

red

M=Light-LED is in critical condition. M=Light-LED can be operated without the M=Light being

damaged further due to operation. However, operation is not recommended since the lamp

might switch off automatically after a short period (temperature >100°C).

I The current temperature of the M=Light LED is > 85°C

Flashing

red

M=Light-LED is defective and has been switched off. This may be the result of the following

causes:

I At least one fan is defective.

LED Array

Setup and Functioning

14/58

20.03.2015

8LE-D23_BA_E

I The electronic assembly for output control is damaged.

Off

M=Light-LED is either switched on, defective or is not supplied with operating voltage.

Figure 3: Lighting angles

The lighting angles are custom-specific, they can be identified via the M=Light Control software.

The angle set for the mounted LEDs is provided in the status display of the software (Figure 5):

Setup and Functioning

Rear Side of the Housing

8LE-D23_BA_E

20.03.2015

15/58

Figure 4: Display of the lighting angle in the software

4.2. Rear Side of the Housing

Item:

Description

1

Voltage supply

connection

2

CAN-bus Out

3

Nameplate

4

CAN-bus In

5

CAN-bus address (MSB)

6

CAN-bus address (LSB)

7

On / Off switch for

manual operation.

Figure 5: Connections and control elements on the rear side

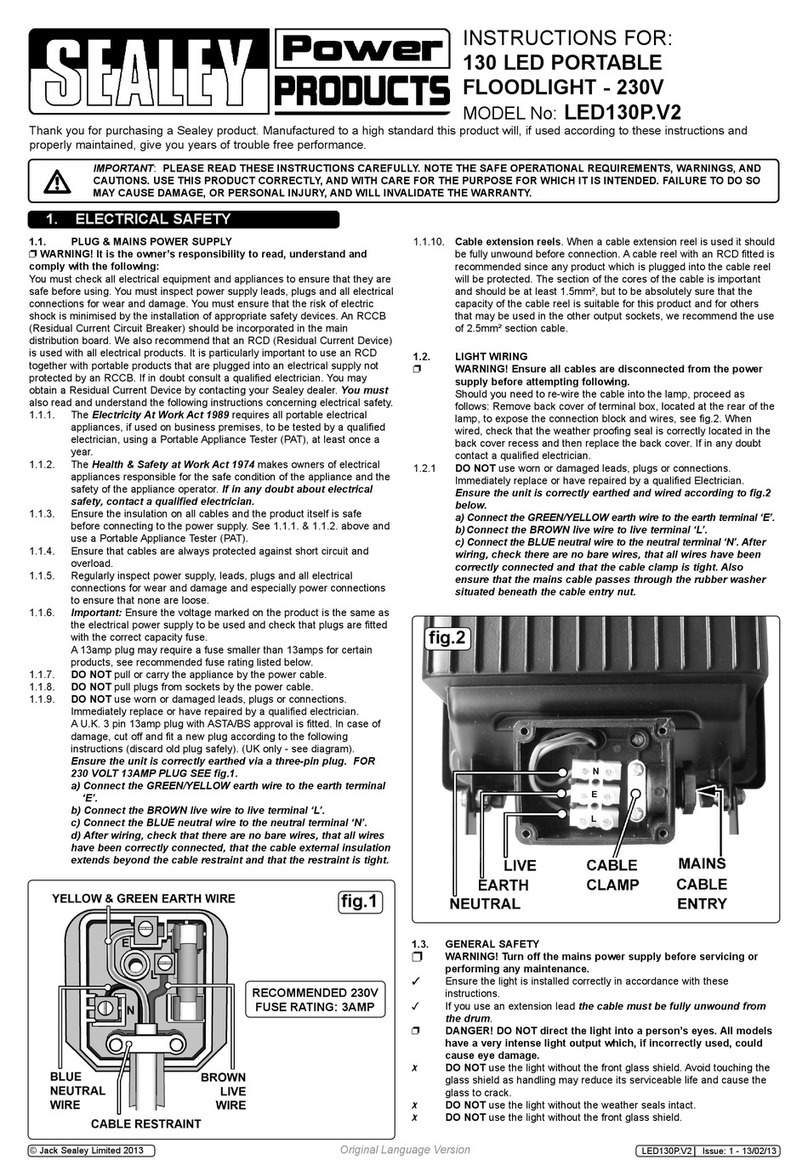

4.2.1. Connecting / Disconnecting Voltage Supply

Connecting Voltage Supply

Establish mains voltage via IEC-320 AC power cord set (Figure 5, Item 1).

Rear Side of the Housing

Setup and Functioning

16/58

20.03.2015

8LE-D23_BA_E

Take into account the power rating (section 7.2, page 50).

Take into account the limit values for frequencies (section 7.2, page 50).

Do NOT supply components via multiple socket outlets.

The M=Light LED is now supplied with operating voltage.

Disconnecting Voltage Supply

Item:

Description

1

Locking device

2

Male connector

Figure 6: AC power cord set with IEC-lock

Pull back the lock at the female connector.

Pull out the male connector.

The M=Light LED is now disconnected from voltage supply.

4.2.2. Establishing Signal Connections

Item:

Description

1

LED +9V I/O

2

CAN-bus OUT (Figure 9, page 18)

3

LED CAN-bus TX active

4

LED V I/O external

5

CAN-bus IN (Figure 8, page 18)

6

LED CAN-bus RX active

7

CAN-bus address (MSB)

8

CAN-bus address (LSB)

Figure 7: CAN-bus on the rear side of the housing

Connect the CAN-bus interface with the control PC.

Connect the RJ45 input IN of the first M=Light-LED with the CAN-bus interface.

Connect the RJ45 output OUT of the first M=Light-LED with the input IN of the second M=Light-

LED.

Setup and Functioning

Rear Side of the Housing

8LE-D23_BA_E

20.03.2015

17/58

Connect additional M=Light-LED accordingly.

For connection of the M=Light-LEDs, use patch cables according to CAT5 EIA/TIA-568 or

higher.

Specify a unique CAN-bus address for every M=Light LED in the same CAN-bus line.

Now, the signal connections have been completely established. The CAN-bus and Flash-bus

are automatically terminated by the internal terminating resistor of the M=Light LED last

connected.

Rear Side of the Housing

Setup and Functioning

18/58

20.03.2015

8LE-D23_BA_E

4.2.3. Contact Assignment of CAN-Bus Connections

Item:

Signal

1

Flash L

2

Flash H

3

GND out

4

+9V out

5

GND in

6

+9V in

7

CAN L

8

CAN H

Figure 8: Contact assignment of CAN-bus IN

Item:

Signal

1

Flash L

2

Flash H

3

Term -

4

Term +

5

GND

6

+9V out

7

CAN L

8

CAN H

Figure 9: Contact assignment of CAN-bus OUT

Item:

Description

Flash L

Input for physical CAN-bus signal for switching the M=Light LED on and off. Also used as output in

Master mode.

Flash H

Input for physical CAN-bus signal for switching the M=Light LED on and off. Also used as output in

Master mode.

GND out

Ground connection to previous M=Light LED (Term-) for switch-off of the terminating resistor at the

Flash and CAN output.

+9V D I/O

9V output connection to previous M=Light LED (Term+) for switch-off of the terminating resistor at

the Flash and CAN output.

GND

Ground connection for 9V output

+9V out

9V output

CAN L

Input for physical CAN-bus signal for parameterization of the M=Light LED.

CAN H

Input for physical CAN-bus signal for parameterization of the M=Light LED.

Term -

Input connection from next M=Light LED for switch-off of the terminating resistor at the Flash and

CAN output.

Term +

Input connection from next M=Light LED for switch-off of the terminating resistor at the Flash and

CAN output.

Setup and Functioning

Support Bracket

8LE-D23_BA_E

20.03.2015

19/58

4.3. Support Bracket

Figure 10: Support bracket

Item:

Description

1

Fixing screw for support bracket

2

Support bracket for attachment of M=Light LED

3

Outer attachment holes, 2 units, ∅10mm

4

Inner attachment hole, ∅10mm

5

Support bracket as base for M=Light LED

Positioning the Support Bracket

Open both fixing screws so much that the support bracket can be turned under light resistance.

Turn the support bracket in position.

Tighten both fixing screws.

Now, the support bracket is in the intended position.

Support Bracket

Software

20/58

20.03.2015

8LE-D23_BA_E

Chapter 5 Software

Contents

5.1. What is the Purpose of M=Light Control Software? 21

5.2. Installation of the M=Light Control Software 21

5.2.1. System Prerequisites 21

5.2.2. Installation Process 21

5.3. Operating the Software 22

Table of contents

Popular Floodlight manuals by other brands

Cocoon

Cocoon HE200074 instruction manual

NightSearcher

NightSearcher SLIMSTAR-PIR Series quick start guide

thomann

thomann stairville dj lase performance 150 RGY user manual

Saxby Lighting

Saxby Lighting Vanguard RP500 manual

Sealey

Sealey LED130P.V2 instructions

MaxLite

MaxLite ELLF Series operating instructions